|

|

|

|

|

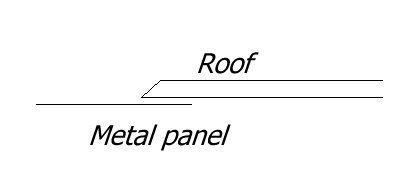

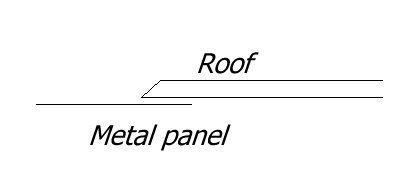

Fibreglassing, yet another thing I've never done before. Having finally committed to pulling my horrible and horribly ill-fitting sunroof out today, I am now left with a big hole in my roof that interestingly enough was cut at about 7º skew to the square of the roof.  I had a plan to do it like many of ther racing Scimitars I've seen, which just have a sheet of metal rivetted to the roof but nicely done and tight to the roof's curves. Having had a go myself today I am even less enamoured with the result than I was with my stupid sunroof. This is a bodge that hasn't worked out, and it's really bugging me. So... maybe it's time to start fibreglassing. My questions are... 1. given that I have a piece of metal with drill holes lined up to the roof, can I re-attach this sheet of metal underneath the roof (ie inside the car) to act as a holding tray for fibreglassing? (ie this piece of metal in the pic below, covered in black vinyl, would be re-bolted inside the car and then I'd start fibreglassing over it, using it to hold the fibreglass up...)  If so... can anyone answer me two questions... 2. what kind of prep do the surfaces of the roof's fibreglass need in order for new fibreglass to bond strongly to it... I'm assuming I'd have to sand down to below the gel coat so the new fibreglass can bond with the old fibreglass. 3. In order to get a nice smooth end result, and allowing for me to sand it all back and smooth in all the overlaps and joins between the old and the new, I presume I would need to build up thick gel coat rather than fibreglass... as presumably trying to sand back fibreglass to get a nice continuous curve is merely going to give me a lot of hairy strands and fluffy stuff, not a nice smooth finish. Is this correct? Does the fibreglass need to stop and sit below the surface? 4. If I am right about 2, then my question is... is it possible to build up gel coat layer by layer until it sits proud and can then be sanded back down and sculpted to be smooth and seamless? * When I say 'sanded' I'm using it as a familiar generic term for abrasion/shaping. |

| |

Last Edit: Mar 8, 2018 22:43:06 GMT by Deleted

|

|

|

|

|

|

|

|

|

|

Ignore that post I didn't read your through properly.

Yeah I cant see why it wouldn't work.

Can you not find a doner roof anywhere?

|

| |

1965 Morris Minor 1000 soon to be 1380

1997 MK1 MX-5 1.8 (sold)

2009 MK3 MX-5 2.0 (sold)

2008 Mini Cooper (sold)

2003 Mini Cooper S (sold)

Fixed wheel Raleigh Clubman (sold)

1982 Yamaha RS125DX (sold)

|

|

|

|

|

|

|

|

I've always shyed away from the donor roof option purely because I think it would be very difficult to measure and cut/shape the exact bit accurately when measuring off a car with wonky trim and a shabby windscreen rubber making it very hard to get a true reading off anything to guide the cutting. Having discovered that the hole in my roof is way off square anyway, that compounds the problem further... I just don't fancy my chances of accurately cutting the right skewed slab of roof. I think it would end up being a bit of a waste or time, money, and roof.

Plus... I work on the kitchen table and I'm not sure my wife and kids would appreciate me covering the kitchen and everything in it in fibreglass powder!

|

| |

Last Edit: Mar 8, 2018 23:11:17 GMT by Deleted

|

|

|

|

|

|

|

|

Having sat here stewing further... I'm now thinking I might rivet the metal inside the car using black rivets, and then have an additional row of rivets holding some black Palight at the right thickness rivetted to the metal sheet, down in the indentation. Palight is very flexible and very easy to cut, so I could probably make it a really snug fit in the indent/ roof hole that will just look like some other kind of flush-to-the-roofline sunroof cover or something. Run some Sugru round the crack to seal it.

I don't know... I'm feeling a bit peeved with this at the moment. I really hate blasting through a small improvement like this and then ending up with less than pleasing results. It looks bloody horrible at the moment. I'm embarrassed. All my neighbours are going to walk past it and think "oh dear he's really ruining that car of his with his awful bodgery".

|

| |

|

|

|

|

|

|

|

What about fixing the metal sheet inside the car as you said, and then using something like bridging filler (filler with fibreglass strands embedded) to fill the depression, then sand it to shape? I'm not sure of the thickness of the original roof panel, so maybe a few layers of matting to start with, though that probably isn't much different to the bridging filler. I'd probably sand the edges of the hole at an angle heading away from the hole, so that the filler forms a bit of a lip. The raw fibreglass edge that it produces might help the filler bond to it, both for leak prevention and to provide some additional surface area.  I'm not sure I'd use rivets to bond the panel in place - there must be some kind of adhesive you can source now that would be good enough to bond it underneath, and if you scuff the panel surface where the filler will go, the filler layer may also help. |

| |

|

|

|

|

Any fibreglassing experts?fr€$h&m1nt¥

@freshandminty

Club Retro Rides Member 99

|

|

|

|

I'm guessing you're trying to avoid outsourcing it and getting a panel welded in that fills the hole?

If so your second suggestion would be the best way - i.e. Fit the larger panel to the underside of the roof and get another panel made that is the same size as the hole and same thickness of the roof and fit that on top and then just fill any gaps.

|

| |

|

|

|

|

|

|

|

I'm not sure of the thickness of the original roof panel It seems to be about 5mm, I can get PAlight in 5mm, but not until I get one of clients to pay me the f^$*%rs. I don't mind rivets. It was seeing riveted panels on racing Scmitars that gave me the idea of replacing my awful leaky sunroof in the first place. That and the fact that my sunroof stood out from my roofline like some kind of viewing platform. |

| |

|

|

|

|

|

|

|

I'm guessing you're trying to avoid outsourcing it and getting a panel welded in that fills the hole? Well, at this point yes, sadly. I had got very excited about handing the car over to somebody local and asking them to get the car looking nice for RRGoodwood. But financial reality has bit hard over the last couple of weeks. I've got outstanding invoices that don't look like they're going to be paid, and January/February have slammed me with lots of bills including a chunky VAT bill where I've had to pay the VAT portion of the the unpaid invoices (they don't care if you haven't been paid, you still have to pay HMRC). The problem with that is that I don't know if/when I'll get my invoices paid, and by the time they come in we'll have sunk into overdrafts and drawn on our savings so I don't really feel I can inform my wife I'm spending £x on car stuff just because an invoice has been settled. My next known payment date is 45 days away thanks to a massive client who gives no damn at all for supplier's terms, so we've got to stretch the next overdue lot a bit further too. So the upshot is I've attempted to be resourceful and to do it myself for free (not really actually free as I had previously purchased the materials Ive now used to do it) and it looks bloody horrible. It's not actually that bad in fairness, but it does look like a home bodge when I was actually aiming for something no-nonsense and somewhat crude,but in a bad ass way. My bodge just looks dorky and stupid. DORKY! & STUPID! |

| |

|

|

|

|

Any fibreglassing experts?fr€$h&m1nt¥

@freshandminty

Club Retro Rides Member 99

|

|

|

I think the best solution is to get an accomplice with an automatic machine gun and use the hole as a roof turret whilst you drive-by shoot the suppliers.   |

| |

|

|

|

|

|

|

|

I'm guessing you're trying to avoid outsourcing it and getting a panel welded in that fills the hole? Wouldn't that be an issue on a Scimitar? |

| |

|

|

|

|

|

|

Any fibreglassing experts?fr€$h&m1nt¥

@freshandminty

Club Retro Rides Member 99

|

|

|

I'm guessing you're trying to avoid outsourcing it and getting a panel welded in that fills the hole? Wouldn't that be an issue on a Scimitar? Oh yeah they’re fibreglass bodies aren’t they. Apologies  |

| |

|

|

scimjim

Club Retro Rides Member

Posts: 1,503

Club RR Member Number: 8

|

Any fibreglassing experts?scimjim

@scimjim

Club Retro Rides Member 8

|

|

|

|

If that metal plate is the right profile, I’d use it as the mould. Cover the underside in release agent (furniture polish), lay up several layers (the roof is pretty thick) and cut to size, then glass in from underneath.

|

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,885

Club RR Member Number: 39

|

Any fibreglassing experts?Darkspeed

@darkspeed

Club Retro Rides Member 39

|

|

|

|

Filling a hole in the roof of a GF car is a RPITA and not something I would advise a novice even attempting - There is only one way of doing correctly. You find a car without sunroof and you take a good strong mould - you then fix the mould to the roof of the car with the hole - you then turn the car upside down and you lay up the repair of the hole in the correct Gel/Tissue/Matt x # layup. Repair needs to stay in the mould for at least 2-3 days to cure. You then turn the right way up and finish.

It is very likely that the sun roof you had fitted would not have been the exact same curvature of the original roof and over time it would have distorted the shape of the roof so chopping out larger and remoulding will be the best way to get a decent and lasting finish.

It is possible to do the repair using a repair section - they may well be available from someone who has a roof mould - and scuffing and laying up the repair section reinforcements from the inside but laying up glassfibre upside down is not something I would do for fun.

The full mould type of repair is something I will be covering some time in the future as I have it to do on a G15 - The mould is sitting on the car at the moment just waiting for me to lift the body off the chassis and then sit it on stands and get on with it.

|

| |

Last Edit: Mar 9, 2018 22:42:22 GMT by Darkspeed

|

|

|

|

|

|

|

|

best way is if that panel has an acceptable profile is use it as a mould , lay up fibreglass on it, finishing with fine tissue , then place panel on top and cut thru the two , so that the new piece drops in (use jigsaw with blade tilted) then glass up from inside and finish the outside again with tissue , that way you can then sand back and the roof will be seamless.

Did a Clan Crusader roof that way

|

| |

retired with too many projects!

|

|

|

|

|

|

|

|

best way is if that panel has an acceptable profile is use it as a mould , lay up fibreglass on it, finishing with fine tissue , then place panel on top and cut thru the two , so that the new piece drops in (use jigsaw with blade tilted) then glass up from inside and finish the outside again with tissue , that way you can then sand back and the roof will be seamless.

Did a Clan Crusader roof that way

|

| |

retired with too many projects!

|

|

|

|

|

|

|

Hey Jim! It's only the right profile when it's screwed into place unfortunately. It's quite thin and flexible, but also springy. if I'm understanding your suggestion right you're saying take it off the car and use it as the base mould to make an oversized fibreglass piece. It's a great idea, but the metal would return to flat once removed again.  My best bet would be to use it as the base in situ therefore. JIM, ARE YOU GOING TO RR GOODWOOD? |

| |

|

|

|

|

|

|

|

Wouldn't that be an issue on a Scimitar? Oh yeah they’re fibreglass bodies aren’t they. Apologies  Haha, I just assumed you were using 'weld' as a generic term. For bonding/gluing/fixing.  |

| |

|

|

|

|

|

|

|

|

Hey Darkspeed, thanks for that post. It's the kind of reality check I think I need.

I have this sense that attempting to make my roof look seamless and smooth by splatting fibreglass around on a cold wet British side street with the car on a camber is just going to result in a lumpy, uneven, dips and peaks laden, off-kilter disaster ... and that actually, a kind of laid-on bodge like I've attempted already would look less imperfect if I could get it better than it is right now.

I think, based on what you've said and my own trepidation, I'm going to leave glassing attempts well alone for now.

Edit: Corerected some stupid and nonsensical auto-correct replacements - 'smooth' where it said 'Smith', and 'camber' where it said 'cancer'. Stupid bloody technology.

|

| |

Last Edit: Mar 10, 2018 0:34:14 GMT by Deleted

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,885

Club RR Member Number: 39

|

Any fibreglassing experts?Darkspeed

@darkspeed

Club Retro Rides Member 39

|

|

|

Page 13 on the Litton thread has a fair bit on what it takes to do a GF repair. The advice I usally give people who want to remove the sunroof on any car is - Clean it, polish it, sell it and buy one without a sunroof.  |

| |

|

|

|

|

|

|

|

Page 13 on the Litton thread has a fair bit on what it takes to do a GF repair. The advice I usally give people who want to remove the sunroof on any car is - Clean it, polish it, sell it and buy one without a sunroof.  Hahahahaha. Too late for that now. I'll get it looking okay soon enough. It's a proper old banger of a car in terms of its looks anyway, so it would be crazy of me to get too precious about it. I just want it to look a bit nicer than a badly done bodge. (FYI if my avatar picture creates the impression my car is shiny and nice, it isn't, that's a very flattering picture that was photoshopped to look as nice as possible. Here is a shot of it taken yesterday on a spritely jaunt around the local lanes...  ... concourse isn't my ambition. I like the way it looks with a few cuts and bruises) |

| |

Last Edit: Mar 10, 2018 0:22:45 GMT by Deleted

|

|

|

|