Thanks for the comments guys, appreciate your time in reading through my ramblings!

A long over due update. I've summarised it rather a lot though!

I’ve been pretty useless at updating this post the last few months but lifes just been busy I guess. The below is a brief skim over the progress.

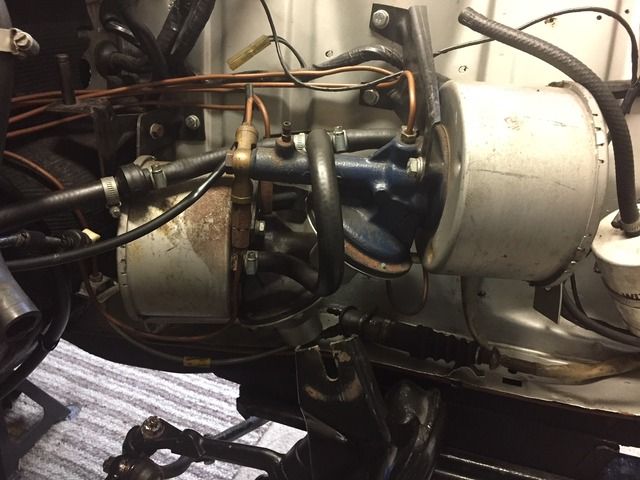

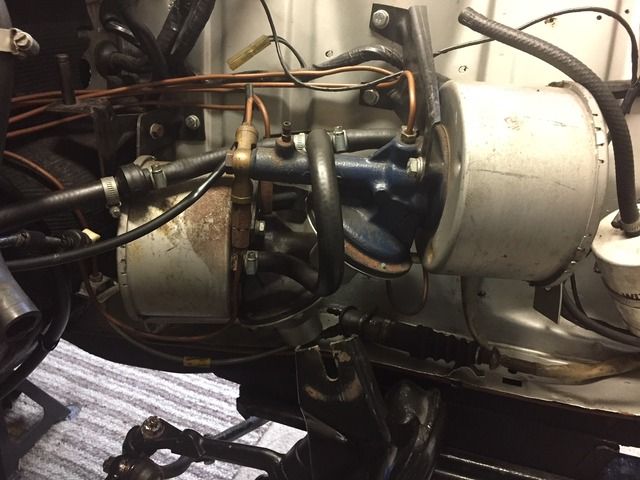

First off was the gearbox, this had been in bits for nearly a year and it really needed to go back together to get the enthusiasm up! We got it all together and it ran through the gears great but the gear stick wasn’t self centering. Having no experience with 2002’s or old gearboxes I thought this was just how they were until I did some digging on the internet. It turns out the selector shaft bushing was turned 180 degrees the wrong way so the indent for the spring and plunger self center system didn’t work. We had this back apart and sorted in double quick time.

Lever test fitted again and now returns the centre, happy days!

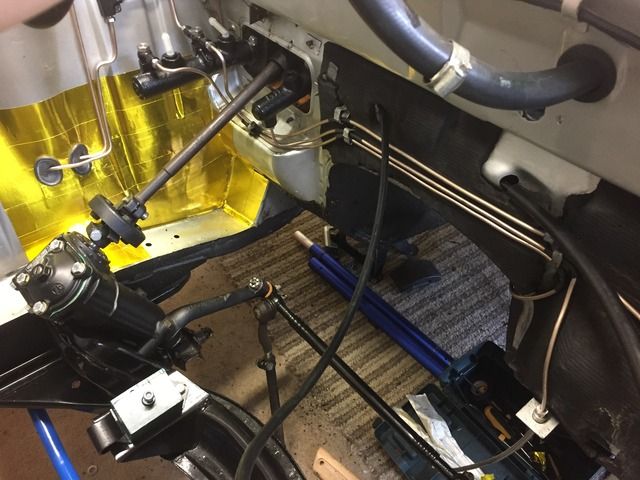

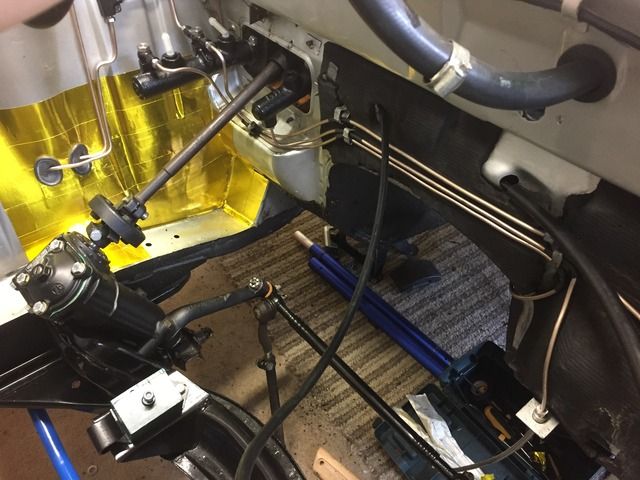

Next job was to bin the servos off and fit a new master cylinder, time to remove these big lumps and the rats nest of brake pipes!

I also bought a bias valve to place in the cabin which will help with the rear brake bias. I used some bulkhead fittings in the transmission tunnel to pipe this in.

Whilst inside I fitted the Ireland Engineering accelerator pedal and also sorted my centre console out. Kooglewerks in USA do a very nice gauge console and dual cup holder so these were duly purchased and fitted up. The Ireland Engineering pedal wasn’t a straight fit on a RHD car but wasn’t much of a problem. I measured up and ordered a needle roller bearing ad a clip which I fitted on the pedal rod, it’s very smooth now and springs back itself.

Finished article, just wiring of the gauges:

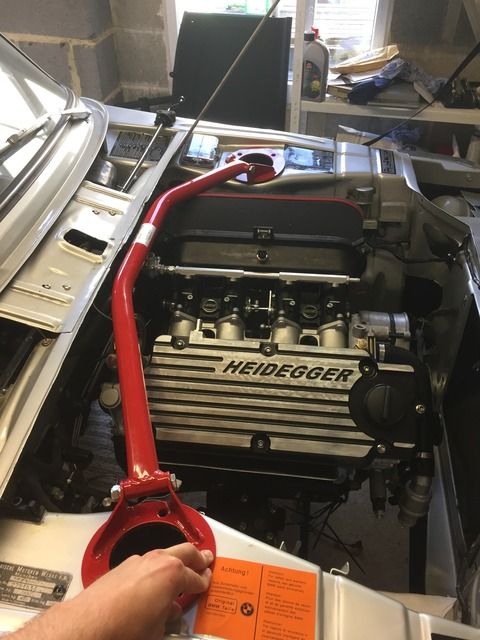

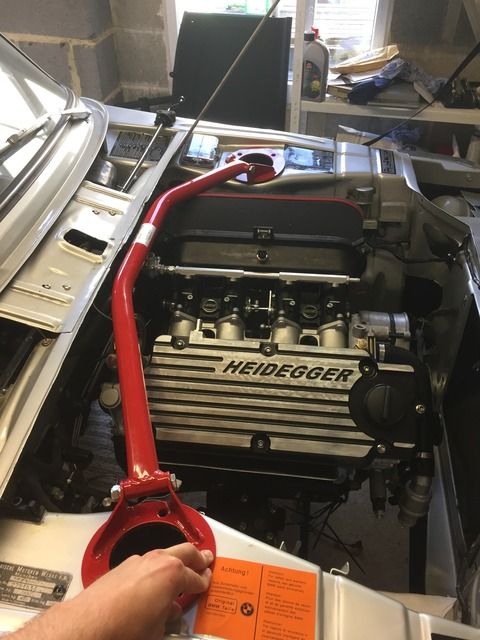

With the brake/ clutch lines all done it was time to get the engine back in:

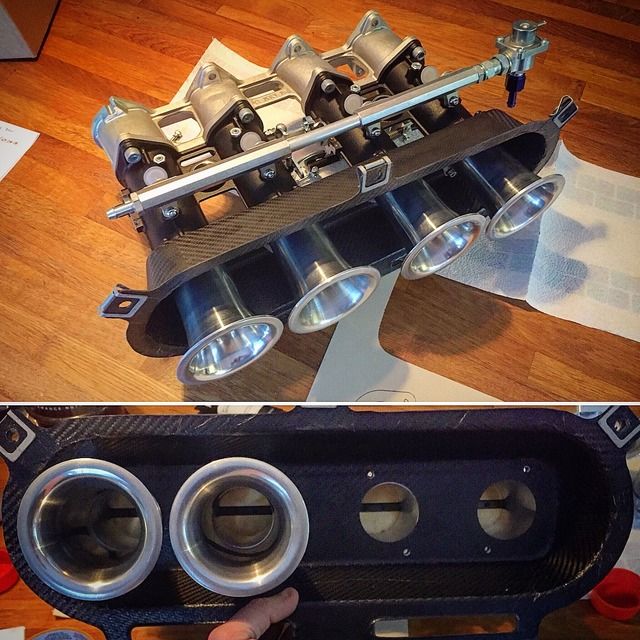

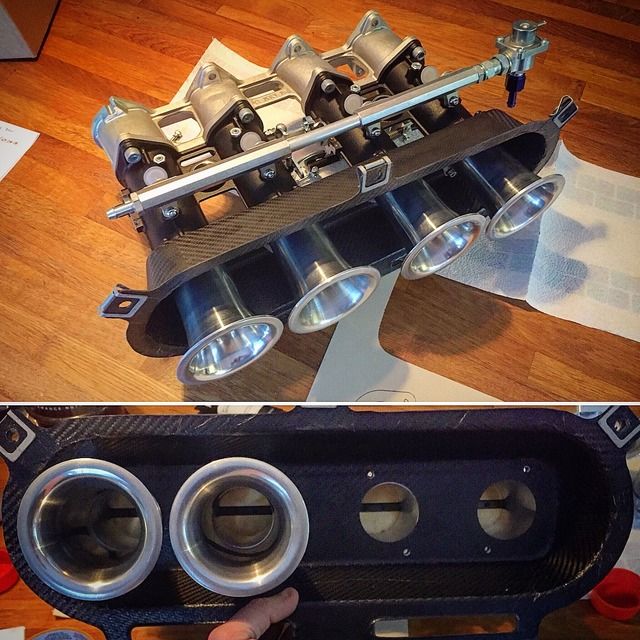

Started fitting other bits and bobs, catch can for instance and also sorted the blank air filter backplate for the itb’s:

Also received the short shifter back that I had had made, really chuffed with this:

And with that the gearbox went in along with the newly refurbished prop shaft which gave the correct alignment of the engine to start test fitting the exhaust manifold in the car. This has been a bit of a pain but will hopefully be worth it. It had to be sent back to have Number 4 rebent, which solved the clash against the side of the engine bay. The rest of the primaries went on fine but number 2 is still a bit too close for comfort, this cant be rebent as it will hit the steering coupling so the engine bay has been ‘massaged’. The collector was supposed to be 2.25 outlet but arrived as 2 inch, this worked out for the best though as a flared it out so it would meet the V band fitting perfectly. This is getting welded on and a lambda boss putting in.

Excuse the duct tape, it’s about the extent of my fab skills!

Ill hopefully get all that sent away for ceramic coating soon, as you can see this is needed as it comes close to EVERYTHING!

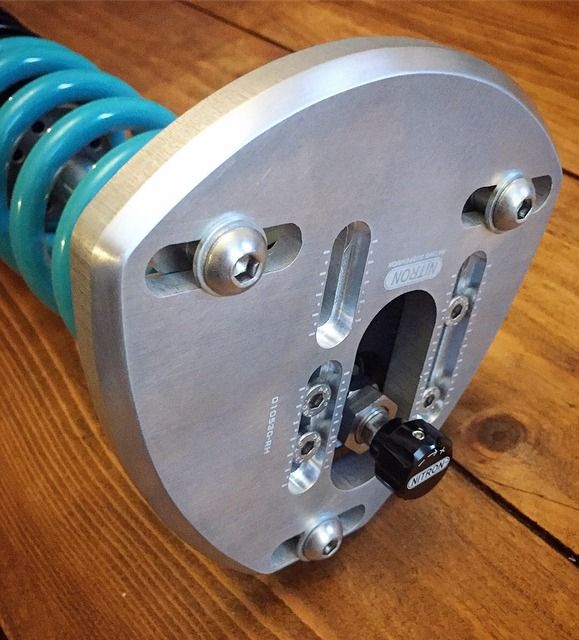

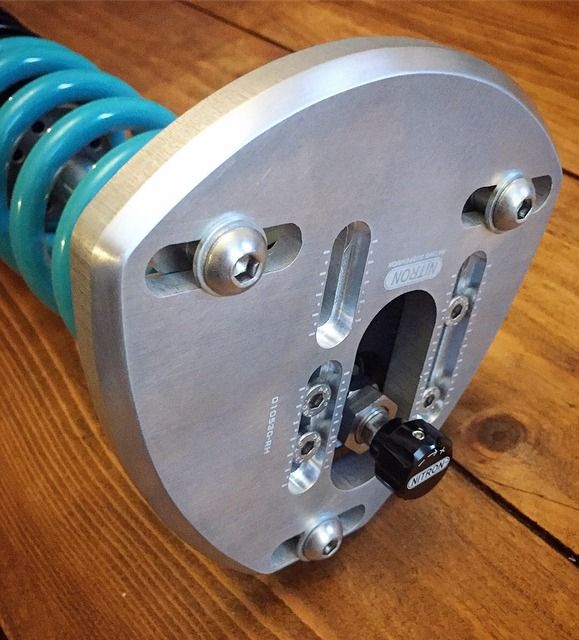

Now the next item is one of my favourite parts of the car. It’s been a long time in the making, where I initially made contact with Nitron before Christmas, half hoping they would tell me they weren’t interested. They were though so that was that! Fast forward and the end result is below:

This is their R1 kit which features combined compression and rebound adjustment. Castor and camber are adjustable up front via the top mounts. I wanted to keep the rear divorced spring/ shock but they will do coilover rears too. The shocks are designed to be mounted with OEM rubber top mounts, I fitted polybushed ones where the hole was larger than OEM so I had to have a sleeve made up to suit.

These are all now fitted up and I'm extremely happy with the quality of the kit, certainly a ‘you get what you pay for’ part. With them fitted I could get the brakes on. I hit a snag with the rears as the VW discs come in 10 & 12mm and I didn’t realised. Typically I ordered the wrong ones, waiting for the right ones to turn up and hopefully that’ll be that sorted.

In the meanwhile I’ve fitted the new slave cylinder for the clutch and refitted a new OEM centre tie rod. The New Moog one has perished even just fitted to the car with 0 miles!

Not a millions miles off now, still need to make seat sub frames, do all the wiring. Send it off for an exhaust once the manifold has been coated, then hopefully itll just be snagging and setting up. I’ve missed the summe deadline now which sucks but not to worry, here’s to enjoying the car in 2019 I hope!

Thanks for reading,

Scott

A long over due update. I've summarised it rather a lot though!

I’ve been pretty useless at updating this post the last few months but lifes just been busy I guess. The below is a brief skim over the progress.

First off was the gearbox, this had been in bits for nearly a year and it really needed to go back together to get the enthusiasm up! We got it all together and it ran through the gears great but the gear stick wasn’t self centering. Having no experience with 2002’s or old gearboxes I thought this was just how they were until I did some digging on the internet. It turns out the selector shaft bushing was turned 180 degrees the wrong way so the indent for the spring and plunger self center system didn’t work. We had this back apart and sorted in double quick time.

Lever test fitted again and now returns the centre, happy days!

Next job was to bin the servos off and fit a new master cylinder, time to remove these big lumps and the rats nest of brake pipes!

I also bought a bias valve to place in the cabin which will help with the rear brake bias. I used some bulkhead fittings in the transmission tunnel to pipe this in.

Whilst inside I fitted the Ireland Engineering accelerator pedal and also sorted my centre console out. Kooglewerks in USA do a very nice gauge console and dual cup holder so these were duly purchased and fitted up. The Ireland Engineering pedal wasn’t a straight fit on a RHD car but wasn’t much of a problem. I measured up and ordered a needle roller bearing ad a clip which I fitted on the pedal rod, it’s very smooth now and springs back itself.

Finished article, just wiring of the gauges:

With the brake/ clutch lines all done it was time to get the engine back in:

Started fitting other bits and bobs, catch can for instance and also sorted the blank air filter backplate for the itb’s:

Also received the short shifter back that I had had made, really chuffed with this:

And with that the gearbox went in along with the newly refurbished prop shaft which gave the correct alignment of the engine to start test fitting the exhaust manifold in the car. This has been a bit of a pain but will hopefully be worth it. It had to be sent back to have Number 4 rebent, which solved the clash against the side of the engine bay. The rest of the primaries went on fine but number 2 is still a bit too close for comfort, this cant be rebent as it will hit the steering coupling so the engine bay has been ‘massaged’. The collector was supposed to be 2.25 outlet but arrived as 2 inch, this worked out for the best though as a flared it out so it would meet the V band fitting perfectly. This is getting welded on and a lambda boss putting in.

Excuse the duct tape, it’s about the extent of my fab skills!

Ill hopefully get all that sent away for ceramic coating soon, as you can see this is needed as it comes close to EVERYTHING!

Now the next item is one of my favourite parts of the car. It’s been a long time in the making, where I initially made contact with Nitron before Christmas, half hoping they would tell me they weren’t interested. They were though so that was that! Fast forward and the end result is below:

This is their R1 kit which features combined compression and rebound adjustment. Castor and camber are adjustable up front via the top mounts. I wanted to keep the rear divorced spring/ shock but they will do coilover rears too. The shocks are designed to be mounted with OEM rubber top mounts, I fitted polybushed ones where the hole was larger than OEM so I had to have a sleeve made up to suit.

These are all now fitted up and I'm extremely happy with the quality of the kit, certainly a ‘you get what you pay for’ part. With them fitted I could get the brakes on. I hit a snag with the rears as the VW discs come in 10 & 12mm and I didn’t realised. Typically I ordered the wrong ones, waiting for the right ones to turn up and hopefully that’ll be that sorted.

In the meanwhile I’ve fitted the new slave cylinder for the clutch and refitted a new OEM centre tie rod. The New Moog one has perished even just fitted to the car with 0 miles!

Not a millions miles off now, still need to make seat sub frames, do all the wiring. Send it off for an exhaust once the manifold has been coated, then hopefully itll just be snagging and setting up. I’ve missed the summe deadline now which sucks but not to worry, here’s to enjoying the car in 2019 I hope!

Thanks for reading,

Scott