|

|

|

May 16, 2022 12:35:21 GMT

|

|

As Stealthstylz says id get it on a rolling road, then you can at least see the curve etc.

From the factory the engine is listed as :

71 bhp on twin carbs.

unless like Darkspeed mentioned the head is very restrictive.

layout of the exhaust manifold seems compromised to me, possibly too short primays. usual rule of thumb was 4-1 was better for top end 4-2-1 better mid range, could be adding to it.

what gearing have you got? & wheel, tyre size?

going to a smaller rolling radius tyre will improve acceleration but at the detriment of top end speed.

Would you consider a turbo concoction?

but as Darkspeed says the valve sizes may well hamper any significant gains even with Boosts.

The D16 Engine is still a long stroke Ø75x90mm

might be better with a Rover K series? if you want to keep it in the family as it were.

|

| |

Take the Next slot right coming up on the left.

|

|

|

|

|

|

Paul Y

Posted a lot

Posts: 1,951

|

|

May 16, 2022 16:54:29 GMT

|

Turbo. That will fix it. P.  |

| |

|

|

logicaluk

Posted a lot

Every days a school day round here

Every days a school day round here

Posts: 1,373

|

|

May 16, 2022 19:54:28 GMT

|

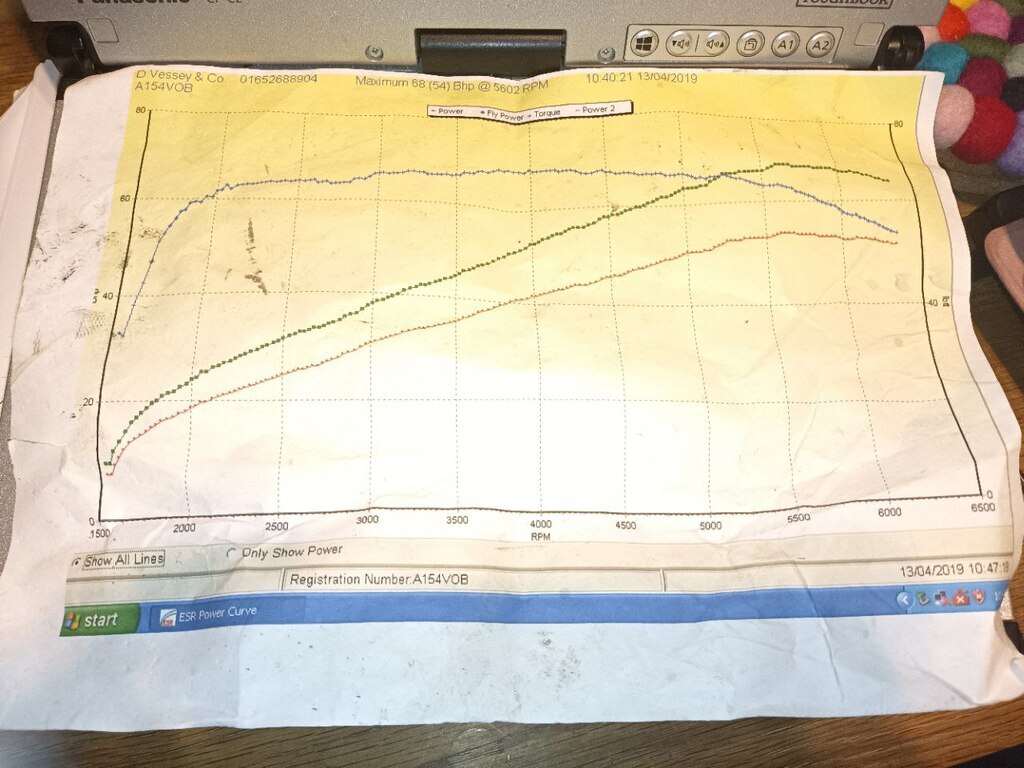

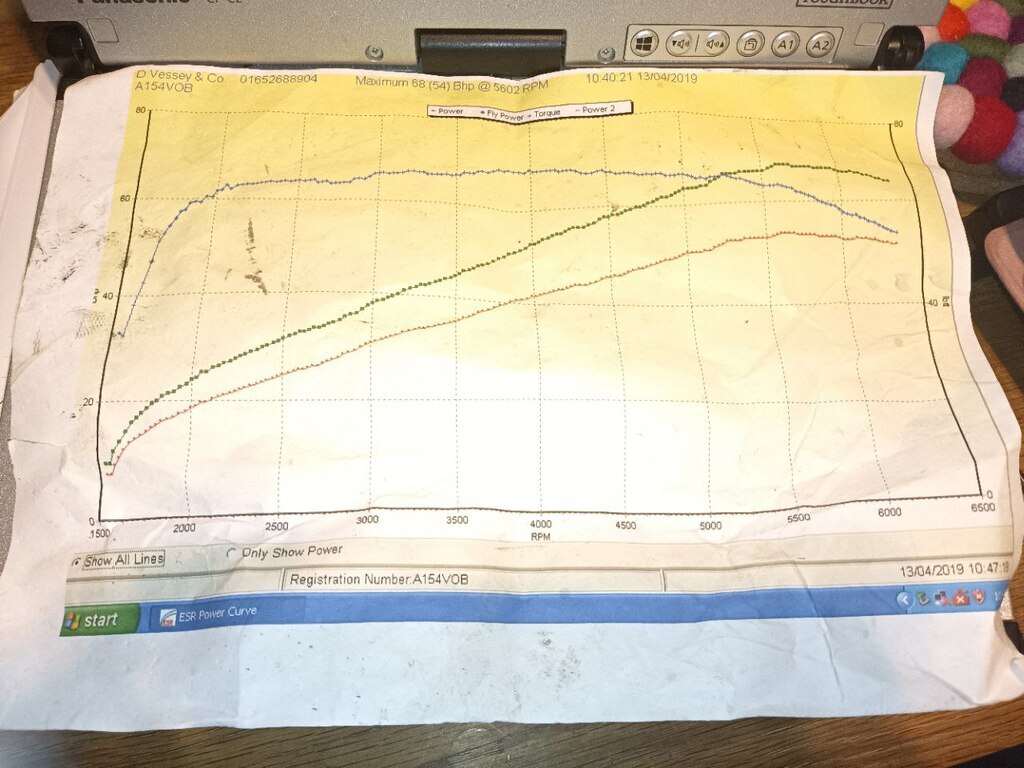

Having spent about 9hrs behind the wheel driving around north Yorkshire today, I've had time to think. But first thanks for your input Has it been on a rolling road? The numbers don't actually matter but the shape of the curve can tell you more about where improvements are needed. Yes, but this plot was on the fuel injection, it feels very similar to the carbs for performance, I had put the flat output down to the throttle bodies I used.  I'm certainly no expert but those standard cam timing figures sound terrible for performance. Do you know the timing figures for the new cam? only +12 deg duration = 240 deg +0.75mm lift You will struggle to get 60-65BHP per litre from that motor. If you want more power you need to get more air in the engine - 36mm inlet valves will scupper anything you try and do. Changing cam may well make it slower as it could move the peak to an area where air cannot flow - so you lose all the low end torque and do not gain any top end as it cannot breathe there. ETA Go faster rule #1 - Go as big as you can fit and then tune it. If you want to go as fast as a 2.0L - buy a 2.0L as usual you got me thinking, I had completely forgotten, theirs a guy who's actually done something with this engine put it in a mk1 civic, so I contacted him more on that later. Cam timing ive not tryed playing with that yet. Go faster rule #1 I didnt want to do an engine swap, I just wanted to squeeze a bit more out of this lump as i felt it was agood basis to work from. As Stealthstylz says id get it on a rolling road, then you can at least see the curve etc. what gearing have you got? & wheel, tyre size? going to a smaller rolling radius tyre will improve acceleration but at the detriment of top end speed. Would you consider a turbo concoction? The D16 Engine is still a long stroke Ø75x90mm might be better with a Rover K series? if you want to keep it in the family as it were. gear ratios 1 2.916:1 2 1.764:1 3 1.181:1 4 0.846:1 5 0.714:1 diff 4.642:1 I did have 165/50/15s on it, and it did feel quicker, but at the moment it's got 195/45/16s Avon built a turbo version of the acclaim, using the standard engine and carbs (possibly with the main jets removed) paired to a turbo technics, Garrett T3 running 6psi and putting out 105bhp @ 5500 rpm and 123lbft @ 3500rpm I have a one from a Subaru Impreza in the workshop, apparently they go well on 1300cc minis The Honda B or D engines would be the correct family. So I contacted Jay about his acclaim engined civic, unfortunately he sold it but did give me some information, his had Goldwing pistons, taking it to 1372cc and a Newman cam (which he said sounds the same spec as mine) with dual Mikuni carbs 4-2-1 exhaust manifold and made 98bhp he didn't know what the compression ratio was but said when compression tested it made 240psi which was pretty much the same as it did on the original cam. I know with std pistons and the rest of my setup it's not going to be 98bhp, but 80 would be good. When I did the compression on frank after the Newman cam was fitted the first time the compression it had dropped from 220psi to 170psi so if I re-time it to make more compression that might show some gains, a direction to move in. Dan |

| |

Last Edit: May 16, 2022 20:00:33 GMT by logicaluk

|

|

logicaluk

Posted a lot

Every days a school day round here

Every days a school day round here

Posts: 1,373

|

|

May 16, 2022 20:22:19 GMT

|

|

Stupid question time, by the sounds of it, I need to advance the cam to bring the power band down? thats the cam being moved forward ahead of the crank, right?

if so, tomorrow I'll try advancing the cam 1/2 a tooth which will be correct to the timing marks, not to where the standard cam pulley fits.

Dan

|

| |

Last Edit: May 16, 2022 20:23:17 GMT by logicaluk

|

|

|

|

|

May 16, 2022 22:18:24 GMT

|

|

While the valves definitely aren't generous, you should be able to get more than 80hp out of them with decent work to the rest of the engine (and the valves themselves). Spitfire 1300s/1500s are happy making more than 100hp on the 36.5mm 'big valve' heads.

Can't speak to everything around around the valve mind. The plug does look quite offset in the chamber, which as Darkspeed mentioned isn't great for flame propagation. How tricky would it be to twin-spark?

|

| |

Last Edit: May 16, 2022 22:19:54 GMT by biturbo228

|

|

logicaluk

Posted a lot

Every days a school day round here

Every days a school day round here

Posts: 1,373

|

|

May 17, 2022 19:18:46 GMT

|

|

Twin spark would be next to impossible with this head.

So working on the cam Timing all measurements are taken from the crank pulley

Cam set at standard acclaim setting is approximately 13 Deg btdc = 6.5 Deg advanced. compression was 200 psi

Cam timed at 5 Deg btdc = 2.5deg advanced compression was 195 psi I think it felt more lively at 4000rpm

Then I split the difference between them and it sounds a lot happier, I'm not sure if it is actually any better to drive from the quick squirt around the block it had, I'll take it out tomorrow for a longer drive and see.

Dan

|

| |

|

|

logicaluk

Posted a lot

Every days a school day round here

Every days a school day round here

Posts: 1,373

|

|

|

|

Here are some pics of my amateur head job exhaust port  Inlet port  Inlet manifold from head side  inlet manifold from carb side  exhaust manifold  i don't know, if these are finished shots or in progress. |

| |

Last Edit: May 18, 2022 6:14:49 GMT by logicaluk

|

|

|

|

|

|

|

|

Do you know the dimensions of your head job? How much have you opened the ports?

|

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

83 Triumph Acclaim SprintDarkspeed

@darkspeed

Club Retro Rides Member 39

|

|

|

|

With head porting you start at the valve seat and valve and work back.

Its a bit like a corridor with a very narrow door at the end where a person can just squeeze through. Its no good starting by making the corridor wider - its the door that you cant get through - in fact make the corridor too wide and or wide in the wrong place and people get lost going in the wrong direction trying to find the way to the door.

Step 1 - Make the door wider.

Step 2 - Shape the corridor as a funnel to guide the people to the door in an orderly fashion

Step 3 - If people are bumping into a support column in the middle of the corridor - make the column as slim as possible and widen the corridor around the column.

ETA

R6 throttle bodies.

The slide will only open fully when there is sufficient air flow - There is not a restriction if they are are only part open, there is just not enough air flow. Like putting a 2" SU on a stock 850 Mini - It will only open as far as it needs to. Not much.

The softest spring is no spring - just remove the spring if you want the slide to open greater than it needs to.

|

| |

Last Edit: May 18, 2022 9:45:03 GMT by Darkspeed

|

|

|

|

|

|

|

|

|

|

Good description there Darkspeed.

I was wondering if the ports are now too large which is reducing cylinder fill due to poor velocity (which I understand is more important with long-stroke/small bore engines). Without access to a flowbench there's a rule of thumb for port sizing which might be helpful. You want the valve throat area (the area about 0.5" behind the valve) to be about 0.85 the diameter of the valve, and then tapering gradually out to the port face. For you that would be a smidge over 30mm.

|

| |

|

|

logicaluk

Posted a lot

Every days a school day round here

Every days a school day round here

Posts: 1,373

|

|

May 18, 2022 10:21:18 GMT

|

|

Unfortunately I can't remember the sizes, I port matched to the gaskets, then blended the transitions and cleaned up the casting marks then I think I eased the short side radius next to the valve. I can get to an un touched head when I get home and measure the ports.

Dan

|

| |

|

|

|

|

|

May 18, 2022 13:53:03 GMT

|

Hum, so did you match the outer diameter on the head face to the gasket and then blend that down to the existing diameter of the throat, or did you take out the whole port to roughly the gasket diameter? Could find a set of old gaskets if you have them and measure that, if that's what you've taken the port out to  |

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

83 Triumph Acclaim SprintDarkspeed

@darkspeed

Club Retro Rides Member 39

|

May 18, 2022 14:20:49 GMT

|

or did you take out the whole port to roughly the gasket diameter? You can follow the cast line from one end of the port to the other so I would think little material has actually been removed. The area around the guide is still as cast.  I would have been tempted to just grind that lot out. This is just a quick port clean up no significant material removal - couple of hours work.   |

| |

|

|

logicaluk

Posted a lot

Every days a school day round here

Every days a school day round here

Posts: 1,373

|

|

May 18, 2022 17:16:25 GMT

|

|

I wasn't confident enough to go further and they didn't seem to need much.

Inlet and exhaust gaskets 34mm ports are 32

|

| |

|

|

|

|

|

May 18, 2022 18:12:59 GMT

|

|

Would a d16 swap not be the cheapest route to double the power? Someone has put one in a mk1 civic so must be possible?

|

| |

|

|

logicaluk

Posted a lot

Every days a school day round here

Every days a school day round here

Posts: 1,373

|

|

May 18, 2022 18:58:07 GMT

|

Would a d16 swap not be the cheapest route to double the power? Someone has put one in a mk1 civic so must be possible? Yes but that wasn't the point, when I took an acclaim engine apart it looked like it could take a lot more power. |

| |

|

|

|

|

|

May 18, 2022 19:02:16 GMT

|

Would a d16 swap not be the cheapest route to double the power? Someone has put one in a mk1 civic so must be possible? Yes but that wasn't the point, when I took an acclaim engine apart it looked like it could take a lot more power. Would the 12v head fit? Or is it the cvv engine already? |

| |

|

|

logicaluk

Posted a lot

Every days a school day round here

Every days a school day round here

Posts: 1,373

|

|

May 18, 2022 19:52:22 GMT

|

Yes but that wasn't the point, when I took an acclaim engine apart it looked like it could take a lot more power. Would the 12v head fit? Or is it the cvv engine already? No it doesn't have the 12v head. IIRC the hot ticket is the acclaim head on the Mk1 civic block. Ive been looking for a 16v head with the same bore spacing as the EN4 engine, ala bmw bike head on a mini block, but ive not come across one yet Dan |

| |

Last Edit: May 18, 2022 20:31:15 GMT by logicaluk

|

|

logicaluk

Posted a lot

Every days a school day round here

Every days a school day round here

Posts: 1,373

|

|

|

|

|

Catching up on yoddnz's Honda gold wing powered Imp, got me thinking.

The shape of the ports, contributing to the torque, has my light porting destroyed it, probably if there was any.

The combustion chamber looks to be a similar layout.

Valves are 33mm / 28mm for a 308cc cyl Vs the acclaims 36mm / 32mm for a 333cc cyl

Compression ratio 10.5:1 Vs 9.5:1, I went with 9.5 as from what I had read it was as high as one would want to go on normal unleaded. Should I have gone higher?

Just thinking out loud.

Dan

|

| |

Last Edit: May 19, 2022 6:46:51 GMT by logicaluk

|

|

|

|