Hi,

Still working hard, but it's not finished yet because I had a set-back.

I thought there was a small patch of rust to deal with in the floor, but it had been 'repaired' badly in the past and was much worse than I thought. Whoever did this made a big effort to hide the rust! New sound deadening had been fitted, over rusty metal, and sprayed body colour in side the car, and lots of underseal underneath, so it all looked OK.

But the area next to the sill had no strength at all and would move/crunch under hand pressure... so a lot more than I expected had to be cut out.

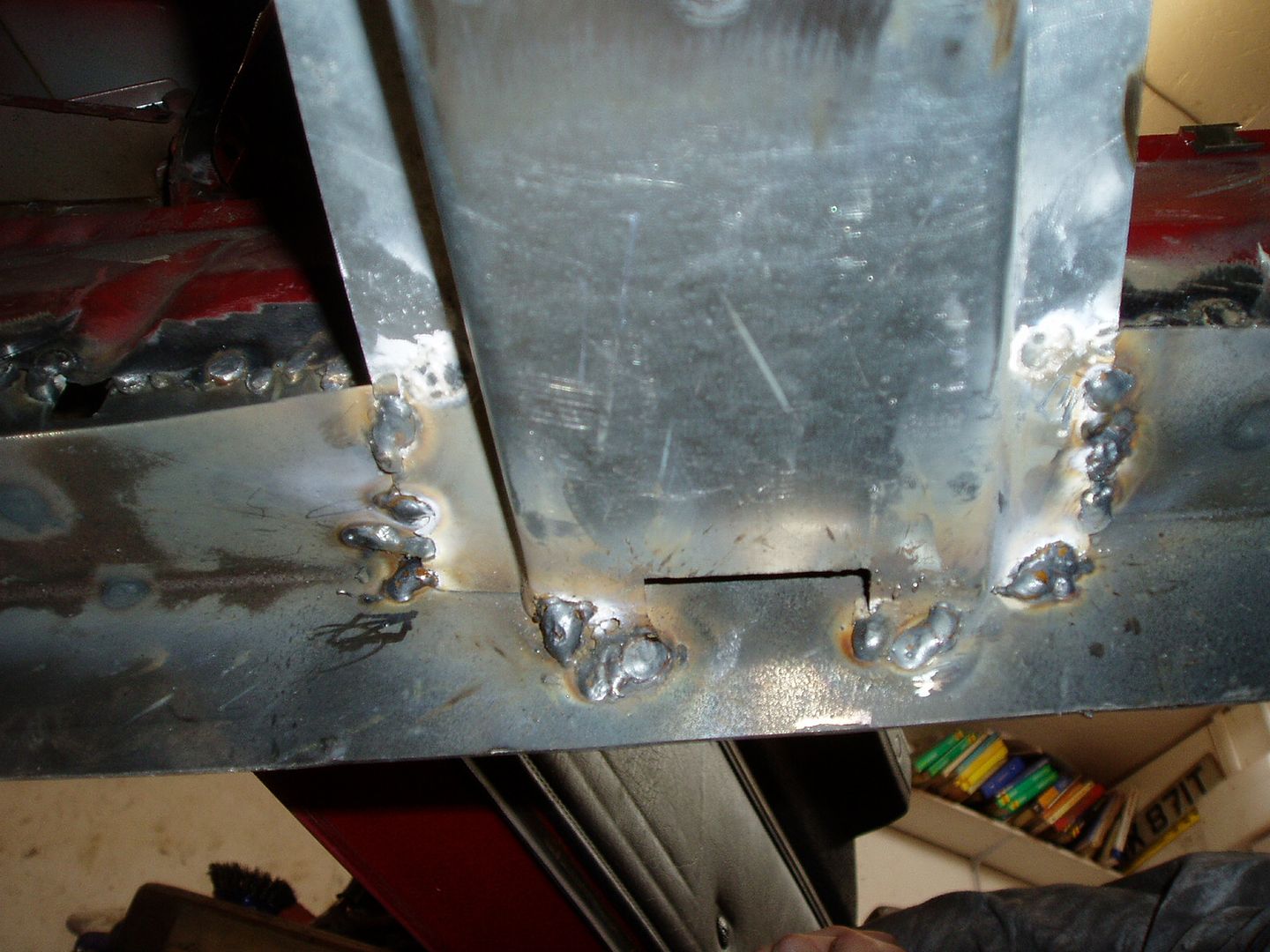

The rectangular tube at the bottom of the photo is a temporary brace welded across the door opening, to avoid the shell flexing. I also positioned axles stands and jacks carefully so there was no bending force on the sill. The seat mounting cross-member, top left, wasn't rusty but had to be cut out to allow access to repair the inner sill.

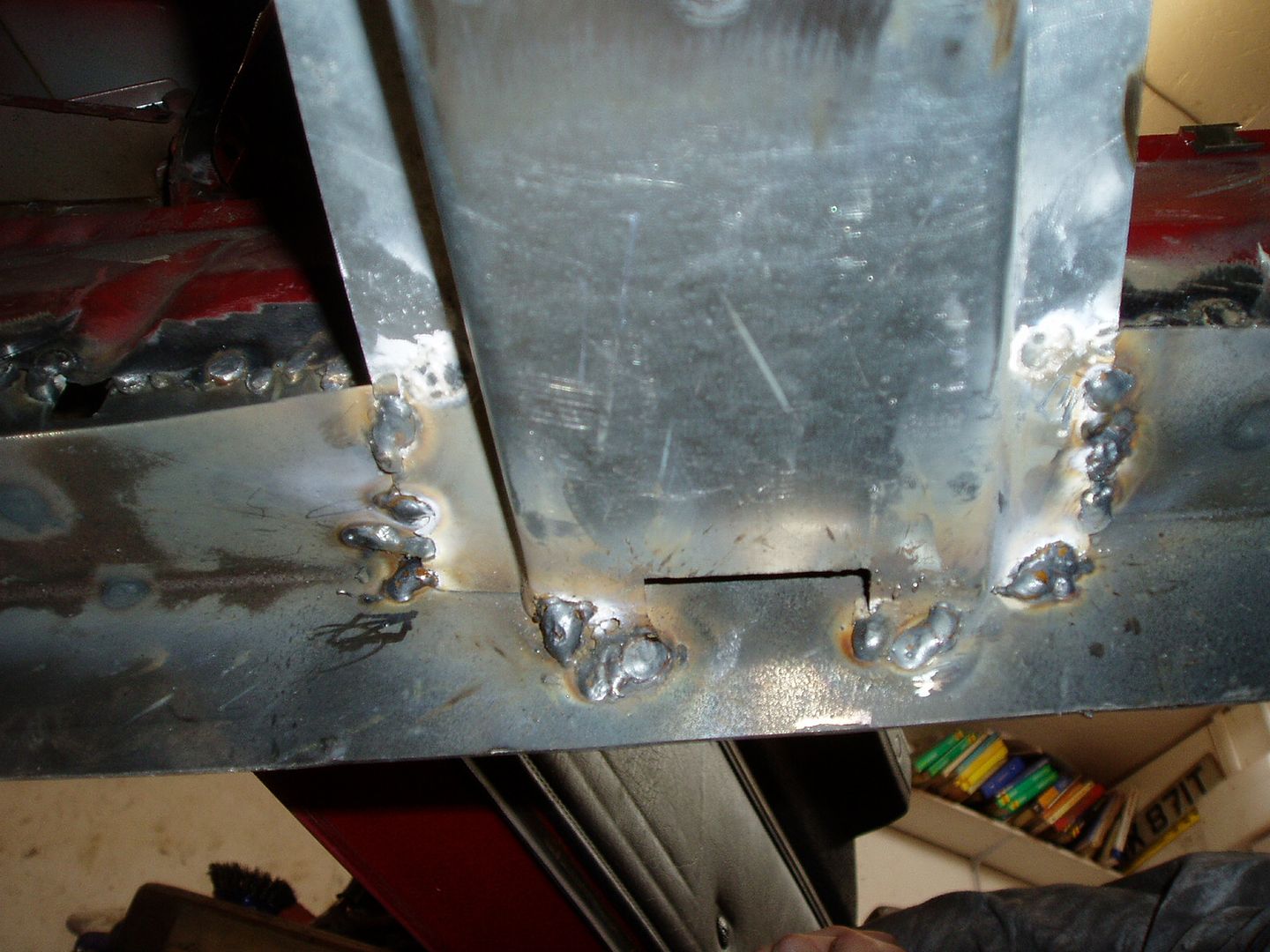

A sample of what was removed

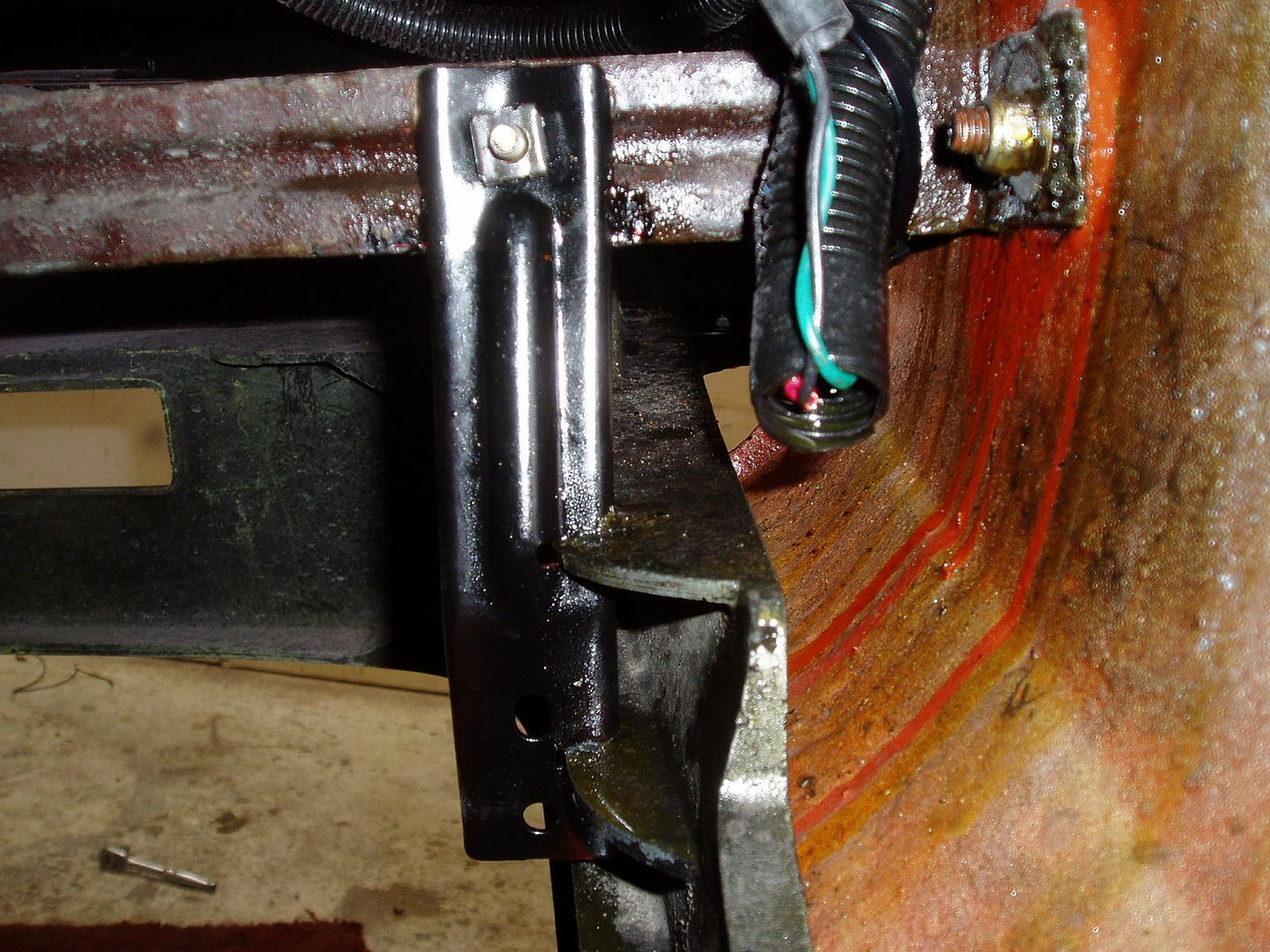

The outer sill is fine. I used a length of strong square steel tube, cut in half to make an L-section repair piece for the inside and bottom of the sill. Hard to get a good photo, because it's mostly inside the sill, but it's partly visible here - the vertical piece.

After the main repair was strongly seam-welded in place, I used the other half of the tube (another L-section obviously) welded on below it, to make a ledge for the floor to sit on and a replacement lip at the bottom of the outer sill. I also made up a new end for the chassis outrigger which we are part way through fitting

The lip will be trimmed down to the right size of course

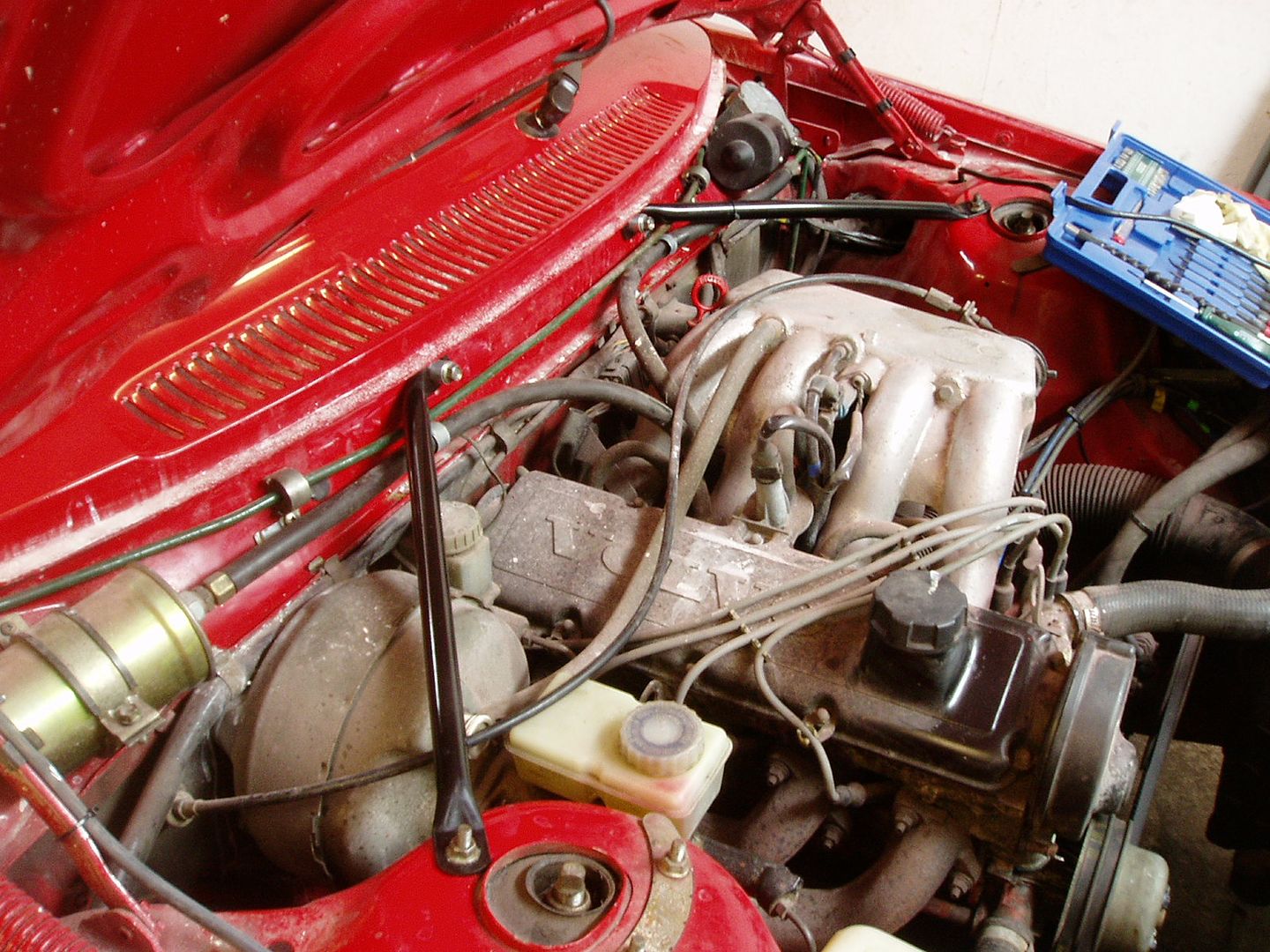

When not welding, Steve was doing electrical work. We now have most of the lights working, and the wiring installed for the new side repeaters.

I'm hoping to get the car through an MOT in the next couple of weeks... it's nearly there now.

More soon

John

Still working hard, but it's not finished yet because I had a set-back.

I thought there was a small patch of rust to deal with in the floor, but it had been 'repaired' badly in the past and was much worse than I thought. Whoever did this made a big effort to hide the rust! New sound deadening had been fitted, over rusty metal, and sprayed body colour in side the car, and lots of underseal underneath, so it all looked OK.

But the area next to the sill had no strength at all and would move/crunch under hand pressure... so a lot more than I expected had to be cut out.

The rectangular tube at the bottom of the photo is a temporary brace welded across the door opening, to avoid the shell flexing. I also positioned axles stands and jacks carefully so there was no bending force on the sill. The seat mounting cross-member, top left, wasn't rusty but had to be cut out to allow access to repair the inner sill.

A sample of what was removed

The outer sill is fine. I used a length of strong square steel tube, cut in half to make an L-section repair piece for the inside and bottom of the sill. Hard to get a good photo, because it's mostly inside the sill, but it's partly visible here - the vertical piece.

After the main repair was strongly seam-welded in place, I used the other half of the tube (another L-section obviously) welded on below it, to make a ledge for the floor to sit on and a replacement lip at the bottom of the outer sill. I also made up a new end for the chassis outrigger which we are part way through fitting

The lip will be trimmed down to the right size of course

When not welding, Steve was doing electrical work. We now have most of the lights working, and the wiring installed for the new side repeaters.

I'm hoping to get the car through an MOT in the next couple of weeks... it's nearly there now.

More soon

John

[/QUOTE]

[/QUOTE]