|

|

|

|

|

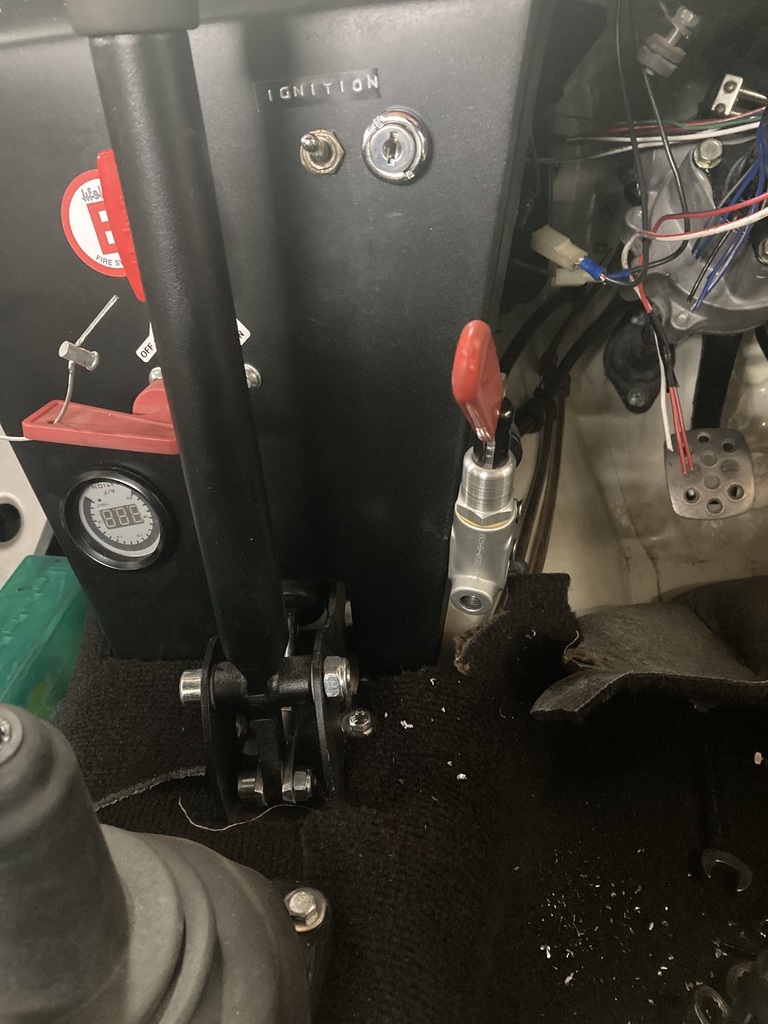

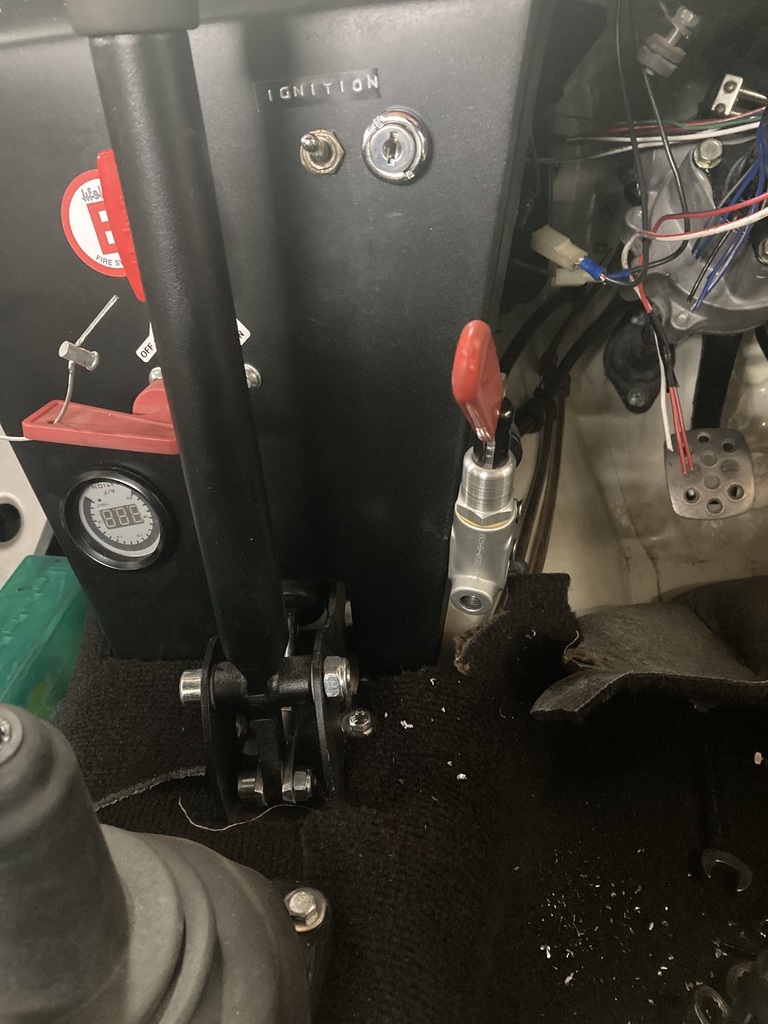

I spent the day in the garage yesterday. My suspension components turned up from Rally Design. The “in situ” adjustable TCAs were fitted.  They came with bigger bolts to mount them, but I couldn’t be bothered to drill the crossmember so reused the originals. As I’ve got new lower/softer springs I removed the struts. I was running 250lb 14” springs. As the engine is considerably lighter and the car is sitting higher, I’ve now got 200lb 10.5” springs. I’ll probably end up changing them again but that’s just how it seems to go with springs a bit of suck it and see.  I’ve also ordered helper springs to stop the springs coming loose(turned up today) when the car is lifted. The lower platform was seized on one of the struts. I tried everything but it would not go higher than a certain point on the strut so I modified it with a hacksaw   I’ve ordered 2 new ones. The compression struts  Shiney. But useless. There is a bracket that sits in the TCA that the flat part of the strut bolts into. They have made the bolt hole bigger and the blade part narrower from the ones I already have. Great. I bought them from Rally Design. The ones on the car are from Rally Design. These are advertised as spares. So I phoned Rally Design but they have stopped taking phone calls. A recording says to email Rally Design. I did this last Friday telling them of my predicament with photos attached, and asked what can be done to resolve the problem. This morning there was still no reply, so I emailed Rally Design again and had a reply just saying “we have changed the design”. And that’s it. I know you’ve changed the design but you didn’t tell anyone!!! Morons. As much as it pains me to give these clowns more of my money, I thought the easiest (and cheapest) solution was to buy the matching brackets that fit in the TCAs, so that’s what I’ve done. That’s the last bit of money they’ll see from me. I’m guessing the phone line has gone because of all the complaints they receive. Anyway, chin up and all that. Next I moved onto another problem. Isn’t it strange how your brain works. I was driving along in work one day a couple of weeks ago, minding my own business, when out of nowhere, a thought popped into my mind. When I plumbed the brake line to the rear wheels, I plumbed it wrong. I have put the bias valve after the handbrake. This means when I reduce the pressure to the rear, I also lower the effectiveness of the hydraulic handbrake. Not good. So I removed this  And replaced it with a straight connector  I bolted the bias valve to the switch panel  It then got plumbed in before the handbrake so when you press the foot brake, the rear brakes see the reduced pressure, but when you pull “the bar” the rear brakes get full pressure. All done   In other news, I had a call earlier to say my axle is ready so I’ll pick that up tomorrow evening. In other other news, I’ve bought a generic wiring loom because I think it’s cheaper than buying just cable  Was this a good idea? Probably not going by recent events |

| |

|

|

|

|

|

|

|

Oct 10, 2024 11:21:32 GMT

|

I was a day off yesterday. Yay. Because I’m working Saturday. Boo. Well actually it’s double boo as it’s also my birthday on Saturday. Well double actually, it’s triple boo as I’m also on call Sunday. Well to celebrate this, my nephew Sean came up yesterday and made a start on the wiring. No photos of any of this, but the front end is pretty much wired and wrapped. Just a couple of earths to terminate. I had collected the axle from the guy changing the CWP to a 5:1 ratio on Tuesday after work, so while Sean went to get some lunch, I got the axle refitted  It appears I did have one photo of the wiring- well the wires anyway  We have cut up the generic wiring loom and are just using the cable. Each cable is conveniently labeled along its length to say what it does, but unfortunately it’s been printed by a Chinese man trying to talk American. Back to this morning, I’m on call (again) so I managed another couple of hours out the garage. I got the rear brakes refitted and replumbed. A changed the routing of the pipes slightly as my brother pointed out that the way I had it, there was a possibility it could get crushed as it was between the axle and the exhaust. It’s only a minute chance, but…. I also did a bit of wiring preparation for when Sean comes back next week. I drilled a hole in the transmission tunnel for the lambda sensor and reverse switch wiring  Another hole was drilled in the bulkhead for the new alternator feed. This needs to go on the battery side of the cut off switch or the engine won’t turn off when the cut off is pulled. No photo. I also drilled the switch panel for a 12v socket and a couple of USB ports.  Finally, the axle was refilled with LSD oil and I also topped up the gearbox oil as it’s lost a bit every time I’ve removed the prop shaft. More next week |

| |

|

|

teaboy

Posted a lot

Make tea, not war.

Make tea, not war.

Posts: 2,125

|

|

Oct 10, 2024 12:11:59 GMT

|

|

I hope that there is cake waiting for you when you get home on Saturday.

|

| |

|

|

|

|

|

Oct 10, 2024 21:39:14 GMT

|

I hope that there is cake waiting for you when you get home on Saturday. Me too Mr T. An apple tart as a minimum. |

| |

|

|

|

|

|

Oct 11, 2024 17:13:12 GMT

|

I got called out at 5am this morning. Boo. Which meant I had to finish work 3 hours early. Yay. I took this time to start putting the front suspension back together. I’d ordered new joints for the compression struts so those could get fitted   The new lower spring seats for the Bilsteins also arrived so I could build those back up with new softer / lower springs and the new helper springs   I covered all the threads with spray grease to help stop the aluminum corroding onto the strut I could then mount the legs back onto the car    All the bolts are currently still loose but everything is back where it should be. No more progress now until after the weekend 🙁 |

| |

|

|

|

|

|

Oct 15, 2024 16:57:29 GMT

|

I was a day off today, as I was lucky(?) enough to have been in work on Sunday. I tightened up all the suspension bolts on the front and gave the suspension a quick adjustment. There’s about 1° of negative camber and the steering is toeing out a bit   The car is definitely sitting a lot lower. I’ll lift the front a bit as I think it’s too low. I also need to wind on a bit more caster as the wheel is a bit far back in the arch and the more the better. All this is by the by, as I will take it back to my brother’s garage to set it up on the 4 wheel alignment thingy. I also did a bit of wiring, moving the alternator feed to the battery side of the cut off switch so the engine stops when it’s activated. No photo. But this did result in my temp bodge alternator bulb being constantly live so I put a switch in line to turn it off when not running.  I had put a set of rally tyres on the back so it has the correct gearing. I then ran the car in gear on the lift. The guy who changed the cwp said it would need to be run in so this should help- a bit. So with this done, I took the car for a quick spin up the road. The car certainly felt livelier. It would spin the wheel pulling off and even a slight spin changing to 2nd gear. However, this is not truly representative as it was wet and the rally slicks are a medium compound and probably over 10 years old. I’m on call tomorrow so I’ll make a few suspension adjustments and if it’s dry, I’ll take it for another spin before work. |

| |

|

|

|

|

|

Oct 16, 2024 11:16:53 GMT

|

On call again, another couple of hours. I lifted the front end by 1.5” and wound on some more camber (1.5° total). I also gave it some more caster. I don’t know how much is on there now. I could have checked using the camber gauge but couldn’t be bothered. Yesterday  Today  The sump guard was refitted  Shame that wasn’t on when I tried to align the suspension the other week. It would have saved my front valance getting smashed up. The mechanical handbrake wasn’t doing much. This side of the cable was out of its bracket  Cables adjusted up on this side  The original indicator bulb holders are wrecked. So I’ve bought some LED side markers and have mounted them inside the original lamps  Hopefully they’ll be bright enough when the lenses are back on |

| |

|

|

|

|

|

Oct 23, 2024 17:06:19 GMT

|

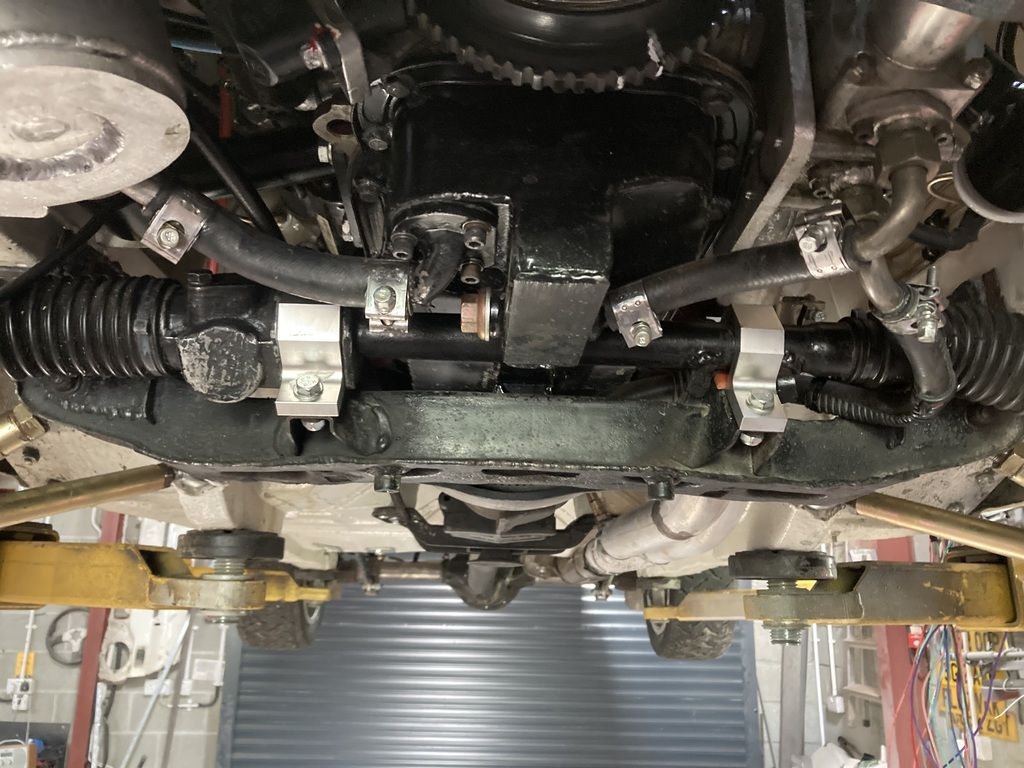

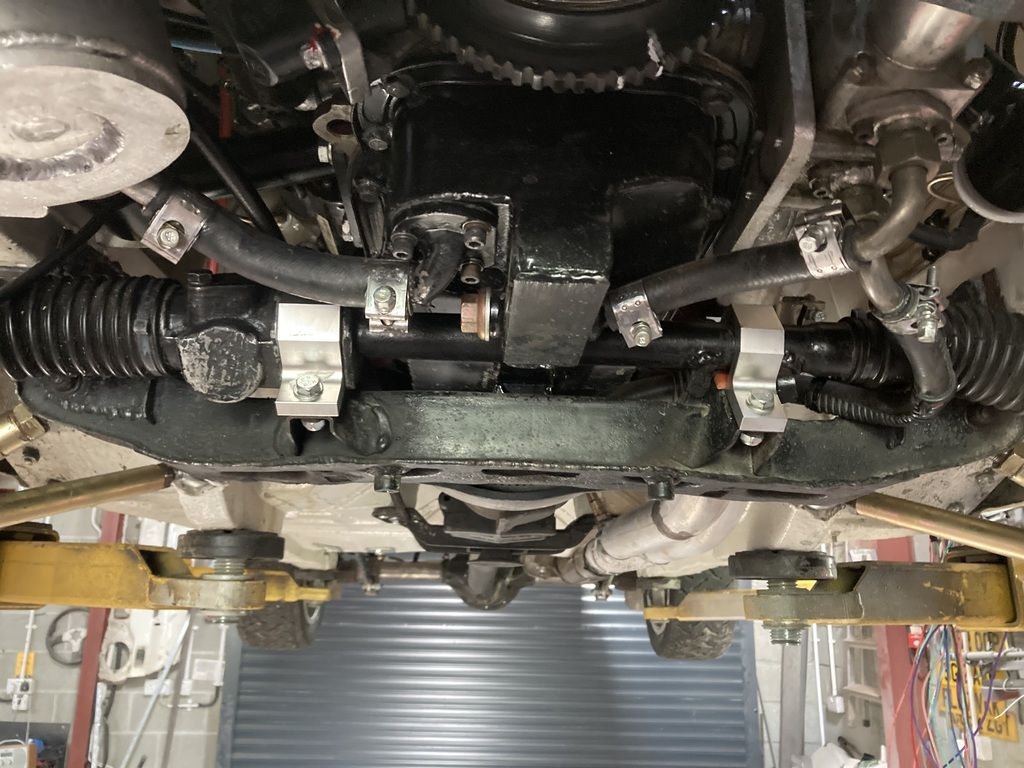

Wiring continues on the Escort. My nephew has put in 2 sessions now which probably amounts to 12 hours. The first session saw the engine bay completed - bar crimping some earths. The second session saw the boot completed. What’s left is all the rest- hooking all the wires to fuses, switches and relays so they can actually do something. No photos of any of this as it’s pretty boring stuff. One thing I noticed “the other day” was that when I shock the driver front wheel, the steering rack was able to move up and down on its mounts. As this is going to be a motorsport thoroughbred, that just won’t do. These mounts are steel with, originally, rubber bushes. I swapped those out years ago for poly bushes  They are either worn, or more than likely, not up to muster in the first place. So I removed them and have bought solid mounts  Like all uprated parts that you can buy for an Escort (even when you pay top dollar), they didn’t fit. The bolt holes in the driver mount were on the radius so the bolts would not have had even pressure on the clamp. I power filed a bit of the radius away to allow a washer and bolt head to sit flat. No photo Also, where the driver side mount sit on the rack is radiused, where the mount was not  So a tickle with the power file so that problem resolved also  The rack and mounts could then be fitted  I’ve also crimped and bolted down all the earths I mentioned earlier but no photo evidence. I’m a day off tomorrow but Mrs Jonsey has other plans for me, but Sean is hopefully calling round in the evening for another wiring session |

| |

|

|

lebowski

Part of things

Hillman Avenger, Clan Clover

Hillman Avenger, Clan Clover

Posts: 488

|

|

|

|

|

I notice that you fitted your helper springs without any separating collar between the main spring and the helper spring. Is there any issue doing it like this? I suppose it won't make much difference but then I'm wondering why anyone bothers with the collars.

Also, do you know if there's any chance of the main spring bottom edge 'catching' onto the top hat section of the spring seat when going from full droop back to compression? Since there's now nothing to keep the bottom of the main spring concentric to the seat in a full droop situation. I guess at worst there might be a brief 'thunk' as it guides itself back onto the seat.

I'm considering adding helper springs to mine so I can drop it a bit lower, but just thinking through any potential issues.

|

| |

|

|

|

|

|

Oct 24, 2024 10:16:09 GMT

|

|

I'm amazed by the amount of performance/aftermarket stuff you can get for Fords, the amount they sell you would have though they could get the stuff to fit!

Are we nearly there yet?!

|

| |

|

|

|

|

|

Oct 24, 2024 21:51:37 GMT

|

I notice that you fitted your helper springs without any separating collar between the main spring and the helper spring. Is there any issue doing it like this? I suppose it won't make much difference but then I'm wondering why anyone bothers with the collars. Also, do you know if there's any chance of the main spring bottom edge 'catching' onto the top hat section of the spring seat when going from full droop back to compression? Since there's now nothing to keep the bottom of the main spring concentric to the seat in a full droop situation. I guess at worst there might be a brief 'thunk' as it guides itself back onto the seat. I'm considering adding helper springs to mine so I can drop it a bit lower, but just thinking through any potential issues. I do have a set of the separating collars but the helper springs compress more than the bottom spring seat height. So the weight of the car would be sitting on just the thin centre part of the separator. If the blue longer spring seats had survived, they would have been ideal. When I lower the car there is some times a gentle twang but as there is a slight rounded edge to the bottom of the spring, it doesn’t cause a problem. We’ll hopefully see in a couple of weeks if it is or not. I’ll try and remember to report back. |

| |

|

|

|

|

|

Oct 24, 2024 22:00:08 GMT

|

I'm amazed by the amount of performance/aftermarket stuff you can get for Fords, the amount they sell you would have though they could get the stuff to fit! Are we nearly there yet?! There is lots of kit out there for these old bangers made by many different suppliers. Sadly cost doesn’t dictate quality. I’ve bought expensive parts and still had to mod them. I’ve bought cheap and quality has been surprisingly good. The compression struts were cheap as chips and had they told me they’d changed the bolt size, I wouldn’t have had any issues. A good chunk of the loom is now done. I’ve only just come in at 10:45 pm. Another couple of hours connecting up the switches should see most things done. The auxiliary stuff like charging ports etc will be left for another day as they won’t be needed for the Motorkhana. |

| |

|

|

|

|

|

Oct 28, 2024 21:13:26 GMT

|

I was on call Saturday. I was out until gone midnight but still got up early to get out the garage. My aim was to change the turbo on the Trafic. My nephew had come up to carry on wiring the Escort and so had my brother. As he is a mechanic, he gave me a hand to get the old one off. I got the new one back in with no major issues. I’d bought a new oil and filter so drained the oil and to my horror, only about 1/2 a litre came out. Burger. With nothing more to loose (well a gallon of oil), I filled it up and ran the engine. It started fine, but was slow to rev up. Took it up the road and it wouldn’t do more than 30mph. Bolls. So I disconnected the MAF plug as this is a usual fault and should run ok once disconnected. Still useless. I asked a few questions on FB groups and got a myriad of answers. Checked the MAP sensor port for blockages- it was blocked, but still useless. Removed the EGR - it was blocked solid. Cleaned it out- still useless. I did an EGR delete - guess what- still useless. I reconnected the MAF and realised that when I was tightening the Jubilee clip it was pushing the MAF off the inlet pipe so not all the air was going through it. Sorted this and it ran great. More powerful than it was before. Worried about the condition of the crank after running so low on oil, there was nothing for it but to get the engine hot to see if the oil light came on or any rattles were heard. So I gave the van a good hammering for about 20 miles this evening and so far all is good. Have I dodged a bullet? Time will tell. Escort - lights work. Wipers (with intermittent) work alternator charges, horn works, fan works, fuel pump works, just warning lights left. And indicators, but waiting on an LED flasher to turn up   |

| |

Last Edit: Oct 28, 2024 21:30:12 GMT by jonsey

|

|

|

|

|

|

|

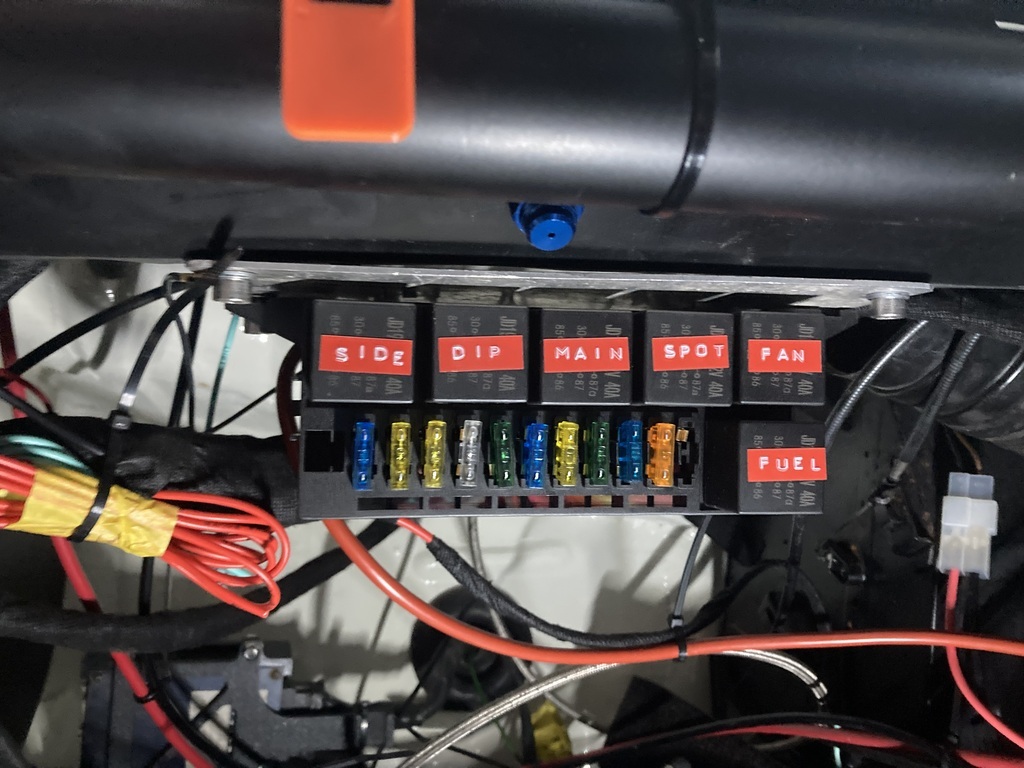

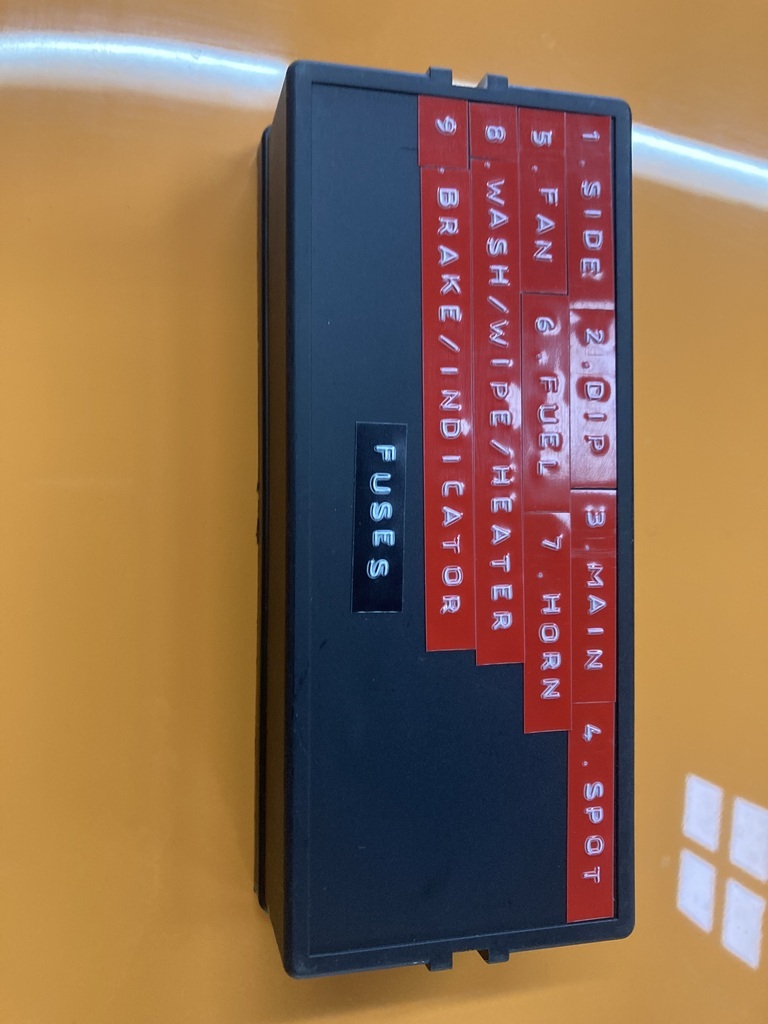

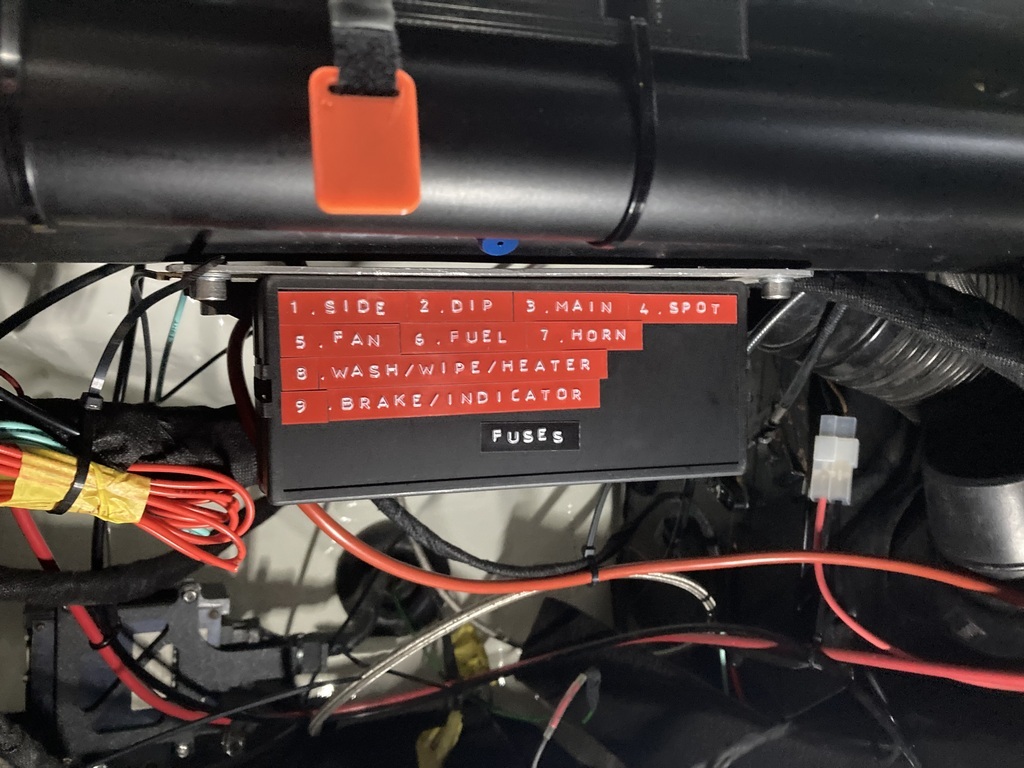

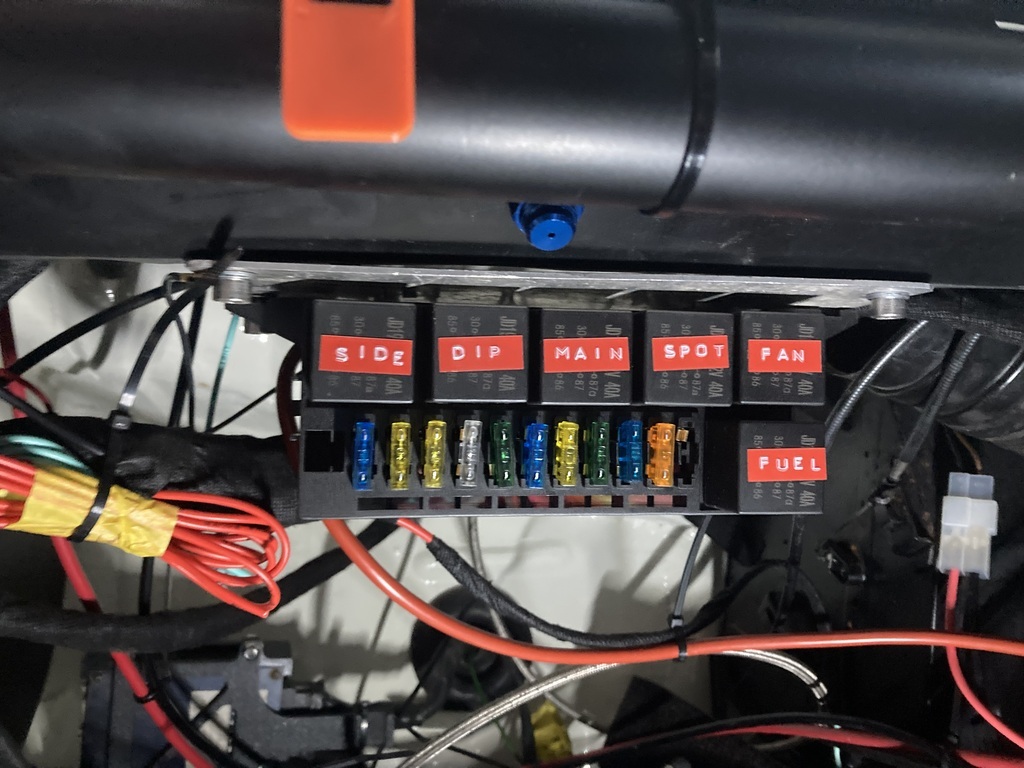

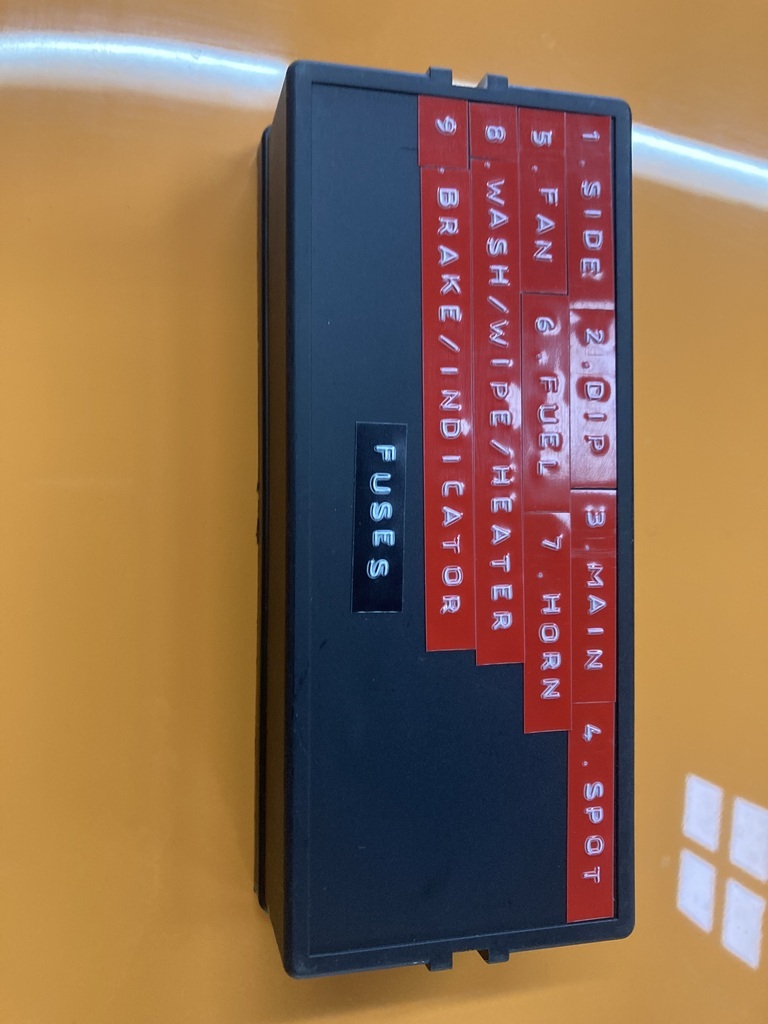

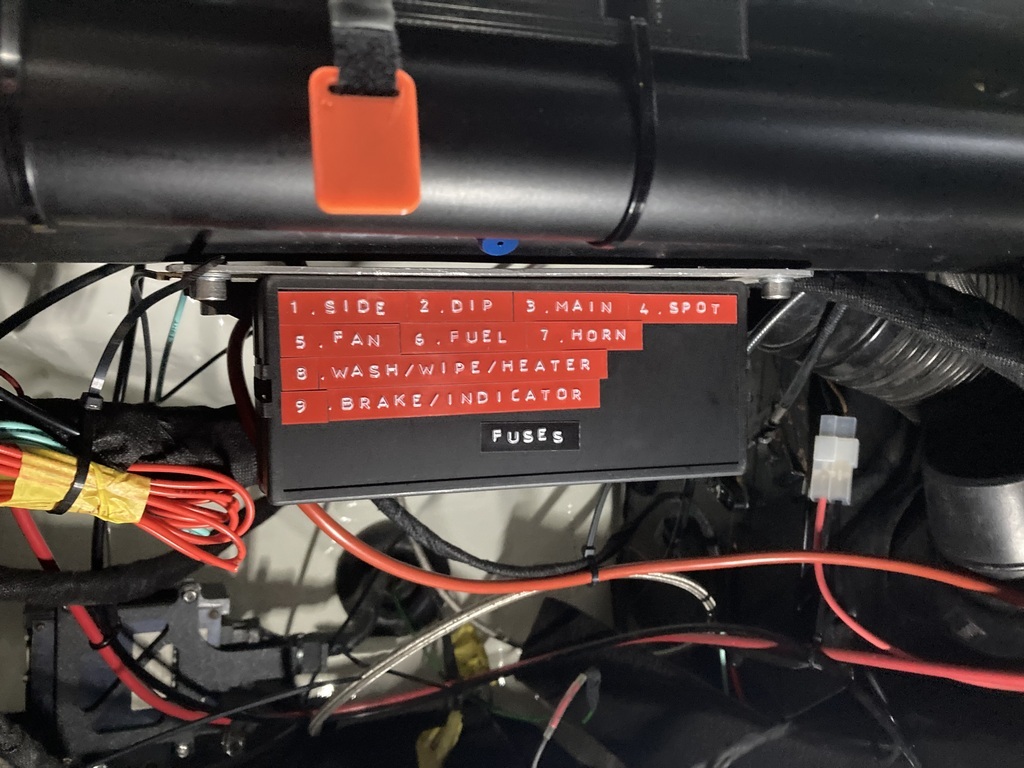

Last Thursday I took the Escort to my brother’s garage. Why? Two reasons. The first, for Sean to finish the wiring and the second, align the suspension. I drove it the 15 miles there to get some miles on the new CWP as it needed running in. On the way home, it was getting harder to get it into 2nd gear. I was supposed to call in the chippy on the way home but by the time I got there the clutch pedal was on the floor. I knew it wouldn’t pull off after I stopped, so I left the car facing down hill whist in the chippy. I got it home ok and the Juniors helped me push it in the garage after tea. A Quick Look on the ramp revealed that I had not tightened the lock nut on the clutch cable so it had just wound the tension off. No pics of any of this. Bad show, I know. Saturday I labelled up the fuse and relay box    I also gave the car a bolt check and tidied up some other bits and pieces. I also took off the good tires and fitted some well used Toyo888s. Why? Because Yesterday was Motorkhana day and the Escort was going to get a shakedown. I was not competing, I was closing car. It was a chance to see how the car handled, was any thing going to break/fall off and most importantly. Did the engine have any go in it. So I filled the van with tools and spare wheels and put the car on the trailer.  The Younger and I were up at 6am to get to Pembrey Circuit by 7. I took the car through noise (88db 👍) and then through scrutineering. All good. I then helped with the scrutineering as thee were 60 cars to get through. Before the first stage there was a sighting lap. We drove around slowly in a procession. It looked really tight. The whole of the 1.5 mile track (including the rally cross track) was a sea traffic cones that we had to negotiate our way through. It looked quite daunting. I’ve not driven competitively for 3 years and the car is nothing like how I last drive it. About the only thing that are the same are the steering wheel, column and radiator. Oh, and the air horn. So the point of the crappy old tires? Well, I didn’t want the back to have too much grip as it’s easier to throw the car around if it slides about a bit. Also, while I was learning the car (and to drive) again, it seamed a waste of some quite expensive tires. So the point of a closing car? Drive the circuit after each stage to make sure everything was where it should be, ready for the next stage. So after about an hour wait while everyone had their run, we approached the start line. My intention? Take it easy. Don’t do anything stupid. I didn’t know how the car was going to react so it was the sensible thing to do. Well non of that happened. The lights went green, the brain was placed in a box and off I went. Flat out from the start. 7500rpm everywhere, sideways everywhere. We finished the stage in 3:18. I knew what time a few others had run in and we were up with them. I was happy The car did under steer for the first few corners but got better as the tires switched on. Stage 2 Sean came out with me and we got a 3:08 Stage 3 Back with the Younger, we had a spin coming off the rally cross track but still got a 3:04. Stage 4 We had a good clean run and managed 3:00. Stage 5 We had a spin going onto the rally cross track and ended with 3:02 Was I happy? I sure was. I was over the moon with how the car and the engine. It pulled well and the car danced around well too. I was also over the moon with me. Although we’d got the the car into some shapes, we’d not hit anything. Only 2 issues all day. The bolt the holds the gearbox to its cross came out. My brother found it on the floor before one of the stages. I ran without it as the engine mount configuration means it can’t really go anywhere. And after one of the stages there was some liquid sprayed on the underside of the bonnet. Brake fluid level hadn’t changed nor had oil level and wrong colour for coolant. I cleaned it off an it didn’t return. Further investigation required. I had lots of compliments of how the car looked and performed which was a great ego boost. I think I’ve also scored a navigator for Jaffa stage over Christmas, if we manage to get a run that is. Still in one piece   |

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,352

Club RR Member Number: 64

Member is Online

|

|

|

|

|

Fabulous.

Car looks utterly fantastic. 👍

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

|

|

Fabulous. Car looks utterly fantastic. 👍 Thanks Glen. I’m well pleased with how it’s turned out |

| |

|

|

|

|

|

|

|

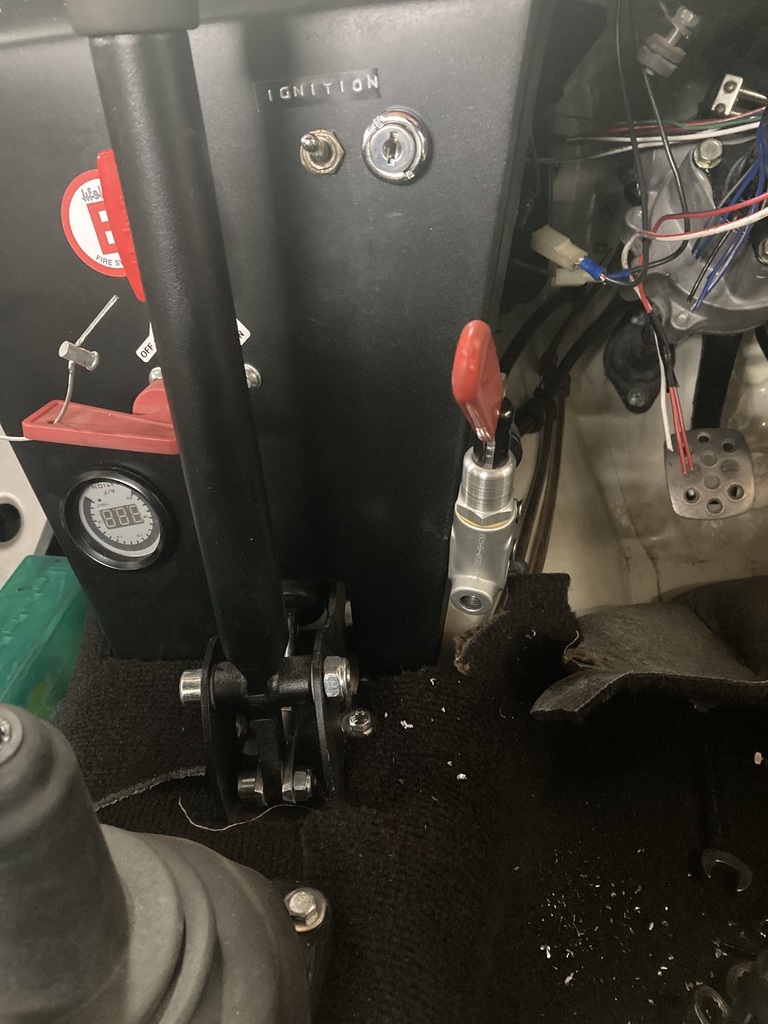

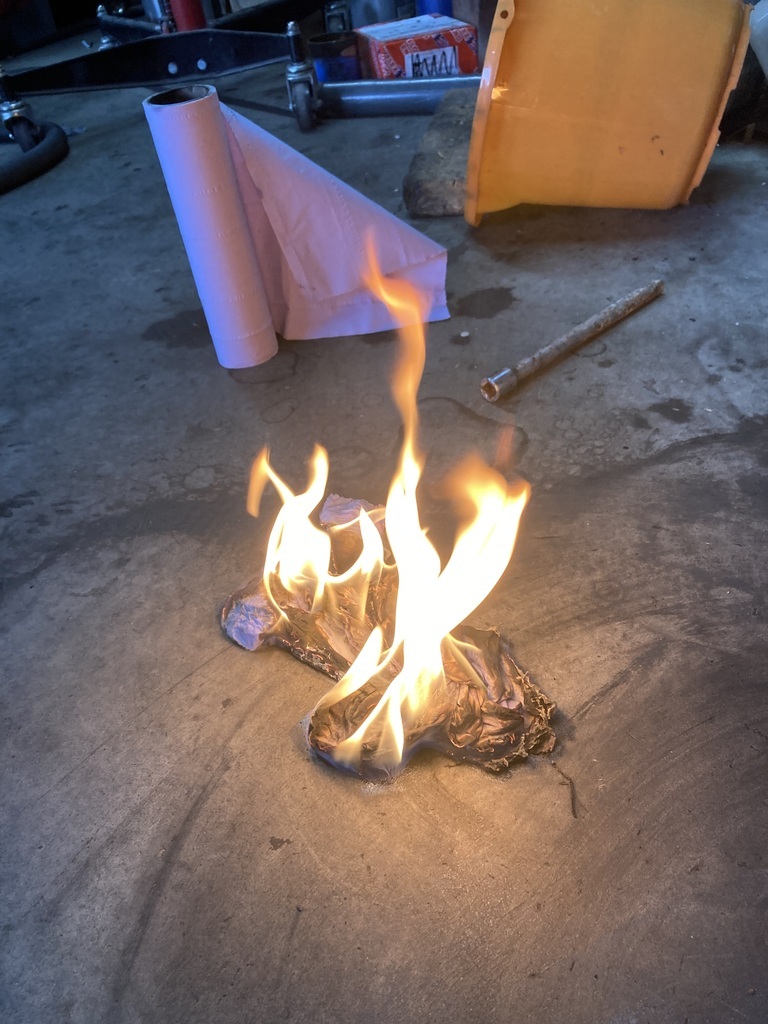

I’m on “stagger” shift this week which means I start at 10:45 and finish at 19:00, so I’ve been getting a couple of hours in the garage before work. Monday I spanner checked the car after the weekends abuse. All was good, except as I’m now revving the car to 7500rpm instead of 6000ish, the gearbox is throwing a bit of oil out of the breather. My brother had this issue before so he welded on a pipe to place a breather in the engine bay Tuesday I took some wheels to my brother’s to get some tyres swapped around and dropped 4 of them off to have 5mm machined off the back of the mounting face like all the other wheels I run. Today I removed the exhaust and lowered the back of the gearbox down to remove the top plate  This is the original breather in the top plate of the gearbox - just a pin hole with a baffle beneath   I didn’t have any 8mm steel tube so I drilled out some 8mm bar, drilled a bigger hole in the top plate and pushed the pipe in   I then welded the pipe to the top plate  And set fire to some blue roll soaked in brake cleaner in the process  Top plate back on with breather hose attached  More tomorrow |

| |

|

|

|

|

|

|

|

Gearbox bolted back up and exhaust back on  The oil light I fitted to the dash was originally on my Autograss Atra GTE that my nephew now owns. I fitted it as I thought it would be nice to have. But it’s fought me all the way. I’ve changed the bulb holder, bulb, played about with it and it still didn’t want to work. So I paid £20 for a Morris Traveller rear stop and tail light to replace it - the same type that I fitted to the rear of Gweek (remember him?). So I removed the old light and in doing so, realised I’d not plugged it back into the loom the last time it played with it. Dumb 4rse. It’s got one more chance  I wired in the instrument lights but accidentally wired them into dipped instead of side lights. Never mind. One bulb is dim so ordered new  Rear brakes look like they’ve got hot.  It didn’t feel like they were dragging though. I’ll check the free play on the hydraulic handbrake in case it’s putting the brakes on when the fluid expands. |

| |

|

|

|

|

|

Nov 10, 2024 19:02:42 GMT

|

Yesterday Went shopping with Mrs Jonsey in the morning but got a few hours in later This is the brake fluid pot lid  Remember I had fluid coming out of the vent? Well I bought this  Which comes with this bellows.  This will hopefully prevent fluid escaping One issue I have is the heat blower doesn’t work. This is a problem as the first rally I hope to do is Christmas Stages. Now, this doesn’t happen in June, it’s on December 29th, so I’m going to need some sort of demist for the screen. The problem is the heater unit is a pain to remove as it’s up behind the dash. Bits removed from the engine bay to get at heater pipes  Foot rear removed and Heater unit out after a good bit of wiggling and jiggling  The motor is dead. I’ve not got another Escort motor, but I do have a couple of Cortina ones. The issue is, the Cortina motor is a lot bigger  It fits in the motor mount, but might not fit back in the car as it was really tight coming out  The fitment is made worse by the fact I welded an m8 bolt to the top of the gearbox tunnel to use as an earth point. The unit would not fit back in place. I hacksawed 10mm off and it fitted in ok  We went shopping again today and got home just after 2 pm. I got another couple of hours in, and connected everything back up and got the car running again. The blower works, but for some reason there is no warm air☹️. Further investigation required. |

| |

|

|

|

|

|

Nov 11, 2024 18:52:35 GMT

|

Another couple of hours in the garage before work  Chinese brake fluid pot = new gearbox breather Thought I had a half nut for it but I didn’t. I did have a full nut though  That I turned into a half nut  I cut a piece of 3mm aluminum, drilled a hole to hold the pot and riveted it to the coil pack heat shield  Bolted on the pot and and connected up the vent pipe from the gearbox  It’s not really accessible but it doesn’t need to be. It is just being used as a vent Wiper stalk is a bit low as I’ve fitted the stalks upside down  I dug out my “wiper stalk adjustment kit”  And set it to a more user friendly position  I then ran the engine up to temperature to investigate why the heater was blowing cold. It was a quick fix. I slid the control to cold and it blows hot. Don’t ask why, I don’t know. There is no way to get the cable wrong. But it works, and thats all that matters. |

| |

|

|