|

|

|

Apr 25, 2024 22:36:11 GMT

|

|

Fair enough. However, getting the most out of a car isn't easy, especially one like mine which isn't the accepted way to go. Brute force doesn't require a lot of experience or skill to go fast, as you say, just balls, but mine will in order to squeeze the maximum performance out of it. Also, having not raced since the mid 80s I am very rusty and the car is very new so practice is vital as far as I am concerned.

The track will not be concrete but the start line will be. Not having to spend hours driving to the Pod in the hope of getting a few runs in or taking a chance booking a spot with Scott on one of his private test days will help to pay for the track. Prepping is no ball ache for me, I am retired so plenty of time on my hands :-)

I won't be on my own. Having my own teat track also allows me to build up gradually and not having to run the full 1/4 mile each time I do a launch test. To me this is a no brainer but, fortunately, we are all different :-)

|

| |

|

|

|

|

|

|

|

Jun 12, 2024 21:37:41 GMT

|

|

After months of looking, including sifting though all the scams on FB I finally found what I have been looking for. The bonuses are that it is local and I know the sellers father-in-law so confident that it is legit. Apologies for the shakiness of the video and my out of breathlessness but I have only just started walking again after around 4 weeks in bed and another couple hobbling around the house having damaged my Sciatic nerve bundle. This has resulted in leg muscle wastage so walking is hard work at the moment.

Hope to get back on to the car next week.

|

| |

Last Edit: Jun 12, 2024 22:20:24 GMT by nalesutol

|

|

|

|

|

Jun 12, 2024 23:10:13 GMT

|

|

Sorry to read of your problems but glad that you are recovering. The trailer looks just right - lightweight, aerodynamic and smooth...just like your Elan!

|

| |

|

|

|

|

|

|

|

Sorry to read of your problems but glad that you are recovering. The trailer looks just right - lightweight, aerodynamic and smooth...just like your Elan! My thoughts exactly :-) Internally it's approx 5.5m end to end and the Elan is 3.9m so a comfortable fit. The 2 storage boxes make a big difference. |

| |

|

|

|

|

|

Jun 13, 2024 12:14:21 GMT

|

|

Sorry to hear about your health. I had sciatica a few years back - fortunately only for a few weeks - worst pain I've ever had and leg wasted away super quick, so I know exactly your problem.

|

| |

|

|

|

|

|

Jun 14, 2024 21:19:47 GMT

|

Sorry to hear about your health. I had sciatica a few years back - fortunately only for a few weeks - worst pain I've ever had and leg wasted away super quick, so I know exactly your problem. Cheers. Yes, the pain is horrible and continuous. However, it is MUCH reduced now and I am taking action to lessen the risk of it happening again. As you say, muscle disappears very quickly if not used. Nerves take a long time to heal so I have to be patient and keep working on it. Finally getting a decent trailer is an added incentive to get the car finished. Working on a suitable graphic for the side of the trailer at the moment. |

| |

|

|

|

|

|

|

|

|

Back on the case. my Life ECU and wiring guru has spent a couple of days sorting out wiring mistake made by the company that made the loom and writing a basic MAP so we could start the car safely. Another wiring issue I have yet to fix is the loom to the alternator has two wires but there are 3 connectors on the alternator.

As mentioned in the video I have to take all the earth connections apart, clean and reattach with copaslip. I will then fill with water with all fingers crossed. The one Elephant in the room is the oil leak at the rear of the engine. It appears to be coming from the sump gasket so I am hoping that a tightening of the bolts fixes it. If not it is engine out as some of the bolts are inaccessible due to the oversized sump. This is where fitting a flip front will have been worth the effort.

I have no idea why the engine suddenly sounded like it was running under water, it sounded OK to my organic ears.

|

| |

Last Edit: Jul 8, 2024 20:40:30 GMT by nalesutol

|

|

jimi

Club Retro Rides Member

Posts: 2,254

|

|

|

|

I'd be wary of using any type of grease on earth connections to improve conductivity as most copper coat/slip type greases are non-conductive, in fact most greases are non-conductive. Specialist conductive greases are available but not cheap or easy to source. By all means use it to prevent corrosion but apply it very sparingly  For general info I'll quote a post I made on this subject a year or so ago on another forum. My information comes from my 50+years experience as an electrician in heavy engineering (half that time as a chief electrician ) and from testing various grease, compounds etc that I used in my job I've done these tests before, with the same results, (and on many more products) but thought it worth repeating them with some pictures. I'm now retired so I don't have access to the same variety of anti-sieze products that I used to have, these are what I have in the garage . I've used a industry standard 500volt Megger Insulation tester to carry out the tests (so well above car operating voltages other than the HT for the ignition) One probe on the metal tin the other clipped to a steel pin to ensure good contact with the anti-sieze compound. First one is Goldfinger (copper based, manufactured to a NCB spec) this tin is at least 35 years old and is still soft and useable As you can see the resistance between the probes is greater than 999 Megohms so non-conductive  Loctite anti-sieze (stick form copper based) a year or two old Again the resistance between the probes is greater than 999 Megohms so non-conductive   This is RS product (silver based) sprayed some into a plastic lid then put both probes into the liquid Once again the resistance between the probes is greater than 999 Megohms so non-conductive   This one is a brand new tin of Molykote (just opened for the test) Again 999 Megohms so non-conductive  This is especially interesting as the label says "good electrical conductivity" ....... not according to my Megger, I know what I and any electrician would trust and its not the label  Meter leads shorted across the metal tin to prove the Megger  The tests confirm what I already knew so quite happy to stand by my previous statement  |

| |

Last Edit: Jul 8, 2024 23:01:04 GMT by jimi

Black is not a colour ! .... Its the absence of colour

|

|

|

|

|

|

|

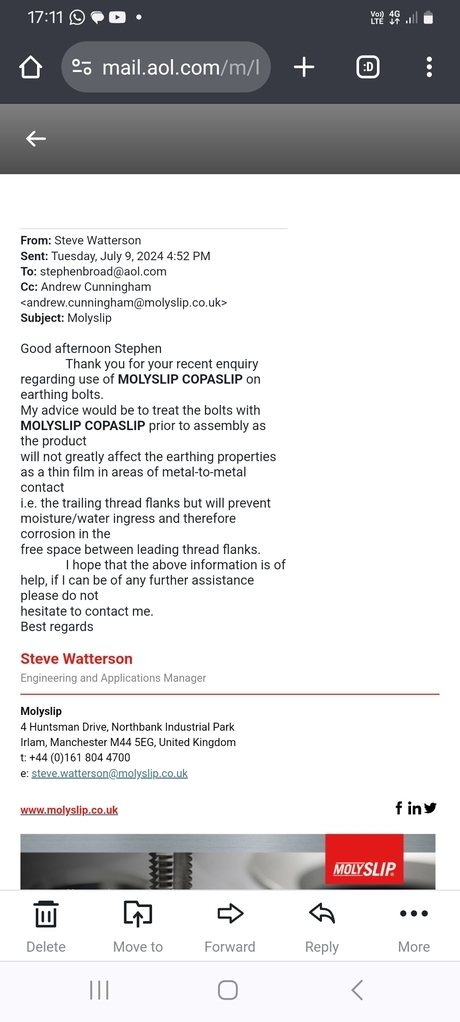

I'd be wary of using any type of grease on earth connections to improve conductivity as most copper coat/slip type greases are non-conductive, in fact most greases are non-conductive. Specialist conductive greases are available but not cheap or easy to source. By all means use it to prevent corrosion but apply it very sparingly  For general info I'll quote a post I made on this subject a year or so ago on another forum. My information comes from my 50+years experience as an electrician in heavy engineering (half that time as a chief electrician ) and from testing various grease, compounds etc that I used in my job I've done these tests before, with the same results, (and on many more products) but thought it worth repeating them with some pictures. I'm now retired so I don't have access to the same variety of anti-sieze products that I used to have, these are what I have in the garage . I've used a industry standard 500volt Megger Insulation tester to carry out the tests (so well above car operating voltages other than the HT for the ignition) One probe on the metal tin the other clipped to a steel pin to ensure good contact with the anti-sieze compound. First one is Goldfinger (copper based, manufactured to a NCB spec) this tin is at least 35 years old and is still soft and useable As you can see the resistance between the probes is greater than 999 Megohms so non-conductive  Loctite anti-sieze (stick form copper based) a year or two old Again the resistance between the probes is greater than 999 Megohms so non-conductive   This is RS product (silver based) sprayed some into a plastic lid then put both probes into the liquid Once again the resistance between the probes is greater than 999 Megohms so non-conductive   This one is a brand new tin of Molykote (just opened for the test) Again 999 Megohms so non-conductive  This is especially interesting as the label says "good electrical conductivity" ....... not according to my Megger, I know what I and any electrician would trust and its not the label  Meter leads shorted across the metal tin to prove the Megger  The tests confirm what I already knew so quite happy to stand by my previous statement  Thanks for that Jimi. However, you haven't checked Copaslip. So, I have just asked Molyslip, who make Copaslip, whether I should use it on the threads. I will let you know what they say. One thought, you are measuring the conductivity over a very long distance compared to what happens in real life. You could get a very different result when measuring over one or two particles, which would be a more realistic test as there is hardly any suspension medium between the particles. Just a thought, Molyslip's response will be interesting. I won't start until I have all the facts as my wring guru has over 30 years experience in sorting racecar wiring problems so I am loath to contradict him yet :-) |

| |

|

|

raumer

Part of things

Posts: 138

|

|

|

|

|

Interesting results with the different greases. In the past I've used auto transmission oil as that is conductive. Although don't know how well it would compare in your tests.

|

| |

Mine: 1938 Scammell Pioneer R100, 1944 Scammell Pioneer SV2/S, 1959 Kraz 255b tractor unit, 1960 Unipower Industrial ballast tractor, 1960 88 Landrover Series 2 SWB, 1983 110 Landrover CSW

Look after:

1935 Scammell Rigid 6, 1951 Scammell Scarab, 1961 Landrover Prototype, 1985 Landrover 110

|

|

jimi

Club Retro Rides Member

Posts: 2,254

|

|

|

|

|

I've tested Copaslip in the past, same results. I've never had the facilities to test at a particle level, but I'd expect any copper based compound to have reasonable conductivity, hence "apply it very sparingly" despite the tests we still used it that way on earth bond connections exposed to harsh conditions offshore.

As you know metal at a microscopic level is not smooth so once you tighten a fastener there's usually still enough metal to metal contact to maintain the continuity.

It can takes very little to affect continuity. as example I worked with V16 EMD engines driving 2500KW generators, the generators were single bearing (DE bolted to the engine flywheel and NDE on a bearing) to protect the bearing from circulating currents the generator shaft was insulated from earth.

When the engine was stopped testing between gen shaft and earth gave a few ohms (through the engine crankshaft) If you kept the meter on and started the engine, as oil pressure increased you could see that few ohms increasing until it was Mohms all down to a molecular film of oil on the bearing surfaces... I found it hard to believe until I saw it with my own eyes (same as pure water being an insulator)

Enough obscure facts, I was more pointing it out as something to be aware of and not to apply it heavily. my advice .. use it lightly and you'll be fine

|

| |

Black is not a colour ! .... Its the absence of colour

|

|

|

|

|

|

|

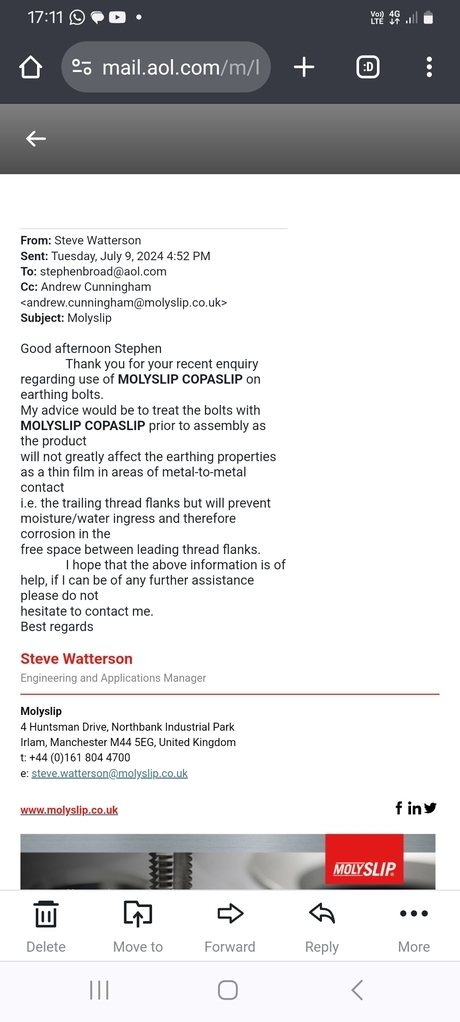

Hi Jimi. I am an information sponge but take nothing as gospel until checked. Your comments have been useful and thought provoking. Molyslip have replied and I would like your thoughts on their response.  |

| |

Last Edit: Jul 9, 2024 22:40:55 GMT by nalesutol

|

|

jimi

Club Retro Rides Member

Posts: 2,254

|

|

|

|

I'd agree completely with their comments, pretty much what I said based on my (and others) experience. It's good to hear it from the manufacturer, their comment about preventing water/moisture ingress is spot on, one of the main reasons we continued to use it offshore was that the gain from helping to prevent corrosion on exposed earth connections far outweighed any minor loss of conductivity as long as it was applied sparingly. As for being an information sponge.... a man after my own heart  Information is king, sorting the wheat from the chaff can sometimes be a problem, take nothing as gospel until checked. Thanks for posting up Molyslip's reply  |

| |

Last Edit: Jul 9, 2024 19:43:18 GMT by jimi

Black is not a colour ! .... Its the absence of colour

|

|

|

|

|

Jul 10, 2024 18:26:27 GMT

|

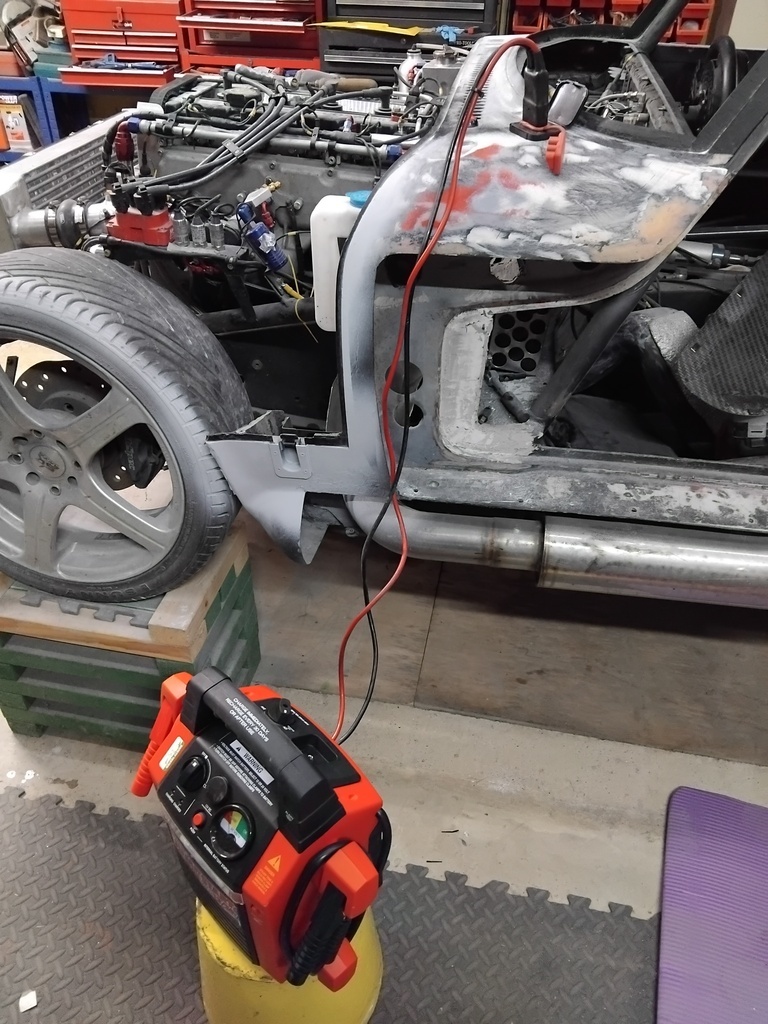

My tiny (less than 1kg) Lithium battery works very well, but struggles after around 5 start ups. So I have bought a heavy duty booster pack that can be connected to the car when in the fire up road to keep battery topped up. To make life easier I will be fitting an Anderson plug next to the external cut off switch (just below the left hand corner of the front screen}. Booster/jump start packs don't come with this fitting so I have added one.   |

| |

Last Edit: Jul 11, 2024 7:59:59 GMT by nalesutol

|

|

|

|

|

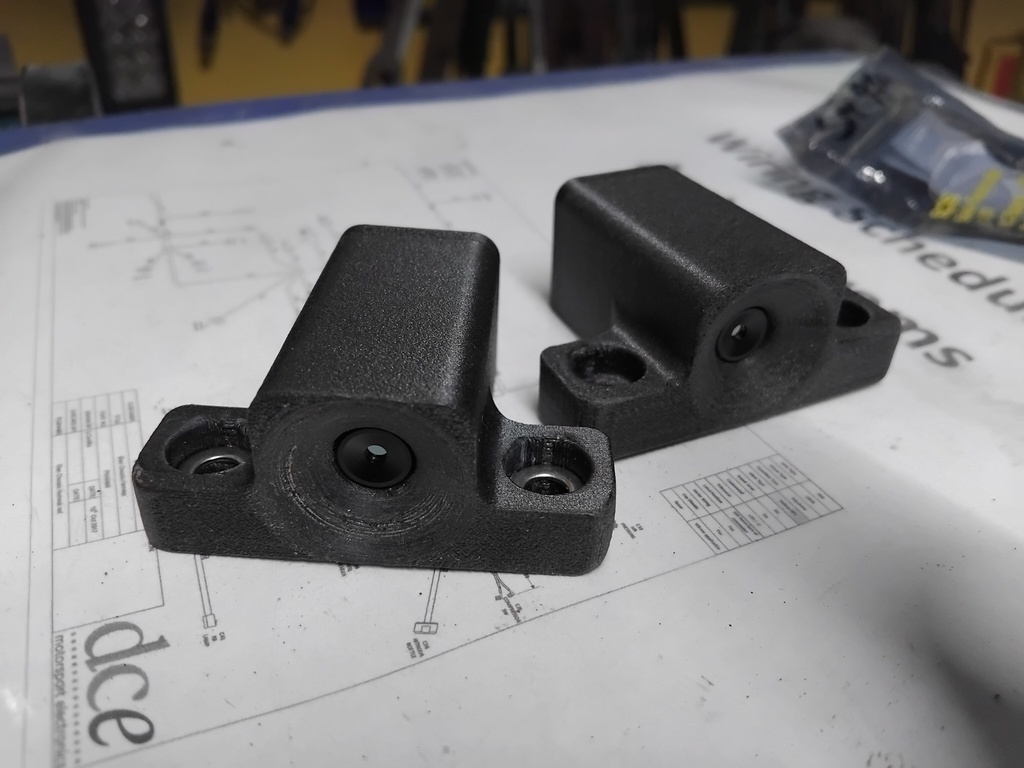

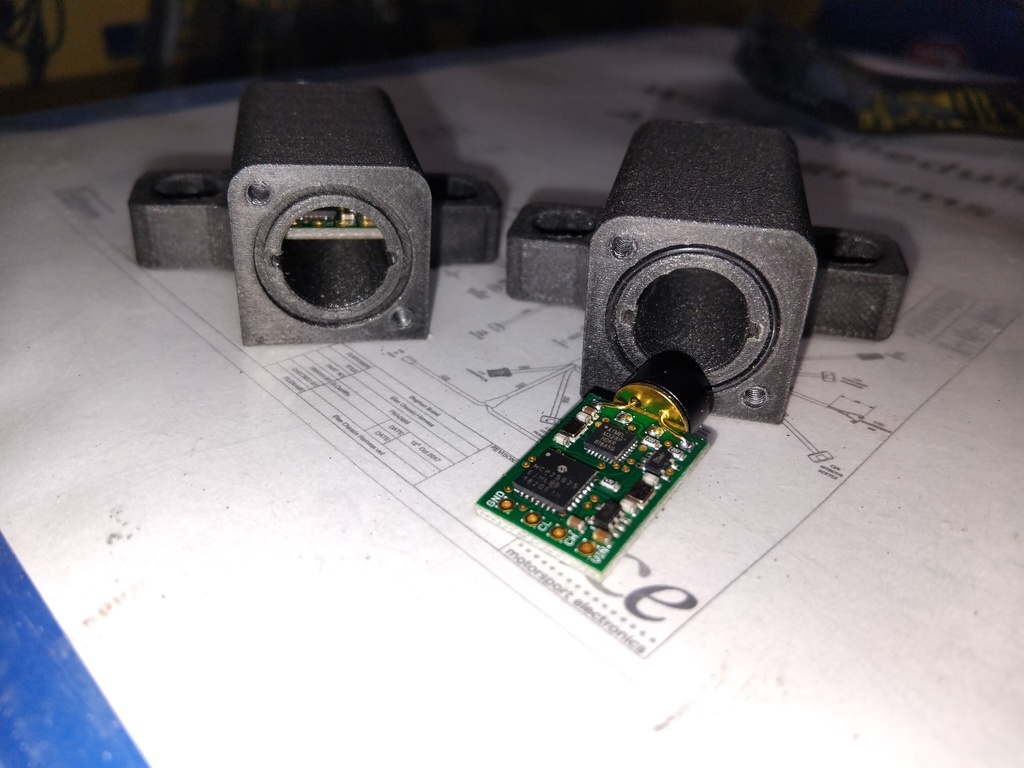

Jul 14, 2024 22:28:57 GMT

|

|

|

| |

Last Edit: Jul 14, 2024 22:30:20 GMT by nalesutol

|

|

|

|

|

|

|

|

What happens when you do a burnout & they get covered in rubber?

|

| |

|

|

|

|

|

|

|

What happens when you do a burnout & they get covered in rubber? Burnout rubber generally goes backwards and upwards. The sensors will be further back, probably recessed into the back panel, so the beam covers the whole tyre width. However, if this proves to be a problem then a removable shield will have to be devised that is removed prior to the run, similar to the parachute safety pin. A bit of a faff but no one said going fast would be easy :-) |

| |

Last Edit: Jul 15, 2024 8:53:54 GMT by nalesutol

|

|

|

|

|

|

|

|

Just though I'd mention it in case you had not thought about that. The rubber is not such an issue, but the track prep glue is an absolute ba5tard to remove. There is a spray the racers use to spray on so the adhesive can be wiped off (more) easily

|

| |

|

|

|

|

|

Jul 16, 2024 22:34:24 GMT

|

Just though I'd mention it in case you had not thought about that. The rubber is not such an issue, but the track prep glue is an absolute ba5tard to remove. There is a spray the racers use to spray on so the adhesive can be wiped off (more) easily Never wrong to mention stuff :-) The track prep issue is a new one to me so thanks for that. I look forward to having these problems :-) |

| |

|

|

|

|

|

Jul 25, 2024 21:45:49 GMT

|

|

|

| |

Last Edit: Jul 25, 2024 21:46:30 GMT by nalesutol

|

|