Will this be the mother of all updates over the last 6 months of working hard on fixing my Granada’s loom damage?

Well…… yes!!

and no…

It’s definitely one to sit down for though! Your knees might not hold out long enough if standing.

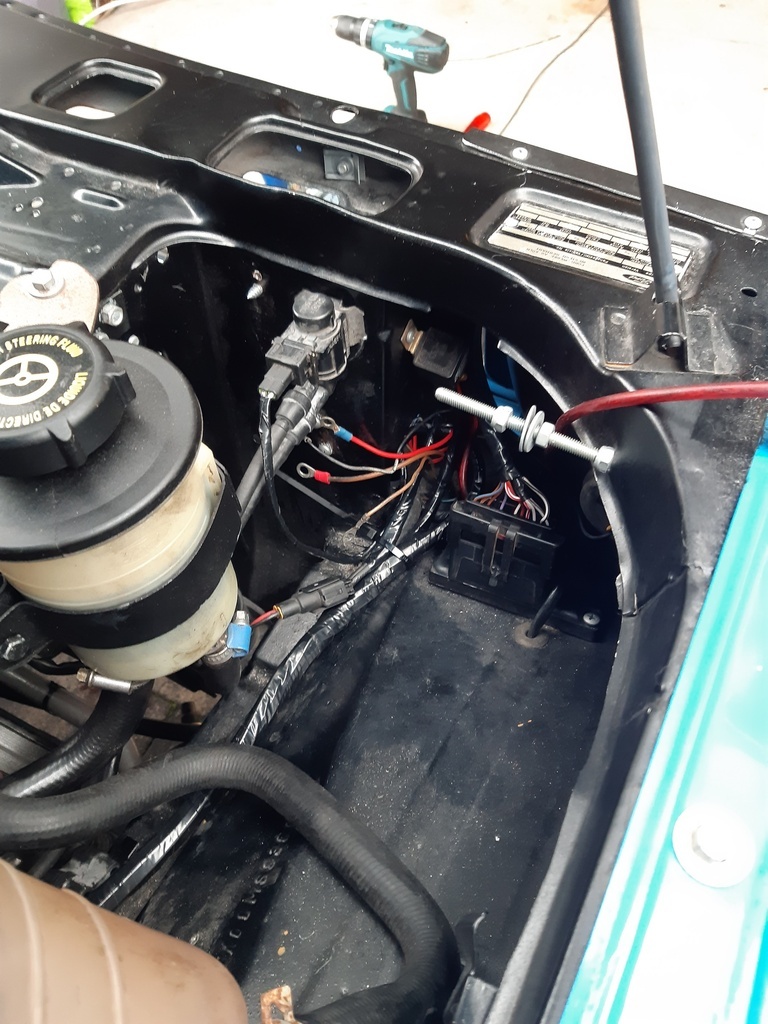

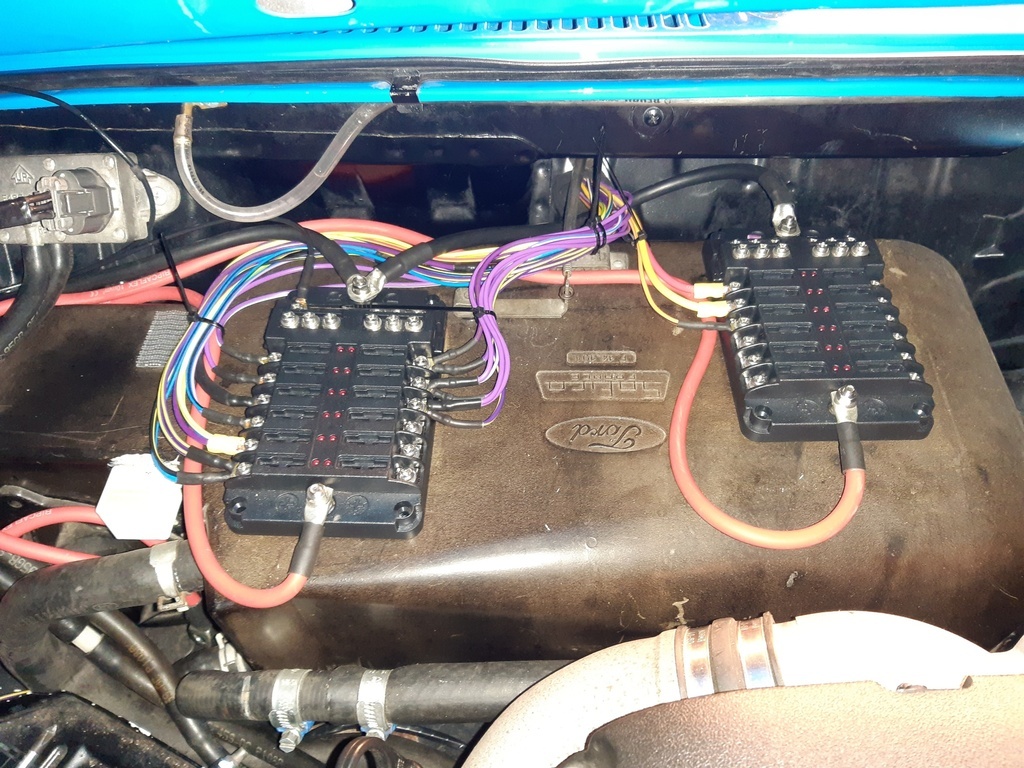

To continue on from where I left it, with the power feeds to the fuse boxes fitted, next up were the earths. I procrastinated a lot about these. I had to drill a 13-14mm hole for the grommet I had, but my step drill was nowhere to be found. Going out several evenings for a bit to find it, I had no luck. Then I was struck by an attack of massive headaches. Simply debilitating headaches. Spent the next two days mostly in bed or on the sofa “watching” tv or napping. But no amount of pills could shift the headaches.

By Friday I thought I felt somewhat better and I was also crawling up the walls so I decided to try and do something at least. It was a nice dry day to boot. I pushed the Granada out and decided for now to just drill an 11mm hole (biggest metal drill I could find) and feed the earths through without a grommet just to get them situated and connected. There’s only 6 or so, so undoing them, feeding them back in and opening up the hole should be easy enough at a later date. And at least that wouldn’t stop me from finding out if the car was going to work.

I quickly felt I had overdone it for my head, but I needed some relaxation as well so I carried on regardless. Hoping that getting a bit ahead on this project would help settle my head. There’s just so many worries going around in it. I’m far from feeling my usual self currently unfortunately.

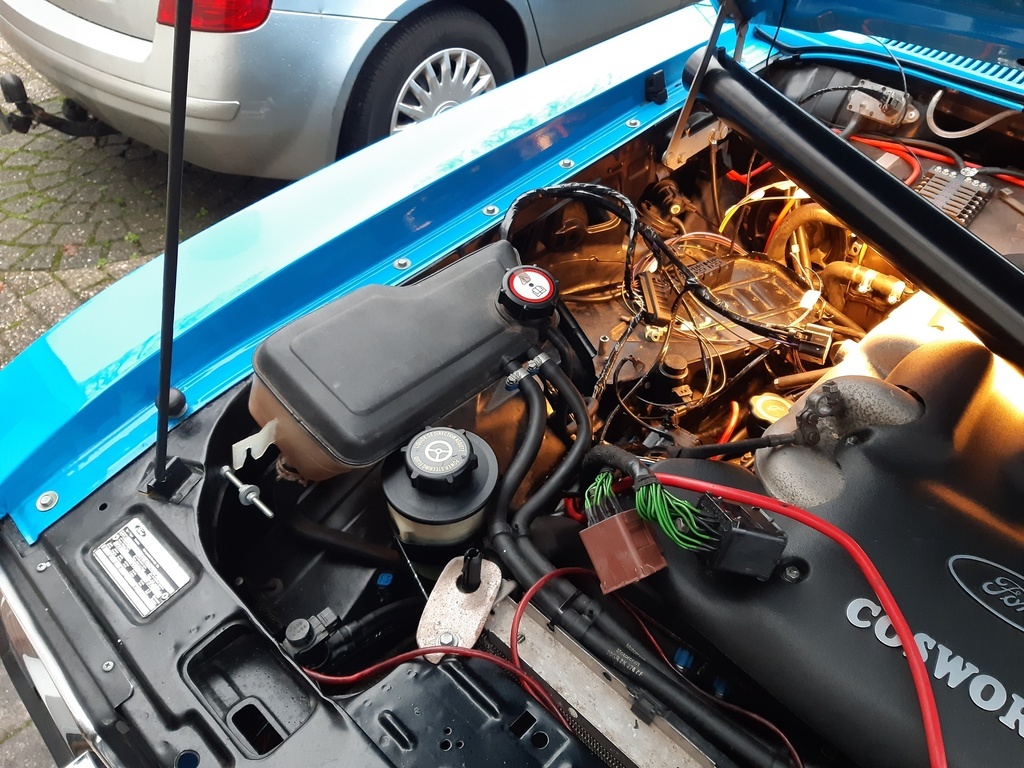

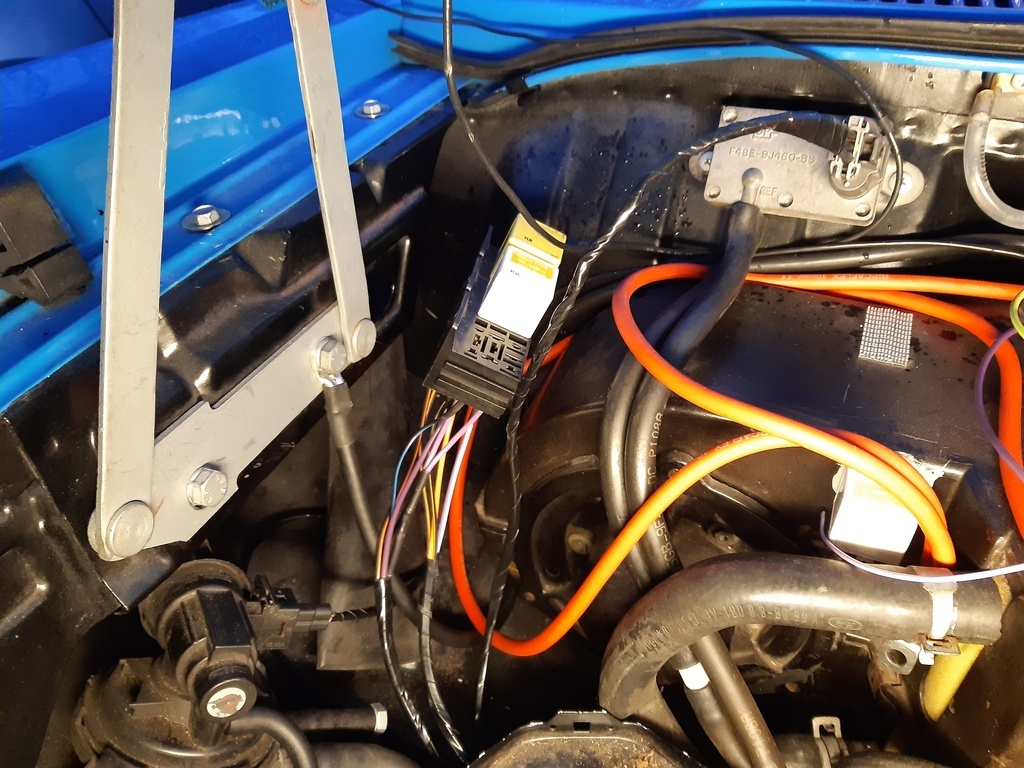

Anyway getting those 6 earths fitted up was rather simple after the 30 or so power feeds. And I had that done pretty quickly. I then shifted my attention to making sure all connectors under bonnet were hooked up/seated fully. I had the edis plugged in but not seated when routing the cables. Same for the ecu to engine and gearbox connectors. So fixed all that. Next up I added the final two earths. One near the fan relay, and the other in the car near the gear shifter. As I had gotten this far and in my hurting head had decided I was now dedicated to working toward a first start I decided to hook up the battery with the old clamps and leads. They are going to get replaced but they themselves weren’t damaged so should do for a test.

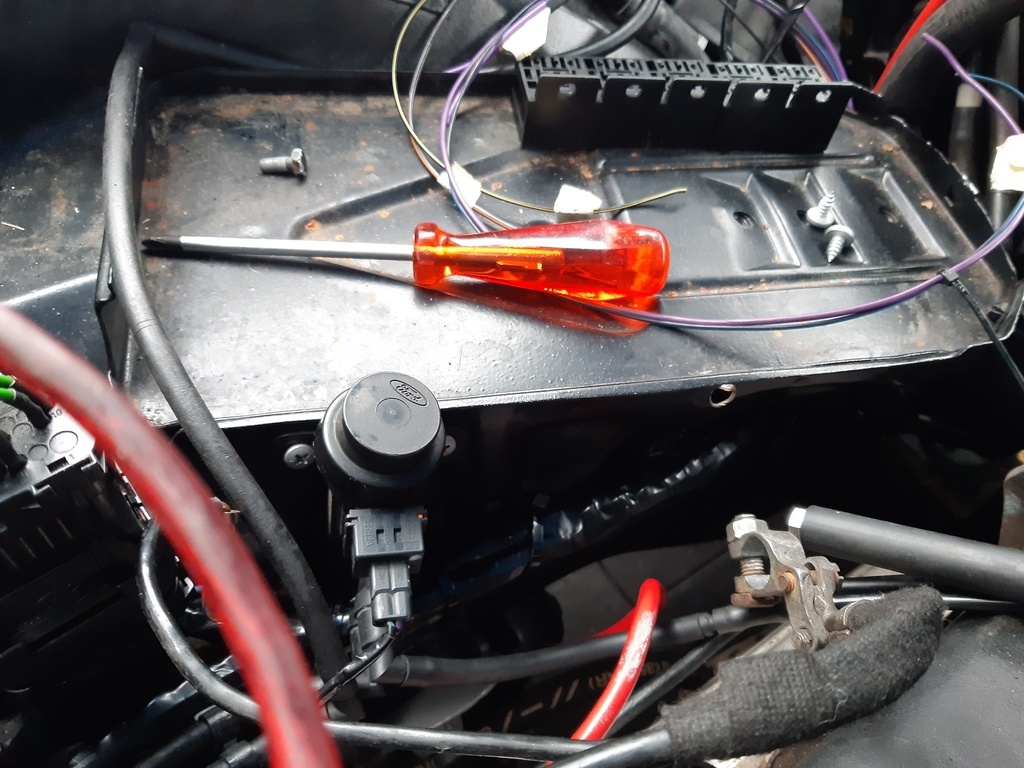

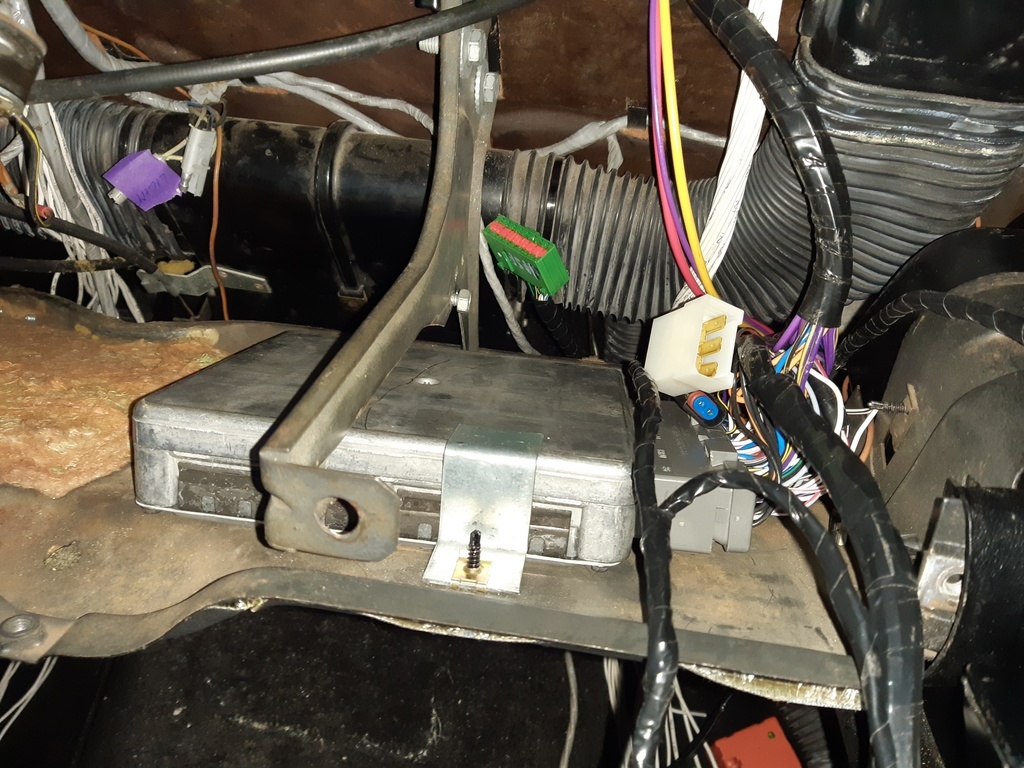

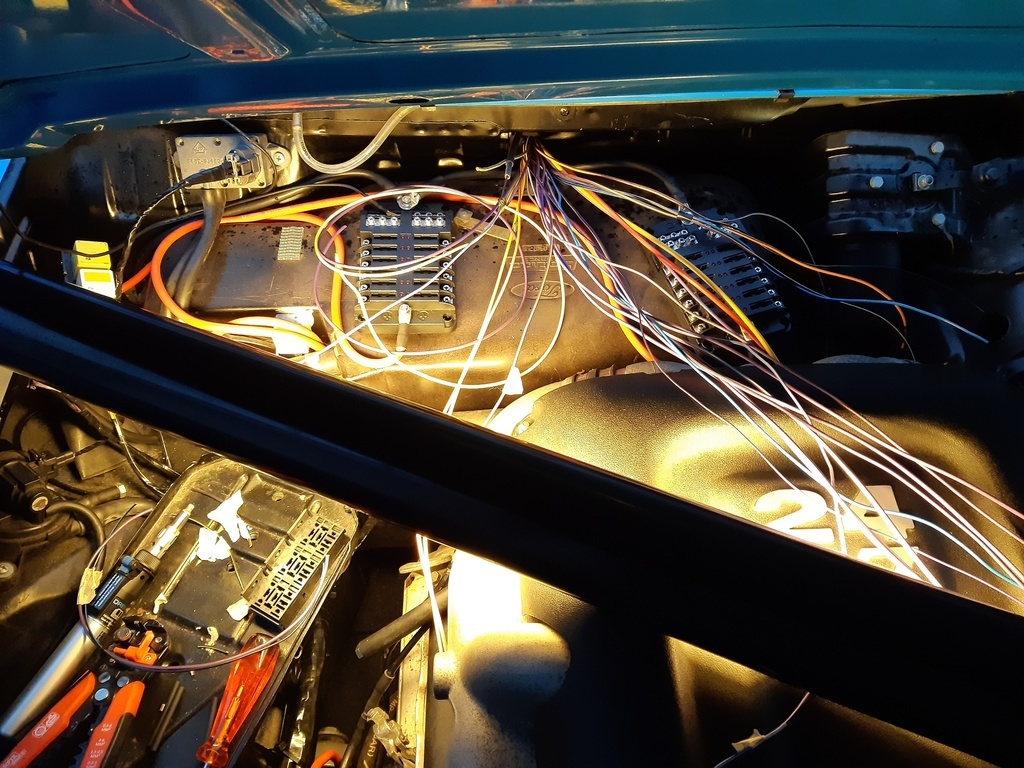

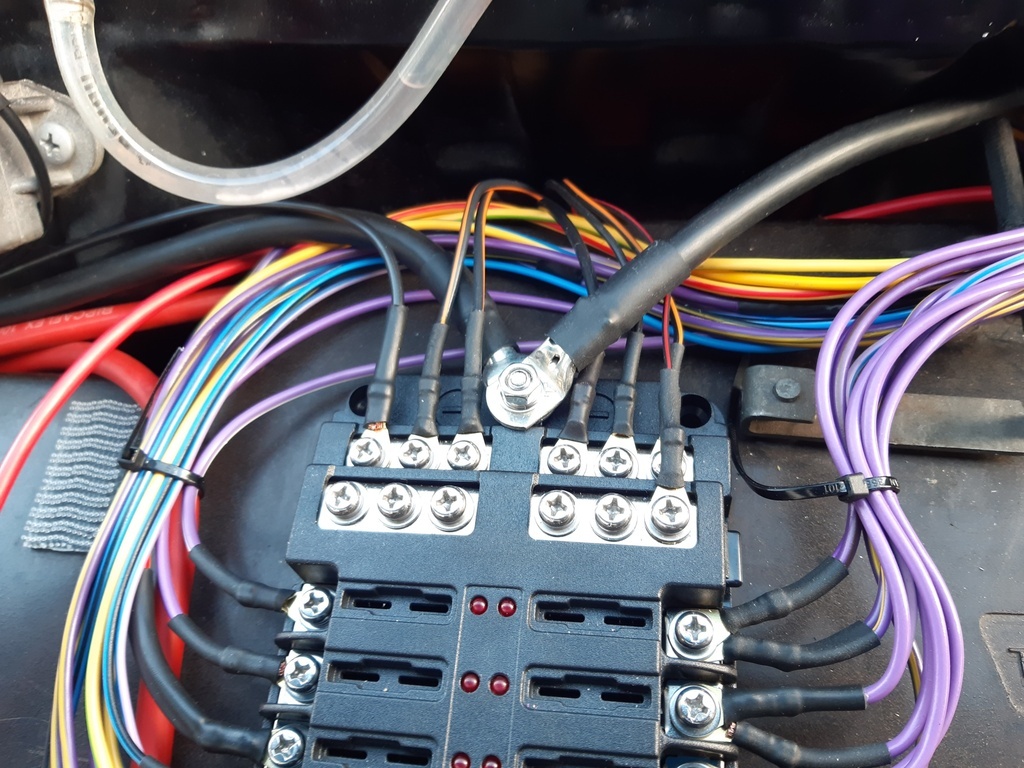

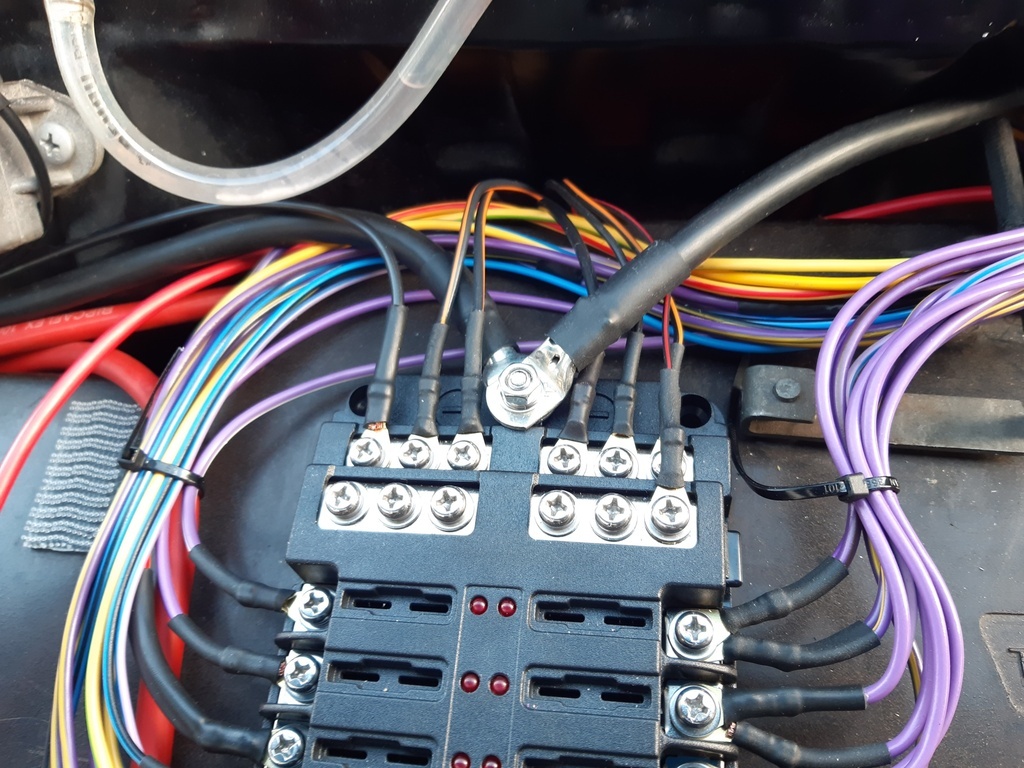

At that point the under bonnet bit could be called done. And I was at a bit of a crossroad. I was pretty close to getting it all hooked up ready for testing, but should I or should I not improve upon the wiring on the in car bits that I hadn’t touched? In the end I decided that having used thicker gauge wires for power feeds I’d carry that on where needed. So I redid the connections to the ignition switch and fuel pump in the same thickness of wire. I hooked up the PATS bits to the ecu and key reader and plugged in the gear shifter. I added the gear shifter light to the loom as well at this point as its length could now be determined and fitted that. After that I was left with basically one last connector to plug in. This carries some dash things and the reverse lights and a connection to the general lighting and the final one to the ignition start. I first took out all the pins that weren’t relevant to clean up the connector a bit. Then I inspected how it was made but any improvement I could do on it would result in practically the same end result. I also saw that the wire thickness wasn’t reason to change out the wires. So I just plugged it in and made it fit better. Getting rid of over lengths and putting on a plug here or there instead of the old cable shoe/bullet terminal. I even went as far as reinstating, only nicer, the rev counter relay that makes the old type counter accept the new type input. With that I only had the diagnostic plug and four led’s to wire up. As the diagnostic plug does nothing that could prohibit starting the car I let that be for now as the light of day was starting to fade. I decided the same for 3 of the 4 LEDs. I just hooked up the PATS LED as that one shows if the key is read or not.

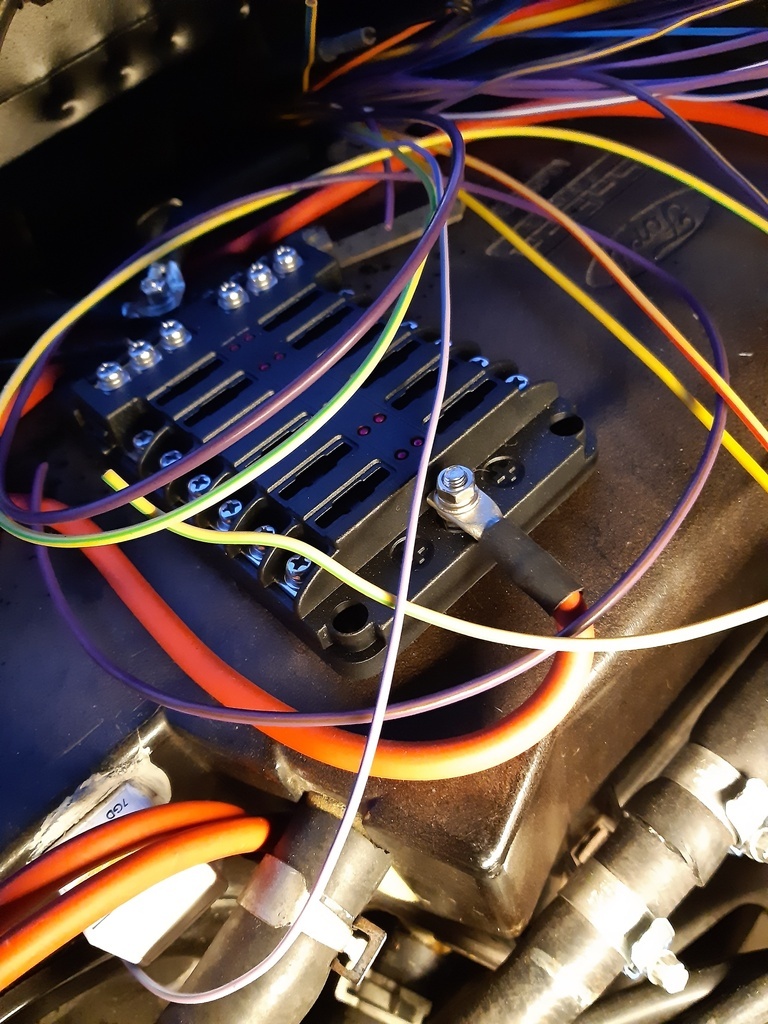

And with that at the end of the afternoon I was ready to fire it up. I was cautious enough to first put on the power without any fuses in my fuse boxes. These should then show a no continuity led. Most of them did but a few didn’t (the fan feeds and one relay feed). I don’t really know why, but they were wired in the same as before which worked so it should be fine.

With the new loom now connected to the ignition feeds, I could also test if the switched fuse box went live with the key turned and it did! I kept it on and put in 10 or so 20 amp fuses and one 10 amp as I didn’t have an 11th 20 amp one. Worst case it would blow. Obviously I did this one by one to see if there was any magic smoke disappearing. But all was fine and I saw the system come alive when the PATS light lit.

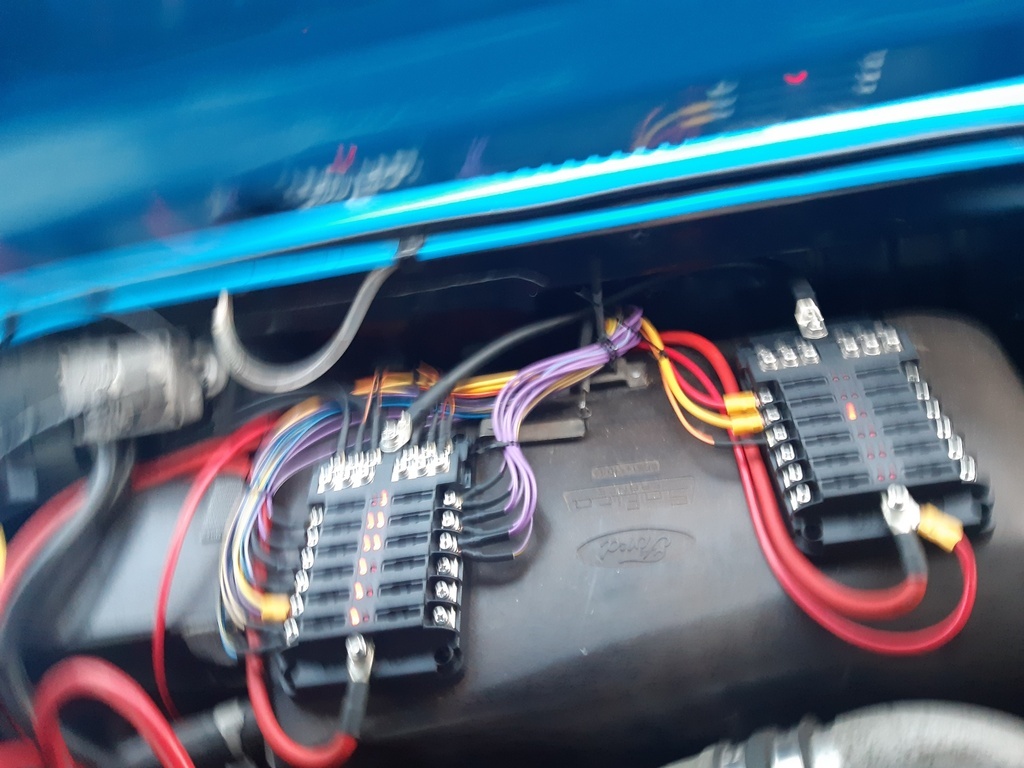

(Sorry for the lousy pic)

So now there was nothing in the way of me testing the car, at least not to my knowledge, right?! So that’s what I did in my enthusiasm and with my pained head, hoping for a real pick me up and boost to mojo….

So I turned the key a few times as the PATS reader doesn’t always read the key in the first try. I tucked it away a bit and that may be the cause. Anyway, the key was read as the PATS light went from blinking to lit! Yes, that is at least a small win I was worried about before. Now there was nothing left to do but turn the key. The engine turned but didn’t fire. Again, and the same. Again and there were hints of trying to run. And then it ran!! It ran!!

But my joy was only short lived……….no time for a happy dance just yet….

The engine ran like utter curse word! Totally uneven and popping everywhere upon a bit of throttle. So something was definitely amiss…I might be a do it yourself mechanic, but I have amassed enough knowledge to know this was not going to fix itself in warming up or anything.

I shut the engine off and could feel that one side of the block was warm and the other almost cold still. So one side was not igniting like it should. No spark, no fuel or no compression was my quick and dirty first evaluation.

It is when I went to shut off the engine that I felt more stupid than I had ever felt before or very close to that. I saw oil dripping onto my relatively new floor mat and the carpeting on the transmission tunnel… I immediately knew why though… In my enthusiasm for FINALLY FF-ing reaching this point I had totally forgotten about the mechanically fed oil gauge. And that line was diligently spurting out oil onto my dash. Fortunately most of it landed on the lower dash panel in a channel, but that channel has holes so from there it dripped. I tried to save what I could but I felt both incredibly stupid and mad at the same time. That panel will need to come out again. With my head on straight this would not have happened. But I was blinded by finally reaching this point. With that misery at least mostly cleaned up the rest of my emotions came running…

I really didn’t know what to feel. Disbelief for it running like curse word and me thinking I can’t have made such serious mistakes in the wiring. Anger and disappointment for not being more successful after such careful preparation and the months of work leading up to this point. Happiness for the wiring not going up in smoke, fuses not blowing, PATS reading the key and the engine at least coming to life. Then obviously the tremendous feeling of stupidity. And feelings of really not knowing why I even persist… persist on pursuing fixing this car but alas also persist in living life when there’s so little to enjoy. All fighting for domination.

As light was fading and I had sports to go to and I needed to eat I quickly cleared the tools away and hoisted the car back in.

And then the thinking really started in anger. Still distraught by the situation there was again or still the impulse to find out what is wrong and fix it. But my mood was ruined and my head even worse.

Next day I obviously fitted the gauge to the oil feed and did some more basic looking/running of the car. It ran two rounds around the block, it shifts etc. but just runs poorly.

Right now I can’t think of anything other than three reasons for it running bad; no fuel, no spark, no compression/timing error.

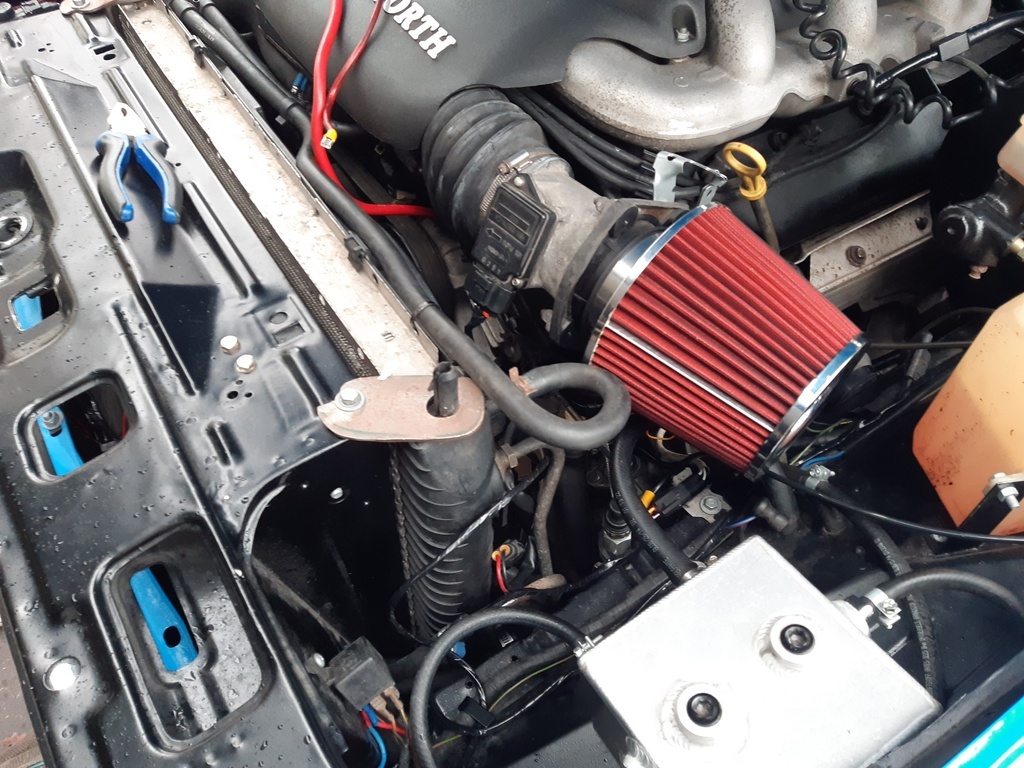

I think spark should be the first to rule out as this engine uses one coil pack and seeing as the one bank does everything it needs to, that obviously is able to do something. The spark plug leads are hooked up same as before as seen on photographic evidence and as these are different lengths, I think it’s hard to get this wrong. Still I’ll check again to be sure. But that sounds too simple, lol. The Edis module is one I had to pay special attention to as it had several wires of the same color combo and it needed some shielded wires so I’m confident there are no errors there.

Fuel is a possibility as the injectors are fired individually. Maybe I put the wrong lead on the wrong injector somewhere? Although again I think I did this based on photographic evidence. Or maybe they aren’t firing, getting a signal. Which would then point to the looms, question is: does it point to my loom or the supposedly good one that was never proved 100% in practice, although in theory it was given a clean bill of health after testing for continuity etc. But were the pinouts tested as well?? Thinking about it now, with this engine and box loom on my first engine (all green wires), the same side of the block was not working properly!!!! Also staying cold. But that was then diagnosed with a compression test to be the engine itself as compression was down on that side and even 0 on one cylinder. A leak test then confirmed the exhaust port to be wide open always. These were indeed found bent upon dismantling of that engine. So is this merely a monumental coincidence? It does feel like a reason to say it’s not my work that is bad… I find it a coincidence hard to ignore!

And then finally, timing or lack of compression. No heat in the exhaust means that there is no ignition of fuel. If there is spark and there is fuel, than that only leaves timing. The timing however cannot be set on these engines other than with the chain. Any timing changes are controlled by the ecu after that. Having experienced once before such an engine running on half of the necessary two chains, I wouldn’t put it past the engine to be broken mechanically. It only takes a jumped tooth or so. Maybe that was the start of all this misery in the first place? So a compression test will be my next move. The realization above that the first engine on this engine loom also behaved badly on this side of the engine and the fact I knew this current engine to be good right until that final attempt to start with dire consequences does however point me more to a problem in that loom. A mislabeling of injectors perhaps? I think that would be the next step if the compression test proves normal. Even if it doesn’t it might be wise to try and ascertain that the injectors are wired correctly. Fortunately all my homework means I know which wires feed the injectors so they can be traced from ecu right up till the injector itself. Problem as usual is access as the injectors are buried in the V valley of the engine under that massive intake system.

But, that is currently the problem… I have all these guesses in my head and one is even harder to test than the other. Fortunately there are still some top blokes in this world as a shoutout to this community’s

SamJ meant I had a compression tester and some new thoughts present within a day. Sam was more inclined for it to be a wiring issue and with my latest epiphany on this loom bit and previous experiences he may even be right.

I guess I should rush that compression test but in reality I can’t do it before tomorrow and although they are advised on a warm engine, I can’t get both sides of the block warm so I’ll have to do it cold for an honest comparison.

Well so that is where I’m at. Not where I had expected to be really. I sort of did take into account that things might not turn out ok in the first go, expecting molten wires and magic smoke, but at the same time I had sort of dismissed the thoughts on that as well. Given my attention to detail. And an issue with a loom bit that was declared healthy and not of my making or even the engine itself I hadn’t even considered.

I’m still in turmoil on it all, yet as always committed to resolving this latest issue as well. I just hope it proves doable. I'm just very disappointed that I still can't drive it...