|

|

|

Aug 10, 2019 14:06:46 GMT

|

|

You know, it never occurred to me until now.

Someone may have put the wrong type of oil in it. That would account for it having trashed the phosphor bronze bearing.

Phil

|

| |

|

|

|

|

|

|

|

Aug 10, 2019 15:42:34 GMT

|

|

Or run it low/dry?

|

| |

|

|

|

|

|

Aug 10, 2019 18:07:33 GMT

|

|

That's also possible.

Phil

|

| |

|

|

|

|

|

Aug 10, 2019 19:08:29 GMT

|

|

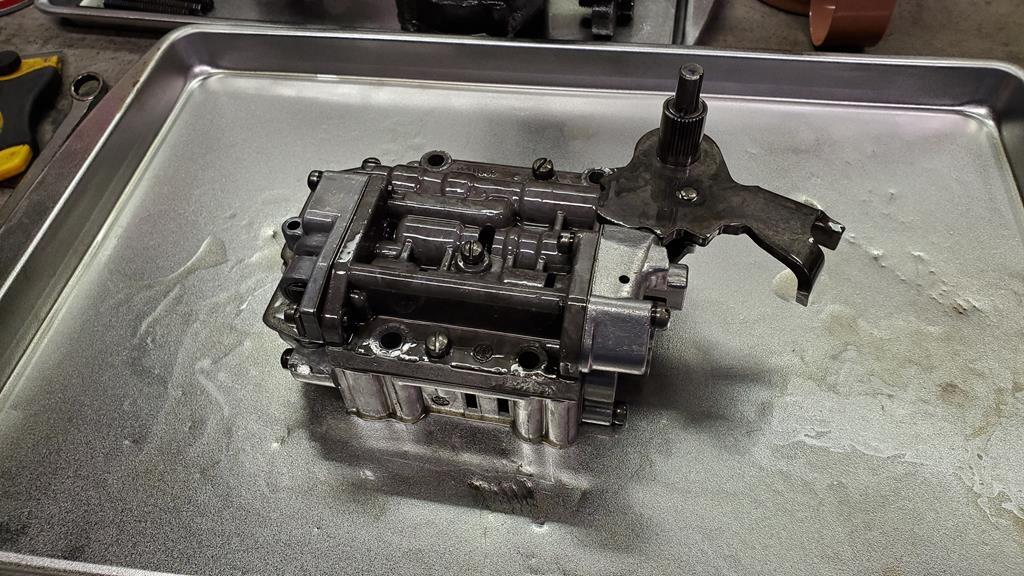

Cleaned out the governor. The B weight would get a little sticky in the bottom of the bore; a thorough cleaning has resolved that and now sees both weights falling freely under their own weight when the governor shaft is rotated.

That'll certainly have been a not-changing-gear issue.

Phil

|

| |

|

|

|

|

1951 Pontiac Chieftainpeteh1969

@peteh1969

Club Retro Rides Member 107

|

Aug 10, 2019 22:20:37 GMT

|

The B weight would get a little sticky in the bottom of the bore. Phil Ooer misses. LOL

Good work Phil not an easy job to do all this.

|

| |

|

|

|

|

|

Aug 10, 2019 23:52:13 GMT

|

The B weight would get a little sticky in the bottom of the bore. Phil Ooer misses. LOL Good work Phil not an easy job to do all this.

It had been hammering too hard all the way in. The head had made an indentation and a burr on the edge was catching. I cleaned up the burr and removed the lipped edge and now the shaft glides smoothly from fully in to fully out A little lubrication helped too Phil |

| |

|

|

|

|

|

|

|

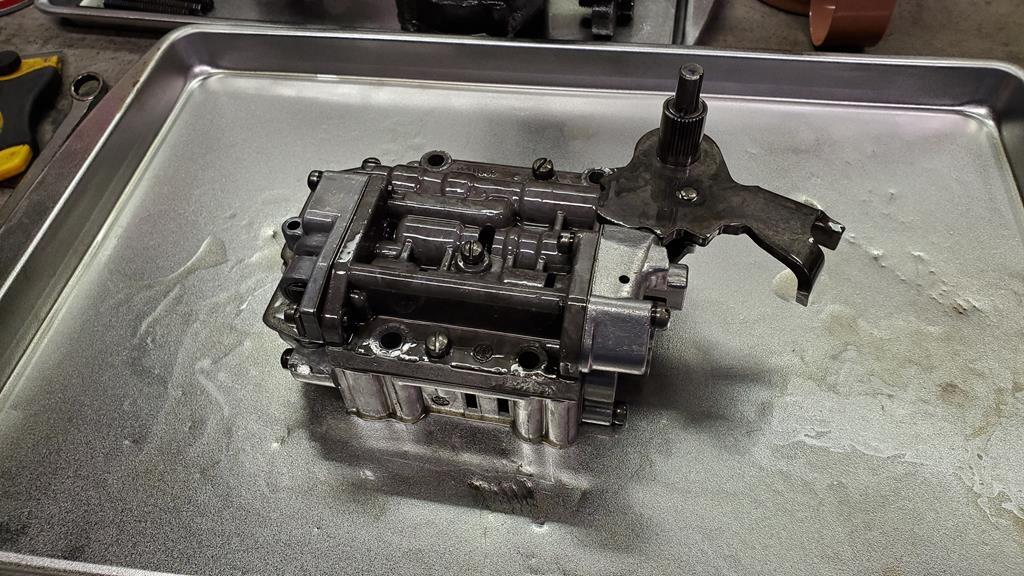

Disassembled, cleaned, checked, fixed up, cleaned again and reassembled valve block. Feeling how the valves and shuttles moved before, little wonder it didn't change gear... Everything moves smoothly now. Win.  Double bonus, thrust washers arrived in the mail today. Phil |

| |

|

|

Clement

Europe

ambitious but rubbish

Posts: 2,095

|

|

|

|

For quite a while now I’ve felt a lot of love for early 50’s American stuff, but figured that were I to indulge I would stay on the manual gearbox side of things. I just wasn’t feeling the early autobox tech honestly; this thread changes that. I love feeling a clockwork mechanism come together perfectly, and reading about you fixing this intricate piece of machinery really gives me that smooth click-clack feel. Please go on  |

| |

|

|

|

|

|

Aug 11, 2019 12:00:49 GMT

|

|

Although this box went on in various guises for about ten years, throughout the time they made it, all they did was improved the design until the TH350 which was significantly better overall.

Phil

|

| |

Last Edit: Aug 11, 2019 12:09:36 GMT by PhilA

|

|

|

|

|

Aug 11, 2019 14:19:18 GMT

|

|

For me this is a fascinating example of how well the American car industry innovated not just in design but also production engineering. All too common to bash American cars but that misses many points, especially for those of us born/raised in Europe but came here at some point and grew to understand the size and history of the country, and how the domestic car industry evolved (then, admittedly, faltered in the 70's, 80's and 90's.)

I've just read a history of Rolls-Royce (by Peter Pugh) that documents how the R-R leadership realized by the late 20's that their heretofore superior automotive engineering was being surpassed by the better American manufacturers, all at much higher levels of consistency and lower costs (the two being closely related, of course); we've likely all read how the Packard-built Merlin engines were in many ways better than those from R-R's own facilities.

This transmission rebuild makes me think about all this, and reminds me of the 79 Oldsmobile Delta 88 my Dad was assigned as a company car when we arrived in 81; esentially a Chevy Caprice with somewhat more luxury, it ran a corporate (Chevrolet) small block 350 with a Rochester Quadrajet carb, TH350 autobox and A/C that could make you shiver in the desert...the only car my (engineer) Dad ever loved (the one he loathed most was a J-reg Maxi bought new in 1970 from Henley's in Bristol). That Olds was the right car for the time and place, making 1000 mile trips (common here) with total comfort and reliability. Yes, the US industry here became flabby and ignored outsiders with better vision (J. Edwards Deming found the Japanese ready to listen when he own countrymen rejected the ideas upon which Toyota et al built their own quality-based systems), but there remains so much for us to wonder at in terms of how Detroit positively affected our lives.

I also dig how you're meeting guys all over the country who have the parts to get your car back on the road. Best, John

|

| |

|

|

|

|

|

Aug 11, 2019 15:11:59 GMT

|

Agreed. For instance, the quality of the casting is impressive.  The metallurgy is good too, different metals for different tasks. This is years ahead of what Qualcast was putting out in the seventies. Phil |

| |

|

|

goldnrust

West Midlands

Minimalist

Posts: 1,889

|

|

Aug 11, 2019 15:58:20 GMT

|

Like everyone else, I'm finding the auto rebuild fascinating!  The engineering is impressive for sure. I'm surprised it drove at all with all the problems you've found. Gonna feel pretty different to use when you take it out with the refurbished gearbox! |

| |

Last Edit: Aug 11, 2019 15:58:42 GMT by goldnrust

|

|

|

|

|

Aug 11, 2019 16:37:33 GMT

|

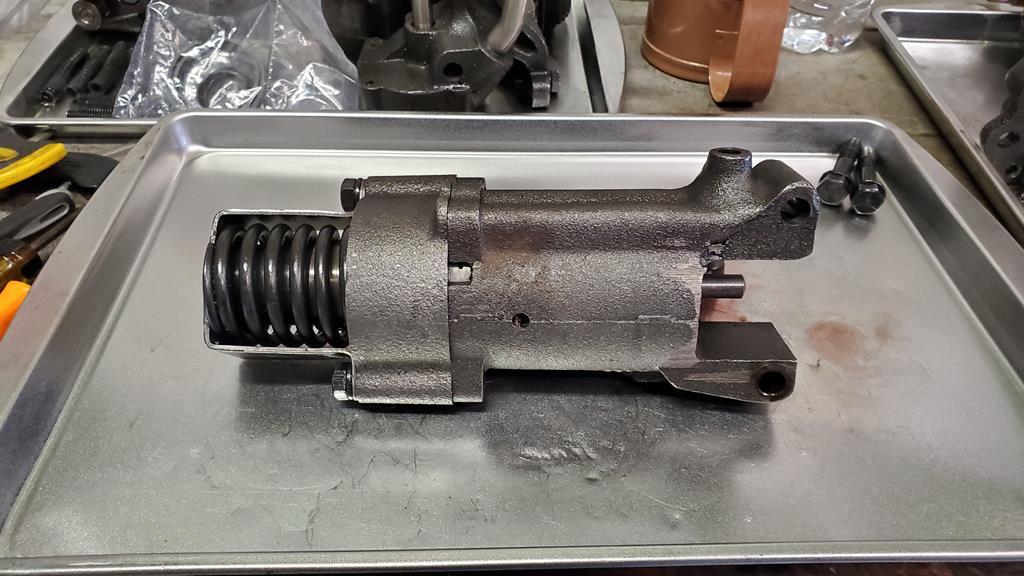

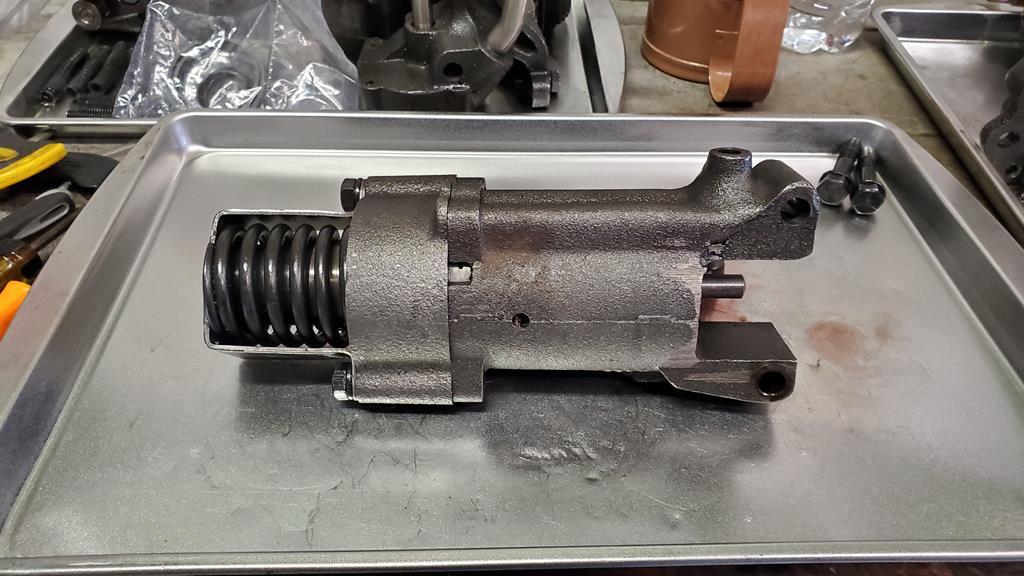

Aha. Root cause of failure found.  Primary servo return spring. Phil |

| |

|

|

|

|

|

Aug 11, 2019 18:34:46 GMT

|

|

To: General Motors Corporation

Stupid Designs Department

c/o Accounts Receivable

Detroit, MI

Dear General Motors Design Team,

Slotted Fillister head screws do not have a place in any application over 10lb/ft.

Thank you

Yours,

Phil Andrews (Annoyed)

|

| |

|

|

|

|

|

Aug 11, 2019 18:41:55 GMT

|

Bought a large screwdriver.  Which, after 3 hours has undone 3 of the 4 screws, one had to be drilled out and the other the head's a bit too messed up to re-use. Removed the rings and the oil seal. Cleaned thoroughly. Removed burr preventing pressure relief from operating smoothly. Too hot to continue, given up for today. Phil |

| |

Last Edit: Aug 11, 2019 18:43:54 GMT by PhilA

|

|

|

|

|

Aug 11, 2019 22:11:25 GMT

|

Glad I read the manual. That gray circle bottom left of the right hand section should have merrily popped up- it's the overpressure relief. It was jammed up tight. That's now freed up.  Also, hallmark moment! First new parts going on.  Used the old seal as the mandrel to knock the new seal in.  This I do like because this is the piece that was leaking so badly. New seal, new rings should resolve that.  Next up, rear servo. Not looking forward to that there spring... Phil |

| |

|

|

|

|

|

|

|

I'm glad I remembered to have a go at the big plug on the side of the front servo. This is a good example of the curse word I've been pulling out of all the hydraulics. Phil |

| |

|

|

|

|

|

|

|

|

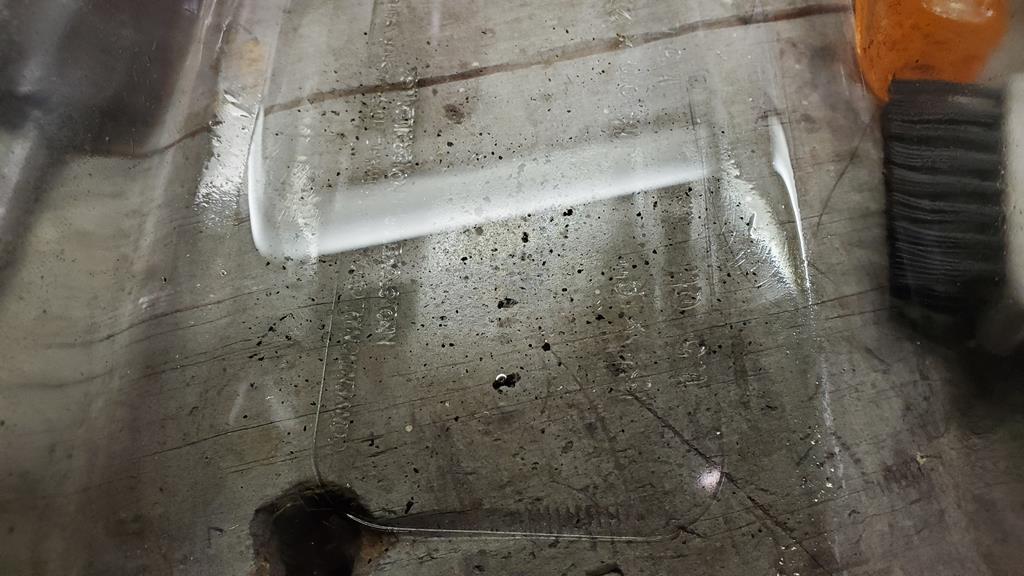

Your constant progress continues to make me smile.

Simple thing I previously noticed, working on baking trays, keep the table clean, so easy.

|

| |

|

|

|

|

|

|

|

jjeffries I thought Packard redesigned it all so they DIDN'T have to make it to such high tolerances

|

| |

Last Edit: Aug 12, 2019 8:43:31 GMT by darrenh

|

|

|

|

|

Aug 12, 2019 12:17:02 GMT

|

Your constant progress continues to make me smile. Simple thing I previously noticed, working on baking trays, keep the table clean, so easy. Trying to keep moving on things, you know how it goes. Also yes, I needed a metal surface to work on that was easy to clean and keep clean, yet not be too hard that it damages machined surfaces. Cheap baking trays (non-Teflon ones) fit that bill when sat on top of a wooden work bench. Also if you break one or split through it accidentally it's not the end of the world. Finally they have a lip to keep the oil from going everywhere. Phil |

| |

|

|

The engineering is impressive for sure. I'm surprised it drove at all with all the problems you've found. Gonna feel pretty different to use when you take it out with the refurbished gearbox!

The engineering is impressive for sure. I'm surprised it drove at all with all the problems you've found. Gonna feel pretty different to use when you take it out with the refurbished gearbox!