|

|

|

|

|

This engine continues to fight me. It should have been rattled apart in about an hour...🙄 Eventually got the clutch off.   Clutch worn out and showing signs of slipping. Blue heat marks on both flywheel and pressure plate. Had originally thought the bolts had been loctited in,but after liberal application of heat didn't help,I started to wonder. Original bolts for this are M8x1mm,( Metric fine) Some genius has managed to bodge M8x1,25mm bolts into the flywheel ,( Metric standard). Flywheel is scrap,but no real loss,as I wouldn't have used it anyway. Another engine full of oil  Looks like the Smurfs had been holidaying in Wales and left their dandruff behind  Sump off,nice clean oil pickup removed,as well as the pressure relief valve. Makes it easier to lie engine down to loosen flywheel nut and front pulley   Came to get the flywheel off, but the locking bar I made last time was for a counterweight,not a solid flywheel. Grrr  Welded onto the other end of the bar.   ...only to discover I have welded it on the wrong way round...😡 Too late to do anything about it last night. So will have to sort it out today. Engine remains unopened.... |

| |

|

|

|

|

luckyseven

Posted a lot

Owning sneering dismissive pedantry since 1970

Owning sneering dismissive pedantry since 1970

Posts: 3,839

Club RR Member Number: 45

|

|

Feb 17, 2019 11:23:30 GMT

|

...only to discover I have welded it on the wrong way round...😡 It's human after all. Phew  |

| |

|

|

|

|

|

Feb 17, 2019 12:22:24 GMT

|

...only to discover I have welded it on the wrong way round...😡 It's human after all. Phew  Errrr....sorry to disappoint.Bit of a blonde moment there. Only drilled three holes in the plate,when originally I drew it with four. Why? Because to loosen the front pulley nut it needs to sit on one way, and to loosen the 54mm hex flywheel nut it needs to stop the engine turning in the other direction. Drilled the missing hole this morning ,and all is good... Well actually it's not 🙄😂😂, this ones a fighter. Right to the death...... |

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,357

Club RR Member Number: 64

|

|

Feb 17, 2019 13:13:01 GMT

|

|

Proof that Johnny Bravo is sometimes wrong: he thought he’d made a mistake. 😜

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

Feb 17, 2019 13:35:34 GMT

|

Proof that Johnny Bravo is sometimes wrong: he thought he’d made a mistake. 😜 Johnny Bravo is constantly wrong....if you believe Mrs Bravo 😂😂😂 |

| |

|

|

|

|

|

|

|

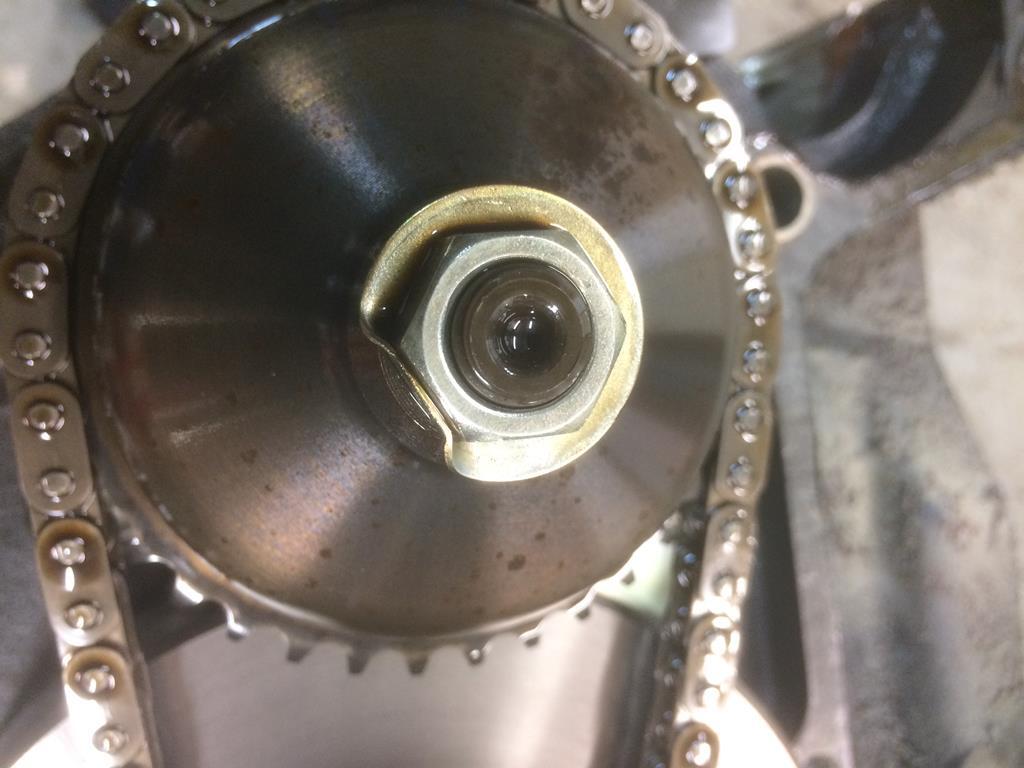

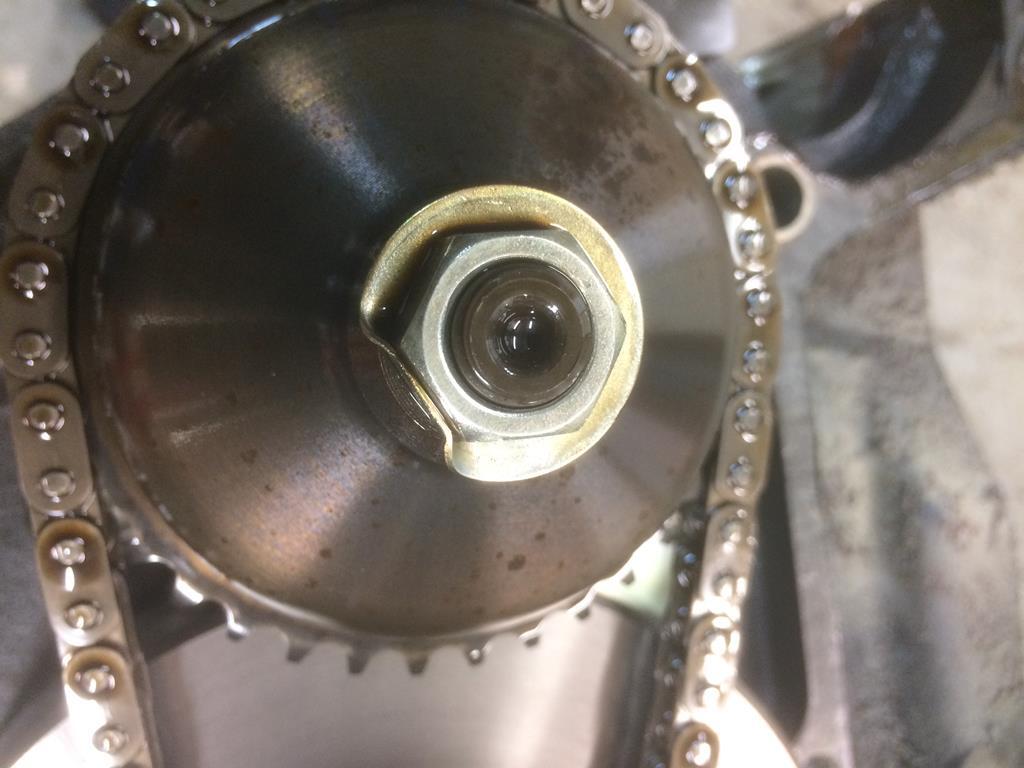

Missing hole drilled and back in business  Breaker bar on front pulley bolt. These can be stubborn on these engines,as they are not the same as earlier engines.  After a bit of heat and a good old heave ho, the dehydrated smurf blood finally gave up its grip.  These have what Mazda called a thermal pellet. Basically a wax thermostat incorporated into the front pulley bolt that alters the flow of oil when cold,diverting more oil away from the oil cooler than through it. Even though it incorporates an o ring, Mazda applied liberal coating of Smurf blood to stop it leaking through the threads,hence can be a real pig to undo.That done,front cover rattled off  Again, oil pump lock washer undisturbed,so motor never been opened.  Front stationary gear removed. Looks good 😊 Time to remove flywheel. Locking bar installed.  Here we go again 🙄 Flywheel has a deep recess,so big socket made to open the last engine doesn't go on deep enough. Engine remains unopened.... |

| |

|

|

|

|

|

|

|

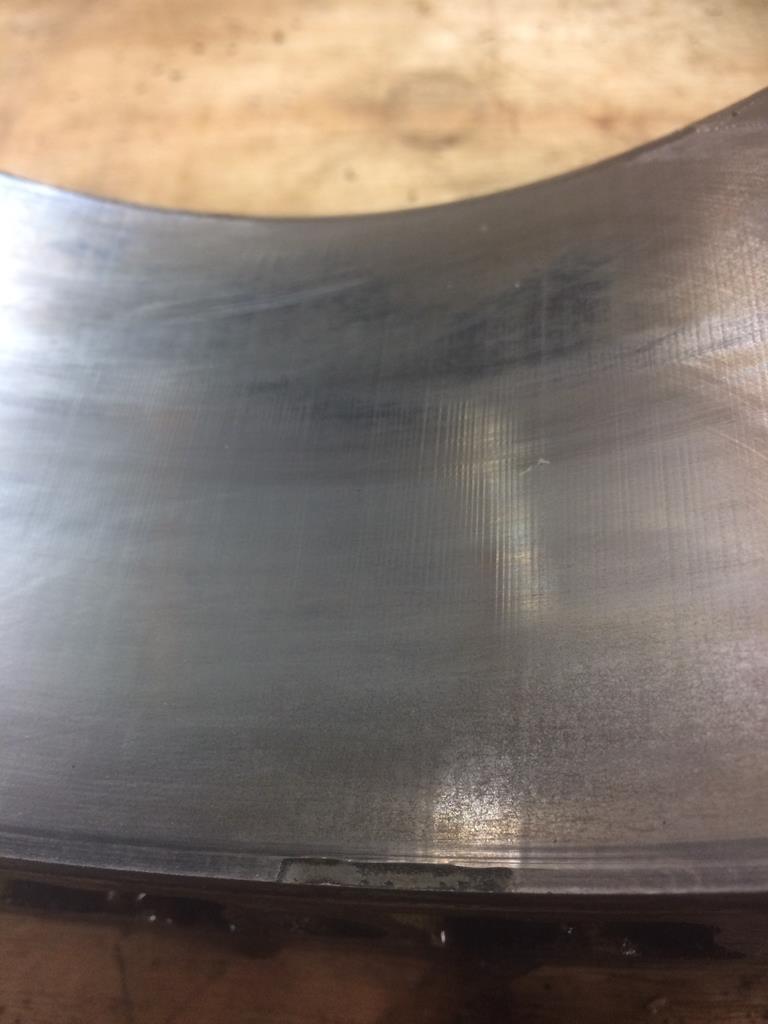

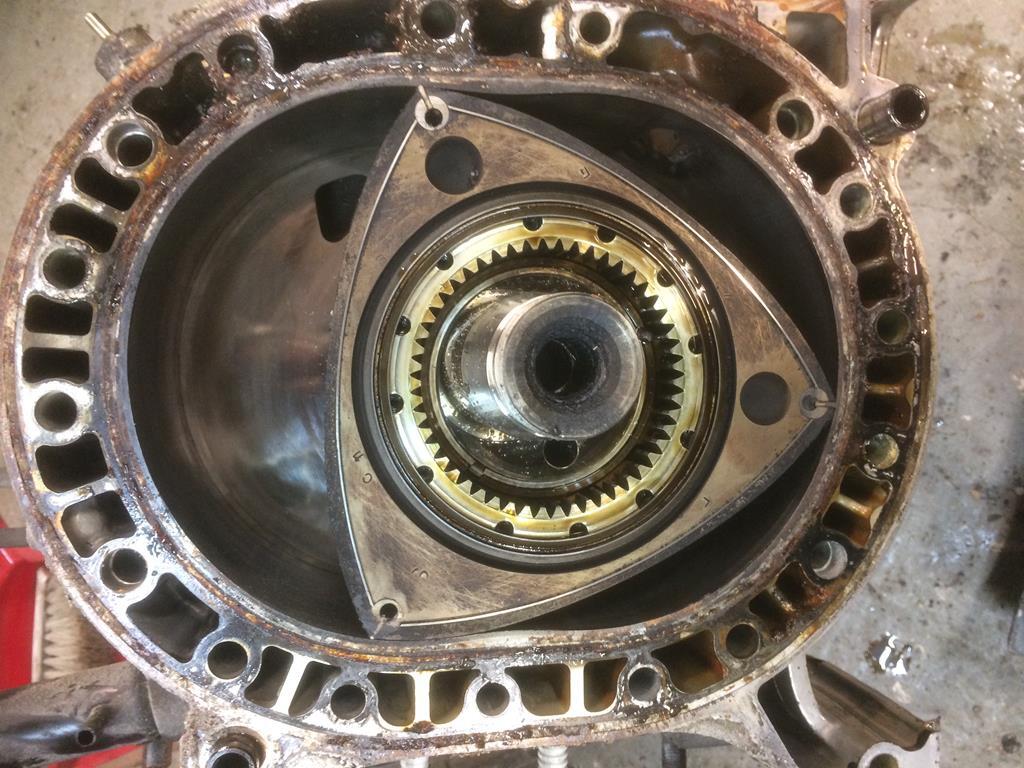

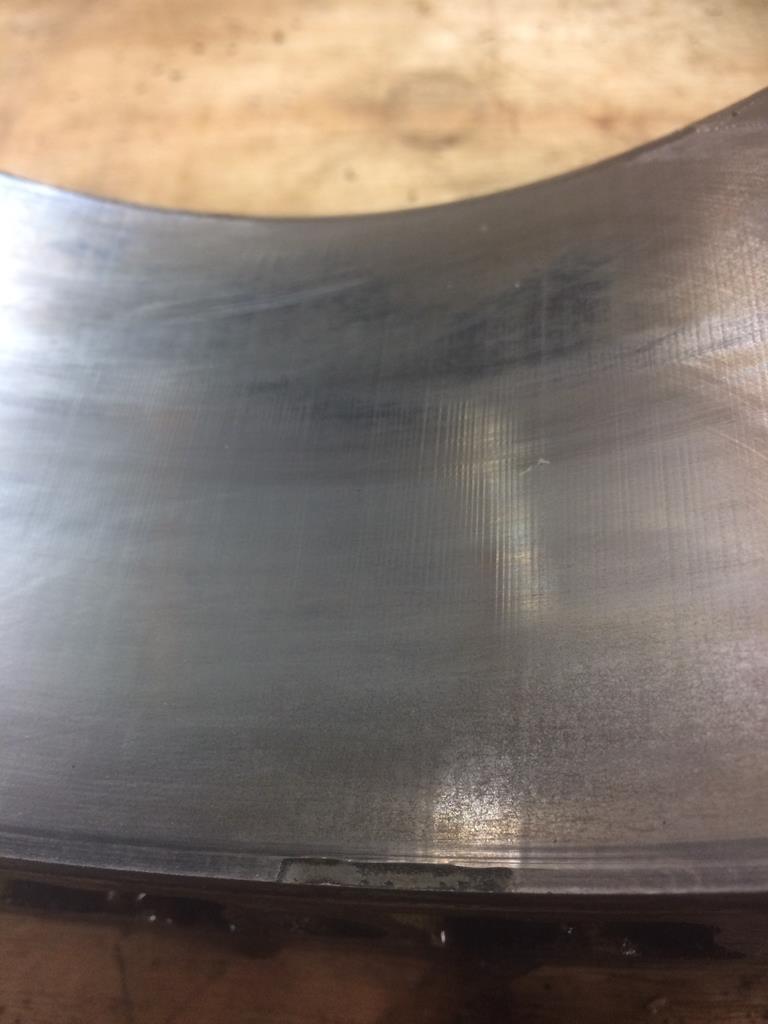

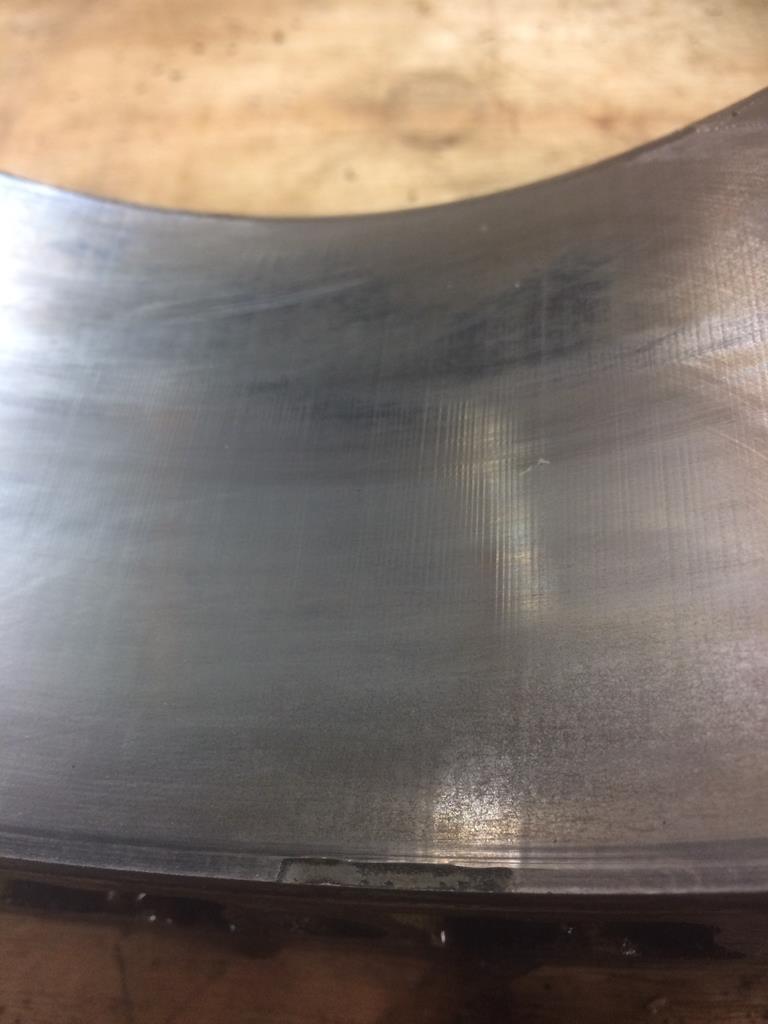

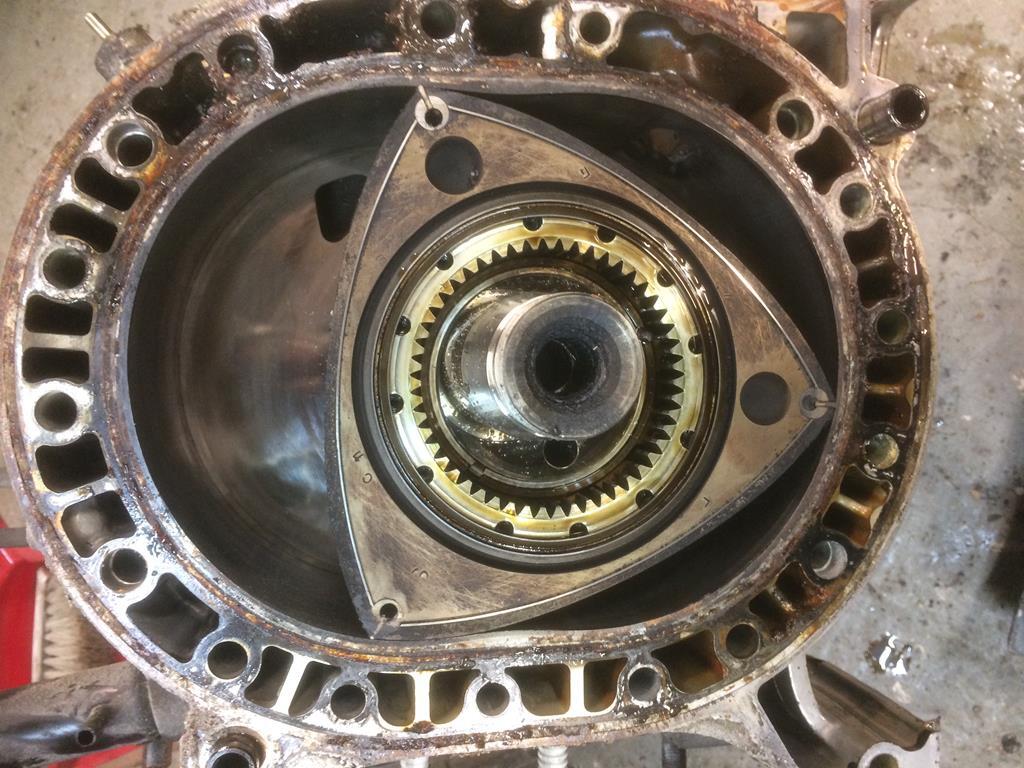

Out with the grinder and cut the socket off the bar  Found a pulley that could be repurposed    Back in business and nut comes off without any further arguments  Rear stationary gear removed and bolts undone   Back plate off revealing a good rotor. No damage and all seals free  Rattled the rest apart. Good plates 😊Good rotors 😊    Good for nothing rotor housings. Times two 😩 Both have flaking chrome that cannot be repaired, and the dreaded chatter marks. The search continues......🙄 |

| |

|

|

|

|

|

|

|

|

|

|

I trust that in the quest to locate an engine with good donor housings you aren't slowing working up to the spend of getting new ones (which I believe I read earlier are available, but eye-wateringly expensive).

I guess this is answered by your earlier point that fortunately the ancillaries were probably worth the asking price.

Enjoying following the progress!!

|

| |

|

|

|

|

|

|

|

I trust that in the quest to locate an engine with good donor housings you aren't slowing working up to the spend of getting new ones (which I believe I read earlier are available, but eye-wateringly expensive). I guess this is answered by your earlier point that fortunately the ancillaries were probably worth the asking price. Enjoying following the progress!! Three new housings will be roughly £2200. |

| |

|

|

|

|

|

|

|

|

This may sound like a silly question, but can't you just make some new housings? Compared to some of the things you've made they look fairly simple, or is it the coating that is the problem?

|

| |

1968 Cal Look Beetle - 2007cc motor - 14.45@93mph in full street trim

1970-ish Karmann Beetle cabriolet - project soon to be re-started.

1986 Scirocco - big plans, one day!

|

|

samta22

Club Retro Rides Member

Stuck in once more...

Posts: 1,276  Club RR Member Number: 32

Club RR Member Number: 32

|

|

|

|

|

B*gger! Had fingers and toes crossed for you.

Does however mean that another road trip might be in store.

|

| |

'37 Austin 7 '56 Austin A35 '58 Austin A35 '65 Triumph Herald 12/50 '69 MGB GT '74 MGB GT V8'73 TA22 Toyota Celica restoration'95 Mercedes SL320 '04 MGTF 135 'Cool Blue' (Mrs' Baby) '05 Land Rover Discovery 3 V8 '67 Abarth 595 (Mrs' runabout) '18 Disco V |

|

|

|

|

|

|

This may sound like a silly question, but can't you just make some new housings? Compared to some of the things you've made they look fairly simple, or is it the coating that is the problem? They have a steel liner cast into the aluminium housing. This is then hard chromed and ground. They are not economically viable to make in small quantities |

| |

|

|

|

|

|

Feb 18, 2019 10:52:06 GMT

|

This may sound like a silly question, but can't you just make some new housings? Compared to some of the things you've made they look fairly simple, or is it the coating that is the problem? They have a steel liner cast into the aluminium housing. This is then hard chromed and ground. They are not economically viable to make in small quantities Ah, more complex than they look in photos then. That's a bummer. |

| |

1968 Cal Look Beetle - 2007cc motor - 14.45@93mph in full street trim

1970-ish Karmann Beetle cabriolet - project soon to be re-started.

1986 Scirocco - big plans, one day!

|

|

luckyseven

Posted a lot

Owning sneering dismissive pedantry since 1970

Owning sneering dismissive pedantry since 1970

Posts: 3,839

Club RR Member Number: 45

|

|

Feb 18, 2019 11:08:43 GMT

|

Good for nothing rotor housings. Times two 😩 Both have flaking chrome that cannot be repaired, and the dreaded chatter marks. The search continues......🙄 The Devil's nail marks  |

| |

|

|

|

|

|

Feb 18, 2019 11:21:40 GMT

|

|

Not having ever had anything to do with these engines this is going to sound stupid to those who have.

Is there anyway to hone for want of a better word or polish them with say a drum sander on a CNC mill with Diamond paste/paper?

Just thinking out the box a bit, not trying to each you how to suck eggs Johnny.

|

| |

|

|

luckyseven

Posted a lot

Owning sneering dismissive pedantry since 1970

Owning sneering dismissive pedantry since 1970

Posts: 3,839

Club RR Member Number: 45

|

|

Feb 18, 2019 11:59:51 GMT

|

|

There's a guy up in Brum who re-surfaces housings (or did, I'm a little out of touch with the inside circle of UK rotangs) but they can't have too deep damage or it doesn't work. Also, I can't speak for how long the process lasts in use. The chrome that Mazda used was, I gather, an incredibly hard and difficult to apply process, and ended up with a coating not unlike that on suspension sliders (which is basically a long, tubular bearing surface). Trouble is, it's eye-wateringly expensive unless you're doing it on an industrial scale.

Some firms like PPRE in New Zealand produce proprietary rotor housings, but they too are terrifyingly expensive

|

| |

|

|

mylittletony

Posted a lot

Posts: 2,425

Club RR Member Number: 84

|

|

Feb 18, 2019 12:55:00 GMT

|

|

Is there a possibility of replacing the chrome with another industrial coating?

I'm thinking DLC

Again, apologies if this is all old ground/egg sucking

|

| |

|

|

|

|

|

Feb 18, 2019 13:04:21 GMT

|

There's a guy up in Brum who re-surfaces housings (or did, I'm a little out of touch with the inside circle of UK rotangs) but they can't have too deep damage or it doesn't work. Also, I can't speak for how long the process lasts in use. The chrome that Mazda used was, I gather, an incredibly hard and difficult to apply process, and ended up with a coating not unlike that on suspension sliders (which is basically a long, tubular bearing surface). Trouble is, it's eye-wateringly expensive unless you're doing it on an industrial scale. Some firms like PPRE in New Zealand produce proprietary rotor housings, but they too are terrifyingly expensive You cannot resurface a surface that’s no longer there 😂😂 |

| |

|

|

|

|

|

Feb 18, 2019 20:40:11 GMT

|

Not having ever had anything to do with these engines this is going to sound stupid to those who have. Is there anyway to hone for want of a better word or polish them with say a drum sander on a CNC mill with Diamond paste/paper? Just thinking out the box a bit, not trying to each you how to suck eggs Johnny. There are ways of cleaning parts of them up, but once the hard chrome has flaked off, the housing is FUBAR...* *Fuckedupbeyoundallrepair...hehehe. 🦊 |

| |

Last Edit: Feb 18, 2019 20:43:27 GMT by Deleted

|

|

Rattled the rest apart. Good plates 😊Good rotors 😊

Rattled the rest apart. Good plates 😊Good rotors 😊