For the record, I considered a few ways of fixing this before "doing it properly". I use the phrase slightly tongue in cheek 'cos all the ideas would probably have been fine.

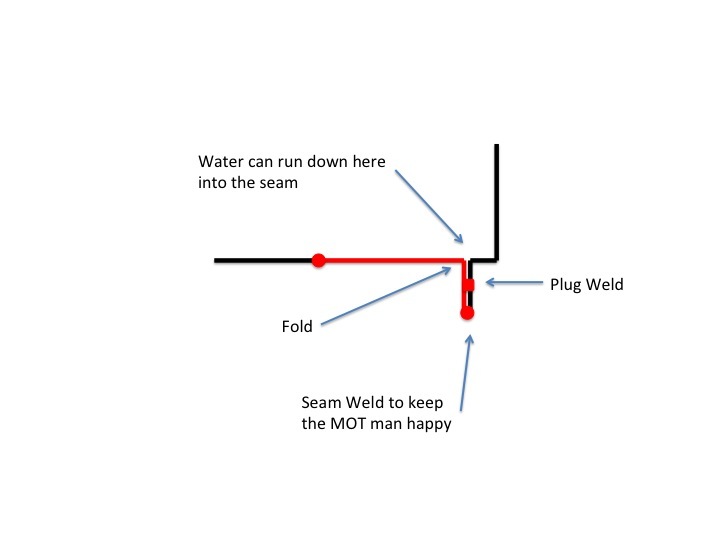

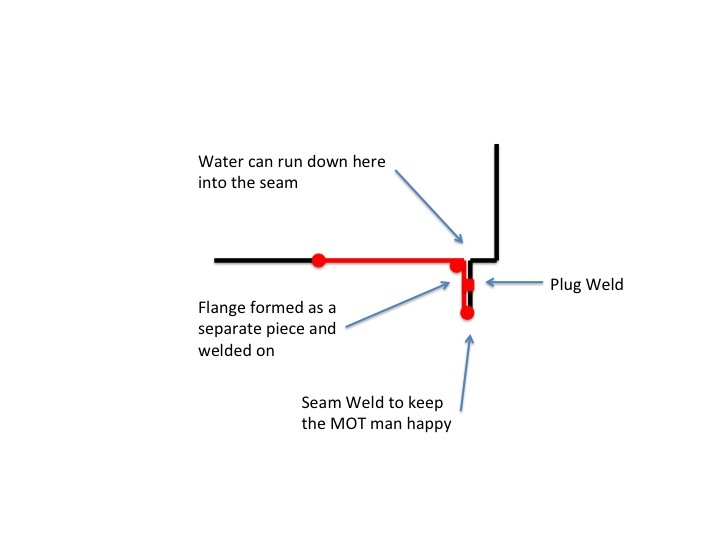

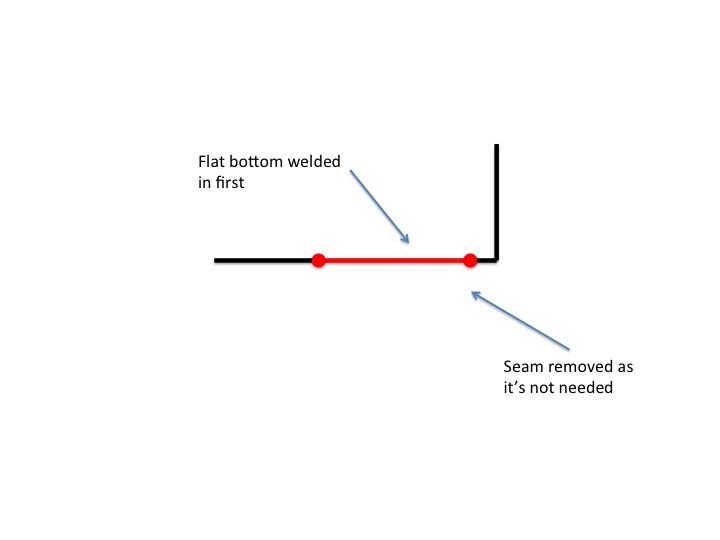

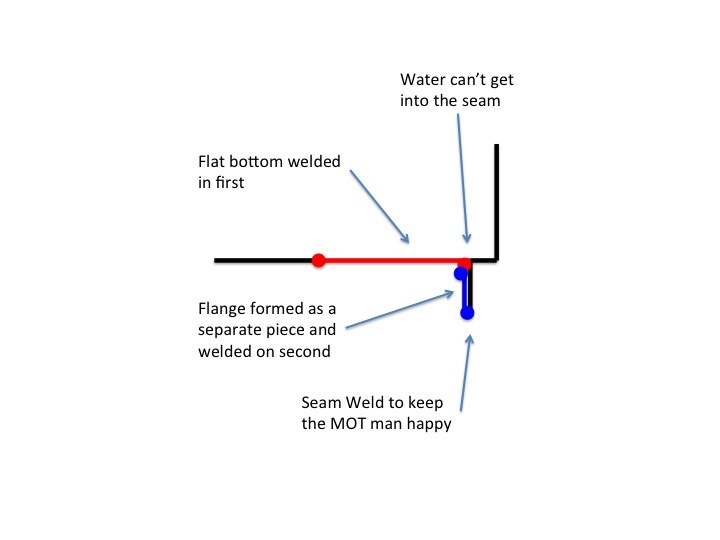

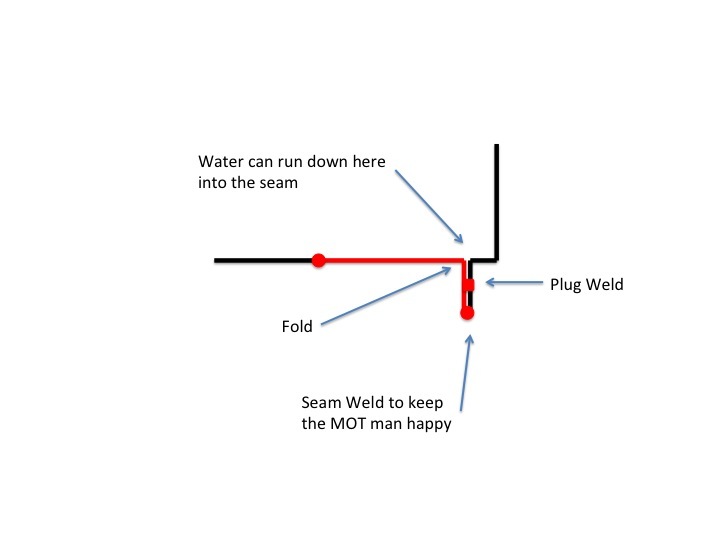

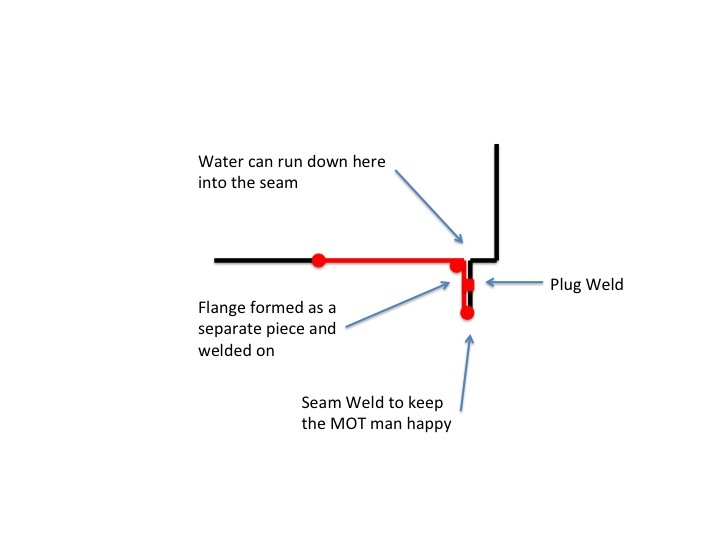

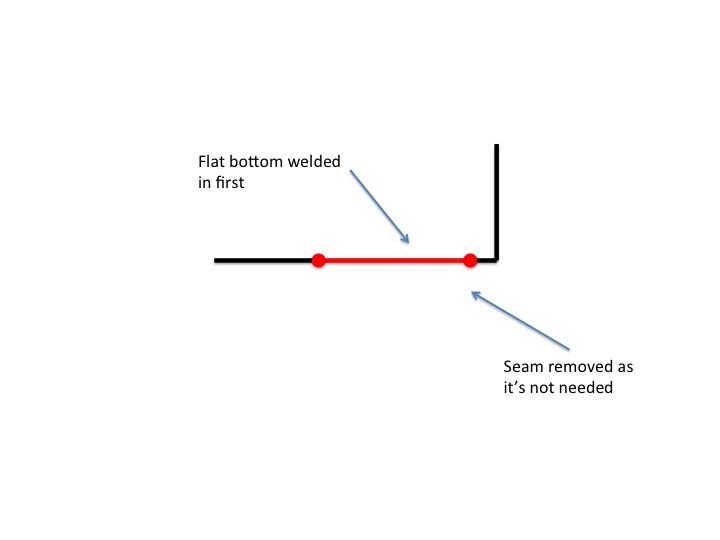

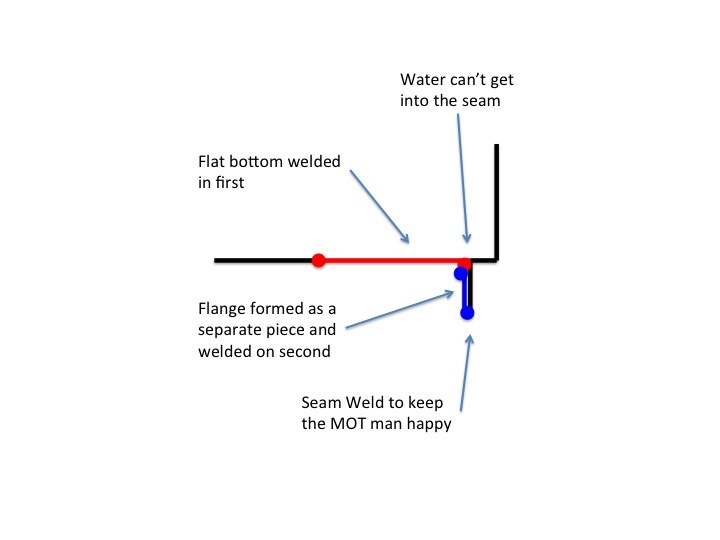

Have some sectional drawings...

What I did was this.

The black bits are the existing car, the red bits are my panel.

So I folded down the seam which is plug and seam welded to the car.

Equally reasonable would be to make the seam as a separate piece and weld it on before fitting the repair panel. Like this...

Both of these have one major problem. The seam still exists.

When the car was made it got dipped in a paint tank and so paint would have run into the seam. The repair can't have paint in the seam though. The paint contaminates the plug welds and the seam weld along the bottom. I can (and do) use weld through primer but that's just going to get burned off by the welding. So, no matter what I do I'm going to have unprotected metal down there.

My best bet is to fill it with cavity wax. Which I will do, just as soon as I buy some!

But what's the seam there for anyway? Surely it's just there so the Toyota spot welding robot could join the panels together? In which case I don't need it and could remove it.

Like this!

Now there is no seam to rust. Happy days.

But then I got to wondering how much strength is added by that fold. (Probably quite a lot.) And is that strength is actually needed? (No way of knowing.) Quite apart from which I wouldn't be surprised if the MOT chap objected.

So as much as I'd like to delete the seam I'm not sure I can.

So, if I was smart I'd have done this.

First weld in the red bits. That effectively closes in the top of the seam so water can't get trapped in it. Then add the flange in a separate pass (the blue bits). Now all the strength is there and water can't get in the seam.

The problem is that it means a lot more "Australian" welding and I don't know if I can actually do that yet.

I played it safe and put it back as Toyota designed it.

So, I hear you ask, how did all this tricky welding go?

Start with breakfast.

And then my new wardrobe.

Having read lots of stuff about people having hot sparky bits in their ears and down their shirt I figured this wasn't for me. If you wish to call me a 'big girls blouse' you go right ahead. I have no problem with that. I did know that I stood no chance of doing a decent weld upside down if I was scared so I bought some proper clothing. At least then if I made a balls of it I had only myself to blame.

What we have is a new pair of gloves, my old ones have holes in them. A welders leather shirt with velcro down the front to keep the evil hot bits out. And the red thing is a hood to stop things bouncing off the floor and into my ears.

Tidy!

It is, I think, a particularly sexy look and could be on the cat walks this autumn. Mrs sweetpea, on the other hand couldn't stop laughing and needed a few goes to get a sharp photo.

To work!

I had thrown some POR15 around inside the box while I had a big hole in it. Before welding I cleaned the edges and bottom of the hole but the inside is inaccessible with the powerfile so the paint was up to the edge. I was expecting this to contaminate the weld a bit and it did. So the first pass was ground back and a second pass bridged over the top to get a decent weld.

This is just after the second pass.

I did find that I needed to turn up the wire speed a fair bit to stop the wire melting and dripping back into the torch.

Next was to plug weld where the spot welds were and grind them back.

Lastly I needed to seam weld along the bottom to keep my MOT man happy.

Everything got ground off to tidy it up. Upside down welds don't sit down into the panel like they do if you are working top down so the welds are quite proud. (I assume this is normal.) While I didn't have to grind it back (it's not exactly on show) I felt the need to do it anyway. I want the car to look like it hasn't really been touched. Not to concours standards, I don't have the skill for that, but by taking the top off the welds they will hide behind the underseal.

By the way, you can see the drain hole in that photo.

And lastly some paint.

Right. What's next?

James