Enbloc

Part of things

Posts: 398

|

|

|

|

|

I've got into the habit of doing this to hardware, it becomes a little obsessive!

I generally drill out the centre to half the bolt size (non-structural) and the difference is very noticeable.

|

| |

|

|

|

|

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,867

Club RR Member Number: 39

|

1970 Ginetta G15 Darkspeed

@darkspeed

Club Retro Rides Member 39

|

Jul 26, 2022 21:49:54 GMT

|

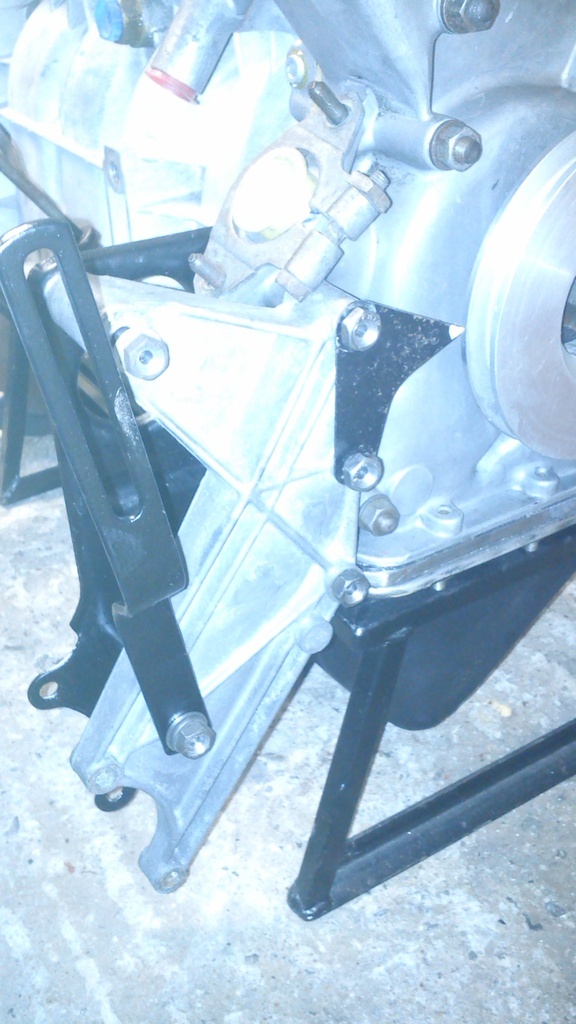

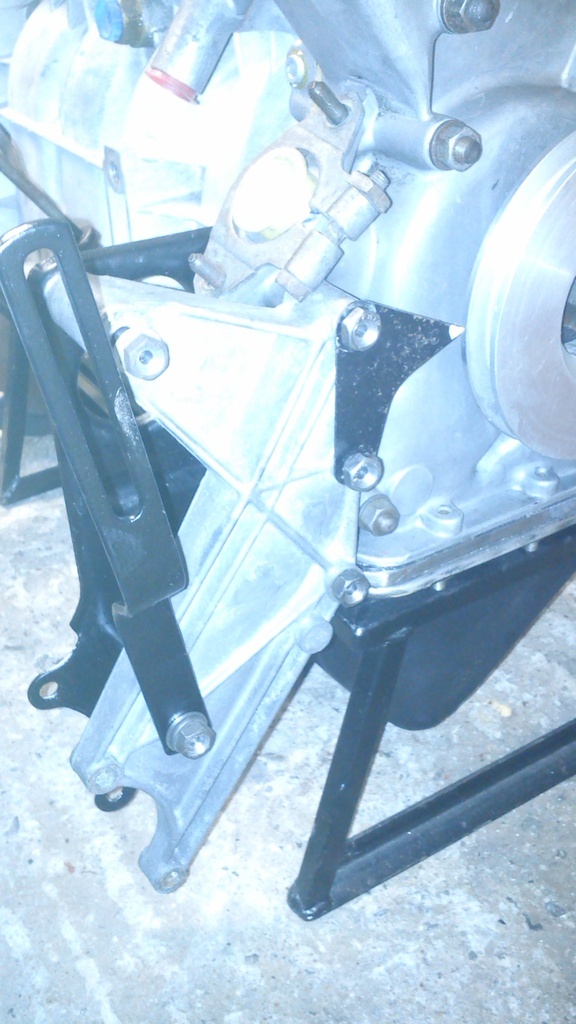

Sorry about the quality of photo's of late - I have been waiting for a particular Sony camera to get back into stock and it appears that its not about to happen any time soon. The Carter is with me and I am adding parts to get it complete.    Adding similar parts to the Chesman as well to get it complete.   Water pumps to do as well as a couple of CD150's to rebuild. |

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,867

Club RR Member Number: 39

|

1970 Ginetta G15 Darkspeed

@darkspeed

Club Retro Rides Member 39

|

Jul 31, 2022 11:13:35 GMT

|

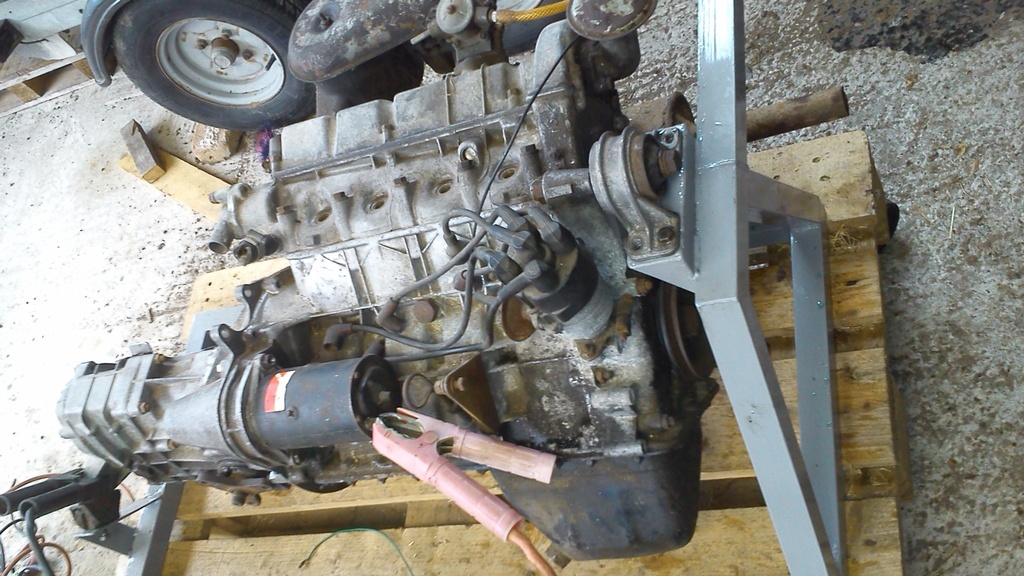

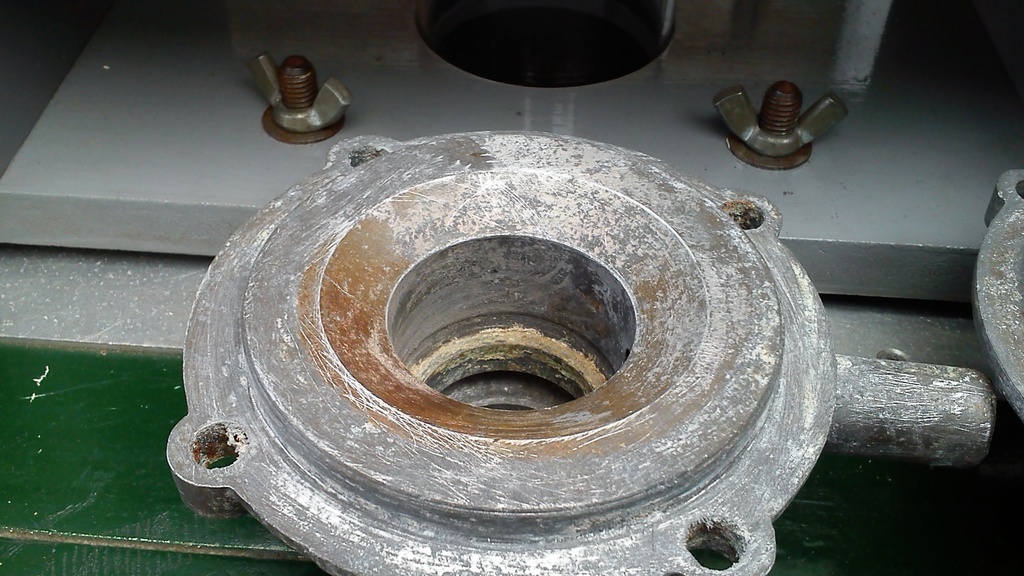

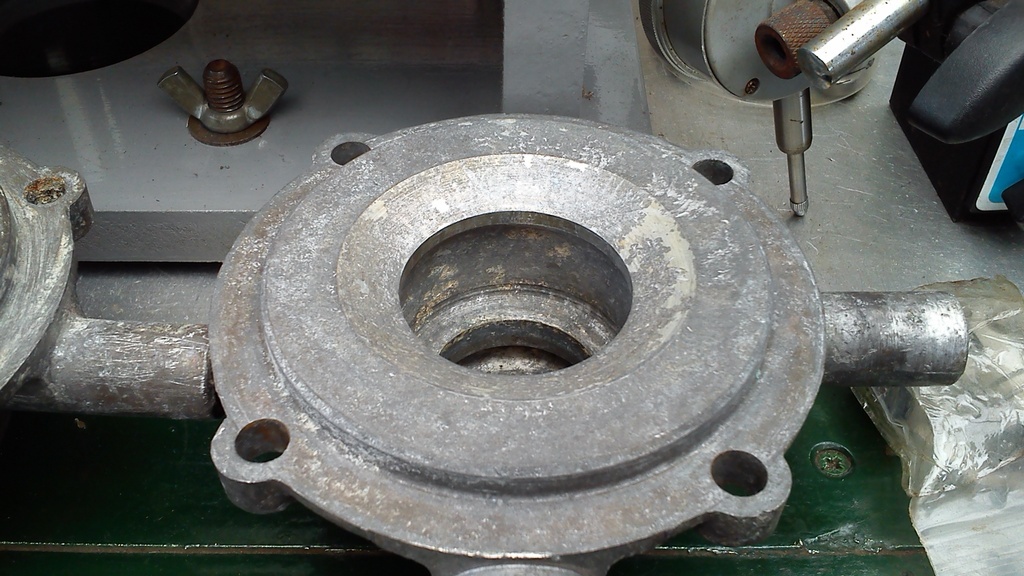

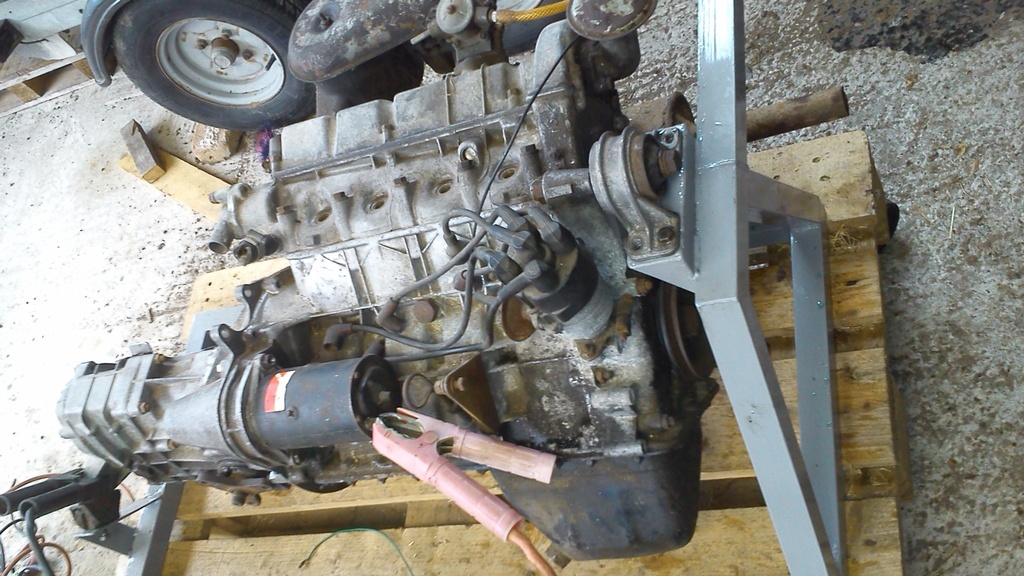

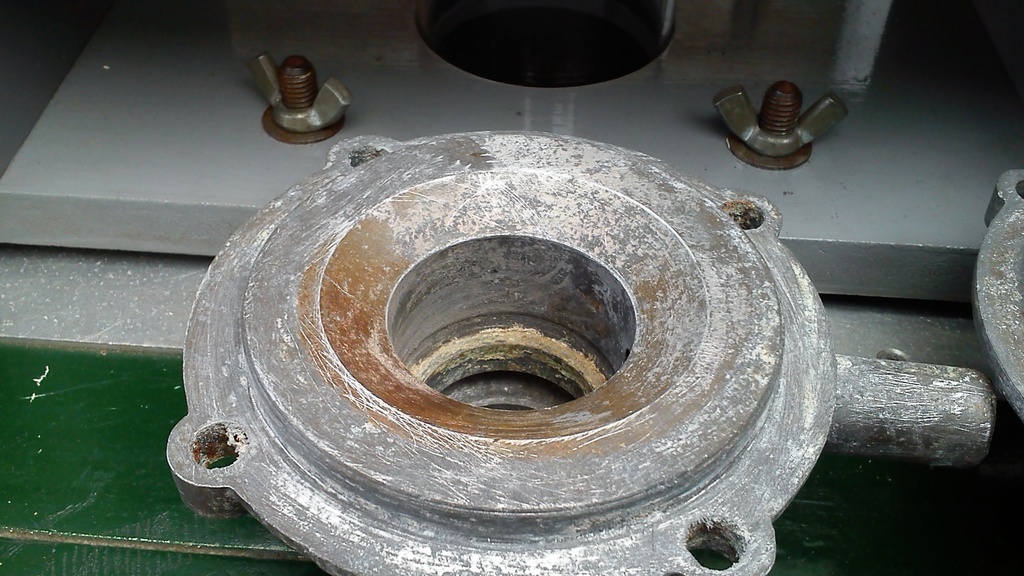

I have half a dozen or so Imp water pumps in various stages of decrepitude that need to be rebuilt and once again the ultrasonic comes into its own for stripping the grime off. The Evans shift doing a great job of removing the alloy corrosion.  Once split apart and the impeller shaft removed a bath in some Phosphoric acid solution sorts out the corrosion on that part and then its in the lathe to take as little as possible off the rotary seal faces to get them flat.  New bearings and seal kits are available from the variety of Imp parts suppliers and its a simple case of reassembly. I wanted to do some comparison measurements on this particular pump as its a Chrysler original pump and when tested it outperformed every other pump by over 50%. There has also been a little bit of action taking place over at the barn. The engine cradle now has an engine and gearbox on and it and over a few evening we will get sufficient parts on it to see if we can coax a cough or two from it.   Its a late model 533 engine - These have the Imp sport cam - double valve springs and an oil drain head - but have the std smaller valves and very restrictive ports and a 17mm choke carb! Found a strange anomaly with the gearbox - its also a very late box with all the stronger casings - but the rear casing is from a really early car as it does not have the gearbox breather. |

| |

Last Edit: Jul 31, 2022 11:16:05 GMT by Darkspeed

|

|

v8ian

Posted a lot

Posts: 3,828

|

|

Jul 31, 2022 11:42:45 GMT

|

|

Somtimes a bigger flow water pump is your enemy, the flow speed increases but the water dosent hang around long enough to pick up the heat from the block or transfer sometimes to the rad, I used to have to run a restrictor plate on an engine to get it to cool

|

| |

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

ndg

Part of things

Posts: 109

|

|

|

|

|

If you were having to slow the flow it's more likely you were getting cavitation somewhere or some other strange flow behaviour (or you were measuring block in temperature maybe?). High flow can only be better from a heat rejection point of view. A well performing system has a lower delta T across both the rad and engine than a poor performing system. The higher flow means that the energy is being transferred to more coolant so the temp increase is smaller.

It's easier to think about in a rad, but this applies to the block too, just in reverse. In the rad more flow means inlet and outlet temps are closer, this means the average radiator temp is higher. The amount of heat rejected by a rad is proportional to the delta between the coolant temp in the core and the air temp. Therefore the more of the radiator you can run close to the inlet temp the better as it gives you a bigger average delta.

|

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,867

Club RR Member Number: 39

|

1970 Ginetta G15 Darkspeed

@darkspeed

Club Retro Rides Member 39

|

|

|

|

Yep Q=M.C.deltaT - But the myths about water flow not allowing heat exchange have been around for so long and like so many other "facts" - "you need back pressure in an exhaust" - etc. that more people believe it than those who know what the science is. If people believe the earth is flat and it makes them happy who am I to argue. I have been working in Hydronics for decades and the amount of times I have had to say "just humour me" to 'experts' in regard to sorting out system issues still astounds me.

In this particular case - these are all the same Imp water pumps - and when we tested a number of them measuring static heads one outperformed the others by a huge margin and I am interested to know why. So far it is physically identical - I was hoping to find a larger impeller or some dimension different but I have split two old Chrysler pumps and they are identical. Castings* - Impellers - Seals - Shims - all the same.

ETA

* Until I looked closer

|

| |

Last Edit: Aug 2, 2022 6:22:05 GMT by Darkspeed

|

|

v8ian

Posted a lot

Posts: 3,828

|

|

|

|

|

what about the clearance with the vanes to the rear of the pump housing

|

| |

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,867

Club RR Member Number: 39

|

1970 Ginetta G15 Darkspeed

@darkspeed

Club Retro Rides Member 39

|

|

|

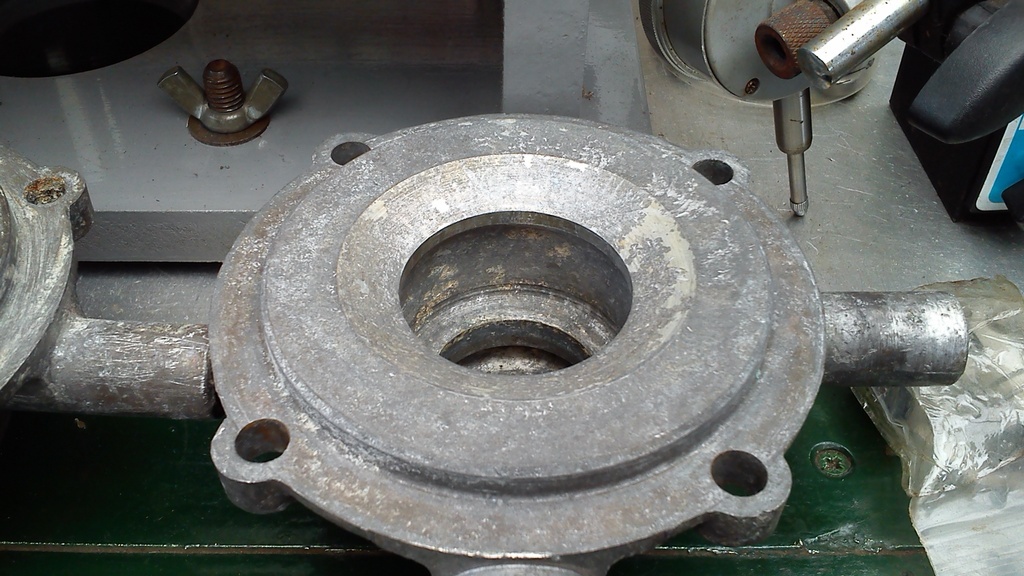

what about the clearance with the vanes to the rear of the pump housing The internal clearances of the vanes to the case are the only thing that could potentially vary but measuring them is not very easy and I need to machine up dummy bearing spacers that are not an interference fit onto the impeller shaft and into the casings so that I can easily drop parts in and out to make the comparisons. The way that the parts assemble there should not be any differences in the clearance - it is fixed by one of bearings being held into the casing by a shoulder and a circlip - the casings are die-cast - the bearing is located by being locked onto the shaft by a sleeve and nut. The way they are manufactured they should all be about the same - as we pretty found during the tests - Apart from this one. So I got to this stage and figured I would go and take more measurements - And After going over the outlet side of the casings - identical and same casting number - I started measuring the inlet side of the casing and right there was something very different.    Unfortunately it is not possible to compare the two inlet side casting numbers   But I do have the casting number for the better performing pump half. That part of the casting has been opened up from 44mm to 50mm. Within that diameter is the the shaft of the impeller which is 31mm so the clearance has gone from 6mm to 9mm - However, I can see that difference changing the shape of the flow curve but not the amount of pressure in a dead head situation so still looking. |

| |

Last Edit: Aug 1, 2022 13:36:04 GMT by Darkspeed

|

|

|

|

|

|

|

|

Interesting. Does it look like it's been taken out by hand or as part of the machining process? Could it be a worthwhile modification to the standard pumps if you can get it uniform enough?

|

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,867

Club RR Member Number: 39

|

1970 Ginetta G15 Darkspeed

@darkspeed

Club Retro Rides Member 39

|

|

|

Interesting. Does it look like it's been taken out by hand or as part of the machining process? Could it be a worthwhile modification to the standard pumps if you can get it uniform enough? Its the factory die casting - there are also subtle differences in the positioning of the inlet connections - I picked up another Chrysler pump with what I think is an earlier casting number so will look if its the same as the other one. I did try and see if I could get it in the lathe to machine out the casting but it would not go into the chuck easily - it could be gone at with a carbide if that is what is found to improve the pump performance. |

| |

|

|

|

|

|

|

|

|

One of the reasons I ask is I replaced the water pump in the Fiat with an aftermarket jobby after the original gave up the ghost and found it was worse at holding its temperature. Sadly I threw away the original (foolish!) but was wondering if I could improve it in some way. I did do away with the gasket and clearance the taller of the vanes so there's less end-clearance which I think improved things.

The other thing is it's just genuinely interesting to see what makes a good or bad pump!

|

| |

|

|

v8ian

Posted a lot

Posts: 3,828

|

|

|

|

Interesting. Does it look like it's been taken out by hand or as part of the machining process? Could it be a worthwhile modification to the standard pumps if you can get it uniform enough? Its the factory die casting - there are also subtle differences in the positioning of the inlet connections - I picked up another Chrysler pump with what I think is an earlier casting number so will look if its the same as the other one. I did try and see if I could get it in the lathe to machine out the casting but it would not go into the chuck easily - it could be gone at with a carbide if that is what is found to improve the pump performance. you might be able to turn up a threaded mandril and mount the pump on thats you can remove the metal at the back? |

| |

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

logicaluk

Posted a lot

Every days a school day round here

Every days a school day round here

Posts: 1,373

|

|

|

|

|

Fascinating stuff DS, I look forward to seeing where this takes you.

Dan

|

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,867

Club RR Member Number: 39

|

1970 Ginetta G15 Darkspeed

@darkspeed

Club Retro Rides Member 39

|

|

|

you might be able to turn up a threaded mandrill and mount the pump on so that you can remove the metal at the back? 100% - I just looked at the easy option first  Thing is, I am just not convinced that would really make any difference to the static head performance - but clearly they did it for a reason. We did test another Chrysler pump at the time of the pump tests and now I have both numbers I can get the other casting number from that pump when molebert returns from Canada and see if that's the same as the best pump or the average one. When we did the testing last September Pump 1 - Bizzo (QH)- Reconditioned pump - Measured head Low RPM - 780mm Pump 2 - Bizzo - Original pump on PHX - Measured head Low RPM - 860mm - High RPM - 2100mm Pump 3 - DS-1 (QH) - Measured head high RPM - 2190mm Pump 4 - Itchy 1 - Measured head high RPM - 2000mm Pump 5 - DS-Chrysler Original - Measured head high RPM - 3400mm ++

Pump 6 - Molebert - Chrysler rebuilt - Measured Head high RPM - 2400mm

Pump 7 - DS-2 - Measured head high RPM - 2310mmPump 8 - DS-Crusty (QH)- Measured head high RPM - 2100mm Interesting to note that all of the Chrysler pumps performed better than any other. DS-2 is that corroded inlet one pictured above. The other Chrysler one I have just picked up is what I will now call the "small chamber" pump. |

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,867

Club RR Member Number: 39

|

1970 Ginetta G15 Darkspeed

@darkspeed

Club Retro Rides Member 39

|

|

|

As can be seen - these things are always pretty rough when you split them.  What I just noticed when writing down the casting numbers is the big chamber half is actually marked Rootes - although the matching half of that pump is marked Chrysler. All other parts are all marked Chrysler. Under the magnifying glass and using the latest crusty pump as a guide this latest one and the corroded one are the same part number as I can now make out parts of the number knowing where to look. Next step is dissecting a QH one to see what's in one of those. |

| |

|

|

|

|

|

|

|

|

As said, interesting stuff.

|

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,867

Club RR Member Number: 39

|

1970 Ginetta G15 Darkspeed

@darkspeed

Club Retro Rides Member 39

|

|

|

As said, interesting stuff. We are a sad bunch  |

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,867

Club RR Member Number: 39

|

1970 Ginetta G15 Darkspeed

@darkspeed

Club Retro Rides Member 39

|

Aug 12, 2022 15:59:49 GMT

|

After a bit of time in the Electro tub and then in the Acid bath the impeller came up okay - and with the casing getting treatment in the ultrasonic bath we have some parts we can work with.  I also managed to get the casing that had a couple of holes in the main inlet connection into the lathe - used this one just in case it all went pear shaped and I ended up wrecking a good casing half - and opened up the casing to a similar shape as the hi-flow "Rootes" pump casing  The seal faces on the impeller will get cleaned up and the holes in the casing JB welded. The best of the S/H functional seals and bearings will get fitted with a home made gasket and I will give it a test to see how it performs. The ex factory demonstrator has come off the rack and is on the roller.   And the chassis is getting a once over to see where we are with it.   The Body will be needing quite a bit of work - it has had a significant shunt at some stage in its life and there are some previous repairs that will need to be..... unrepaired. The roof will need to be chopped out and replaced as will most parts of the N/S front wing and the full front end to remove the "race" spoiler. The new owner has also commissioned a refresh of another 998 we have kicking about. |

| |

|

|

|

|

|

Aug 12, 2022 16:24:56 GMT

|

|

I love these sort of threads,

The quality of the work carried out, both body / chassis work and engineering work is first class,

Not only readable but educational as well,

Nigel

|

| |

BMW E39 525i Sport

BMW E46 320d Sport Touring (now sold on.)

BMW E30 325 Touring (now sold on.)

BMW E30 320 Cabriolet (Project car - currently for sale.)

|

|