Today was a loooong day, planned that way so that mate Martin and I could get a lot of the bigger jobs that need a spare pair of hands all done and out the way.

Total,mileage for the day was 150 miles or 240km.

Woken at 05.00 by Harley the garage cat, squeaking to get out, and also for her breakfast, I then came back to bed, dozed till 05.45, surfed the web till 06.15, then got going. Out the house before 07.00 and met Martin at his local service station to fill our motorbikes.

With this whole bloody "refugee" thing at Calais, and the Euro-Tunnel, and Operation Stack, closing the M20 Coast bound, which was most of our route, we were reroute do on secondary roads, which turned out to be a much nicer road than racing down the motorway. We even stopped for a McD's Coffee on the way.

Got to Brenzett to the Mazda MX5 breakers where we had been offered a fan and blower unit for sensible money....... If we removed it ourselves. Martin and I have previously used him before and his stock and prices are always good.

So I was the tool boy, and Martin the brains and brawn today.

Spending about 30 minutes, mostly upside down.....

RESULT !!!

The owner was recently given a retired race horse, what an awesome animal, and he loves being with people, and of course as usual I had to get my hands on him.

Thanks to Ian's photoshopping skills.....

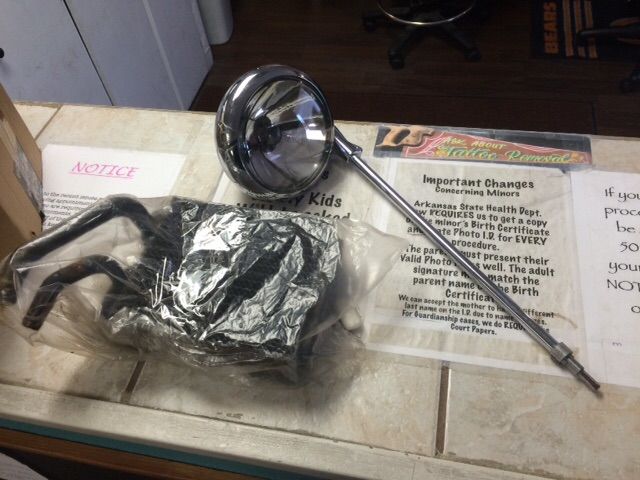

So the result of part one of our trip was this lot, next to the original Chevy blower unit. Smaller, but comes with a four speed blower, and also the controls which will be modified to suit my needs and taste. Again, "mates rates" meant all this for £10.00

With a bit of Dremmel action on the original metal case, and letting in the thermal switch unit, it should be better than new soon.

So from the Mazda breakers we shot a few miles down the road for Martin to investigate a sandblasting company.

In the same yard we also met up with and chatted to the owner of this beauty...... 98cubic inches of Triumph.

Note the Poppy on the side cover, this guy has his head screwed on right.

Once done there it was the trip back to Martin's place to move some stuff about, get his engine onto his engine stand, then get the engine hoist into the car and shoot over to my place for part three.

Of course, as is often the case, Martin got distracted, and we ended up sorting his bed sides out, as he had to choose the best set to work with, and also cut a section off one for Paul Y to fit to Woody, his truck.

As fate would have it, Martin's one dog possibly knocked the precariously placed motor off the trolley it was perched on, and it made a soft landing on the two original bed sides......... Martin almost burst into tears, seeing his bed sides destroyed.

So out came the air saw, and cutter discs........ Reducing even more of his original truck to scrap.

After this, we managed to mount his motor onto the engine stand, dismantle and carry the hoist through his house into the car and came over to my place, where Nicola had cooked us a MASSIVE PIZZA for lunch....... Hero girl.

After this we assembled the engine hoist, proceeded to remove all final bits keeping the engine attached to the frame, body etc.......

Some wires duly photographed, no idea why as its getting a completely new harness.

What is this part up against the bulkhead for?

Here is a shocker....... Grizz in Safety boots.

How long have we been waiting for this?

Leaving a gaping hole with engine perches back in place.

Engine mounts will be getting replaced, I suspect with high end poly items, rather than the standard rubber mounts.

All bump stops are getting replaced too.

Next was placing the engine and gearbox safely onto the pallet and pallet truck........all good with blocks of support.

]

I also agreed to buy his FelPro gaskets off Martin for £25.00 as my engine is a bit leaky.

Pushed the truck (well, what's left of it) out of the garage to push the engine and box into the rear of the garage........ Martin was driving, with me navigating. A disconnect resulted in the pallet truck stopping and the motor continuing its trip.

So we had to remove the already packed away engine crane from the Mondeo, reassemble it, lift the motor and get it all back together. Funny how you get better every time you repeat stiff.

So the next job will be to dismantle and clean up the front of the chassis, lift the cab to replace the cab mount rubbers, and paint the chassis.

A long day, but this was a great result, again I have to thank Martin for his help (yes, we both help each other, but I am happy to do public thanks) and also Nicola for sorting out our lunch, and letting me get on with the build, tomorrow is Bootfair, then home, shower etc and off to IKEA which is all she asked for in return.

Thanks for looking in and all your comments and support so far.