|

|

|

Dec 31, 2015 20:03:41 GMT

|

|

^^

Why thank you sir. Glad my little project pulls you out the depths of lurkiness... Been bit preoccupied with other things recently. Normal service to resume next year ,lol

|

| |

|

|

|

|

|

|

|

|

|

One thing I want to do is get the Mazda home. It's all fine and well at work, but having to move it in and out the workshop after every session is becoming a right royal pain in the Glutemus Maximus. So roll on operation replace the side door on the garage... Lots of planning had gone into this. Found a door down in Rye for the pricey sum of £5. That was duly painted ready for the big day. Here was the old door. Owner never had the key so never bothered. Was going to board it up, but I said I would sort it out as its a pain having to move two cars in the driveway to open the garage door.  Unbeknown to me, the sill was five thousand coats of enamel around a whole lot of nothing with a couple of rotten wood shards thrown in for good measure  That didn't go well. Should have consulted someone with sawdust in their veins, but I didn't. Out with my finest wood working gear....  Wentand checked in my consumable cupboards. Big empty space where it should have been.Just need to wait for the hardware shop to open so I can get some wooden wire for the mig, and weld it together...... |

| |

Last Edit: Jan 2, 2016 6:28:51 GMT by Deleted

|

|

|

|

|

|

|

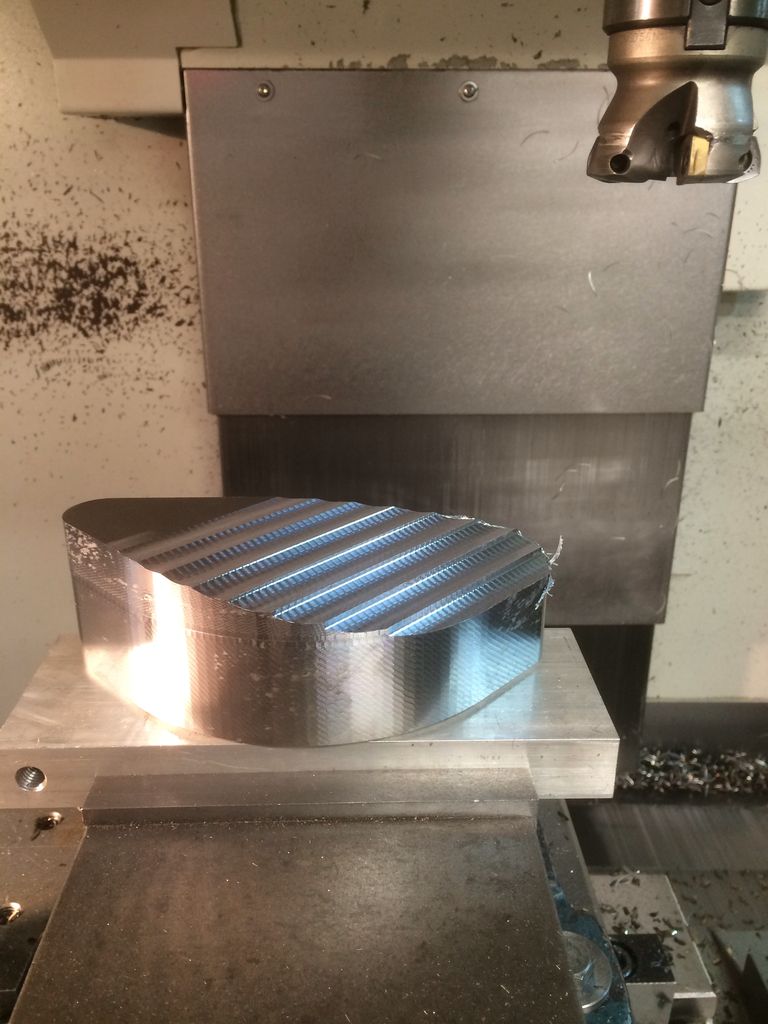

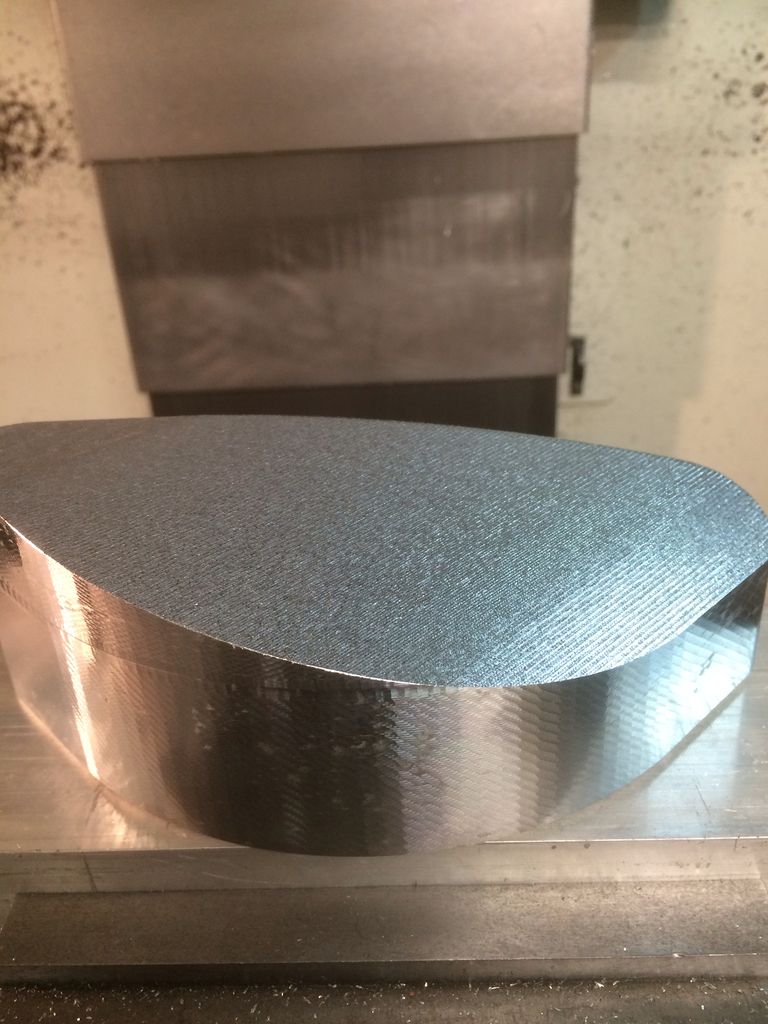

Default grey skies and filthy weather really didn't inspire me to carry on with the door this morning. Fitted the door, locks,etc yesterday,so it was just the sill to sort out. Decided to leave that for a day with less liquid sunshine pouring out the sky. And I'm quite glad I did too... Have been wondering how to machine the lower inserts for the side panel tool for some time now. So I had a little play. Definitely a school day today. Decided to bolt the pre machined insert down with the flat side to the back. Then I rotated the drawing on the computer 45 degrees. Wrote a programme ,but instead of machining from left to right, I decided on machining at 45 degrees as well. Works a charm... Roughing out  Pre finishing, this time machining at 135 degrees. This is now full 3D milling where you have all three axis's moving simultaneously. Me likey....  Finished insert, prior to polishing  So end of play, that's the bottom half of the tool finished machined. Just needs polishing and all the heights of the punches setting up.  I am really enjoying this build. I am learning a lot. Because there are no time constraints it affords me the opportunity to try machining things in different manners.... Every day a school day. This has also made me decide this is the way to machine the last two parts for the top. Hopefully tomorrow. So, even though I haven't managed to get totally finished before work starts up again, I am more than happy with what I learnt and where I did get up to ! |

| |

|

|

|

|

|

|

|

|

It's 50 past midnight Johnny.... Thanks, just finished reading every word and entry in this thread.

Weird how you miss stuff when you get busy, preoccupied or distracted in various ways.

Anyway, on old years day, I decided to take Johnny up on an old offer of using his press to do the ball joint in my Chevy's lower control arm, except that the job had already been done.

So this would be a quick social visit to his workshop.

Armed with milk, biccies and rusks (it's a South African thing) I headed out on the 27 miles to his place.

4 hours later, a trip to the garage, both skips (which yielded treasures) multiple coffees and much amazement at his skills, I left....... Ohhh, and it turns out we both know Era well, and I met the RX2 years ago in Dummer.

Great to meet you Johnny, and seeing just how grounded you are gives me much hope for mankind

.

This build has some ways to go, but the attention to detail and problem solving is way off the scale.

Thanks for your hospitality.

|

| |

|

|

|

|

|

|

|

Have you thought about a steel sill plate instead? Unless you're using hardwood it'll last just as long. And a bit easier to find mig wire for it.  |

| |

|

|

|

|

|

|

|

Have you thought about a steel sill plate instead? Unless you're using hardwood it'll last just as long. And a bit easier to find mig wire for it.  Wooden mig wire all,gone rotten,or so the supplier tells me  Just ordered an ally threshold with draught/water excluders. Job done ! |

| |

|

|

|

|

|

|

|

It's 50 past midnight Johnny.... Thanks, just finished reading every word and entry in this thread. Weird how you miss stuff when you get busy, preoccupied or distracted in various ways. Anyway, on old years day, I decided to take Johnny up on an old offer of using his press to do the ball joint in my Chevy's lower control arm, except that the job had already been done. So this would be a quick social visit to his workshop. Armed with milk, biccies and rusks (it's a South African thing) I headed out on the 27 miles to his place. 4 hours later, a trip to the garage, both skips (which yielded treasures) multiple coffees and much amazement at his skills, I left....... Ohhh, and it turns out we both know Era well, and I met the RX2 years ago in Dummer. Great to meet you Johnny, and seeing just how grounded you are gives me much hope for mankind . This build has some ways to go, but the attention to detail and problem solving is way off the scale. Thanks for your hospitality. Great to meet up with you Grizz. Thanks for the kind words,and your hospitality  |

| |

|

|

Wilk

Part of things

Posts: 528

|

|

|

|

|

If your up to bartering I could always make you a hardwood cill in exchange for some unobtainium panels !

|

| |

Last Edit: Jan 3, 2016 8:19:14 GMT by Wilk

If it can be fixed with a hammer, then it must be an electrical fault

|

|

|

|

|

|

|

If your up to bartering I could always make you a hardwood cill in exchange for some unobtainium panels ! Thanks for the offer. Bits ordered and paid for last night. Will sort it out one evening next week |

| |

|

|

|

|

|

|

|

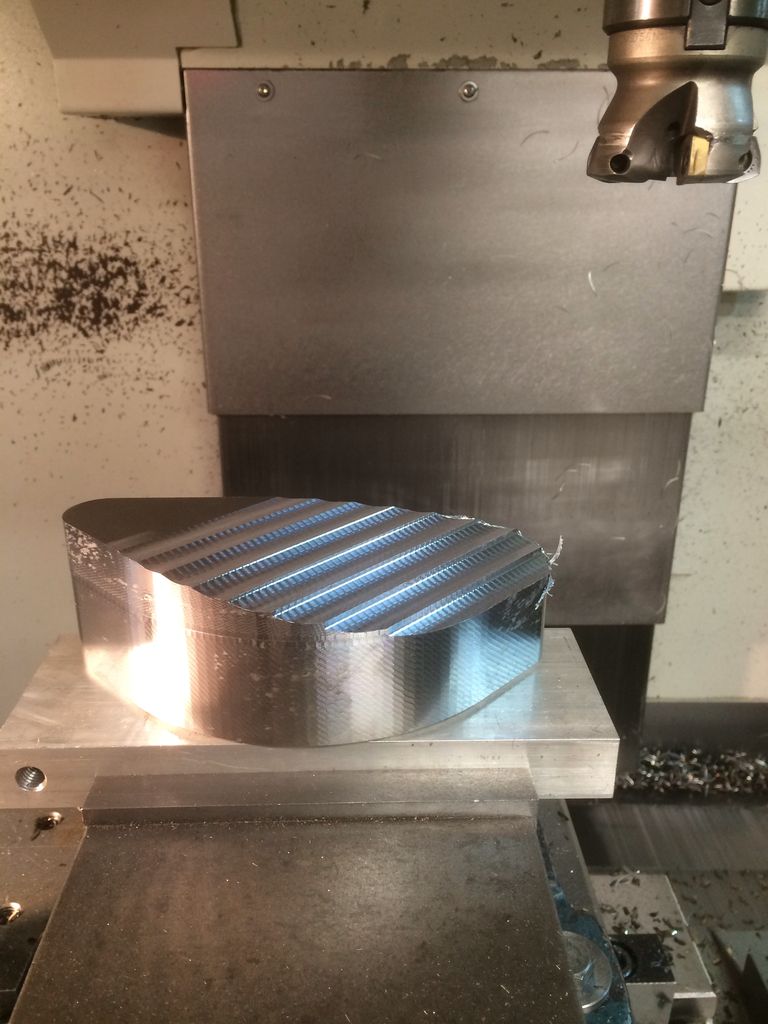

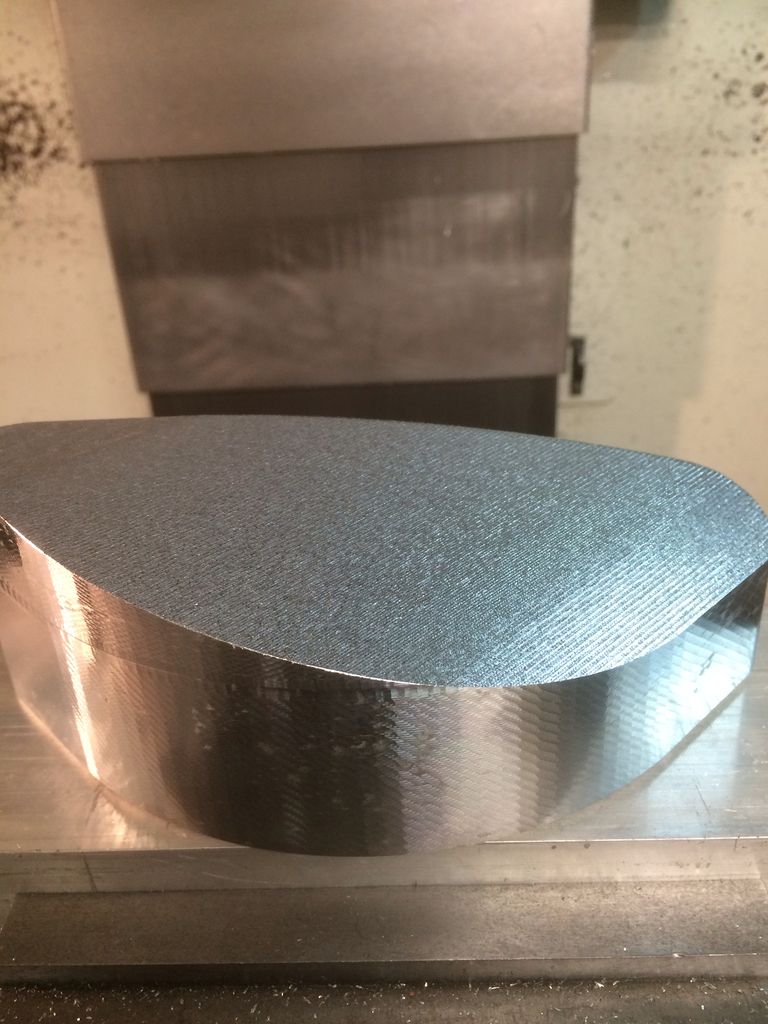

Cracked on with the last inserts today. Took longer than anticipated as there is a lot more material to remove on these two upper inserts. Roughed out contour and pocket  Finished pocket  Lower punch fits ok with the required clearance for the material  Measured the pocket it needs to go into. Still had 0,2mm left on  So left it running. Will switch off when it's finished. Only one more to go..... |

| |

|

|

|

|

|

|

|

|

Progress.....

And now I have another thread to keep checking up on every few minutes.

I got my LCA sorted out earlier too. Thanks for checking up.

|

| |

|

|

realvc

Part of things

Posts: 13

|

|

|

|

|

Just finished reading your thread. It was mentioned on one of Grizz's truck build threads that I follow.

I've now joined this forum so I can keep up with your progress.

I'm a shade tree mechanic at best and amazed at your skills and your dedication and desire to go so far to restore your RX 2.

It will be the best one ever built when your through.

Thanks for sharing your build.

|

| |

If it's too loud you're too old.

|

|

|

|

|

|

|

|

|

Just finished reading your thread. It was mentioned on one of Grizz's truck build threads that I follow. I've now joined this forum so I can keep up with your progress. I'm a shade tree mechanic at best and amazed at your skills and your dedication and desire to go so far to restore your RX 2. It will be the best one ever built when your through. Thanks for sharing your build. Welcome Vince !! You must have been real impressed to register on here. How is retirement going ? |

| |

|

|

|

|

|

|

|

|

Just finished reading your build after following a link Grizz posted on another board, signed up so I could stay up to date. Really is a great read, looking forward to more!

|

| |

-Sam

|

|

samta22

Club Retro Rides Member

Stuck in once more...

Posts: 1,276  Club RR Member Number: 32

Club RR Member Number: 32

|

|

|

|

|

Simply epic thread, I too have just spent hours reading from start to finish - I doff my cap to your skills sir.

Restoring a rusty old Japanese rarity myself I sympathise with the trials and tribulations of tracking down body panels around the globe. Alas I've not got the ability or equipment to make my own but would love to pop by and say hello next time I'm passing through Northiam (I regularly head down to Peasmarsh).

Off topic - do you know what's happened to the pedal car museum?

|

| |

'37 Austin 7 '56 Austin A35 '58 Austin A35 '65 Triumph Herald 12/50 '69 MGB GT '74 MGB GT V8'73 TA22 Toyota Celica restoration'95 Mercedes SL320 '04 MGTF 135 'Cool Blue' (Mrs' Baby) '05 Land Rover Discovery 3 V8 '67 Abarth 595 (Mrs' runabout) '18 Disco V |

|

|

|

|

|

|

Just finished reading your build after following a link Grizz posted on another board, signed up so I could stay up to date. Really is a great read, looking forward to more! Thank you Sir! |

| |

|

|

|

|

|

|

|

Simply epic thread, I too have just spent hours reading from start to finish - I doff my cap to your skills sir. Restoring a rusty old Japanese rarity myself I sympathise with the trials and tribulations of tracking down body panels around the globe. Alas I've not got the ability or equipment to make my own but would love to pop by and say hello next time I'm passing through Northiam (I regularly head down to Peasmarsh). Off topic - do you know what's happened to the pedal car museum? Thanks for the kind words. Home in Northiam,where hopefully the car will be in the next couple of months once the double garage is knitted out. It's at work just outside Maidstone at the moment. What Japtin you restoring? As for the pedal car Museum,I think Jeremy bought it. In the process of being remodelled if rumours are to believed. He bought a lot of railway stuff years ago that was stored in a house in Newenden, that has been emptied in the last six months. Rumour doing the rounds is that the two will be combined and open in the summer.... |

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,874

Club RR Member Number: 39

|

|

|

|

|

My expectation is that the March episode with start with a photo of all of the panels, parts, jigs and dies being loaded into the skip. This shock swiftly followed by the step by step detail build of how a Mazda sized 3D printer was built to produce a new titanium bodyshell.

I am in awe of the fabrication skills employed in the manufacture of the tools to progress make the restoration of the car possible, a thread that can be read again and again.

Andrew

|

| |

|

|

|

|

|

|

|

|

If all goes to plan, tooling will be in the skip by February.....

|

| |

|

|