The Doctor

Club Retro Rides Member

Posts: 3,445

Club RR Member Number: 48

|

|

|

|

So yours will probably rev over 8000 as standard? Apparently the early aw11s had a rev limit of 8200, whilest the Celica aa63 where mine comes from has it at 7800. No idea why,as it's basically the same engine configuration. Sorry, I was going to reply to this and forgot... I hadn't heard that the Celica had a different rev limit to the MR2. Do you have the part number for your ECU? I'll see if it's the same as the one fitted to mine. There is a definite thing that the later (Red Top) 4A-GEs fitted to the post '87 MR2s weren't supposed to be as revvy as the earlier engines. That seems to be because Toyota retarded the ignition timing at high revs a little. Not sure why. There is a speculation that this was about the time unleaded fuel came into the UK so Toyota were a little more conservative with the ignition maps. I had a 16 valve 3S-FE in a '92 Carina for a while and you wouldn't have guessed it was 16 valve apart from the badging. It wasn't rev happy. James It should be 89661-14070, I found this number on the wonderful Toyodiy.com parts catalog database thingy, as I know I made a picture of the ecu for the number for future reference, but for the life can't find it!  I guess they changed the mapping a bit as the Celica is about 1250-1300 kg, and it still went quite well with the tiny 4age under the bonnet. I guess the 3sfe is quite lazy? My father has a 105 bhp 4afe carina and that goes quite well. |

| |

|

|

|

|

|

|

|

|

|

Oh my. I've had an epiphany... Over on the MR2 MK1 forum there was a discussion about 4A-GE ECUs a while back. We believe there were 3 versions fitted - all starting 89661... Blue Top - 17030 Early Red Top - 17070 Late Red Top - 17140 Now The Doctor says the Celica had a 14070 fitted. So, quite possibly, the Celica had different maps and a different rev limit. Maybe tuned for more torque for a heavier car? Anyway, that moment of clarity I just had in the shower... There were 3 ECU's for the MR2. Presumably another pile for the supercharged GZE and yet more for the US cars with mass airflow sensors. Maybe more for other markets with different fuel availabilities? And then all that again for the Celica. And again for the Corolla GTI? And then there is small port 4A-GE in all the models and markets. And again for 2 versions of the 20 valve... That's dozens if not over a hundred ECUs? And that's just the 4A-GE. Multiply that by all the other fuel injected engines Toyota made... Their ECU development program must have been utterly massive. How many engine dynos did they have testing all this? |

| |

|

|

|

|

|

|

|

Good Scrap, tristanh, Thanks for the idle valve suggestions. I knew somebody here would have ideas! I'll take a look but I fear that's a long term project. Thanks again! James

|

| |

|

|

The Doctor

Club Retro Rides Member

Posts: 3,445

Club RR Member Number: 48

|

|

|

|

And what about the FWD Celica GT that got the 4a-ge? Or the 4 door Carina AA63 GT-R etc. etc. I guess my ecu might indeed be tuned for lower down torque, so maybe the T-VIS is different too? I drove the Celica long time ago, it belonged to a mate years ago, i remember the T-VIS butterflies opened around the 4k -4k2 rpm mark. The pinout is the same, i believe, so they might be swapable. Might be fun to try it out sometimes  //edit: i love the toyodiy reverse search. All the number you gave, where only used in EU spec AW11's. No cross reference to any other Toyota what so ever. Same for the FWD Celica ecu. And of course all Japanese ECU's have the 180km/h restriction in them, so they're all different again. I know my friends 3S-GTE ran quicker on a Japanese ECU, untill the speedlimiter kicked in  |

| |

|

|

jimi

Club Retro Rides Member

Posts: 2,154

|

|

|

|

|

Worldwide there's a lot more than 3 ECU's for the MK1

UK

89661-17030 Small case Mk1a

89661-17070 Bigger case Crossover 1b

89661-17140 Case as 070 Later 1b

89661-17020- :01 :8412-8608 :COMPUTER, ENGINE CONTROL :AW11..MTM

89661-17021- :01 :8608-8708 :COMPUTER, ENGINE CONTROL :AW11..MTM

89661-17030 Nov 1984 to Aug 1986 UK MTM

89661-17050- :01 :8508-8608 :COMPUTER, ENGINE CONTROL :AW11..ATM

89661-17051- :01 :8608-8708 :COMPUTER, ENGINE CONTROL :AW11..ATM

89661-17070 Aug 1986 to Aug 1987 UK MTM

89661-17201- :01 :8708-8712 :COMPUTER, ENGINE CONTROL :AW11..GT..USA CALIFORNIA SPEC

89661-17130- :01 :8708-8803 :COMPUTER, ENGINE CONTROL :AW11..SPC..USA CALIFORNIA SPEC

89661-17140 Aug 1987 to Dec 1989 UK MTM

JDM

89661-17010- :01 :8406-8608 :COMPUTER, ENGINE CONTROL :AW11

89661-17090- :01 :8608-8702 :COMPUTER, ENGINE CONTROL :AW11..SPC

(SUBS) : :89661-17091- :01 : : :

89661-17060- :01 :8608-8709 :COMPUTER, ENGINE CONTROL :AW11..TWC

89661-17091- :01 :8702-8709 :COMPUTER, ENGINE CONTROL :AW11..SPC

(SUBS) : :89661-17180- :01 : : :

:

89661-17180- :01 :8709-8805 :COMPUTER, ENGINE CONTROL :AW11..SPC

(IRRG)

89661-17160- :01 :8709-8809 :COMPUTER, ENGINE CONTROL :AW11..TWC

(SUBS) : :89661-17161- :01 : : :

89661-17161- :01 :8809-8810 :COMPUTER, ENGINE CONTROL :AW11..TWC

(SUBS) :89661-17162- :01 : : :

89661-17161- :01 :8810-8904 :COMPUTER, ENGINE CONTROL :AW11..MTM..TWC

(SUBS) :89661-17162- :01 : : :

89661-17210- :01 :8810-8904 :COMPUTER, ENGINE CONTROL :AW11..ATM..TWC

SUBS) :89661-17211- :01 : : :

:

89661-17220- :01 :8805-8912 :COMPUTER, ENGINE CONTROL :AW11..ATM..SPC

:

89661-17230- :01 :8805-8912 :COMPUTER, ENGINE CONTROL :AW11..MTM..SPC

89661-17162- :01 :8904-8912 :COMPUTER, ENGINE CONTROL :AW11..MTM..TWC

89661-17211- :01 :8904-8912 :COMPUTER, ENGINE CONTROL :AW11..ATM..TWC

General

89661-17040- :01 :8411-8608 :COMPUTER, ENGINE CONTROL :AW11..GEN

89661-17080- :01 :8608-8708 :COMPUTER, ENGINE CONTROL :AW11..GEN

:

89661-17100- :01 :8608-8708 :COMPUTER, ENGINE CONTROL :AW11..FRG

89661-17190- :01 :8708-8803 :COMPUTER, ENGINE CONTROL :AW11..ARL

(SUBS) : :89661-17191- :01

89661-17140- :01 :8708-8912 :COMPUTER, ENGINE CONTROL :AW11..EUG

89661-17150- :01 :8708-8912 :COMPUTER, ENGINE CONTROL :AW11..GEN

89661-17170- :01 :8708-8912 :COMPUTER, ENGINE CONTROL :AW11..FRG

89661-17140- :01 :8803-8912 :COMPUTER, ENGINE CONTROL :AW11..RHD..GEN SINGAPORE SPEC

89661-17191- :01 :8803-8912 :COMPUTER, ENGINE CONTROL :AW11..ARL

Abbreviations

TWC = Twin cam (the NA)

SPC = Supercharged

ATM = Automatic Transmission

MTM = Manual Transmission

EUG = Europe General

ARL = Australia Spec

FRG += Federal Republic of Germany Spec

|

| |

Black is not a colour ! .... Its the absence of colour

|

|

|

|

|

|

|

Does the Singapore spec one allow for sudden acceleration and deceleration between traffic lights and a lane guidance system that ensures you always straddle a paint line?  |

| |

|

|

v8ian

Posted a lot

Posts: 3,828

|

|

|

|

|

So, just out of interest,what is the safe rev limit for Silvertop 16v, on itbs and Emerald ecu, I'm guessing 8k

|

| |

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

|

|

|

|

|

So, just out of interest,what is the safe rev limit for Silvertop 16v, on itbs and Emerald ecu, I'm guessing 8k Have you still got all the original fuel injection from your engine Ian? Maybe that idle valve that James needs is there?😊 |

| |

|

|

v8ian

Posted a lot

Posts: 3,828

|

|

|

|

So, just out of interest,what is the safe rev limit for Silvertop 16v, on itbs and Emerald ecu, I'm guessing 8k Have you still got all the original fuel injection from your engine Ian? Maybe that idle valve that James needs is there?😊 I'll have a look on my spare engine |

| |

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

|

|

|

|

|

Does the Singapore spec one allow for sudden acceleration and deceleration between traffic lights and a lane guidance system that ensures you always straddle a paint line?  If so, we got a similar version, only with a crawl function away from lights, like the very act of overcoming inertia is all too much. The rest of the map is the same.  |

| |

Last Edit: Jun 6, 2019 10:51:14 GMT by georgeb

|

|

|

|

|

|

|

This thread has just topped a million views. James And I reckon half of that is since you started with the click bait titles.  Now deny it! Actually, that's a fair old achievement. Just looking through my bookmarks and three or four top the quarter million mark, but nothing close to the million. Good going!  |

| |

|

|

|

|

|

|

|

|

I do recall a mate with a D reg that revved seemingly to the moon ! had a Longlife twin tailpipe system so it wasn't especially quiet and had the usual Japanese 2k rpm cold idle which soon dropped down to 1500.

felt bloody quick for someone that hadn't ever been in anything like it before.

|

| |

|

|

v8ian

Posted a lot

Posts: 3,828

|

|

|

|

|

I have had a look over my spare engine, sorry No idle Valve, BUT I do have a couple of 16v ECUs, what are you looking for?

|

| |

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

|

|

|

Jun 15, 2019 21:20:59 GMT

|

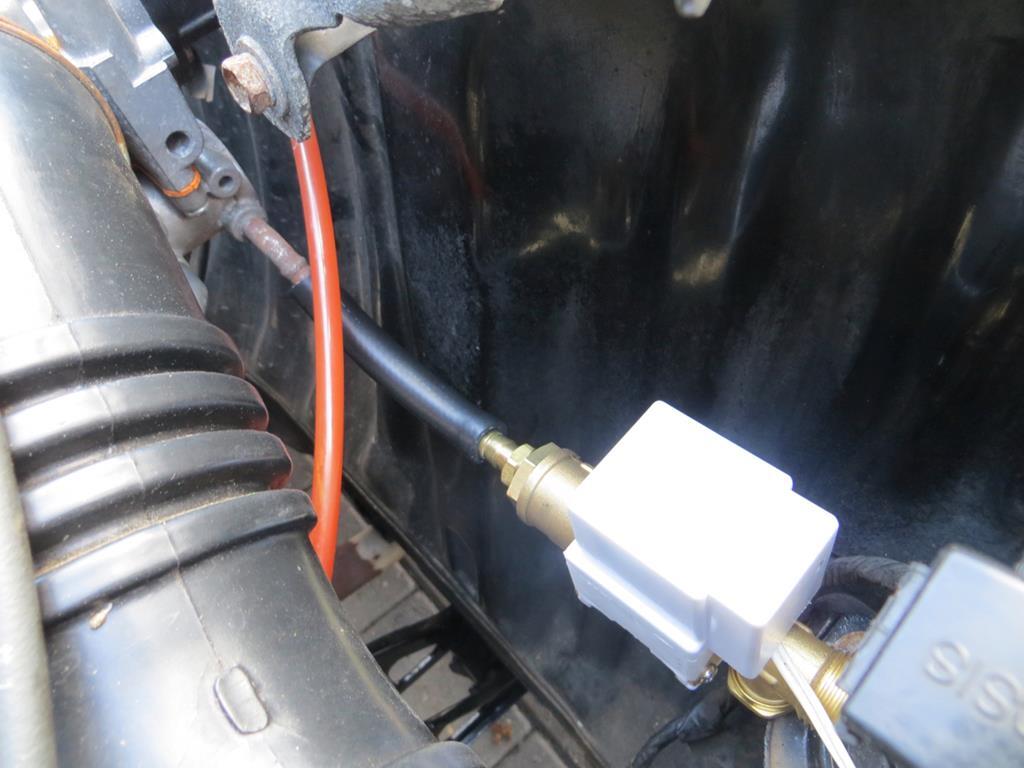

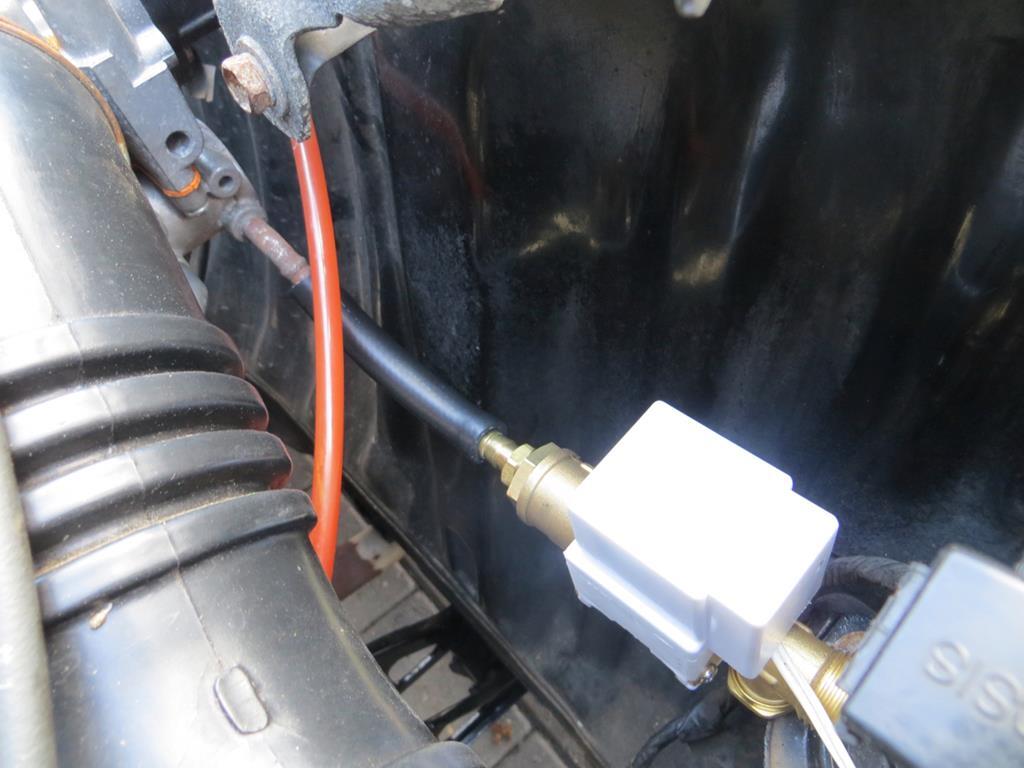

I have had a look over my spare engine, sorry No idle Valve, BUT I do have a couple of 16v ECUs, what are you looking for? Thanks v8ian , I could have used a waxstat but I suspect they are all trashed. The ECU is the one bit that does work! Anyway, all this talk had me wondering how they'd done the cold idle on the 20 valve with throttle bodies. As far as I can tell there was a valve bolted to one end of the bodies and a pipe that distributed air between them. So that was no help. Besides the parts are probably as rare as hens teeth in the UK. Anyway, just a brief update. First of all I’d managed to break the negative battery clamp while I was doing the big ends. I have no idea how. Well, I say that but, in truth, I do know how it got broken. I over tightened it. You see I’m of the school of thought where you tighten something until either the threads strip or it breaks. Then you back it off half a turn. That’s how it broke. I’ve been over tightening it.  So I fitted a nice new one. Pretty isn’t it. I also said I’d been ordering bits to make my own cold idle valve. Well here they are…   The white valve is the sort of thing you find on the back of a washing machine. Except it has a 12V coil rather than a mains one. Poor car very nearly got crushed and turned into washing machines. Now I’m going to make it look like one! The hose is actually fuel hose but it’s the right diameter and won’t collapse under the vacuum. The hose fittings are standard airline ones and there are some pipe fittings to fit them to the valve. And lastly is the little circuit board. It’s a temperature sensor with a relay on it. Hopefully it’ll be fastened to the cooling system somewhere to monitor engine coolant temp and turn the valve on and off. The box was to put it all in but it’s way too big. In order to get the width right it’s far too tall and deep. The biggest question is… Does it flow enough air to raise the idle significantly? There is a handy air inlet pipe in the bottom of the old wax stat. So I roughly connected the valve to it with a wire I could tag onto the battery.   Here’s a video… Remembering that the engine is quite warm at this point so the idle valve would be closed… It’s lifting it to about 2000 revs. When cold that’d probably be 200 or 300 revs lower? Anyway, by pure fluke it’s right in the ball park. Yippee. So I need to make some sort of bracket to so I can bolt it to something and I need to wire it to the temperature thingamajig. James |

| |

|

|

johnthesparky

Posted a lot

Posts: 3,517

Club RR Member Number: 6

Member is Online

|

|

Jun 15, 2019 21:28:40 GMT

|

|

It’s quite noisy though!

|

| |

|

|

|

|

|

Jun 15, 2019 21:38:52 GMT

|

Ah well, that's because the other end of the valve is open to the atmosphere so you hear it hissing. There is a pipe on the air cleaner that it needs connecting to. Then it'll shut up. |

| |

|

|

johnthesparky

Posted a lot

Posts: 3,517

Club RR Member Number: 6

Member is Online

|

|

Jun 15, 2019 21:45:12 GMT

|

Ah well, that's because the other end of the valve is open to the atmosphere so you hear it hissing. There is a pipe on the air cleaner that it needs connecting to. Then it'll shut up. That’s ok then  |

| |

|

|

jamesd1972

Club Retro Rides Member

Posts: 2,917  Club RR Member Number: 40

Member is Online

Club RR Member Number: 40

Member is Online

|

|

|

|

|

Sweet. Cold start check this morning ?

You just need to make it into a kit to sell to other MR2 owners now !

James (the younger)

|

| |

|

|

|

|

|

Jun 16, 2019 21:30:40 GMT

|

Sweet. Cold start check this morning ? You just need to make it into a kit to sell to other MR2 owners now ! James (the younger) Test footage coming up shortly. Making a kit.... Nah. For a lot of reasons. Firstly I've got better things to do with my time. And secondly, MR2 genius Paul Woods already makes one. His is a 'manual choke, switch on the dash' version. Apparently people don't wish to pay for the more complex timed or automatic versions. Now I could probably come up with something and even undercut him price wise (he's doing it commercially as part of his business - I wouldn't be) but I don't wish to do that. Paul is generous with his ideas (I think the initial concept of this was one of his) and it wouldn't do to pinch them! James (the marginally older) |

| |

|

|

|

|

|

Jun 16, 2019 21:40:05 GMT

|

I know this isn't much of an achievement but...  1000 posts! Yay! Heartily encouraged by yesterdays test I thought I’d start “the final solution”. Given the box is stupidly big I’m going to leave the valve in the engine bay on it’s own. It so happens that the one I got has a cover on it so I’ll run a small bead of silicone in the joint to seal it and hold it on. I’ll leave the cable entry open so any damp can dry out. We’ll see if this is a good idea… I need a bracket. Here’s one I made earlier…   It bolts onto one of the mounts for the air filter box. Sort of like this…   The hose looping round the induction air pipe and connecting to the filter box is the intake side of my valve. So, how well does it work when the engine is cold and with the full air plumbing? I tagged the valve across the battery and started it up. Have another video. Well now… 1300, 1400 revs. That, my friends, is bob on! Can’t believe I’m so lucky to pick a load of random bits off the internet and have them work. Might have to do the lottery. I’m not sure that this valve would work if you wanted to put it in the boot though. I suspect the additional pipe run would cut down the air flow too much. So pleased was I that I took it for a trundle in the sun. Put another 30 miles on the new bearings. When I first got the car on the road it really was utterly terrible. I’ll admit I was a bit disappointed. Now it’s starting to become quite a nice car. I’m trying to keep the revs down below 3500 and keeping my foot off the loud pedal until the bearings run in a little. I’m not sure the car appreciates this however. It seems to be whispering “put your bleedin’ foot down and let’s have some fun for God sake!” Now the power train has a little more refinement it’s sure showing the suspension up as being knackered. Back to the plot… To make the old girl look a little less like a washing machine I took it all off for paint.     If I’m honest I’m a little concerned that the bracket I made might be too strong and the engine movement leaning on the hose, pushing the bracket around might fracture the air filter mount. I guess I’ll find out. Electronics next. That going in the boot. I’m not even going to put it in a box. I’ll just mount it on a bracket behind the trim. Here’s the start of it.   And that’s as far as I got. James |

| |

|

|

Now deny it!

Now deny it!