ovimor

North East

...It'll be ME!

Posts: 929

|

|

|

|

|

Making a 'wonder how it should be welded up so sits right' frame....

Best be drawn out on CAD [cardboard aided design] or hardboard... That way you can hack holes for bolts and rattle stuff around and come up with a .. top/middle/bottom .. image 👍

GR8 stuff here, m8

OVIMOR

|

| |

Knowledge is to know a Tomato is a 'fruit' - Wisdom, on the other hand, is knowing not to put it in a 'fruit salad'!

|

|

|

|

foxy99

Posted a lot

Posts: 1,453

|

|

|

|

Thanks ovimorI'm thinking I'll just go with my original oblong, which was going to need feet/legs anyway to clear the sump, and tilt it by making a long leg and a short one  |

| |

1974 Daimler Double-Six VDP

1965/67 Hillman Imp pick-up

1984 VW Polo breadvan

1970s Yamaha Twins (4)

1976 Honda SS50ZK1

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,873

Club RR Member Number: 39

|

|

|

|

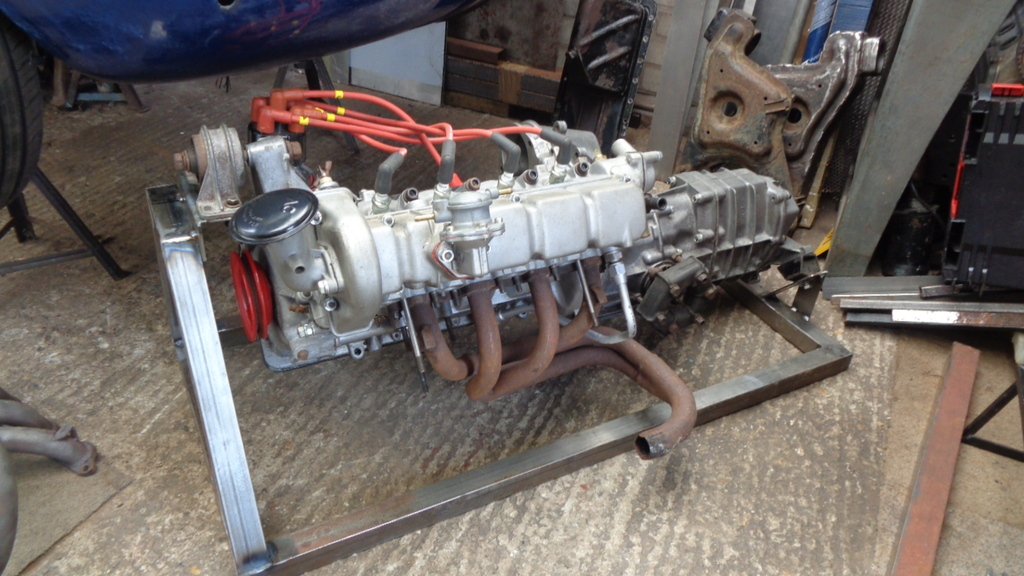

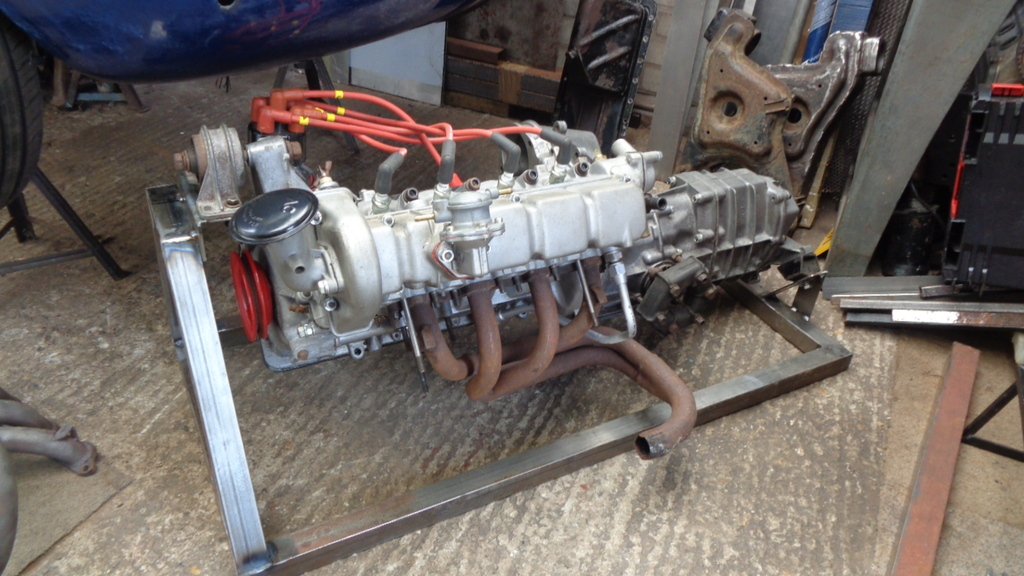

The photos of the water outlets are taken with the engine sitting on a frame I just finished - details in the G15 thread. I made it full drivetrain length so I can test the entire thing before dropping it in the car - Just need to make a lower frame for it on casters so it can be moved around easily.  |

| |

|

|

foxy99

Posted a lot

Posts: 1,453

|

|

|

|

|

|

| |

Last Edit: Apr 3, 2022 10:59:11 GMT by foxy99

1974 Daimler Double-Six VDP

1965/67 Hillman Imp pick-up

1984 VW Polo breadvan

1970s Yamaha Twins (4)

1976 Honda SS50ZK1

|

|

foxy99

Posted a lot

Posts: 1,453

|

|

|

|

So Saturday night was back to the engine-stand. I spent a bit time cleaning muck off the 533 head but didn't get as far as lapping-in the valves like I intended. I have the pasts and stick from doing this on my Mondeo a while back and the difference in performance after it was amazing. Anyway the revised idea was to find a good position for the bottom of the frame to be parallel to the flat part of the sump and catch as many studs as possible and keep the starter-motor area free. I found that I could catch two studs on the bottom left corner of the frame and satisfy the other conditions but the top left corner was obscuring the thermostat housing. I haven't managed to liberate this from the 533 head yet but I could see it wouldn't fit. I therefore cut that corner off and welded in a new sloping piece which caught two more studs  I did the last cuts all by hand as I thought I'd make an  of the angles doing it on a chop-saw but this time I used a grinder with thin blade and it was much quicker and still pretty accurate  When I offered up the starter it struck me that the next obstacle might be the flywheel contacting the frame  The stud protrude about 1 1/2" from the face of the bellhousing and the frame is 1" thick so that doesn't leave much room for nuts or a gap between the frame and casting. So that was it for the night but I took a stud out to check size/TPI to order bolts which would take their place. I made them 3/8 UNC (16 TPI) and will but like 3" or longer bolts but will offer up the crank and flywheel before I commit. I also want some tubing to weld onto the frame and slide over the 'studs' so that they are not just waggling about in holes in the frame. I've bought various sizes of tube in the past and weirdly they seem to fit metric & Imperial applications very well. Like the OD listed is some random 12.7mm and when you take off the thickness of the walls it becomes exactly 3/8" ID   frame parallel with sump frame parallel with sump  but now encroaches on thermostat position but now encroaches on thermostat position  corner cut off frame corner cut off frame  new sloping piece welded to corner new sloping piece welded to corner  frame still clears starter frame still clears starter |

| |

Last Edit: Apr 5, 2022 0:23:40 GMT by foxy99

1974 Daimler Double-Six VDP

1965/67 Hillman Imp pick-up

1984 VW Polo breadvan

1970s Yamaha Twins (4)

1976 Honda SS50ZK1

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,873

Club RR Member Number: 39

|

|

|

|

|

1 of 4 that may be of interest whilst you rebuild.

|

| |

|

|

foxy99

Posted a lot

Posts: 1,453

|

|

|

|

1 of 4 that may be of interest whilst you rebuild. Watched the videos. Very interesting but wish he'd included the bit about getting the thermostat housing off with his BBQ  I'm still playing with mine and noticed (like the head-bolt tappings) that they are open on the head casting. I'm pretty sure it'll be corrosion on the studs that's stopping the housing from coming off so it might be possible to remove the studs or at least one of them to get some movement going. This worked for me on the carb-bowls. The stud could be wound down or up to get it going. Also watched the Aston martin block-cleaning vides that came after the Imp ones. That was of interest due to the problems I had with my V12. Was pleased to see he used Devcon for pitting on the block. I had seen videos on YouTube with ppl using JB Weld for problems like that but wasn't sure if they were fantasists or not. I know you can get heads welded or skimmed to d/w pitting but as Andy said in the vids this can then distort the component or upset all the other related clearances so filler is an attractive option imo |

| |

1974 Daimler Double-Six VDP

1965/67 Hillman Imp pick-up

1984 VW Polo breadvan

1970s Yamaha Twins (4)

1976 Honda SS50ZK1

|

|

foxy99

Posted a lot

Posts: 1,453

|

|

|

|

Well I got basically nothing done on projects last week as I worked 6 days. However the bits I needed to progress the stand arrived (bolts & tube) So, today, I cut the tube into short lengths to create the gap between block and frame to allow room for the flywheel. It went ok but am not altogether happy about what I may have done to the threads in the block. I ran a tap thru them to clean them and despite no actual force used or cutting taking place it seems like the threads are slacker now. I've encountered this before and suspect it may be the cheapo tap & die set that's to blame. Perhaps the teeth don't have the right profile. Anyway with the 4 existing frame-holes connected it left one more to sort out.... Funnily enough the piece I cut off the corner would have worked well, welded inside the frame, but the legs were a bit too short so I just went for a new single piece. So that's the transmission end sorted and I now want something for the timing end. I suppose I could have legs/rails welded to the frame I just made that would run under the engine but it might still want to topple or tilt if they weren't long enough. The problem with the timing end is it only has one connection-point. If the engine is in the car it's basically a big bolt thru the timing-case casting that goes into a rubber-bushed bracket which sits on the bodywork (crossmember). No matter how sturdy the bracket etc are it strikes me that all the weight is taken by the relatively meagre alloy casting but with the transaxle attached perhaps the bulk of the weight is all supported up front and the rear is just for location/balance. Whatever the physics of it are there's nothing more I can add to it so my timing end contraption will need just need to attach there. It just so happens that the tube I used for the sleeves at the other end fits exactly in the hole (12.7mm OD tube just happens to be 1/2") so I'll work from there next visit. I'll obviously need to leave room for the pulley etc but want the tube part to be as short as possible to reduce 'leverage' strain on it   new 3/8" UNC bolts 3 1/4" long to replace original studs new 3/8" UNC bolts 3 1/4" long to replace original studs  12.7mm OB tube with 1.5mm wall thickness 12.7mm OB tube with 1.5mm wall thickness  pieces cut off tube to use as sleeves over bolts pieces cut off tube to use as sleeves over bolts  frame fitted to block at 4 points. offcut could have worked on position #5 frame fitted to block at 4 points. offcut could have worked on position #5  short perpendicular piece welded in instead short perpendicular piece welded in instead   with sleeves and longer fasteners added frame now stands off block giving room for flywheel with sleeves and longer fasteners added frame now stands off block giving room for flywheel  tube used for sleeves may be good starting point for frame at other end of engine tube used for sleeves may be good starting point for frame at other end of engine  tube is very snug fit in timing-case hole tube is very snug fit in timing-case hole |

| |

Last Edit: Apr 12, 2022 18:48:33 GMT by foxy99

1974 Daimler Double-Six VDP

1965/67 Hillman Imp pick-up

1984 VW Polo breadvan

1970s Yamaha Twins (4)

1976 Honda SS50ZK1

|

|

foxy99

Posted a lot

Posts: 1,453

|

|

Apr 17, 2022 13:47:00 GMT

|

So, not as planned, I'm doing more work on my 'original' 533 head. One of the reasons for this is that I think I'm going to have big problems finding the original hoses for the Sport head. I'm pretty sure I'll still have whatever ones were on the car when I got it, to use with the 533 head, but whatever the case there doesn't seem to be any supply of original types for either standard or Sport  . So the remit for the 533 head is basically: clean it thoroughly, lap the valves in, re-assemble it with new gaskets throughout. Don't think I'll bother getting it skimmed either. I started lapping-in the valves on Friday night. They really were in VGC  but the seats looked a little marked. I just used the fine paste for a couple of minutes and got good continuous rings on both. One of the things I needed to do if I was using the Sport head was rob the 'stat-housing from the 533 so I did plan for this but even if I'm using the 533 head it would make sense to check/renew the 'stat so would need to get it off anyway. Yesterday I dragged the hotplate out after spending hours trying to free the housing with conventional methods. There is quite a bit of room between the studs and the housing and after lots of penetrating-fluid and a bit prising and the help of a heat gun I could clearly wiggle the housing at one of the studs. You'd think the movement would be enough to break the bond on the other stud but it didn't. As mentioned before I also thought that I could perhaps remove the free stud by locking 2 nuts on it and therefore get much more swivel on the stuck one. The nuts weren't gripping it as they were too near the end so I tried grips on it and this naturally didn't work. So I put the head on the hotplate and quickly covered it with a very slack Kingspan box to keep the heat in then went and did something else. The box was soon smoking so I assumed everything was roasting but it was actually just a load of oil that was trapped where the oil-drain would be. Perhaps a question for another day but would there have been any downsides to running a car with a head that has the oil-drain provision but having the port blanked? Anyway as things were hot I took the chance to quickly remove the steel hose-spouts before it cooled and one came out with just a little pressure. The other seemed reluctant so I didn't force it as they don't really need to come out. I just wanted to see if they would. After that I worked on loosening the housing but long story short it wasn't budging. After a few more hours of wiggling and penetrating fluid I decided to drill the stud. This normally goes pear-shaped very quickly when the component is wobbling about on the floor held with one hand and you are guessing your drill is straight in the other. Well the hole started pretty much bang-on centre and stayed that way as I widened it out till only a thin shell was left. I drilled down about to what I thought was high enough above the head casting to leave me something to grab onto once the housing was off but also be insignificant enough to not stop the housing breaking free. Once there was no more I could drill without cutting into the housing I tried punches etc to upset the thin shell and flooded it with fluid and lots more wiggling and levering and it still would not let go. I could actually see minute movement of the housing round the remains of the stud. It was getting near midnight by this time and I was determined to get it off so I resorted to (linear) force. Never a good idea but there was a tiny bit of the housing on the stuck-stud side that I could strike with a hammer and screwdriver and sure enough it started to move along the stud a fraction. After that it was just a case of tapping it back down again then up then more fluid then wiggle then tap. You get the idea. So it's off and the studs should come out ok as I've scraped away the corrosion where they meet the head and left them soaking in ACF50 and will put the head back on the hotplate till it's good and hot. Only bit I'm not happy about is I caught the top of the housing with the drill and it's enlarged the hole but it's fine at the bottom. Just caught the top of it   valve-seats prior to lapping valve-seats prior to lapping seats after light lapping-in seats after light lapping-in valves after lapping valves after lapping makeshift oven makeshift oven head on hotplate head on hotplate steel spout came out of head fine after hotplate steel spout came out of head fine after hotplate drilling stuck stud drilling stuck stud even with most of stud out, pool of penetrating fluid and wiggling housing would not yield even with most of stud out, pool of penetrating fluid and wiggling housing would not yield  finally off finally off still some work to do still some work to do  snug-fitting (8.5mm) drill bit shows some damage to housing at top of one stud-bore snug-fitting (8.5mm) drill bit shows some damage to housing at top of one stud-bore  |

| |

Last Edit: Apr 18, 2022 21:25:26 GMT by foxy99

1974 Daimler Double-Six VDP

1965/67 Hillman Imp pick-up

1984 VW Polo breadvan

1970s Yamaha Twins (4)

1976 Honda SS50ZK1

|

|

foxy99

Posted a lot

Posts: 1,453

|

|

|

|

|

|

| |

1974 Daimler Double-Six VDP

1965/67 Hillman Imp pick-up

1984 VW Polo breadvan

1970s Yamaha Twins (4)

1976 Honda SS50ZK1

|

|

|

|

foxy99

Posted a lot

Posts: 1,453

|

|

|

|

|

|

| |

1974 Daimler Double-Six VDP

1965/67 Hillman Imp pick-up

1984 VW Polo breadvan

1970s Yamaha Twins (4)

1976 Honda SS50ZK1

|

|

foxy99

Posted a lot

Posts: 1,453

|

|

|

|

|

Just got some clarification on the Sport valves thing...

The 533 head was never fitted with Sport valves but for some reason they used the double springs on the inlet valves and the no stem-seal arrangement

|

| |

1974 Daimler Double-Six VDP

1965/67 Hillman Imp pick-up

1984 VW Polo breadvan

1970s Yamaha Twins (4)

1976 Honda SS50ZK1

|

|

ovimor

North East

...It'll be ME!

Posts: 929

|

|

|

|

|

There appears to be logic in only drilling some of the tappet holes... Racers AFAIK will drill all 8.

The oil hole in the cam end might be ground about 1/4" into a 'bathtub' sort of relief = allows slightly more oil into the bucket/followers. Grinding a groove all the way around play hell with oil pressure, I think..

Keep At It 👍

OVIMOR

|

| |

Knowledge is to know a Tomato is a 'fruit' - Wisdom, on the other hand, is knowing not to put it in a 'fruit salad'!

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,873

Club RR Member Number: 39

|

|

|

|

|

Pretty sure that the 533 uses the MK2 valve sizes - Sport Cam and therefore carrier - Double valve springs throughout - Springs chosen to match the cam performance - and is fitted with the head to block drain.

As your 533 head has been down spec'd to MK2 standard - there is no need to use the head drain if it has the single springs and the stem seals fitted. However, there is no harm having stem seals and the head drain.

The reason for the buckets sat different heights will probably be due to the underside of the bucket sitting on the edge of the spring retainer - there is no need for the top of the retainers or the underside of the bucket to be even or to a tolerance as the shims sit on the top of the valve stem and the ground "seat" on the underside of the bucket.

|

| |

|

|

foxy99

Posted a lot

Posts: 1,453

|

|

|

|

So it's been about a month since I worked on the frame but, unexpectedly, made a little progress late tonight. I've been busy getting my Mondeo ready for MOT most of week but was using the MIG for a couple of things and had a couple of hours to spend before midnight home-time so turned to the frame. I basically needed something to support the tube coming from the timing-chain casing. An apex perhaps  So there was a piece of the old frame that I've been cutting up which had a ready-made right angle so I drilled a strong 12mm hole in it and slid that over the tube. This gave me a triangle thing with one long leg and one short. I cut the spare bit off the T-shape frame remains and welded this to the short leg. After that I cut both of the legs at 45 degree angle about 45cm length. I could then turn it right way up and see how it sat. The legs are a bit short but I'm adding 'feet' to the transmission end anyway so can do this on the legs also. The legs are probably far enough apart as it and making them longer would have increased this. If I'd made the apex-angle sharper it would also have brought the legs closer together but we'll see how it develops.  bits of the old frame. T-shape bit was starting point for tonight's work bits of the old frame. T-shape bit was starting point for tonight's work  T-piece turned into a triangle with no base T-piece turned into a triangle with no base  engine roughly how it will sit engine roughly how it will sit feet need to be added at both ends feet need to be added at both ends |

| |

Last Edit: May 15, 2022 11:38:53 GMT by foxy99

1974 Daimler Double-Six VDP

1965/67 Hillman Imp pick-up

1984 VW Polo breadvan

1970s Yamaha Twins (4)

1976 Honda SS50ZK1

|

|

foxy99

Posted a lot

Posts: 1,453

|

|

May 23, 2022 22:06:43 GMT

|

I'll not go into all the whys & wherefores but got a bit further on the Imp project. I've been raking thru big tubs stacked in my cupboard (technically a pram-store) in the flats to unearth Imp bits I've not seen for a long time. Was hoping to find stuff I'll need for the engine fire-up: Water-pump, radiator bits, ignition-coil etc etc and have found everything I think I need apart from the water-pump/alternator alloy mounting-bracket. I'm not sure exactly how all that fits together and I do have the metal bracket that works in tandem with it but no sign of the alloy bit. I've even checked old old photos to see if there was one on the engine when I got it and there is but I just can't find it. It must be somewhere as the chances of having lost it are very slim. A lot of the stuff in the tubs was parts I had powder-coated about 30 years ago and the alloy bit wouldn't have got that so that might explain why it's not in the tubs. I searched a lock-up the Imp was in for about 20 years and it's not there and looking at photos of when the engine went to the barn (2018?) it wasn't on the engine so am thinking it might be in a different lock-up where the trailer the engine lived on for decades is parked. I recently found the exhaust on the trailer so will have a look there. I could get another one I'm sure but there are at least 2 types. For some reason the Sport had a different one despite the Sport also using a Dynamo like the standard models. And just to confuse matters further my car had an alternator from day 1 I believe. More on that later perhaps but I found the rear-bracket for the alternator in the 'powder-coated' tubs and after posting a pic of on Imp Facebook page it seems they are very rare. I know very late Imps had alternators but not sure how little of the production-run this applied to. So I've been examining the various cables etc and cleaning the very oily fan parts but my next repair will be to the radiator side-brackets. These were neatly wrapped in bubble-wrap and pretty corroded in parts. They obviously didn't get the powder-coating as they had to be repaired first and iirc I couldn't weld back then. I don't think it'll be hard to repair them. Will post on that later. I've been taking the parts down to the barn on my bike so some awkward parts haven't made it down yet. The alternator and water-pump are a bit heavy and the 'square' radiator cowl is light but an awkward shape to put in a bag One thing that's puzzling me is what do the cowl and the bottom of the radiator sit on in the engine -bay. I can see there are two brackets on the top of the radiator, to hang it from the body. but there seems to be fixing-points at the bottom of the parts too.The reason I'm curious is that I'd like to incorporate them into the engine-frame I'm making  1st batch of exhumed parts to make it to barn 1st batch of exhumed parts to make it to barn  starter solenoid c/w cables; engine rear support-bolt; alternator/dynamo bracket starter solenoid c/w cables; engine rear support-bolt; alternator/dynamo bracket  2nd batch 2nd batch  radiator brackets radiator brackets  rusted bit retained all these years rusted bit retained all these years  fan rather oily fan rather oily  fan-cowl; rubber gaiter; red thing fan-cowl; rubber gaiter; red thing   one of the large clips which secures gaiter to cowls. hope to find the other one of the large clips which secures gaiter to cowls. hope to find the other  this must be original belt for alternator this must be original belt for alternator I also made another small step with the frame. It feels good to be upcycling the frame made many years ago (to act as a cradle for the car) into this frame and the size of the tubes is actually much more suited to this sort of task than supporting the whole car. So of the frame I've beet cutting up and using there was a bit just about right size to complete the triangle I've made for the timing end. I've got plenty of it left to make 'feet' and something for the battery and perhaps the radiator. I put the sump back on the other night to give me an idea of where to weld the bottom bar of the triangle  sump back of for visual check sump back of for visual check  another piece of the old frame can be cut and welded in here another piece of the old frame can be cut and welded in here |

| |

Last Edit: Jun 7, 2022 22:22:18 GMT by foxy99

1974 Daimler Double-Six VDP

1965/67 Hillman Imp pick-up

1984 VW Polo breadvan

1970s Yamaha Twins (4)

1976 Honda SS50ZK1

|

|

jimi

Club Retro Rides Member

Posts: 2,199

|

|

May 23, 2022 23:40:34 GMT

|

I very much doubt thats the original belt, that's what I know as a link belt, you can adjust the length by adding or removing links, normally used as a temporary (or emergency) belt. From what I remember Imps used standard v belts. |

| |

Last Edit: May 24, 2022 18:35:31 GMT by jimi

Black is not a colour ! .... Its the absence of colour

|

|

foxy99

Posted a lot

Posts: 1,453

|

|

May 24, 2022 16:51:57 GMT

|

I very much doubt thats the original belt, that's what I know as a link belt, you can adjust the length by adding or removing links, normally used as temporary (or emergency) belt. From what I remember Imps used standard v belts. Ah I see. I'd never seen one like it before so assumed (in 1988) it was just ancient and .'. the original  |

| |

1974 Daimler Double-Six VDP

1965/67 Hillman Imp pick-up

1984 VW Polo breadvan

1970s Yamaha Twins (4)

1976 Honda SS50ZK1

|

|

jimi

Club Retro Rides Member

Posts: 2,199

|

|

May 24, 2022 17:25:58 GMT

|

It certainly looks ancient  I used those type belts when I worked for the NCB ( late 60's to late 80's) and I've seen them offshore. You can still buy them, mostly used in industry, its a very old design originally made from leather IIRC.  |

| |

Black is not a colour ! .... Its the absence of colour

|

|

foxy99

Posted a lot

Posts: 1,453

|

|

May 25, 2022 22:52:04 GMT

|

So I have a lot of pictures of the bits n pieces from last few days and it'll take quite a long time to comment on them all. I haven't really stuck to my original plan at all - which was to have very few words and lots of pics but hey that's the way I am. Anyway I did find the bit I was looking for, along with another bit I was sort of concerned about. After raking thru one of my lock-ups and finding nothing Imp related, apart from 2 (faded) tax discs from the windscreen that recently smashed, I had another look in the pram-store and there was one more tub of Imp bits and the alloy dynamo/alternator come water-pump bracket was there along with the metal yoke for the water-pump which the fan attaches to. I'll mb never get to the bottom of the Sport/non-Sport bits fitted/not-fitted to my Imp originally but, so far, I've found it doesn't have Sport driveshafts; radiator cowl (square) or radiator and there was no T on the oil-pump/crankshaft gear. The next item(s) for scrutiny are the brackets for the pump/generator. Looking at the parts list there are (at least) 4 types shown for the alloy one and 2 for the accompanying steel one. The summary seems to be Sport/non-Sport (up to 1969) then 1969 with alternator then remaining years with alternator. I've no idea why the alloy part would differ from Sport to non-Sport if both types came with a dynamo. The later brackets, for alternator-equipped cars, appear to only differ due to a captive-nut on the metal part and some corresponding difference on the alloy bit but I'm not sure of the specifics. Strangely both my metal part and alloy part have a bolt-hole missing. Could have been damaged or perhaps a bodge to fit an alternator to brackets suited to the dynamo. I have the special (apparently rare/desirable) rear bracket for the alternator so you'd expect the front brackets to also be the right type but it seems that the alternator option wasn't available to 1969 so could be retro-fitted. The alternator has a tag on it which could mb date it. Then there is the aspect that Police Imps apparently had alternators prior to 1969 so mb my car got that option. Anyway it's all guesswork just now and all I have to go on is the casting number on the alloy bracket. These are not the same as the part number but, as with the various cylinder-heads, an expert might know what casting numbers were on what brackets. I can also look at my wiring to see if the connector for the alternator looks like a homemade bodge or not. Going back to the tax discs I mentioned.... They are very faded and are valid for 1986 and 1987 and I think I can make out an M reg-suffix on them. When I bought it there were a bunch of spares from another Imp in the load area. I remember a set of gold doors which were the later type. I'd never imagined my car was still on road in 86/87 so I'm pretty sure the recently-smashed windscreen was from this spares batch and it's also possible that the alternator was taken from a late car - like M-reg. I think I really need to get down to Paisley/Johnstone very soon and start quizzing anyone connected with the car before it's too late.   generator bracket and water-pump yoke unearthed generator bracket and water-pump yoke unearthed casting number on alloy bracket 7010044 1/2 casting number on alloy bracket 7010044 1/2 original alternator ? original alternator ? tag on alternator may be useful for dating tag on alternator may be useful for dating  (rear) mounting bracket for alternator (rear) mounting bracket for alternator |

| |

1974 Daimler Double-Six VDP

1965/67 Hillman Imp pick-up

1984 VW Polo breadvan

1970s Yamaha Twins (4)

1976 Honda SS50ZK1

|

|

|

|

of the angles doing it on a chop-saw but this time I used a grinder with thin blade and it was much quicker and still pretty accurate

of the angles doing it on a chop-saw but this time I used a grinder with thin blade and it was much quicker and still pretty accurate