|

|

|

|

|

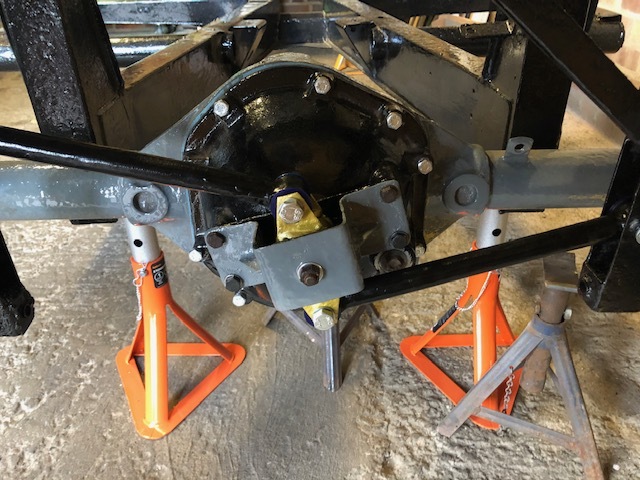

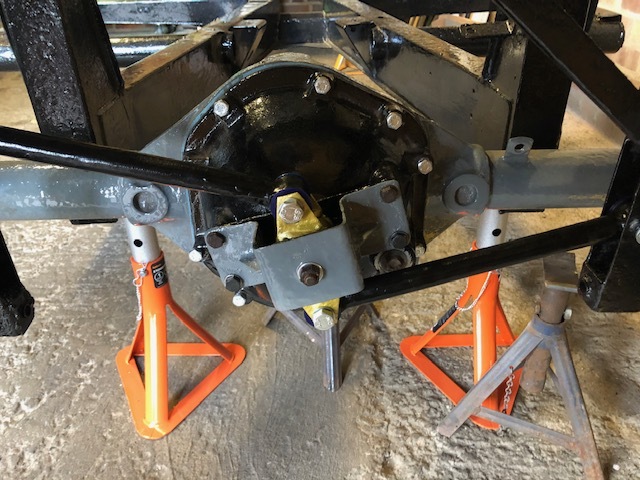

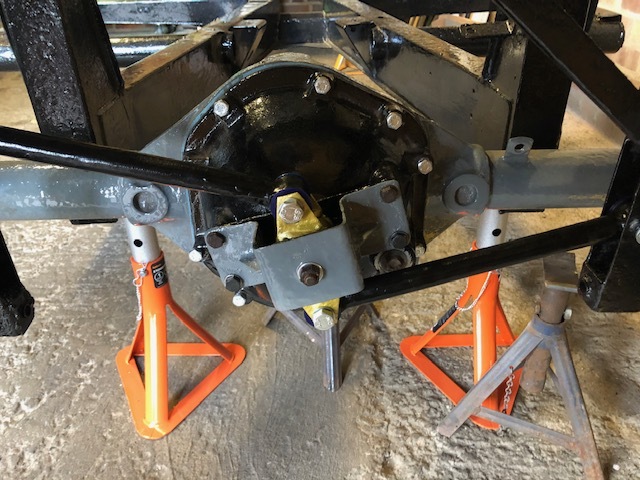

Managed to get the rear watts linkage bushes in and fitted back on the car, everything is ready for the rear end to be put back on its wheels.  Jumped in the car and drove down to Selby (about a 2 hour drive from me) to pick up the new gearbox. As I said earlier I have ditched the RX8 plan and gone for a much stronger box that doesn't need anything skimmed off belhousings etc. Just an adaptor plate. It is the 5 speed ZF gearbox from a BMW E39 530D they are known as a strong gearbox, I have a friend using one with 450bhp, it has been to Germany and back 3 or 4 times and done 8,000 miles with no issues. put that with the clutch, flywheel set up I am using and all should be good.  Hats off to the guy I bought it off, I had looked around for a few weeks for a decent box at a sensible price, it seemed that if a breaker went to the trouble of pulling the box out and photographing it to advertise they knew how much they are worth so struggled to find anything less than £400. I sent a message to a guy advertising breaking a 530D on facebook asking how much for the box he suggested £150 . I offered £120 and he accepted. I arranged to collect it on Sunday, he sent me a message at 5am on the Sunday morning saying he had been called in to work to do a night shift and would now go and remove it from the car. I set off at 9, he had pulled the box out and cleaned it by the time I got to him. He looked exhausted. He had a video of it working in the car, I paid him and off I went. I am going to line it up once I have made the engine mounts in the next few weeks, It looks like I will get away with using the original gearbox mounting plate that bolts to the chassis with some BMW bushes and some angled box section welded on so that's ideal. |

| |

|

|

|

|

|

|

|

|

|

Got the chassis levelled out on axle stands this weekend with the engine hung over it, I have cut the original mounts off the chassis and cleaned them off. It looks like I will be able to weld them back on in a slightly different position and then cut and weld steel pipe to make the mounts quite simply. Most things are cut and ready to be tacked into place for a final measure. That will be this weeks job.  |

| |

|

|

|

|

scimjim

Club Retro Rides Member

Posts: 1,503

Club RR Member Number: 8

|

|

|

|

|

That’s a good looking chunk of alloy 😀

|

| |

|

|

|

|

|

Jul 19, 2019 10:26:55 GMT

|

That’s a good looking chunk of alloy 😀 I can't deny opening the box and going "ooooooh so pretty"!!! |

| |

|

|

Phil H

Posted a lot

Posts: 1,448

Club RR Member Number: 133

|

|

Jul 19, 2019 11:26:35 GMT

|

|

I'd call that well worth the money based on the pics. Was there mention that the gearbox might need a tickle for the starter? If that's the only fiddling needed, then that's not bad at all.

|

| |

|

|

|

|

|

Jul 19, 2019 12:10:29 GMT

|

That's automotive porn  |

| |

|

|

|

|

|

Jul 19, 2019 14:20:28 GMT

|

I'd call that well worth the money based on the pics. Was there mention that the gearbox might need a tickle for the starter? If that's the only fiddling needed, then that's not bad at all. Yeah the kit comes with a diagram of what goes where and says the ZF box will be canted over slightly to the drivers side (only very slightly) and that the bell housing will need a little trim if you want to run the standard starter. The annoying bit is the Flex plate, I didn't see the bit about needing an auto flex plate on the list (it was clear enough so entirely my fault) I deliberately chose the saab doner car I had because it was an Auto in the theory that automatic and 40,000 miles means it hasn't been ragged. But i pulled the auto box, torque converter and everything that went with it off and scrapped it with the shell. Its annoying buying a part I should have if I had thought it through. |

| |

|

|

|

|

|

|

|

Its taken a few weeks longer than planned but I managed to get the engine and box fitted onto the chassis this weekend. I had ordered some laser cut plates for the engine mounts which cuts the job down slightly, they fit straight up against the block perfectly, I cut the original mounting plates off the chassis as they were too far forward and at angles for the old essex V6. I made new ones and moved them back slightly, the engine mounts themselves are made from cold steel plates welded to steel tubing and then to a steel disc that then screws onto the rubbers. Everything seems to work well, the engine mount welds aren't as pretty as I would like but they are strong. Gearbox mounts are made using cut and angled box section welded onto the original gearbox mounting plate that bolted onto the underside of the chassis. I did have to turn it round, and re-drill holes to move the plate forward slightly. Overall I wanted to be able to remove the mounts and drop the engine out through the chassis rather that out the top. That looks to be easy enough to do. Happy with where it is sitting, plenty of room between the top of the engine and the bonnet, shouldn't need any cutting to the bulkhead and lots of room in front for front mount, radiator and oil cooler too. The sump sits slightly below the bottom of the chassis but wont matter as I will need to make a rear bowl sump anyway. The only clearance issue is the oil filter housing is tight but wont be much of an issue, I will be using a remote setup anyway.     |

| |

|

|

|

|

|

Sept 24, 2019 10:09:29 GMT

|

Sorry for the lack of updates. I got married 4 weeks ago so the planning, the big day then following honeymoon etc has kept me out of the workshop. Back to reality and on the tools now though! I didn't want to go too much further without getting the body back on the chassis to make sure A. the engine and box sat where I wanted and B. to see some quick progress. I loaded the chassis onto the truck and took it home, spent 4 hours lifting the body with engine cranes and brute force.  The end result was a smashed rear valance and the body sat on the chassis! I couldn't be happier with how the engine sits, no cutting to the bulk head, loads of room in front for intercooler, rad etc and plenty of space down the sides for alternator, manifold, intake and turbo etc. The only clearance issue I can see is the oil filter housing but I knew that anyway so planned to remote that - plus they look cool. Gearbox sits perfect too, the selector lines up with the original factory hole so ideal.   Next job is to strip the interior all the way back, doors off, glass out then begin the A post and sill repairs- who knew a scimitar would have rust issues? Their is a metal reinforcement in the sills, it rusts and expands causing the sills to crack, pretty simple repair, cut the sill out, replace the metal, re glass the sill in place, happy days. The A post is more tricky it seems. A metal post sits inside the front wings that holds the door hinges, again they rust and causes the doors to droop when they open so they need cut out remade and replaced. |

| |

|

|

|

|

|

|

|

|

|

I decided to get stuck in stripping the interior down and pulling windows etc out so pulled the rest of the interior out, took the doors off, pulled all the dials etc from the dash and the dash itself all out. Easy enough just being careful to keep everything labelled. Most of it wont be going back in but I like to have it just in case. I haven't decided what to do with the gauges yet, I will be using a GPS speedo so will probably switch to gauges to match that.  I cut the passenger side sill out - there is supposed to be a strip of steel for reinforcement in here!  |

| |

|

|

|

|

|

|

|

|

hi there

there's also metal in the tops of the front wings,a and b posts,sill and a few other places.

Cheers - mike

|

| |

|

|

Rob M

Posted a lot

Posts: 1,915

Club RR Member Number: 41

|

|

|

|

I decided to get stuck in stripping the interior down and pulling windows etc out so pulled the rest of the interior out, took the doors off, pulled all the dials etc from the dash and the dash itself all out. Easy enough just being careful to keep everything labelled. Most of it wont be going back in but I like to have it just in case. I haven't decided what to do with the gauges yet, I will be using a GPS speedo so will probably switch to gauges to match that.  I cut the passenger side sill out - there is supposed to be a strip of steel for reinforcement in here!  Bulging sills syndrome! I had that on my old 5A I much preferred working with fibreglass than welding metal. As has been said, there is metal elsewhere. Check it all before you put everything back together, it may save you future ball aches. Great build! |

| |

Last Edit: Oct 1, 2019 13:12:36 GMT by Rob M

|

|

omegod

Part of things

Posts: 166

|

|

|

|

|

Great project, would an R25-28 Omega box not have bolted straight up to the engine ?, it's a well traveled road with Saab installations

|

| |

|

|

|

|

|

|

|

I decided to get stuck in stripping the interior down and pulling windows etc out so pulled the rest of the interior out, took the doors off, pulled all the dials etc from the dash and the dash itself all out. Easy enough just being careful to keep everything labelled. Most of it wont be going back in but I like to have it just in case. I haven't decided what to do with the gauges yet, I will be using a GPS speedo so will probably switch to gauges to match that.  I cut the passenger side sill out - there is supposed to be a strip of steel for reinforcement in here!  Bulging sills syndrome! I had that on my old 5A I much preferred working with fibreglass than welding metal. As has been said, there is metal elsewhere. Check it all before you put everything back together, it may save you future ball aches. Great build! Yep the sill work doesn't seem to bad of a job just want to make sure I use a decent stainless so it wont happen again. Yeah, the passenger A post seems solid but the drivers has serious door droop so I will cut both out and replace with new stainless, my theory is it will only every be this far stripped back and unpainted once so may aswell get it all sorted now - as much as its an itchy PITA job to do. |

| |

|

|

|

|

|

|

|

Great project, would an R25-28 Omega box not have bolted straight up to the engine ?, it's a well traveled road with Saab installations Thanks! Yeah the omega box does bolt straight up and they seem to last ok upto about 300ish bhp. I plan on going for about 350-400bhp which would probably be ok given how light the car will be but I want to run super wide rear tyres with uber sticky rubber so my theory is go with the BMW box which is becoming more common on Saab RWD set ups that can take stupid power and I can still get them for £150 a box whereas the omega boxes are becoming harder to find and more pennies for a lesser box. I only have to by the adapter plate once (I hope) |

| |

|

|

|

|

|

|

|

Got some more fibreglass cutting done this weekend, both inner arches cut at the front to get into the cavity where the door posts are, no wonder they rust, it was 2inches deep with leaves and rubbish so easy to see how moisture gets in there.   I also cut the other sill out to find it just as bad as the passenger side, I will be replacing those along with the door supports in stainless to protect them going forward. Next job is to look at cutting and widening the arches so once that is done I can re glass everything in one go to limit the itching! |

| |

|

|

|

|

|

|

|

|

Amazing project. Hadn't known about PMC before but checked out their site: most impressive. These early Scimitars are such a beautiful yet practical car IMO. I worked at a SAAB dealer once upon a time, so I look at that engine and think "D.I. module"; maybe a more reliable solution is now available? Excellent work, John.

|

| |

|

|

|

|

|

|

|

Amazing project. Hadn't known about PMC before but checked out their site: most impressive. These early Scimitars are such a beautiful yet practical car IMO. I worked at a SAAB dealer once upon a time, so I look at that engine and think "D.I. module"; maybe a more reliable solution is now available? Excellent work, John. Yeah PMC are excellent! the quality is fantastic. This scimitar probably wont be able to be called practical after I'm finished with it (cage, harnesses, fuel cell etc) but as I am over 6 foot it is one of the smallest car from the era I can fit in comfortably. I know what your saying about the DI pack, there are a few cars running aftermarket solutions but that means running a new ECU etc and would cost well over £1000 all in, for the power I am wanting (350-400bhp) the DI will do it no problem - plus i have a few spare ones lying around. There is a civic with a B204 running an interesting set up (plus some other insane mods) he is an ex saab engineer. you should check that out - link below |

| |

|

|

tristanh

Part of things

Routinely bewildered

Routinely bewildered

Posts: 990

|

|

|

|

|

Why do you need the auto flex plate?

|

| |

Whether you believe you can, or you cannot, you're probably right.

|

|

|

|