|

|

|

Jan 19, 2018 21:08:25 GMT

|

More of the same old profile pounding I'm afraid   But the nearside front wing & both front panels are very close to completion - just a couple of minor areas in the morning then they can be skimmed with glaze prior to a final light sanding - at that stage the panels need to come back off the body and the flange edges tidied up / profiled then they need to go back on but this time with the wing piping which will require cutting to length and the bolt holes stamping through - then its a final panel fit check before primer & paint can commence  I have purposely left the offside front wing off has profiling the front panel is easier with the wing off rather than on Meanwhile the rear wings were fastened up - minor reshaping as required with the hammer & dolly and are now ready for profiling   |

| |

|

|

|

|

|

|

|

Jan 19, 2018 22:26:04 GMT

|

|

What's the plan for the wheels?

|

| |

|

|

|

|

|

|

|

|

its really starting to take shape now, Grumpy!

looking good...

JP

|

| |

I know its spelled Norman Luxury Yacht, but its pronounced Throat Wobbler Mangrove!

|

|

|

|

|

Jan 20, 2018 10:58:22 GMT

|

What's the plan for the wheels? They will stay factory original but will come off and have the tyres removed (new tyres & tubes already fitted to get the van mobile) - then a good shot blasting although the rims are fine to go again they are very heavily pitted and will require some detailed work prior to paint - The vans left the factory with black wheel rims - but with the wings / radiator cowl & roof all being black I think the rims would better in the body colour of maroon but it's up to the owner who I will consult prior to painting them (should be the last thing that I paint on the van) - the rims also have hub caps some were painted same has the rims but with this being a rare variant 'Utility' model it's having chrome hub caps which with exception of the 3 door handles and the wiper arms is just about the only chrome on the van. |

| |

|

|

|

|

|

Jan 20, 2018 21:46:40 GMT

|

Had another few hours on the van today  Front panel on the offside profile glaze applied / sanded back and all about there on the outer profiles  Now removed and the flange edges filled ready for profiling up tomorrow   Nearside front wing again put into glaze - sanded back & outer profiles completed - I will remove the wing in the morning and straighten the flange edges up which will also allow access for the nearside front panel to be skimmed with glaze & profiled   Rear wings were given an initial skimming of filler and guide coated - I will make a start on profiling them back tomorrow |

| |

Last Edit: Jan 20, 2018 21:52:47 GMT by Deleted

|

|

vulgalour

Club Retro Rides Member

Posts: 7,285

Club RR Member Number: 146

|

|

|

|

|

Doing the updates as you go really makes the reader appreciate just how much work is involved in getting panels right and how much work is completely invisible with a good paint job.

|

| |

|

|

|

|

|

|

|

Doing the updates as you go really makes the reader appreciate just how much work is involved in getting panels right and how much work is completely invisible with a good paint job. Thanks - I had hoped that was the case but some readers must get fed up of just seeing more posts of more profiling followed by yet more - same work & same principle but a different panel - however getting closer by the day now that the profiling will be complete and then I can start on the paint prep |

| |

|

|

vulgalour

Club Retro Rides Member

Posts: 7,285

Club RR Member Number: 146

|

|

|

|

|

Not me! I enjoy tuning in to see what you've been up to and learning new stuff along the way.

|

| |

|

|

|

|

|

|

|

|

whats the glaze that you use like, is it quite runny to get into all the light scratches or thicker like a filler, i have tried using a putty type fine filler in the past for fine scratches before paint and found it to be to soft so it just came out when sanding before primer. also i enjoy seeing the amount of work on just preping panels before the paint process as most of us just don't know quite how much prep goes into these top quality paint jobs, having smoothed and painted my old astra a few years back i couldnt understand why i could see scratch marks in the paint but i only did about half the prep stages you are doing on this van.

|

| |

|

|

|

|

|

|

|

|

Amazing work grumpy! I see that you draw lines in panels - why is that?

|

| |

1966 Ford Cortina GT

2018 Ford Fiesta ST

Full time engineer, part time waffler on Youtube - see Jim_Builds

|

|

|

|

|

|

|

Jan 21, 2018 10:26:03 GMT

|

whats the glaze that you use like, is it quite runny to get into all the light scratches or thicker like a filler, i have tried using a putty type fine filler in the past for fine scratches before paint and found it to be to soft so it just came out when sanding before primer. also i enjoy seeing the amount of work on just preping panels before the paint process as most of us just don't know quite how much prep goes into these top quality paint jobs, having smoothed and painted my old astra a few years back i couldnt understand why i could see scratch marks in the paint but i only did about half the prep stages you are doing on this van. I'm back in the workshop today - I will take some pics of the glazes along with a few pics of the glaze in use and update the post / thread with an explanation of the benefits |

| |

|

|

|

|

|

Jan 21, 2018 10:33:06 GMT

|

Amazing work grumpy! I see that you draw lines in panels - why is that? Ah - without being smug - here's an answer I prepared earlier  So it's a working technique taught to me by a very wise & thorough old school chap that I was apprenticed to 40 years ago - when working large areas of skimmed filler / complex panels / multiple panels / bodyshells etc - It becomes all too easy to loose your way has to what areas are completed / part worked / require further work / skimming etc - During the filling process your hand is the main detector of low / high spots / defects / areas that require further working etc - sight is also used along with guide coats - most people will mix a batch of filler up and then just before application will use said hand to reassess the areas on the panel has to how much filler is required / location on the panel etc - With my method of working I assess the panel first then mark out the areas with pencil prior to mixing enabling the filler to go straight on (remember that you have a product that is now starting to cure since you mixed it - if you have several areas to address you may find the filler has cured before you have had the chance to apply it has you work around the panel - especially in summer months) Ideally you need a process that allows you the time to apply the filler quickly & easily but one that allows you the time to apply it neatly & smoothly - the rougher the application - the more wasted filler / abrasive / time spent in getting it profiled correctly - so that's the first part. Second part - when you have a lot of profiling to do - it's a laborious, intensively mind numbing process - it's easy to loose your way when working multiple panels - apply paint over poorly worked areas / panels and it will look dreadful regardless of how good / shiny the paint is - once I have a panel complete I drag pencil lines diagonally down it - when working around a complete car with a process has boring has this it's important that you have something that motivates the process - the more panels you have pencilled out the further on you are - it's good for focusing on what needs to be done / completed and from here you can target your days work to completion - critical when you have acres of profiling day after day after day to get done - with some large panels taking several skims before you achieve the correct results. You won't see this process in most bodyshops / vehicle restorers - it's a system that works for me - and the guy that taught me - it gave him a immediate picture of the progress on the restoration - along with the client and anyone else that visited the workshop / viewed the work. Most restorers / bodyshops will just roll their eyes into the back of their heads if I explained the process to them - but again it's what achieves the right results for me and is critical in a market where many, many others fundamentally judge on a 10 second glance of a completed vehicle restoration. |

| |

Last Edit: Jan 21, 2018 10:33:44 GMT by Deleted

|

|

|

|

|

Jan 21, 2018 16:54:24 GMT

|

Amazing work grumpy! I see that you draw lines in panels - why is that? Ah - without being smug - here's an answer I prepared earlier  So it's a working technique taught to me by a very wise & thorough old school chap that I was apprenticed to 40 years ago - when working large areas of skimmed filler / complex panels / multiple panels / bodyshells etc - It becomes all too easy to loose your way has to what areas are completed / part worked / require further work / skimming etc - During the filling process your hand is the main detector of low / high spots / defects / areas that require further working etc - sight is also used along with guide coats - most people will mix a batch of filler up and then just before application will use said hand to reassess the areas on the panel has to how much filler is required / location on the panel etc - With my method of working I assess the panel first then mark out the areas with pencil prior to mixing enabling the filler to go straight on (remember that you have a product that is now starting to cure since you mixed it - if you have several areas to address you may find the filler has cured before you have had the chance to apply it has you work around the panel - especially in summer months) Ideally you need a process that allows you the time to apply the filler quickly & easily but one that allows you the time to apply it neatly & smoothly - the rougher the application - the more wasted filler / abrasive / time spent in getting it profiled correctly - so that's the first part. Second part - when you have a lot of profiling to do - it's a laborious, intensively mind numbing process - it's easy to loose your way when working multiple panels - apply paint over poorly worked areas / panels and it will look dreadful regardless of how good / shiny the paint is - once I have a panel complete I drag pencil lines diagonally down it - when working around a complete car with a process has boring has this it's important that you have something that motivates the process - the more panels you have pencilled out the further on you are - it's good for focusing on what needs to be done / completed and from here you can target your days work to completion - critical when you have acres of profiling day after day after day to get done - with some large panels taking several skims before you achieve the correct results. You won't see this process in most bodyshops / vehicle restorers - it's a system that works for me - and the guy that taught me - it gave him a immediate picture of the progress on the restoration - along with the client and anyone else that visited the workshop / viewed the work. Most restorers / bodyshops will just roll their eyes into the back of their heads if I explained the process to them - but again it's what achieves the right results for me and is critical in a market where many, many others fundamentally judge on a 10 second glance of a completed vehicle restoration. That makes sense - I'll give this a try! Thank you |

| |

1966 Ford Cortina GT

2018 Ford Fiesta ST

Full time engineer, part time waffler on Youtube - see Jim_Builds

|

|

|

|

|

Jan 21, 2018 19:02:12 GMT

|

|

Nice to watch a craftsman at work; reminds me of the time I was a vehicle re-finisher back in the late 1960's! Once renovated and resprayed a Jowett Javelin; had a soft spot for the marque ever since.

|

| |

|

|

|

|

|

Jan 21, 2018 20:31:52 GMT

|

Hi been looking at your in-depth thread with great interest, I have just purchased a Jowett Bradford that is not fully finished and some of the work needs addressing. It has been in storage at my workshop 18months, but I never really took any notice of it as I was storing it for a friend, who now has given up on the prospect of Finnishing due to life changes The veh has had a full new ash frame several years ago, I have known the previous owner for several years and, know most of the veh has been done to a professional standard but never finished. I the chassis and engine were fully rebuilt and chassis looks like that still, the engine was also rebuilt to a high standard. I am after help and advice on sourcing some parts ie gutter rails and side trims, and info on what the panels round door frames were like. I hope you will be a world of knowledge and help thank you.    |

| |

|

|

|

|

|

Jan 21, 2018 20:50:02 GMT

|

Hi been looking at your in-depth thread with great interest, I have just purchased a Jowett Bradford that is not fully finished and some of the work needs addressing. It has been in storage at my workshop 18months, but I never really took any notice of it as I was storing it for a friend, who now has given up on the prospect of Finnishing due to life changes The veh has had a full new ash frame several years ago, I have known the previous owner for several years and, know most of the veh has been done to a professional standard but never finished. I the chassis and engine were fully rebuilt and chassis looks like that still, the engine was also rebuilt to a high standard. I am after help and advice on sourcing some parts ie gutter rails and side trims, and info on what the panels round door frames were like. I hope you will be a world of knowledge and help thank you.    Welcome to the forum - I can certainly help out with advice & suppliers PM sent - Check the message box at the top of the page (while logged on) in a little while and will attach my contact details - Chris |

| |

|

|

|

|

|

Jan 21, 2018 21:12:28 GMT

|

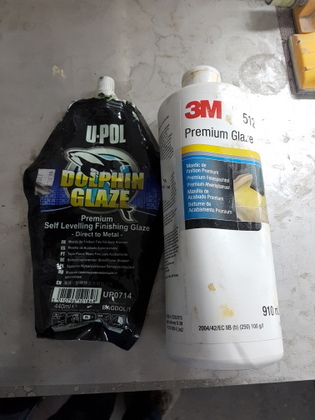

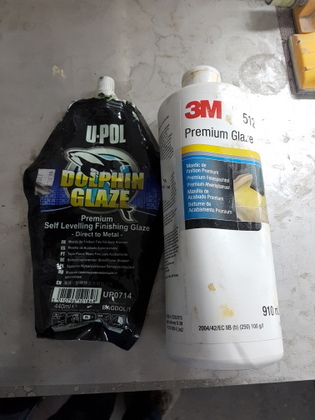

whats the glaze that you use like, is it quite runny to get into all the light scratches or thicker like a filler, i have tried using a putty type fine filler in the past for fine scratches before paint and found it to be to soft so it just came out when sanding before primer. also i enjoy seeing the amount of work on just preping panels before the paint process as most of us just don't know quite how much prep goes into these top quality paint jobs, having smoothed and painted my old astra a few years back i couldnt understand why i could see scratch marks in the paint but i only did about half the prep stages you are doing on this van. I'm back in the workshop today - I will take some pics of the glazes along with a few pics of the glaze in use and update the post / thread with an explanation of the benefits So You have more or less answered you own question the polyester glazes that are available in the refinishing market are semi liquid type filler - ideal for pin holes / light scratches / minor defects / minor panel or profile undulations - can be applied to bare metal or over painted surfaces providing they are prepared correctly - more than anything I use glazes has my final skimming coat to remove minor undulations / ripples etc - they are several manufactures in the market but these are the two that I use and that I can recommend  U POL Dolphin Glaze - Fairly fluid and self levelling - thin enough to wipe in / brush into areas that have awkward access - it's good stuff - even better if you can apply it whilst the panel is horizontal 3M Premium Glaze - Slightly denser than Dolphin - but still very easily spread into panel areas - semi self levelling (sometimes pays to warm the bottle up for a few mins in colder weather to make it a little more workable (just run it under a warm water tap or place it on a radiator for a few mins) Just mix it with the hardener has you would normal filler This is 3M Glaze ready to be mixed with the hardener  Here it is applied - it spreads / applies easily (nearly has easy has margarine on bread) therefore you can keep close to the profile - it's also very fine - but apply with care otherwise you will have it running or sagging off the panel if you apply it densely   Takes the same time has normal filler to cure - about 20 mins in conditions above 15 degrees c - guide coat applied (matt black aerosol)  I sand back with P80 normally can be sanded back with finer paper from here if needed  Result is a profiled panel with no undulation or deviation and ready for prepping for primer - this would take more effort to achieve with normal fillers however you need to be capable of attaining the correct panel profiles with polyester fillers before you start applying glazes |

| |

Last Edit: Jan 21, 2018 21:35:02 GMT by Deleted

|

|

|

|

|

Jan 21, 2018 21:56:15 GMT

|

So has you can see in the previous post the nearside front panel has had polyester glaze applied to it and it sanded back - it now needs to be removed and the inner flange edge with the inner wing trued up along with the bottom return flange which I will do in the morning Elsewhere - the nearside front wing has been removed and just awaits the flange edge being sanded back in the morning  Nearside rear door - the blanking off / making good of several rebates in the doors ash frame for the old door catches have now been completed & reprofiled  The door skins on all of the doors are just nailed onto the ash frames - inevitably this leaves a edge gap in places to harbour water between the frame & the door skin - plan here is apply a etch primer to the flange on the door skin and then apply a thin bead of automotive sealer between the frame & skin - not original but this goes on to preserve the van for many, many years  Made a start on profiling the rear wings  Removed the offside front panel and completed the flange edges then refitted it  Enabling the offside front wing to be fastened up which means the profiles on this can commence in the morning   |

| |

Last Edit: Jan 21, 2018 22:29:18 GMT by Deleted

|

|

|

|

|

Jan 21, 2018 22:05:14 GMT

|

Thanks - I had hoped that was the case but some readers must get fed up of just seeing more posts of more profiling followed by yet more No, carry on... it’s quite therapeutic reading these posts  I don’t think I have the patience to attempt bodywork properly, and reading lots of posts from you is still a lot quicker than doing it |

| |

|

|

vulgalour

Club Retro Rides Member

Posts: 7,285

Club RR Member Number: 146

|

|

Jan 21, 2018 23:31:32 GMT

|

|

Surprised they didn't use some sort of putty or primitive sealant on that bottom edge. Perhaps they didn't expect the vans to last long enough in service to warrant the extra cost and time?

|

| |

|

|

|

|