Rob

Part of things

Posts: 252

|

|

|

|

These cars do go better with a 2.5, but then 3.45:1 diff is needed...... It is possible to get them to go well with a 2L but more effort (and expense) needed on the engine. FWIW, all the earlier heads are big valve. They reduced the exhaust valve size later on to reduce the cracking risk. Good luck with the “new” engine....... Thanks, beggers can't be choosers and all that, 2.5 litre Triumph engines don't exactly grow on trees over here, one came up for sale about 2 hours away from me (that is local in Norwegian terms) a few weeks ago, first one i've seen for a couple of years at least, it spiked my interest then, little did I know that I might actually need it myself. Seems legit, have spoken to the seller, MM engine code with 219016 head and the correct 45D6 distributor, really can't be any worse than what I had. Has been used in a small chassis Triumph so it has a GT6 / Vitesse overdrive box on it but I can probably sell that on without too much problem. Of course this means putting a front plate on for the engine mounts and a few other jobs but hey that's where the fun is, right? Yeah, best go and check which diff I have, do you know what numbers i'm looking for? Do you know how much an engine and gearbox weigh? engine and box are close to 300kg fully dressed. very heavy. chris witor has a diff id page, there will be a number stamped on it, if the cars a 2000 then probably a 3.7 i run a late 2500 engine, 016 head, hs6's, wade 013 cam, elec ignition, witor sports exhaust and an early mk2 4 speed non od box. my diff is the 4.11 one. it revs well and is a bullet to 90mph. but is doing 4500rpm then. I'm going efi and a t5 5 speed this winter. they're a good engine but weight is killer. i get why andyborris did his bmw one..... |

| |

|

|

|

|

|

|

|

|

|

|

300kg is perhaps a bit pessimistic - I place my bid at 250kgs. The small chassis gearbox is about 35kgs and the engine around 200 depending on what ancillaries are with it.

The small chassis box should sell, just don’t say it’s been behind a 2.5...... They die easily enough behind a 2L!

Nick

|

| |

1967 Triumph Vitesse convertible (old friend)

1996 Audi A6 2.5 TDI Avant (still durability testing)

1972 GT6 Mk3 (Restored after loong rest & getting the hang of being a car again)

|

|

|

|

|

|

|

|

Just to add, when inspecting a used Triumph engine (running condition or not), it is important to check the the crankshaft endfloat as it is not unknown for them to drop thrust washers, causing damage to crank and block.

Grab hold of the flywheel or front pulley and push/pull along the the crank axis. A small amount of "clonk" is acceptable - book figure is something like 0.006" - 0.010", but up to around double that is acceptable on a used engine, though much over 0.010" suggests dropping the sump and fitting new thrust washers would be wise. Movement in millimetres is not ok as it indicates the washers have worn to the point that they have dropped out. The engine can still run quite sweetly like this but may make nasty noises when the clutch is depressed and clutch action may be odd.

Repair may be possible - it depends how long the engine has been run like that - but you are taking a risk so it should be cheap!

Happy hunting!

Nick

|

| |

1967 Triumph Vitesse convertible (old friend)

1996 Audi A6 2.5 TDI Avant (still durability testing)

1972 GT6 Mk3 (Restored after loong rest & getting the hang of being a car again)

|

|

|

|

|

|

|

Just to add, when inspecting a used Triumph engine (running condition or not), it is important to check the the crankshaft endfloat as it is not unknown for them to drop thrust washers, causing damage to crank and block. Grab hold of the flywheel or front pulley and push/pull along the the crank axis. A small amount of "clonk" is acceptable - book figure is something like 0.006" - 0.010", but up to around double that is acceptable on a used engine, though much over 0.010" suggests dropping the sump and fitting new thrust washers would be wise. Movement in millimetres is not ok as it indicates the washers have worn to the point that they have dropped out. The engine can still run quite sweetly like this but may make nasty noises when the clutch is depressed and clutch action may be odd. Repair may be possible - it depends how long the engine has been run like that - but you are taking a risk so it should be cheap! Happy hunting! Nick All good info, thanks. Unfortunatley the words Norway and cheap are very rarely, if ever, heard in the same sentence. Price might well be a stumbling block here.  |

| |

|

|

|

|

|

May 30, 2019 19:13:35 GMT

|

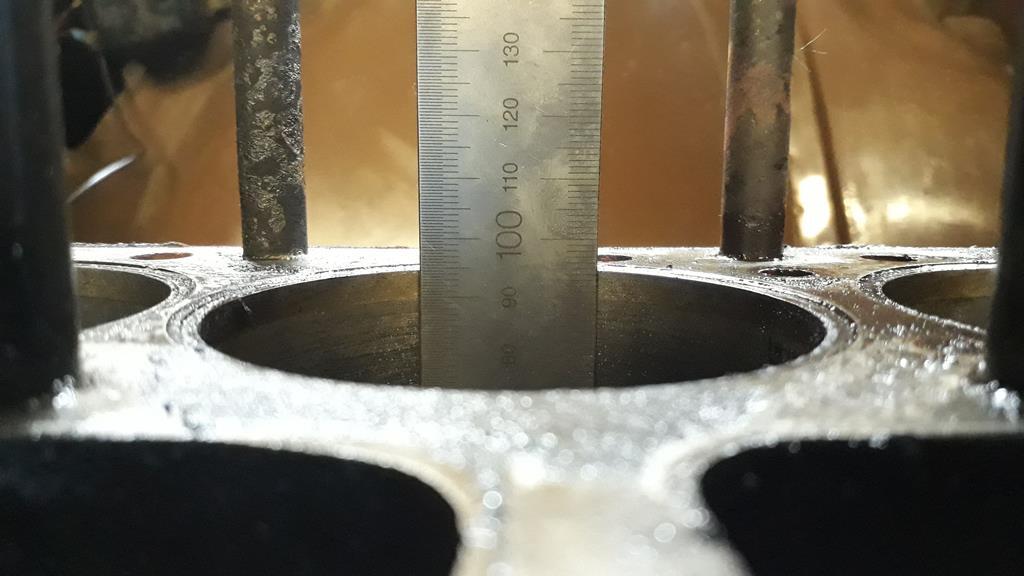

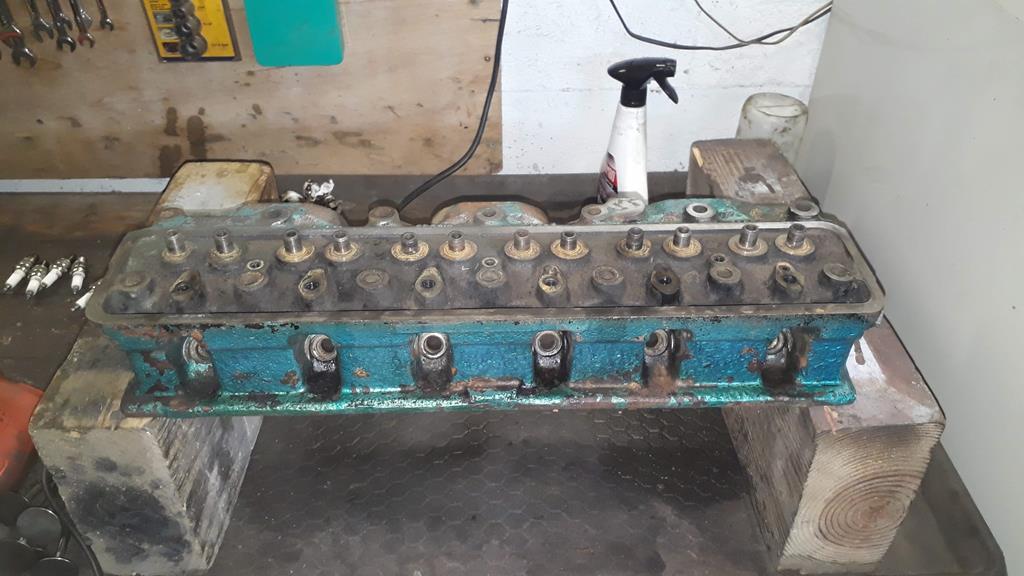

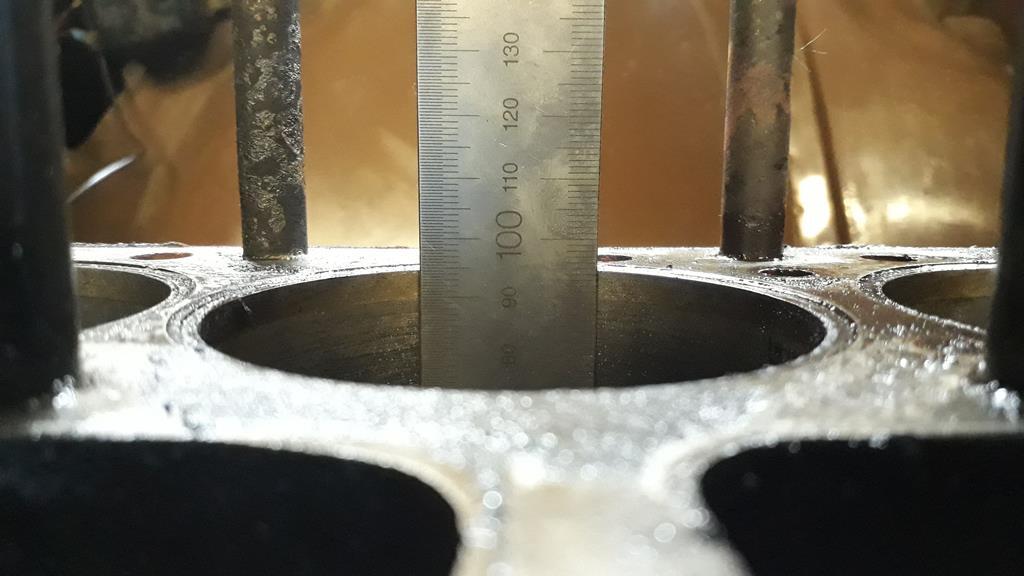

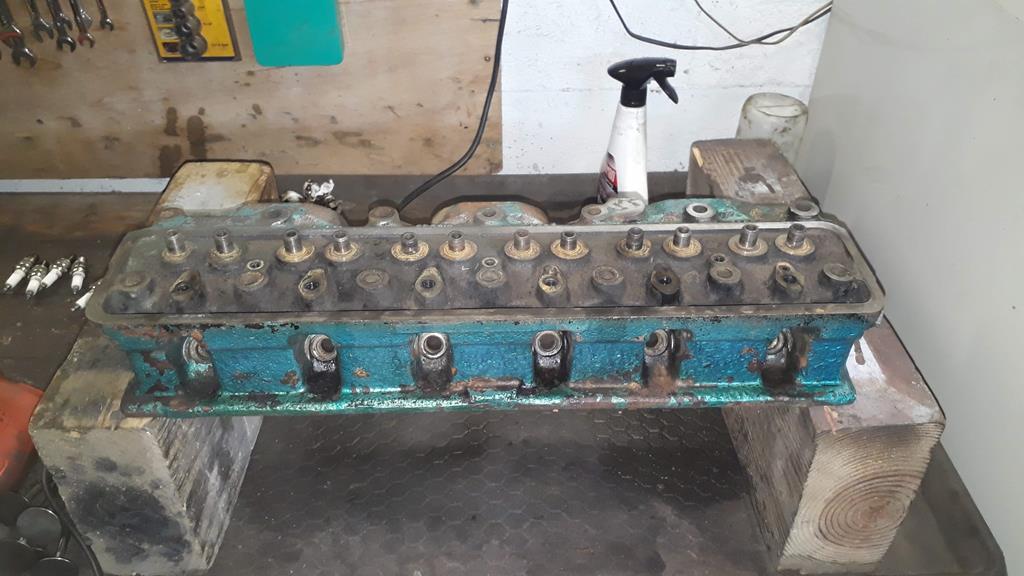

So i took a trip to the workshop today as it is a bank hoilday here in the land of brown cheese, and all I can say is: Never ASSUME… it makes an ASS out of U and ME.... Unless my eyes are decieving me, you were sooooooo right vitesseefi just look at this..  If I'm not mistaken that gives me 2498cc - well actually a tiny bit more since my pistons are +.030 but hey, happy days. The block is from a 2 litre, some sly fox has changed the crankshaft. I hate the person who built this engine a little bit less. U know ME, the ASS in assume. So what now? I have inspected cylinder 1 bore and astoundingly it appears undamaged, I'm happy to give it another go. I have a spare head that I thought wouldn't work with my block but now it should slap straight on ?   This is the thickness of the spare head...  This is the thickness of the previous head that went pop...  But this also begs the question what cam is in there? Maybe I should whip the cam out too while I have the head off? Just a matter of removing followers, the timing chain and cover? I also need to check the pushrod lengths too. It might also be prudent to consider sending the head off to a specialist to get it cleaned up, crack tested and skimmmed. I will initially be running SU HS4's but the goal is EFI so what would be the optimum head thickness to aim for? So work to do but things suddenly aren't looking so glum, I can avoid buying another unknown engine and save myself the hassle of getting the block out and then in again. Better the devil you know at this point I think. |

| |

Last Edit: May 30, 2019 20:55:27 GMT by omnipod

|

|

|

|

|

|

|

|

Hah! Thought the pistons looked a long way down......

219016 is the 2.5S head - considered the best by some (Chris Witor for one) as it has a different profile to inlet valve throat compared to any other Triumph head and flows well as standard. It has the smaller exhaust valve (to reduce the crack risk) and is bit thicker than most 2.5 heads giving a deeper combustion chamber and lower CR. These last two points are considered a problem by some, but my view is that the smaller valve doesn’t matter unless you are chasing big power and it’s easily skimmed if you want to up the CR.

The 2500s engine doesn’t look that great on paper - only 106bhp IIRC but good torque spread makes them deceptively quick and nice to drive. Also pretty good on fuel. They had HS6 carbs on the long manifold from the factory.

That head, perhaps with a skim to bring it to the standard height of the PI head and either the early PI 308778 cam or a Newman PH1 with injection and the TR6 manifold should get you into the 140s with great torque. My PI made 160lb/ft from 1800 to 5200 - went well!

Nick

|

| |

1967 Triumph Vitesse convertible (old friend)

1996 Audi A6 2.5 TDI Avant (still durability testing)

1972 GT6 Mk3 (Restored after loong rest & getting the hang of being a car again)

|

|

|

|

|

|

|

I really want this car back on the road and am not looking for power increases at the moment so I'm considering just cleaning up the head, lapping the valves, putting it all together and seeing what happens. I can get it skimmed in the winter if it needs it. I see the advantages of increasing the compression ratio a bit but I think that can wait. But... looking at the the tech info on Witor's site I see this for the 219016 head..... casting number 313248 Mine looks like casting number 313247 do you know if there are any differences from the 313248 casting vitesseefi ? Where to buy a decent head gasket? anywhere else besides Witor? |

| |

Last Edit: May 31, 2019 10:10:38 GMT by omnipod

|

|

|

|

|

May 31, 2019 12:28:43 GMT

|

|

Rimmer Bros in the UK should do Triumph stuff?

|

| |

|

|

|

|

|

May 31, 2019 12:31:48 GMT

|

Rimmer Bros in the UK should do Triumph stuff? They do, and their international shipping is second to none but are the ones they sell any good, some of thier stuff is cr@p |

| |

|

|

|

|

|

May 31, 2019 13:05:55 GMT

|

|

I was speaking to Chris Witor in person (his place is only 30 minutes away) a couple of weeks back and he told me that there is a problem with the current Payen gaskets for the recessed blocks (AK280 IIRC) where the fire-rings are not properly formed.

I think he said he has a solution but I wasn’t listening properly as all my 6s have flat blocks......

Putting the head on more or less as is should be an improvement on the miserable object that was on there.

Nick

|

| |

1967 Triumph Vitesse convertible (old friend)

1996 Audi A6 2.5 TDI Avant (still durability testing)

1972 GT6 Mk3 (Restored after loong rest & getting the hang of being a car again)

|

|

|

|

steveg

Posted a lot

Posts: 1,586

|

|

May 31, 2019 16:02:58 GMT

|

|

It's sort of a good thing you have had a problem as it least you know what engine you have in the car now ! My 2000 didn't go too badly in standard form even with a burnt valve. I made the mistake of buying a complete rebuilt head from Rimmers only to find all of the valve stems were cracked. It smoked worse than it did with the original head on it !

A friend had a PI so I went the 2.5 engine route. I got hold of a recently re-bored S engine and had the head rebuilt through one of Chris Witors contacts and fitted a better cam which he said would give similar performance to a PI without the injection setup.

You might find you are missing some power if the correct carbs and manifold and distributor haven't been fitted but sorting the head should improve things a lot. I fitted the S carbs and manifold but wasn't sure which distributor was best. The car felt faster with the S spec distributor fitted but was smoother with a PI spec one but fitted with a vacuum adavance.

I'm not sure now which diff I fitted. It had a 3.7 auto diff as the car was originally an auto but the biggest gain on going to the 2.5 is the torque. I think I had planned on fitting a 3.45 one but not sure if I did it now !

|

| |

|

|

|

|

|

|

|

It's sort of a good thing you have had a problem as it least you know what engine you have in the car now ! My 2000 didn't go too badly in standard form even with a burnt valve. I made the mistake of buying a complete rebuilt head from Rimmers only to find all of the valve stems were cracked. It smoked worse than it did with the original head on it ! A friend had a PI so I went the 2.5 engine route. I got hold of a recently re-bored S engine and had the head rebuilt through one of Chris Witors contacts and fitted a better cam which he said would give similar performance to a PI without the injection setup. You might find you are missing some power if the correct carbs and manifold and distributor haven't been fitted but sorting the head should improve things a lot. I fitted the S carbs and manifold but wasn't sure which distributor was best. The car felt faster with the S spec distributor fitted but was smoother with a PI spec one but fitted with a vacuum adavance. I'm not sure now which diff I fitted. It had a 3.7 auto diff as the car was originally an auto but the biggest gain on going to the 2.5 is the torque. I think I had planned on fitting a 3.45 one but not sure if I did it now ! Yes! I kind of agree, not knowing what capacity the engine actually was was in fact starting to prey on my mind a bit, it also means that I'll now 'have to' take the cam out to see what it is too, unless it's possible to see the number by just taking out the cam followers? This is exactly what I mean about Rimmers, you just never know what you are going to get. I have a few distributors but the plan is to go EFI with Speeduino so the timing and advance I should be able sort one way or another. Yeah, I need to check the diff too, I think i have it noted down somewhere. So next job is to clean up the spare head, it came with the car disassembled and without any note of which valves, pushrods or followers went where. I'll just have to make it up. Looking a bit down at heel but it should clean up OK, just a bit odd / worrying that the valve guides are pushed in to different depths.    |

| |

Last Edit: Jun 1, 2019 17:16:55 GMT by omnipod

|

|

Rob

Part of things

Posts: 252

|

|

|

|

|

get the head skimmed before fitting to bump the cr up, make sure you use the hs6s and correct manifold and try to get a tubular exhaust manifold. nows your chance to buoold a really nice big 6

|

| |

|

|

steveg

Posted a lot

Posts: 1,586

|

|

|

|

|

Just a thought about the valve guides, are they protruding into the port the same amount as the others ? Provided they don't cause problems with the valve spring/caps, the heights won't make a lot of difference.

|

| |

|

|

|

|

|

Jun 16, 2019 20:22:47 GMT

|

Yeah I did indeed check the valve guides more closely after I wrote my last post and none of the ones that are lower than the rest actually protrude throught the casting and into the port so we are good there. I ordered a head gasket and various other bit's and pieces from the UK a couple of weeks ago but they haven't arrived yet so I have been able to look at this spare head and fully dismantle the old one, the old one will now be used as my EFI throttle body mock up. So while relieving the old head of it's valves I found another oddity, quite a thick washer used as a valve pedestal. Now all the valves and stems look OK so I'm not really sure why this would have been like this unless it is just a plain and simple bodge.  Either way the more I look at this now scrap head the less i trust that the bottom end isn't hiding some nasty or other too. The strip down also showed that the old head had double valve springs while the spare head has single, I still don't know what cam is in the engine but I'm guessing it will make minimal difference whether I reuse the single or double springs for a normal road car? Obviously the green Hammerite paint job had to go too, so I degreased and wirebrushed the unmachined surfaces, masked it up and gave it some paint, looks a bit purpley here but it is black.  Still got to clean up the top of the block, clean up the rocker gear, making sure the oilways are clear and lapp in the valves, so work to do yet. I did consider getting the head skimmed but unfortunately with the 'local' engine shops being a four hour round trip either East or West from here and both having backlogs of work meaning they couldn't get to mine immediately then I have decided to just use the top unskimmed for now just to get the car back on the road. I only have HS4s and getting hold of a set of HS6s with the correct manifold over here would be a miracle, I could import some but cost is also a factor here as I am planning on EFI eventually and I already have a set of PI manifolds for this purpose. I do have a GT6 twin down pipe manifold though. Have to sse how much time I'll get to work on with this during the week. |

| |

Last Edit: Jun 16, 2019 20:27:19 GMT by omnipod

|

|

|

|

|

Jun 16, 2019 21:28:47 GMT

|

|

When I fitted double valve springs to my old Autograss car (Astra GTE 16v the springs needed to be shimmed until there was a certain clearance between spring coils. They needed 3mm shims so I used washers under them like this. But all of them not just one. Perhaps for some reason one spring platform has been machined so shimmed back up with whatever was to hand to make sure the spring was tensioned?

|

| |

|

|

steveg

Posted a lot

Posts: 1,586

|

|

Jun 16, 2019 22:06:59 GMT

|

|

If it wasn't the spring seat as mentioned above has that valve seat been re-cut or a different length valve been fitted ? Looks better with a fresh coat of paint though.

|

| |

|

|

|

|

|

Jun 16, 2019 23:10:39 GMT

|

|

I'd be very much inclined to use the double valve springs to reduce the risk of valve bouncing at high revs.

|

| |

|

|

|

|

|

|

|

I'd be very much inclined to use the double valve springs to reduce the risk of valve bouncing at high revs. Looking on Chris Witors site I see he has written the following about the single valve spring sets: "We find these springs overkill for their application, and for greater valve train durability recommend CW2906" CW2906 being the doulbe spring sets. So looks like I'll be using those. None the wiser about the washer that has been used though, all the valves and valve seat are identical apart from the knackered ones in the first cylinder obviously, but this washer was on cylinder 5. Doesn't really matter much in the big scheme of things, I'll just build up the spare head with standard parts.  |

| |

Last Edit: Jun 17, 2019 8:55:07 GMT by omnipod

|

|

|

|

|

|

|

|

Have you measured the free length of all the springs?

could it be someone has used this a bodge for a relaxed spring?

|

| |

|

|

|

|