|

|

|

|

|

|

Hi, excellent. A good touch with lining the all screw head slots the same way, a common proper coachbuilding practice. Did you choose slot head screws on purpose instead of cross head? Or is it still common practice to use slot head on boats? It must make the use of power screwdrivers a delicate art.

Colin

|

| |

|

|

|

|

|

|

|

|

|

|

Great update, good to see the progress!

|

| |

Ich habe kein Geld!

|

|

|

|

|

|

|

|

Loads of progress, are you living on board while you work on it?

|

| |

|

|

Frankenhealey

Club Retro Rides Member

And I looked, and behold, a pale horse! And its rider's name was Death

Posts: 3,888

Club RR Member Number: 15

|

|

|

|

|

Good to see an update. Trouble is now we've go to wait for the next. I love this thread.

|

| |

Tales of the Volcano Lair hereFrankenBug - Vulcan Power hereThe Frankenhealey here |

|

dikkehemaworst

Club Retro Rides Member

Posts: 1,640

Club RR Member Number: 16

|

|

|

|

|

Its like reading chinese , havent got s clue wat it's on about, .but I'm loving it! And it has an engine , so its bookmarked. Lovely job , great skills

|

| |

|

|

Smiler

Posted a lot

I no longer own anything FWD! Or with less than 6 cylinders, or 2.5ltrs! :)

I no longer own anything FWD! Or with less than 6 cylinders, or 2.5ltrs! :)

Posts: 2,492

|

|

Aug 10, 2015 10:22:11 GMT

|

|

Hooray! Updates! Fantastic reading as ever. Really does put my 'projects' to shame.

|

| |

www.Auto-tat.co.uk'96 Range Rover P38 DSE (daily driver) '71 Reliant Scimitar SE5 GTE 3.0ltr Jag V6 Conversion '79 Reliant Scimitar SE6A 3.0ltr 24valve Omega Conversion '85 Escort Cabrio 2.0 Zetec - Sold '91 BMW 525i - Sold '82 Cortina 2.9i Ghia Cosworth - Sold '72 VW Campervan - Sold '65 LandRover 88" - Sold

|

|

|

|

|

Aug 10, 2015 13:25:45 GMT

|

I've just sat and read through the lot - flip me you've done some absolutely cracking work on her. I'd go round the twist trying to work out all the different angles needed where each different piece of wood intersects with another; I have enough trouble just cutting a straight line through a piece of 2" x 1" Total and utter legend. I also now have an urge for a feck off great spotlight - not that I have a use for one at all!  Steve |

| |

|

|

|

|

|

|

|

Loads of progress, are you living on board while you work on it? I think It's been continually occupied since it was first bought! Even when the facilitys were bit "basic" ...! Cheers for all the comments. |

| |

|

|

|

|

|

|

|

|

Wow, great work! I know nothing about boats so it's really interesting to see the techniques you're using.

|

| |

|

|

bazzateer

Posted a lot

Imping along sans Vogue

Imping along sans Vogue

Posts: 3,653

|

|

Aug 15, 2015 14:00:07 GMT

|

|

Love this!

|

| |

1968 Singer Chamois Sport

1972 Sunbeam Imp Sport

1976 Datsun 260Z 2+2

1998 Peugeot Boxer Pilote motorhome

2003 Rover 75 1.8 Club SE (daily)

2006 MG ZT 190+ (another daily)

2007 BMW 530d Touring M Sport (tow car)

|

|

|

|

|

|

|

Aug 18, 2015 20:30:05 GMT

|

|

Super update thanks. You have great skills.

|

| |

14 Audi A3 Sportback - Easy driver

05 Audi TT MK1 3.2 DSG - Damn quick

73 Triumph 2000 - Needs work

03 Range Rover 4.4 V8 petrol. Had to get it out of my system.

|

|

qwerty

Club Retro Rides Member

Posts: 2,422

Club RR Member Number: 52

|

|

Aug 20, 2015 12:12:11 GMT

|

Wow, great work! I know nothing about boats so it's really interesting to see the techniques you're using. My thoughts exactly. Really enjoy this thread despite not having a scooby doo about boats. |

| |

|

|

|

|

|

|

|

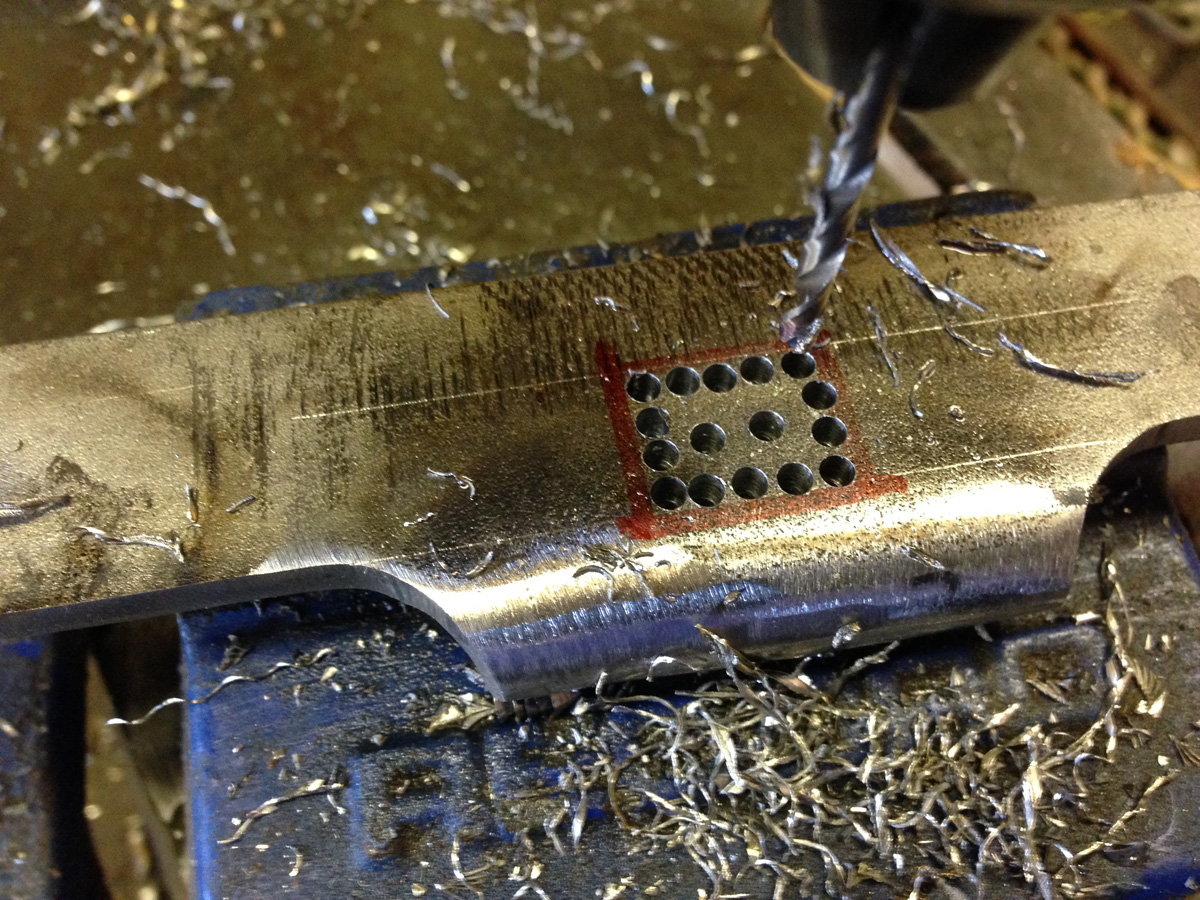

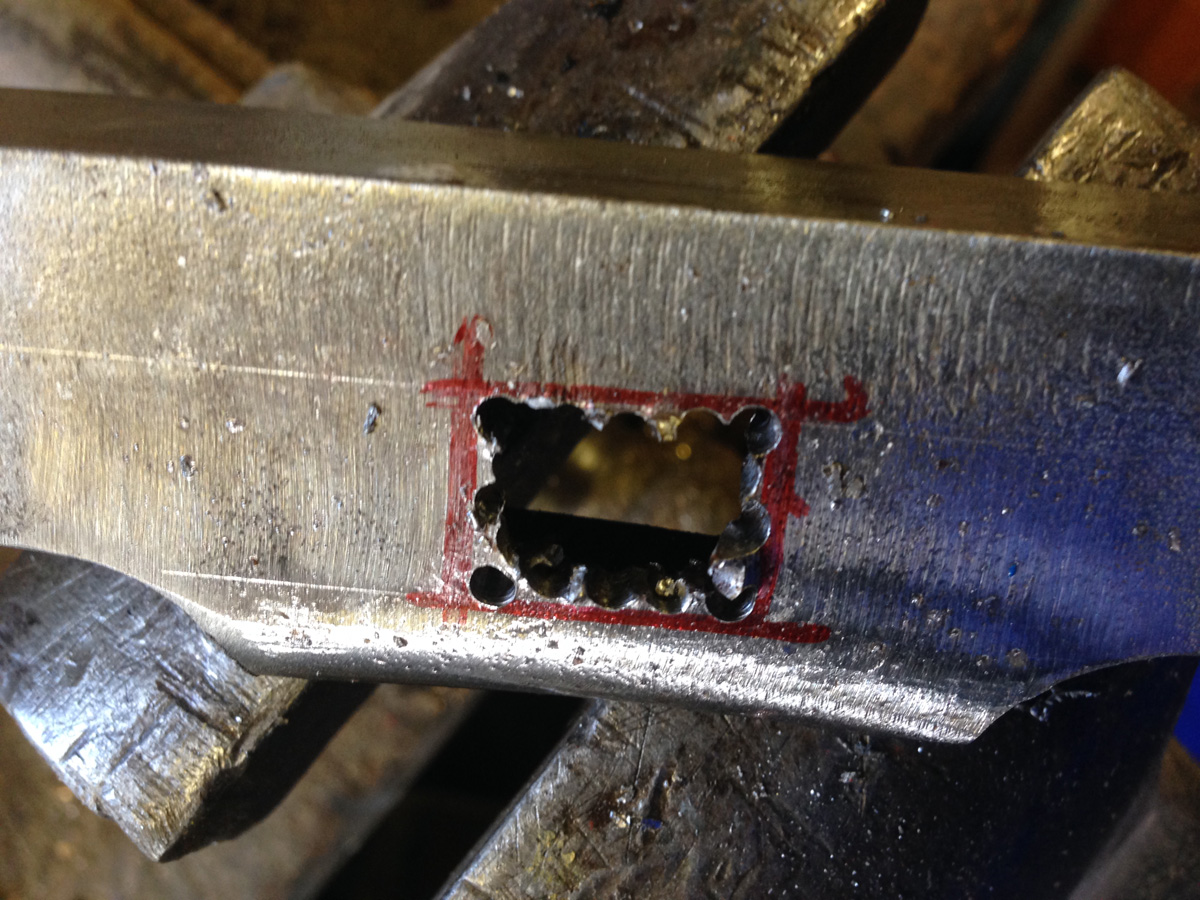

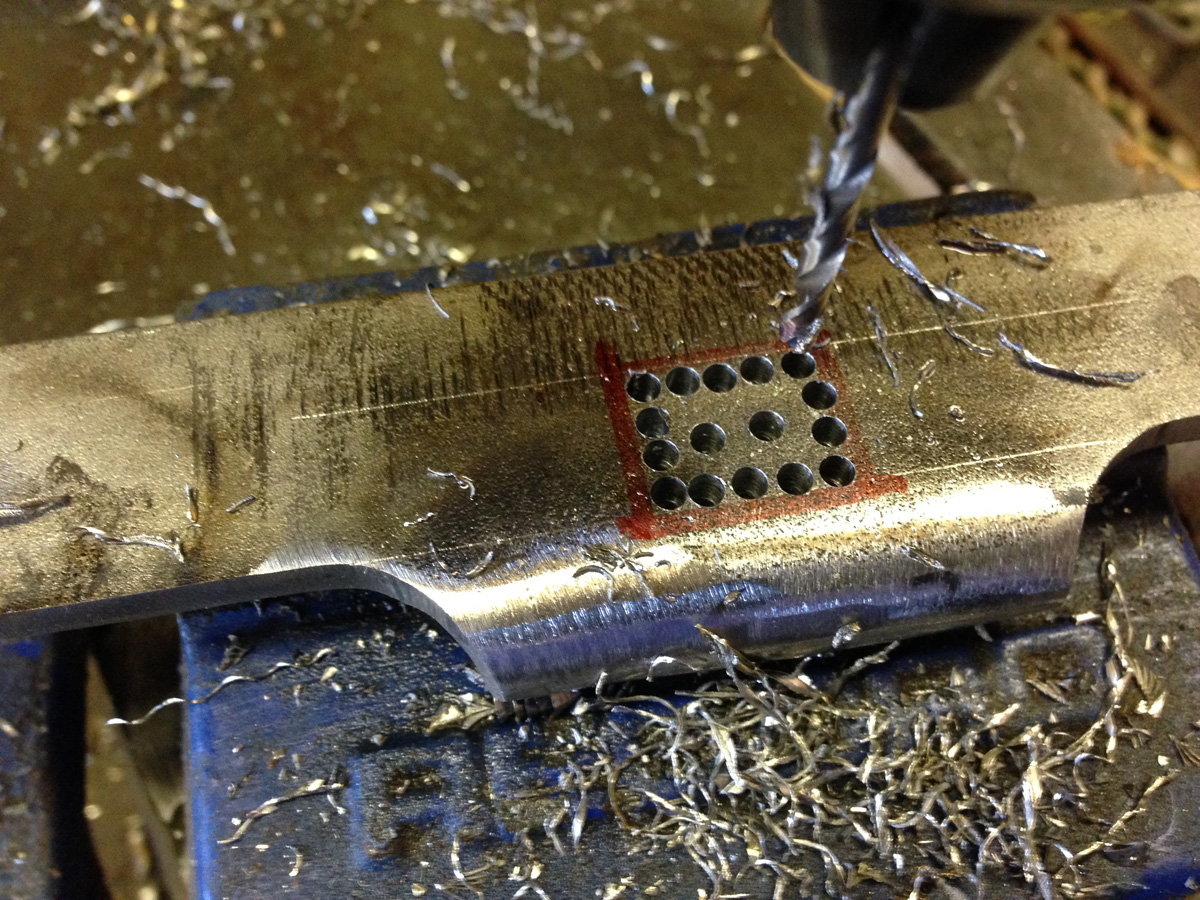

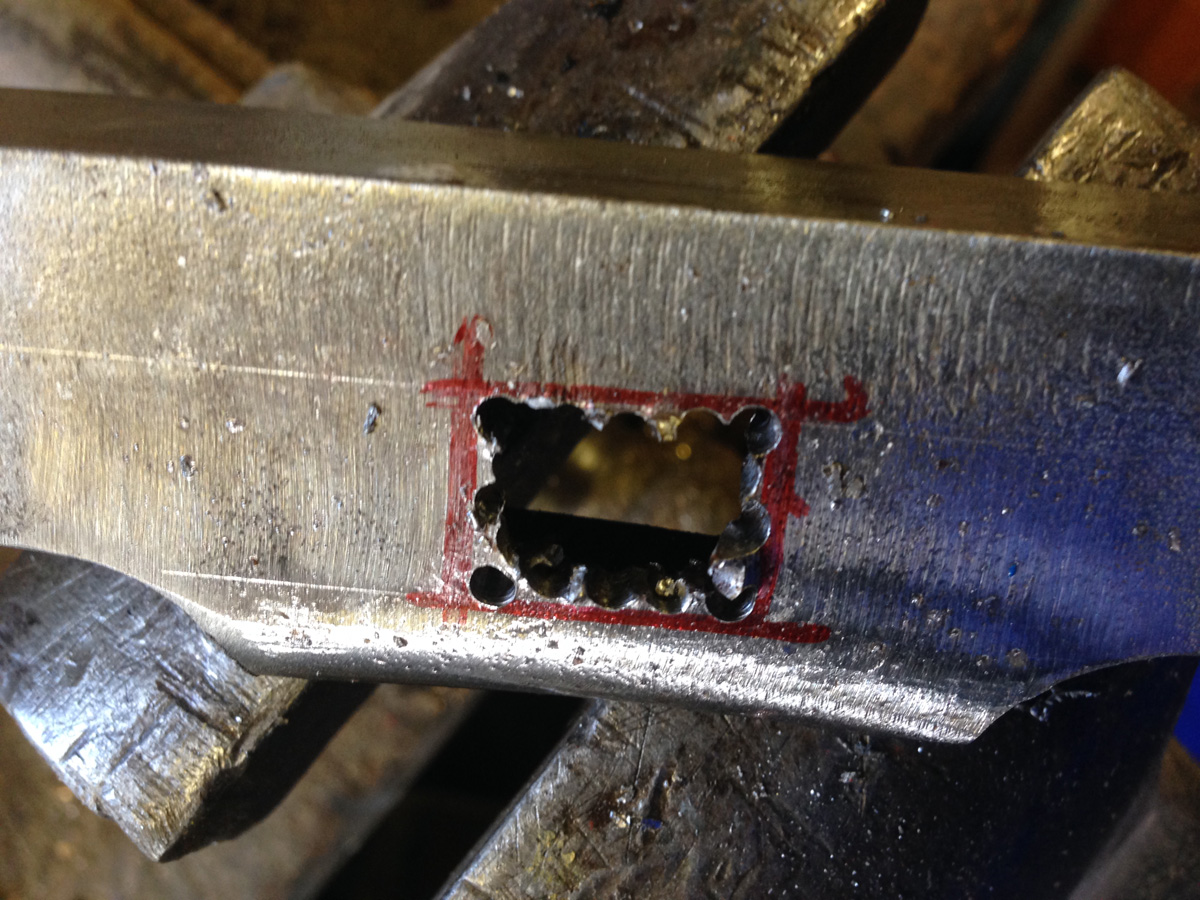

Bit of an overdue update this one so i'll split it into a couple of posts... This shows progress on making some of the replacement fittings to go on the new aluminium hatches - I'm going to re-use the old hinges but the rest will be made out of stainless steel. These are the brackets that hold the hatches open by clipping to the retaining stunchions shown in earlier posts Original steel bracket at bottom and the first two stages of making the stainless replacements:  Marked and drilled:  Cut using a .8mm ultra thin disc on the angle grinder:  Ground to shape with the grinder:  Clamped against a piece of alloy as a former ready for heating with oxy acetylene:  After heating and hammering to shape:  Cleaned up with a flap disc and marked out for the retaining pin hole:  Chain drilling using a 3mm drillbit:  Breaking out the unwanted bits with a cold chisel:  Ready to tediously hand file to shape - theres five of these in total:  These have since been finished and are ready to fit to the hatches - it might not look a lot but theres actually three days work and £60 of stainless in these five brackets! Cheers Dave |

| |

|

|

|

|

|

|

|

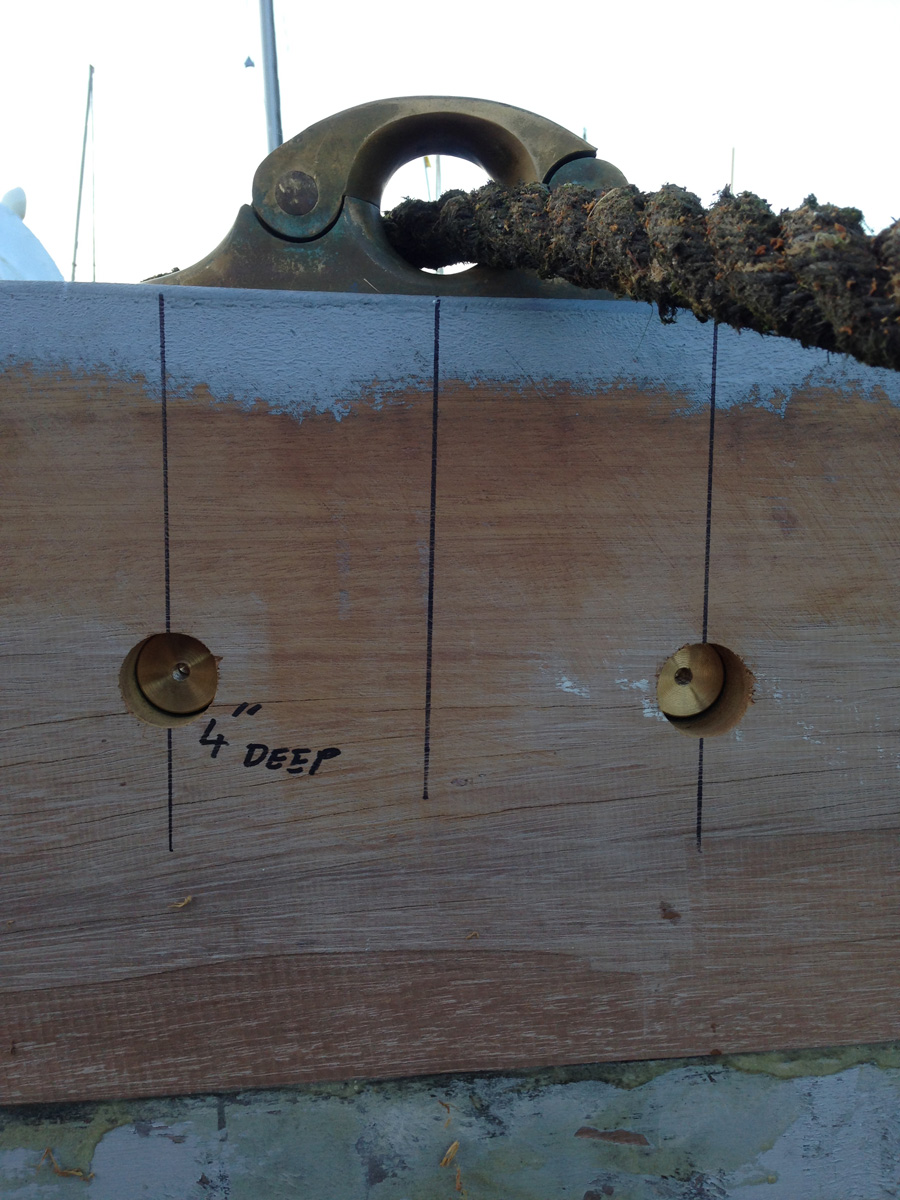

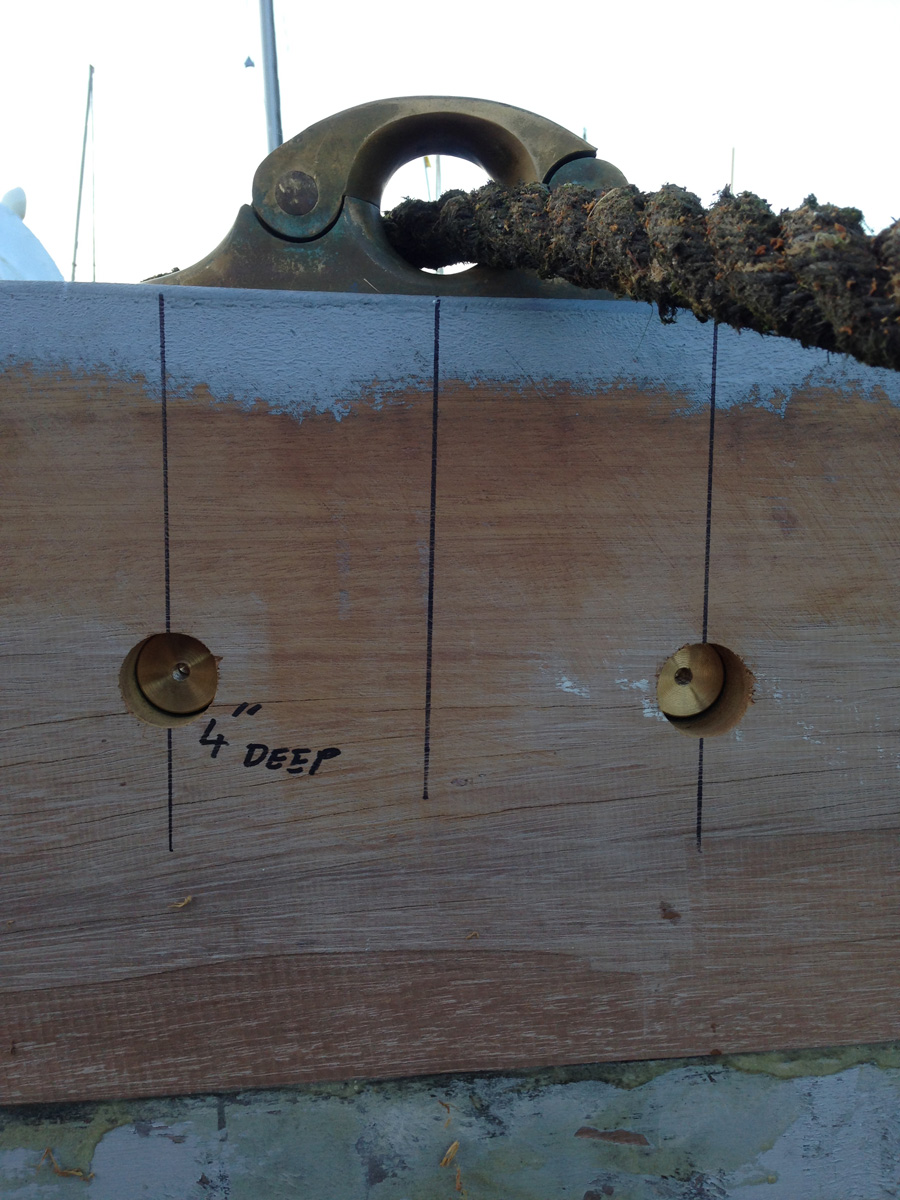

This updates a bit poorly represented photographically - inevitably when I'm in the middle of doing something i forget to take pictures so you end up with a series of before and afters! I completed the top of the transom a while back and am finally in a position to fit the fairleads I bought to go on top of it about 5 years ago, the originals were fabricated steel and got binned as they were beyond redemption and not very nice to begin with. This pair of bronze ones came from Beaulieu boat jumble for £100 the pair i think. Because they're mounted on the top of the transom fastening them down is a bit interesting - screws wouldnt really be man enough so i've used barrel bolts/gallery bolts which should hopefully be explained by the photos - this is the first time ive ever used these and getting the two drillings to line up is quite a task! Barrel Bolt made on my old myford out of scrap bronze prop shaft:  Showing the bolts fitted to a fairlead:  These are Lifeboat fairleads and are pretty unique in the way they open and lockshut:  Fitted - in the end i used large admiralty brass screws in place of the center bolt as it seemed overkill to use three bolts when two would do. the two gallerys you can see the barrel nuts in are blind holes so don't go right through the transom and have since been plugged with wooden dowels so are now invisible:  Overview, Note the covering boards around the edge of the cockpit are now finished and painted:  My dinghy has also had a bit of overdue TLC - it mostly gets used as a work platform and has been out of the water for a year or two after getting various holes in it culminating on it sinking and getting crushed between my boat and the 50ft ex PLA launch i'm alongside. I've done a ridiculous amount of fibreglass repairs and replaced the missing wooden seat with a replica made out of teak from my old cockpit floor - I just need to sort out some toe straps and rudder hangings and I might actually get the rig for it out one weekend and sail it again! :  Cheers for reading, Dave |

| |

|

|

|

|

|

|

|

Hi, excellent. A good touch with lining the all screw head slots the same way, a common proper coachbuilding practice. Did you choose slot head screws on purpose instead of cross head? Or is it still common practice to use slot head on boats? It must make the use of power screwdrivers a delicate art. Colin I bought a few boxes of old stock nettlefolds chrome brass screws from my local hardware store about 5 years ago when they were having a clear-out, with the intention of using them for interior joinery. In the end i had to buy a couple of hundred more old stock ones off ebay (in packs of ten!) to finish of those slats as i couldn't get modern ones that matched. modern brass screws are rubbish compared to old stuff as well, really soft and more of a platinum colour - less copper i guess. Screwheads are one of those things i'm a bit OCD about - if they're on show i like to line them up, don't really use power drivers on the boat as its all hardwood and easier to feel if your going to snap the screw/split the wood with a hand screwdriver. I also like to fit nuts on bolts with the letters/numbers facing outwards and with the rounded face of stamped washers facing outwards even if you cant see them  |

| |

|

|

|

|

|

|

|

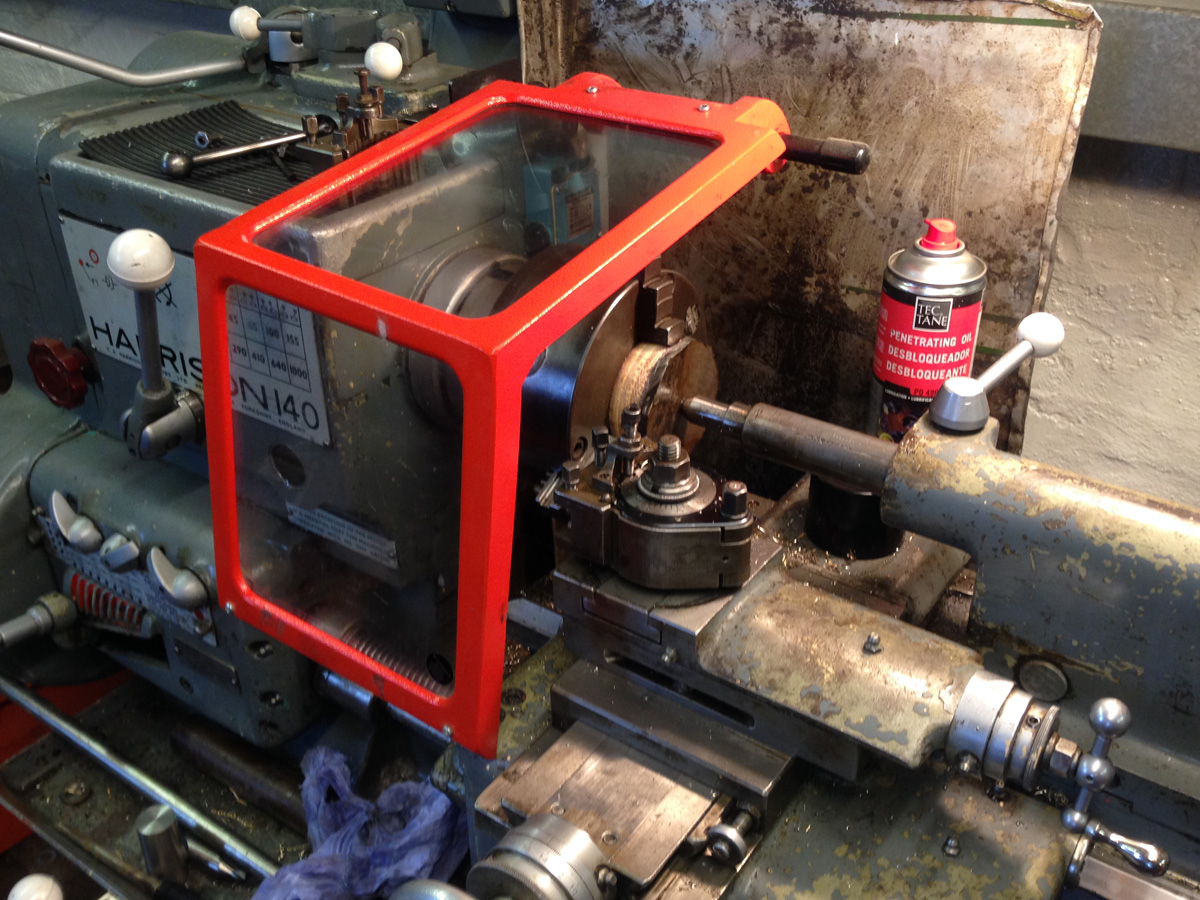

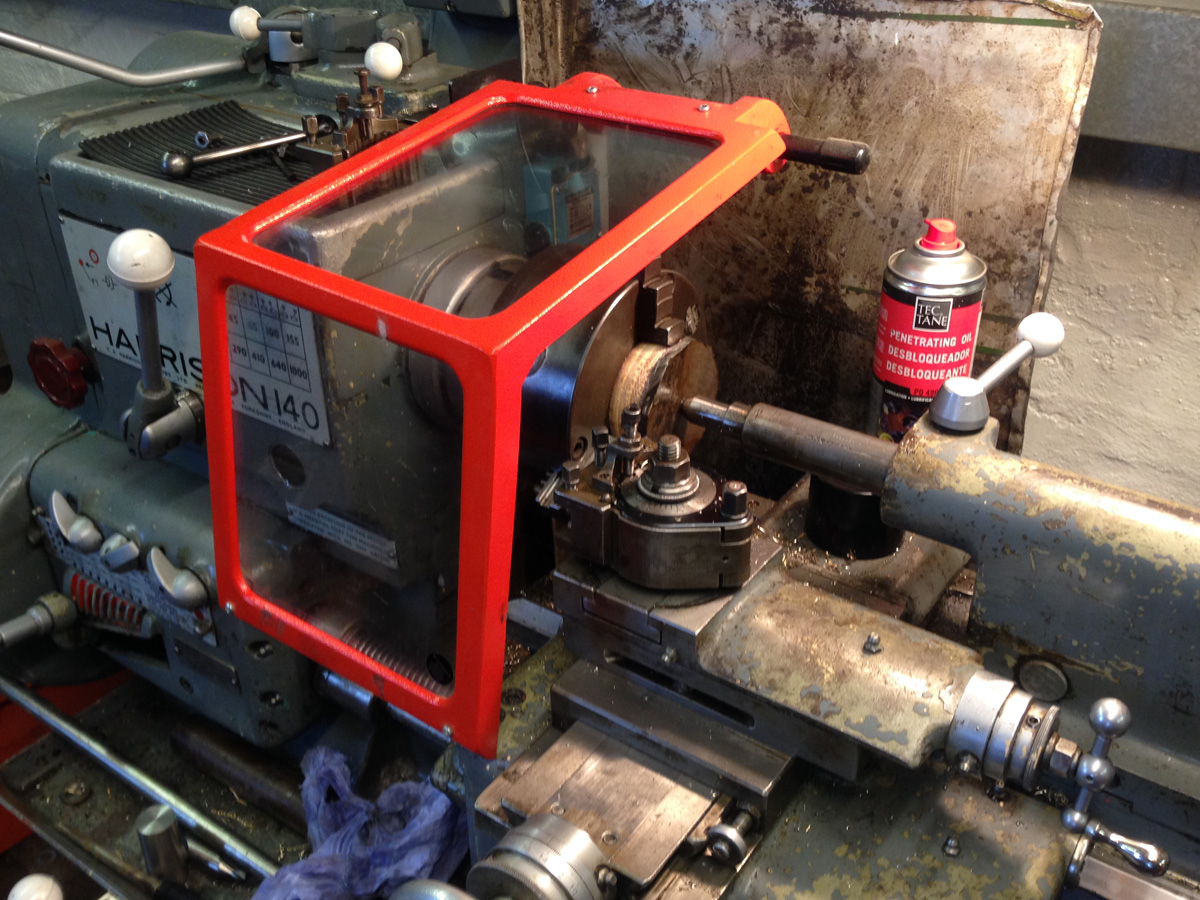

As part of my new aluminium hatch project I'm remaking the handles in stainless steel - The main part of the handle was too large a diameter to turn in my myford late so they're with an ex shipyard machinist who has done various bits for me in the past. I needed to make 5 discs out of 8mm plate for the flange that the handle passes through (see earlier posts for a photo showing the full assembly) I'd hoped to cut these discs on the piller drill but stainless being stainless it didnt work out and just mullered the holesaw i was using. I had a go turning one on the myford but couldnt work out how to hold the metal and attempts to grip it using a bolt through the middle werent a sucess. I recently bought a larger lathe and have taken to watching youtube videos of other latheists machining things (I know, I need to get a girlfriend) on one of my youtube sessions I came across a video which gave me an idea of how to cut the discs. Original flange and a completed stainless replacement:  Stainless blanks cut out using .8mm ultra thin grinding discs (I love these things they're even better and more lethal than the 1mm zippy discs used for cutting stainless etc)  1" thick plywood disc the diameter of the finished flanges and a pot of high temp contact adhesive:  Ply disc in the lathe chuck with the face coated in glue:  Stainless blank glued to the ply disc and held against it and centred by the tailstock (a live center would have been better but i don't have one yet)  Turning:  Finished item removed from the chuck ready to chisel off the ply disc:  Stack of 5 finished flanges, now awaiting boring the centres and tig welding a tube through the middle:  Thanks for reading/commenting Dave |

| |

|

|

Smiler

Posted a lot

I no longer own anything FWD! Or with less than 6 cylinders, or 2.5ltrs! :)

I no longer own anything FWD! Or with less than 6 cylinders, or 2.5ltrs! :)

Posts: 2,492

|

|

|

|

|

Epic as always, thank you for taking the time to share.

|

| |

www.Auto-tat.co.uk'96 Range Rover P38 DSE (daily driver) '71 Reliant Scimitar SE5 GTE 3.0ltr Jag V6 Conversion '79 Reliant Scimitar SE6A 3.0ltr 24valve Omega Conversion '85 Escort Cabrio 2.0 Zetec - Sold '91 BMW 525i - Sold '82 Cortina 2.9i Ghia Cosworth - Sold '72 VW Campervan - Sold '65 LandRover 88" - Sold

|

|

melle

South West

It'll come out in the wash.

Posts: 2,013

|

|

|

|

[...] one of those things i'm a bit OCD about [...] That's not OCD, just good engineering practice! |

| |

www.saabv4.com'70 Saab 96 V4 "The Devil's Own V4" '77 Saab 95 V4 van conversion project '88 Saab 900i 8V

|

|

|

|

|

|

|

|

Brilliant update, thanks.

The work going into this is staggering.

|

| |

|

|

|

|

|

Oct 10, 2015 14:34:59 GMT

|

|

Just read the whole thread - Amazing work!

Thanks for sharing and looking forward to seeing more progress.

|

| |

|

|

|

|