jonomisfit

Club Retro Rides Member

Posts: 1,790

Club RR Member Number: 49

Member is Online

|

|

Mar 21, 2013 21:32:49 GMT

|

|

Its a space framey tube frame chassis... ish.... sort of :-)

Thanks for the comments.

Its not the best shell in the world, but its not too bad. For a car from 1946 its in better condition than a lot of cars i've seen from the 70's / 80's. most of the cut out are to make room for the chassis where I need it. Some were a bit rusty anyroads so needed cut out for replacement.

|

| |

|

|

|

|

|

|

|

|

|

|

Nice build! Looks like you've got a great workshop to play in too!

|

| |

1965 Mk1 Mini 1989 Porsche 911 3.2 Carrera Sport 2004 Audi A2 TDi 2007 Lotus Exige S 2011 Mini Cooper SD |

|

jonomisfit

Club Retro Rides Member

Posts: 1,790

Club RR Member Number: 49

Member is Online

|

|

|

|

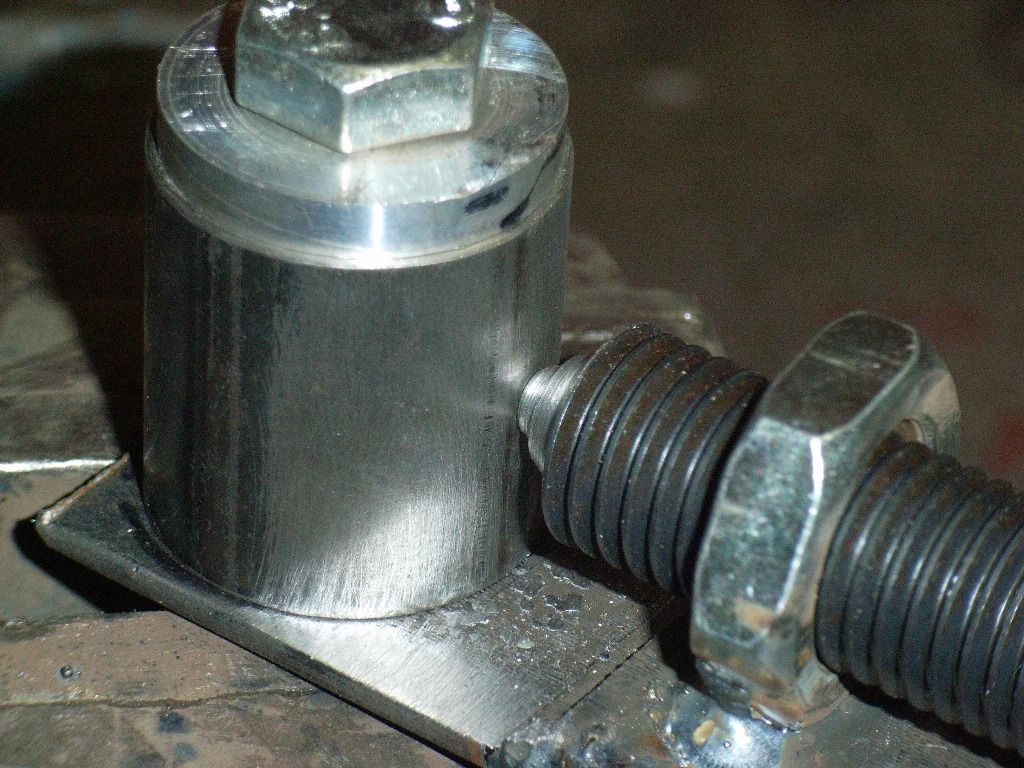

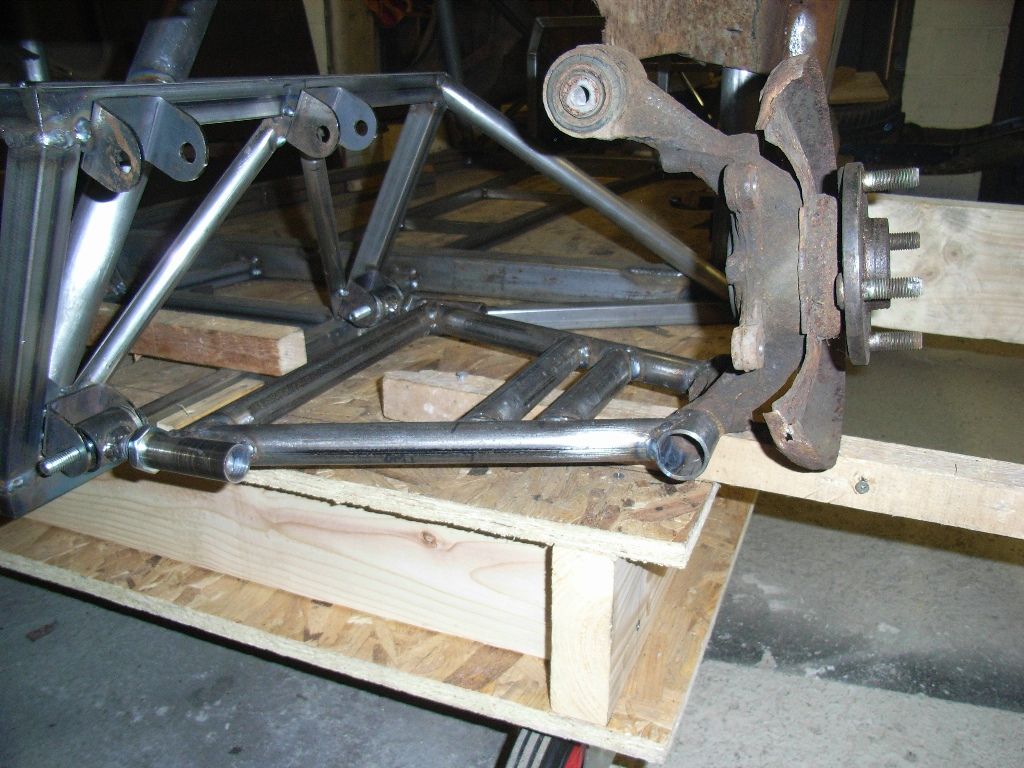

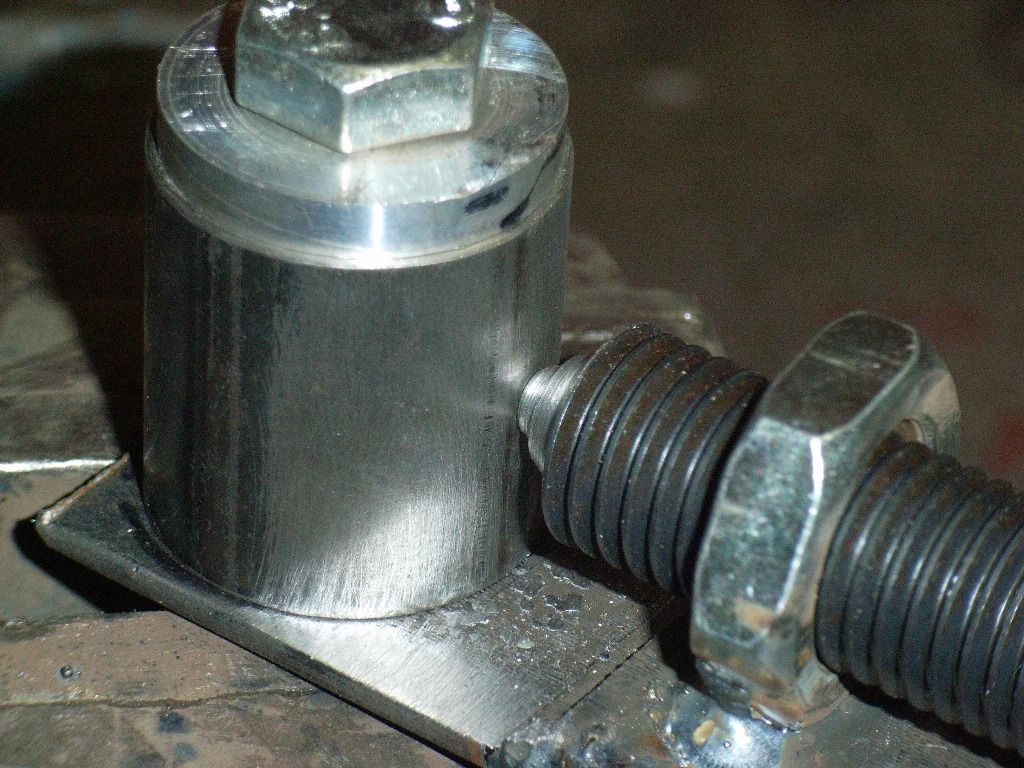

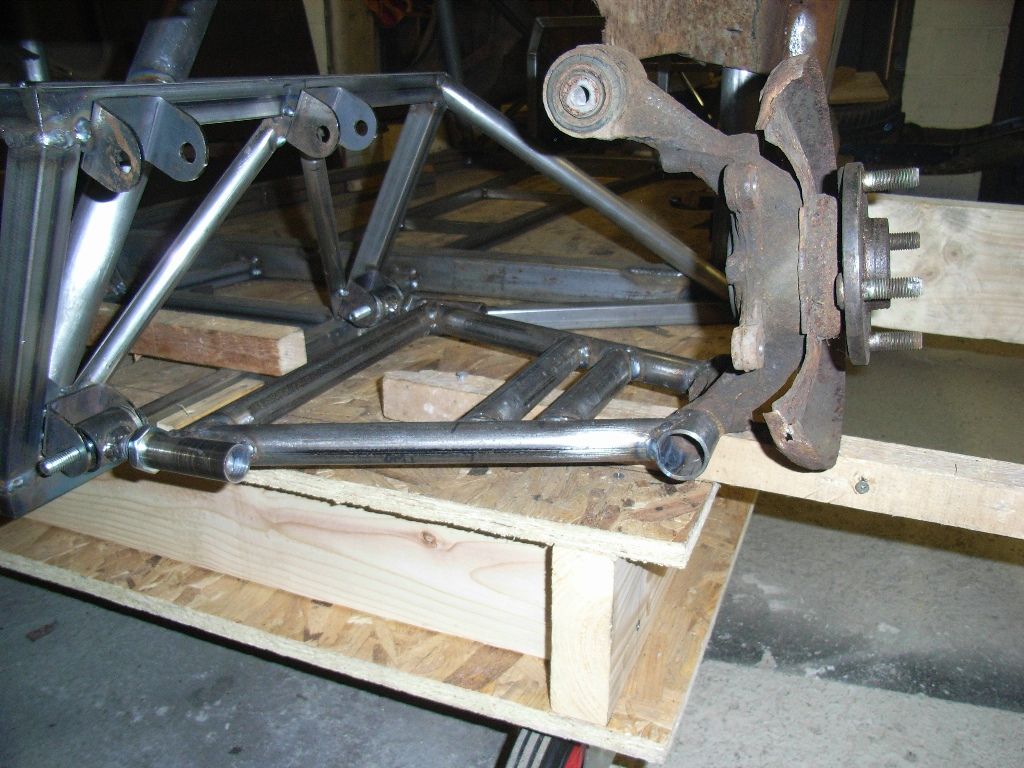

Yep, pretty lucky on the workshop front. It may have been a contributing factor in the house purchase.... Anyway, got a small amount of time in the workshop as had a load of stuff on - final bits of recording guitars, selling the caddy, and having to sort my car as it blew its radiator :-( Tacked in the basis of the transmission tunnel.   Then made a start on the lower rear wishbone.      tacked  welded  Set everythign in position, clamped it up. Cut tubes, welded tubes. Then I needed to make the camber / toe adjusters so needed them pretty straight to the bush tubes so made a little jig.  I turned a taper on the end to ensure I could get penetration right to the center  then built up the weld in layers   Then once they were done decided to see what they looked like on the chassis   I then stuck an old small wheel that was lying about on to get a sense of the track verses the body width..  I may need to extend the wheel arches out slightly..... It's now likely to be a few weeks till i'm working on the car again as i've a million other things on, including house things...  |

| |

|

|

|

|

|

|

|

|

Is there a reason you build bespoke wishbones instead of using something from another car?

|

| |

|

|

jonomisfit

Club Retro Rides Member

Posts: 1,790

Club RR Member Number: 49

Member is Online

|

|

|

|

|

The main reason for using my own bespoke wishbones is so I can set the suspension etc the way I need it for my chassis / car design. My pickup points are quite different from an MX5 so my chassis would have been quite different to suit.

The fabricated ones are also much lighter. The pressed steel ones weight quite a bit.

Plus... i just like making things. :-)

|

| |

|

|

|

|

|

|

|

All excellent reasons, carry on  |

| |

|

|

jonomisfit

Club Retro Rides Member

Posts: 1,790

Club RR Member Number: 49

Member is Online

|

|

Apr 15, 2013 16:50:54 GMT

|

Was away this weekend, but got some work done last week before I left. Started on lower rear wishbone for the other side - Abridged photos as same a as other side...    Also made a start on the floor.   it'll prob be a while till I get much more done, as taking one fo the room back to brickwork and re-building it. |

| |

|

|

jonomisfit

Club Retro Rides Member

Posts: 1,790

Club RR Member Number: 49

Member is Online

|

|

May 12, 2013 20:18:56 GMT

|

So made a little bit of progress with the morris. Made the jig for the upper rear wishbones.   Also went and picked this up as a parts car for the morris. Was rather fun driving it, so have decided to drive it round for a while. Managed to source a load of parts from a local crashed MX5 both bits for the morris, and bits for the MX5.  The passengers side rear arch looked ok, but something didnt seem right to me so thought i'd have a dig about with my trusty exploring hammer......   Unsurprisingly it was uber bodged. Welded plate over the rust hiding it all in side. It looked like there had been two previous repairs made to it, and all the poor work hidden by about 1/2" of filler. I started making some quick repair pieces and got to use my shrinker / stretcher i bought a good while ago but never needed to use.  Was surprising easy to use, and really effective.    I've bought some sill patches and will hopefully fit them next weekend. I'm only intending to do a couple of quick tidy up / fixes them actually use the mx5. don't wont to spend loads of time doign that instead of the morris. |

| |

|

|

jonomisfit

Club Retro Rides Member

Posts: 1,790

Club RR Member Number: 49

Member is Online

|

|

May 27, 2013 18:54:25 GMT

|

So got the mx5 put back together, fitted new suspension and gave it some death. Forgot to take any photos of it though. Rest of my weekend was spent doing house type stuff although did manage to get some time on the car today. Made the first upper rear wishbone although did manage to take any pics until I'd finished it.    Also stuck the spare gearbox I got in to check how things are space wise. Just need to cut the temporary engine box brace out and trial fir the engine as well.  Then decided to stick one of the wheels I got for the mx5 on the car to get a proper idea of the width of the thing. Ignore the camber as I havent adjusted the lower wishbone properly.  The arches may have to have a bit of width to them.... I think the wheels look quite good on the car, although are a bit small. Will have to see if there are some larger modern ones about I can think of getting.   Should hopefully get a bit more done next weekend, in between doing bits on the house and sorting the mx5. |

| |

|

|

jonomisfit

Club Retro Rides Member

Posts: 1,790

Club RR Member Number: 49

Member is Online

|

|

Jun 23, 2013 18:39:02 GMT

|

|

|

| |

|

|

|

|

Dez

Club Retro Rides Member

And I won't sit down. And I won't shut up. And most of all I will not grow up.

Posts: 11,790

Club RR Member Number: 34

|

|

Jun 23, 2013 19:17:17 GMT

|

|

those home-made joints are pretty ill-advised. why not just buy the right thing and do it properly?

|

| |

|

|

jonomisfit

Club Retro Rides Member

Posts: 1,790

Club RR Member Number: 49

Member is Online

|

|

Jun 23, 2013 19:50:53 GMT

|

|

You got some links to where to get them? As when I've looked for them in the past I've not been able to find any, at least not any that aren't made the same way.

Or if not, any idea what the proper name for them is?

|

| |

Last Edit: Jun 23, 2013 19:56:35 GMT by jonomisfit

|

|

Dez

Club Retro Rides Member

And I won't sit down. And I won't shut up. And most of all I will not grow up.

Posts: 11,790

Club RR Member Number: 34

|

|

Jun 23, 2013 20:02:03 GMT

|

these are what I usually use, as they're cheap but from a reputable source. they need to be one piece and forged to be safe. www.speedwaymotors.com/Speedway-Forged-Steel-4-Bar-Rod-Ends-5-8-18-RH-Thread,25122.html looking again at yours, I also think youll find the threads are too coarse to offer any kind of meaningful adjustment, even half a turn most be getting on for a mm of travel? |

| |

Last Edit: Jun 23, 2013 20:02:48 GMT by Dez

|

|

jonomisfit

Club Retro Rides Member

Posts: 1,790

Club RR Member Number: 49

Member is Online

|

|

Jun 23, 2013 20:06:25 GMT

|

|

Thanks. I'll look into those.

|

| |

|

|

jonomisfit

Club Retro Rides Member

Posts: 1,790

Club RR Member Number: 49

Member is Online

|

|

|

|

After a long time of not doing much, i mocked up the car on its wheels to get an idea of how its going to sit and how much i'd have to widen the arches by.    FatboyDW came round to help me give it a sense of scale. For reference Grant is 12ft 7.... oh no wait its just somewhat close to the road.  Wheels arent the right size, but give an idea of how it might sit. Its about 80mm to widen at the front and rear. The other half of the floor went in but I didnt get round to taking any pictures. I also discovered that despite what someone on a kitcar forum had said, BMW tie rod joints do not have the correct taper for a mx5 hub. Looks like i'll need to order the proper MOOG ones from the US. Not sure when i'll be working on it again next, but a lot of tube work is in my future.... |

| |

|

|

v8ian

Posted a lot

Posts: 3,832

|

|

|

|

|

|

| |

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

jonomisfit

Club Retro Rides Member

Posts: 1,790

Club RR Member Number: 49

Member is Online

|

|

|

|

|

Thanks.

Useful catalogue.

|

| |

|

|

jonomisfit

Club Retro Rides Member

Posts: 1,790

Club RR Member Number: 49

Member is Online

|

|

|

|

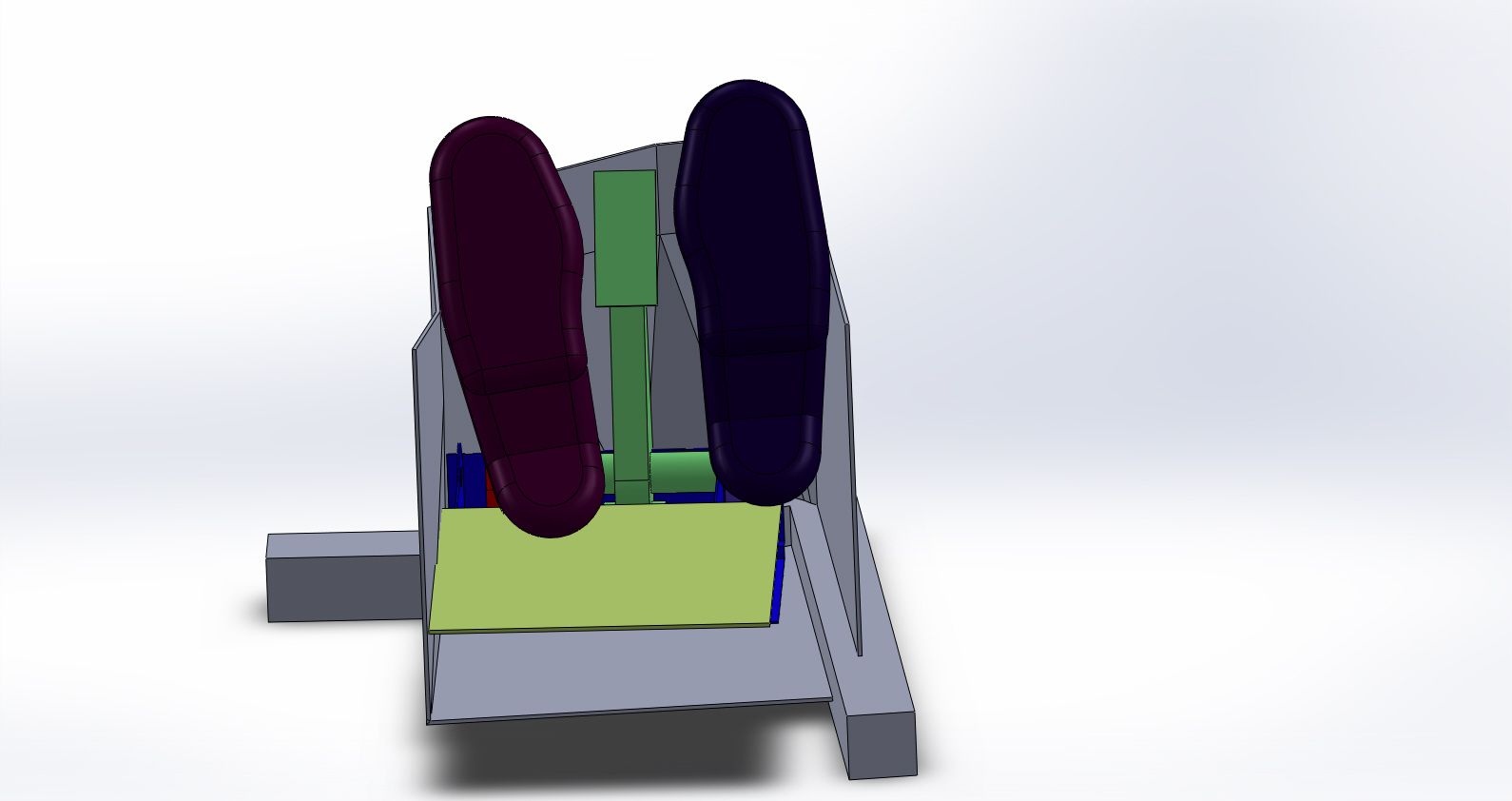

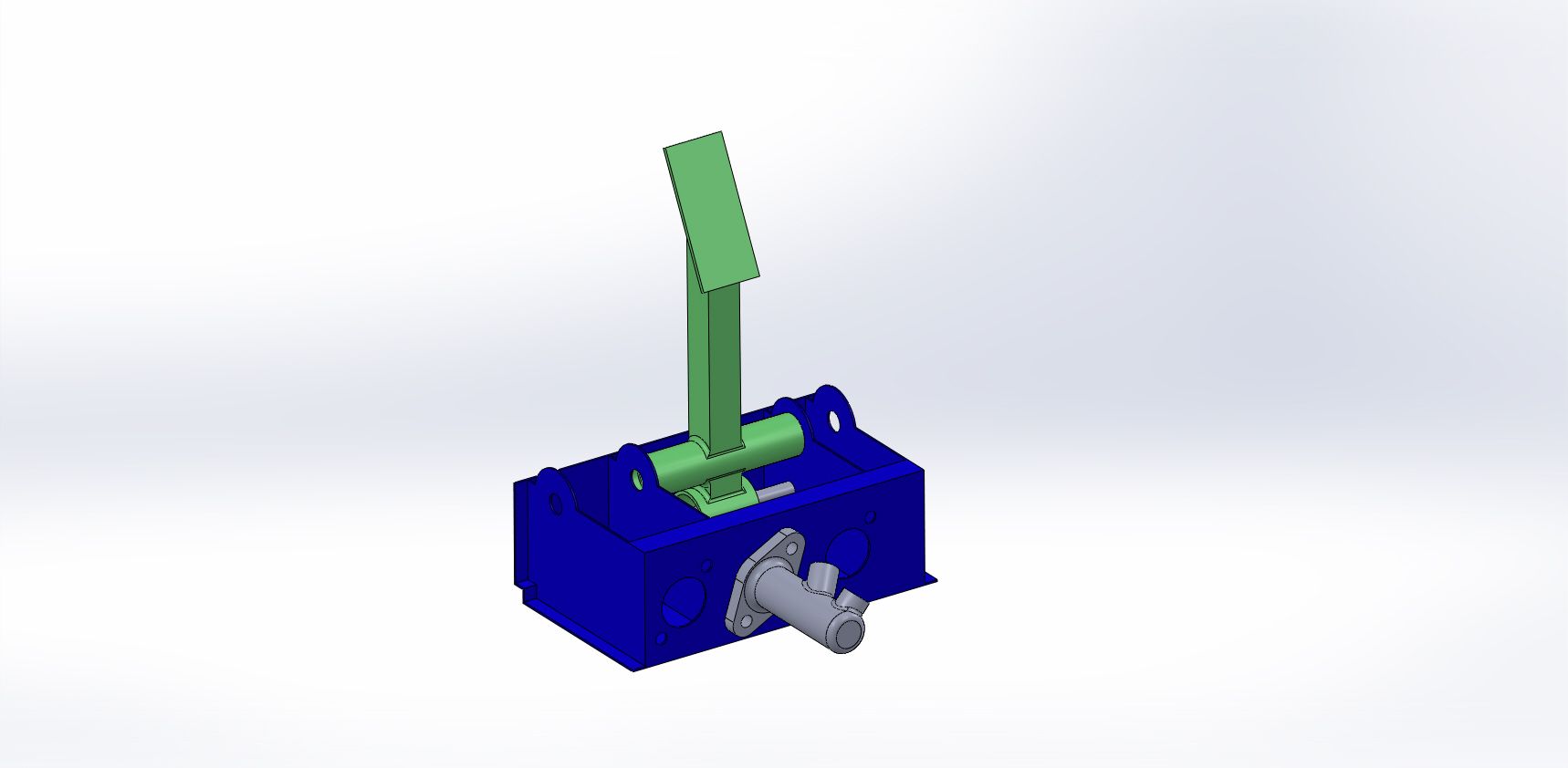

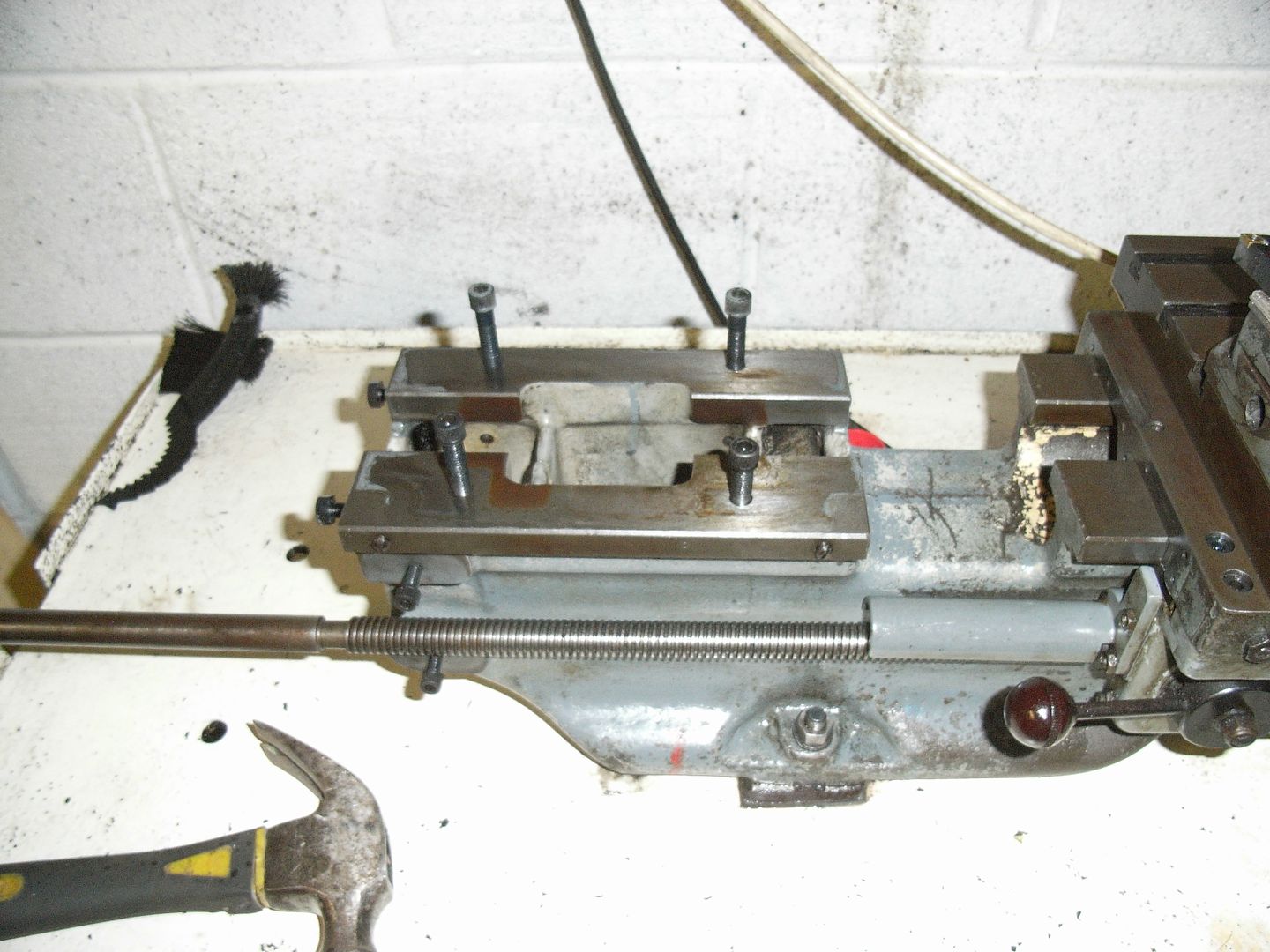

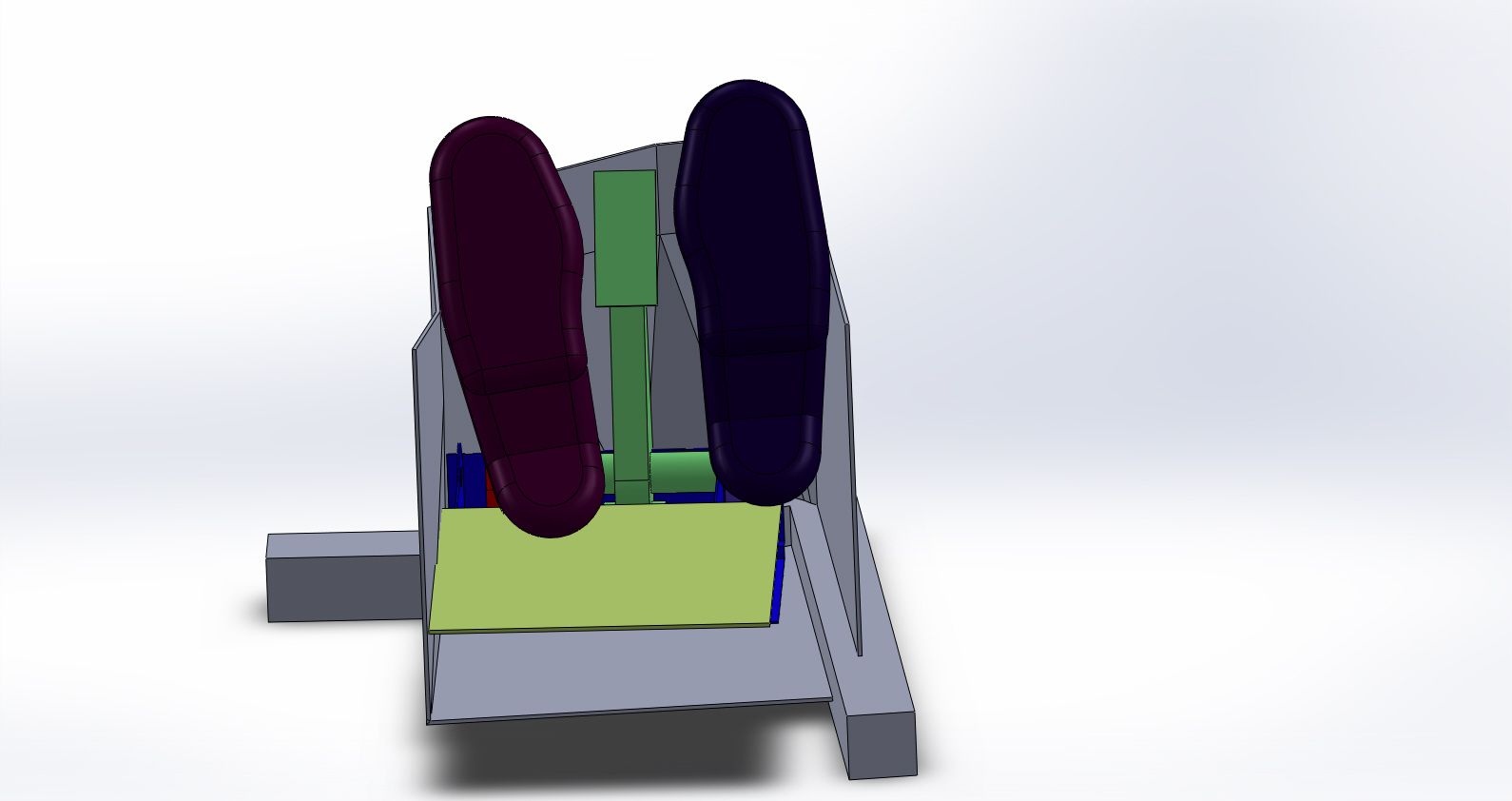

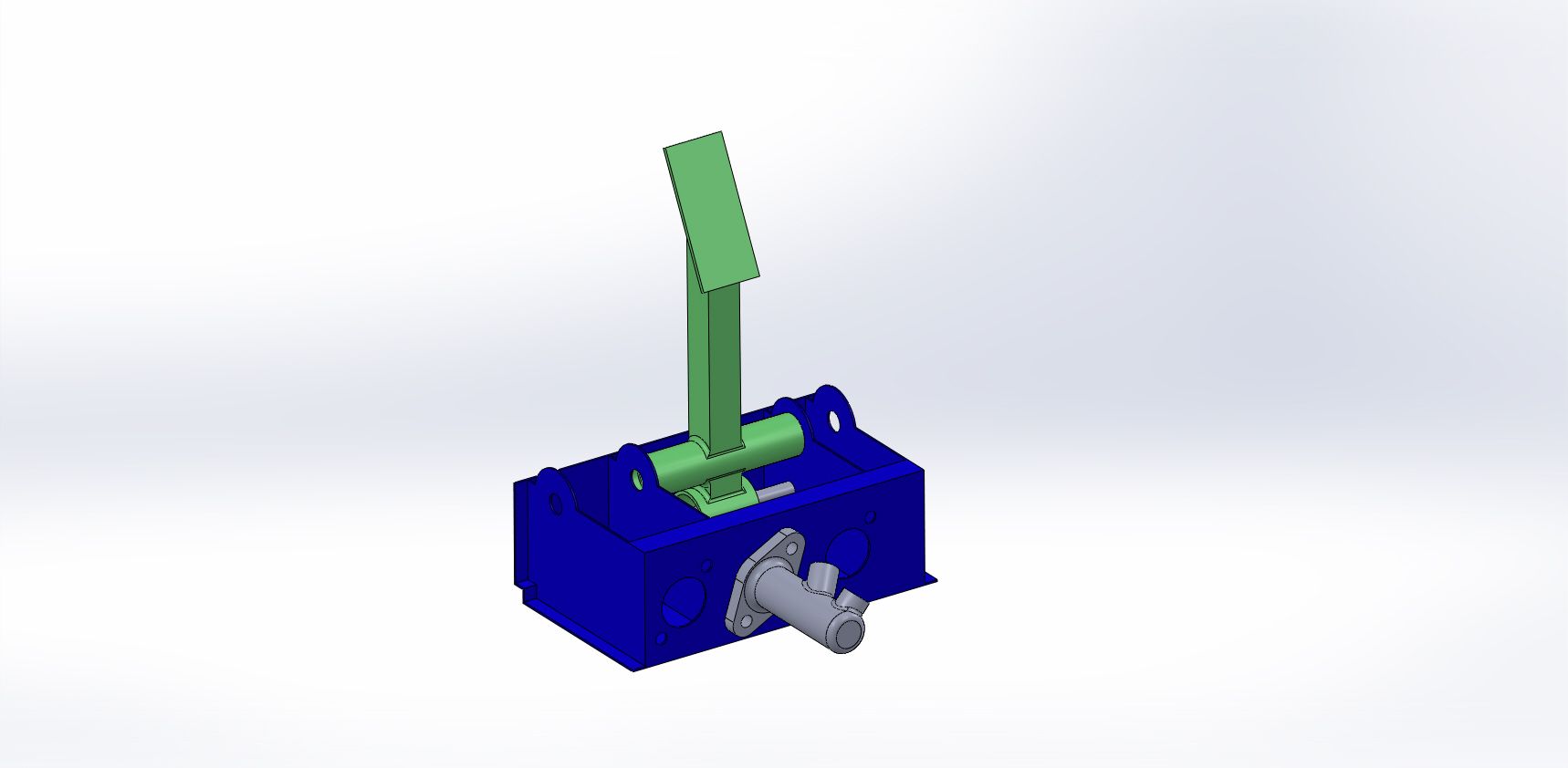

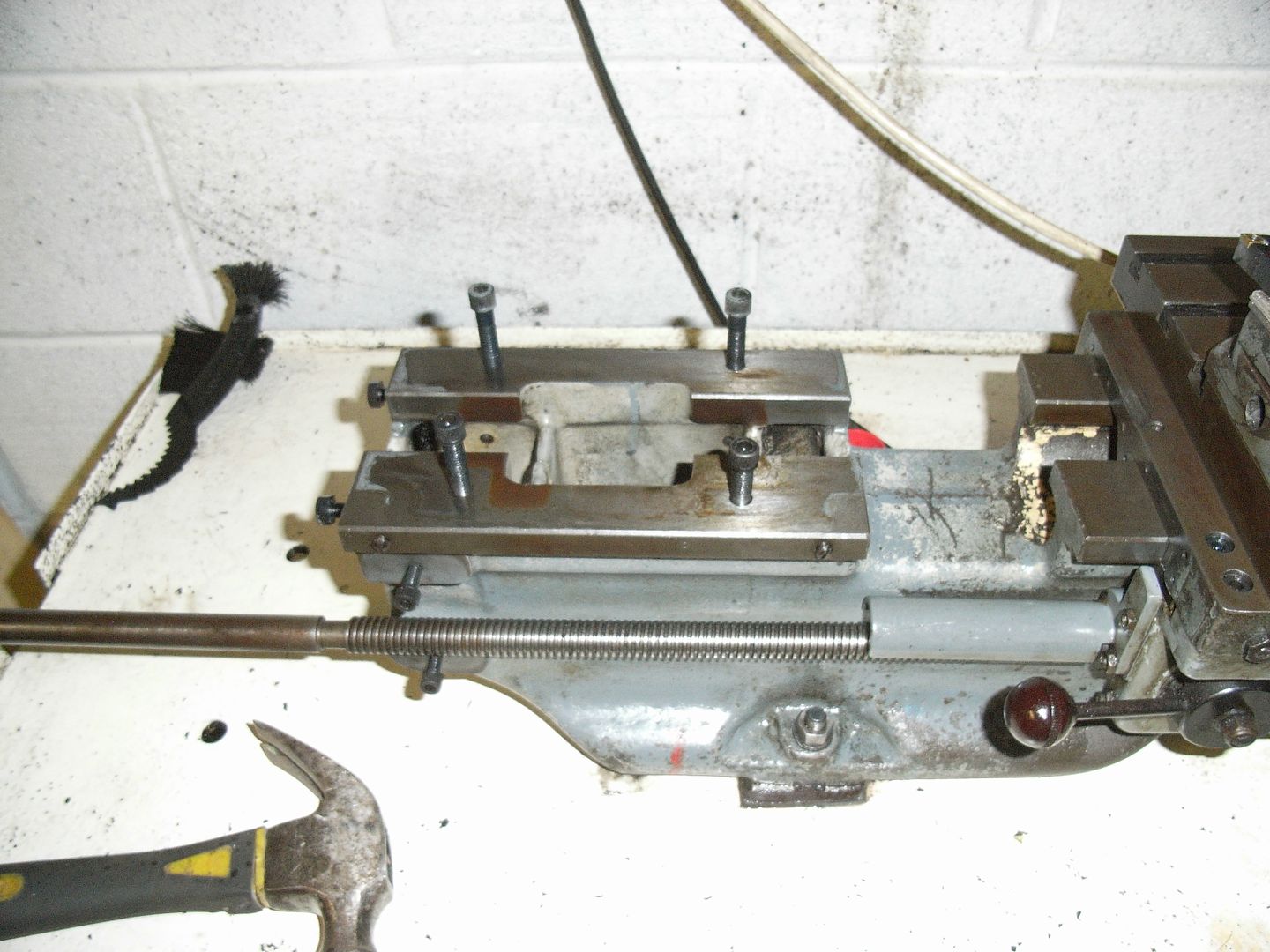

Not really had chance to do much on the morris for a while. I've been doing a fair bit of work on working out what i'm going to do pedal wise. It is very tight around the footwell. Still, having made some models i think there is just about enough room width and length wise to get it all in.  The grey box is showing the space envelope for the pedal area. This is fixed by the bulkhead and gearbox tunnel. Doable, but wont be able to drive in boots though....  This is the start of the actual assembly to be made (the other is a rough mockup). I may have got a bit carried away with it as all the pedals presently feature roller bearings in them... Apart from that i've welded in the roof cross braces and made up the harness bar.... but forgot to take any pics. I was using the lathe to make up some bobbins for a removable front cross brace and the power tripped off. After doing some investigation it turned out one of the windings has failed and iscauing a earth leak. Que new motor... This turned up and I decided that i may as well replace the belt at the same time as they're all looking a bit worn. When setting up to do this I noticed how filthy the lathe was (i hadnt cleaned it fully after the last owner used it to machine some wood)so decided to give it a bit of a once over..... I may have got carried away.....         Turns out that its all in pretty good order. A small amount of wear is starting on the main shaft bearing, but its only minor and there's no movement on it. The other bearing are pretty good too. Today i should have been doing more, but having been out last night my productivity has been very low. |

| |

|

|

|

|

|

Dec 19, 2013 17:46:57 GMT

|

|

A really interesting project, and the chassis construction is typical of your usual high standard.

With a full donor car as well as the other parts, have you settled on an MX5 drivetrain as well as its suspension parts now?

That might not be a bad idea, as a larger engine with a proportionally larger clutch/ flywheel and gearbox may have left even less footwell space in such a small car.

With the position of the cage tubes, I was wondering if you have allowed for a small roof chop there too? It is a bit too late now, but if the arches need widening as well and a new shorter screen is needed it might have been a possibility to widen the whole car by, say, 4 or 6 inches to give a bit more internal space?

It sounds like you have become a little bit too attached to the 'donor' car? I once bought a 'structurally scrap' early manual SD1 V8 just for its drivetrain and ended up repairing it and using it as my daily driver for more than four years!

I think some nice banded steel wheels would look very good on this car to help preserve an original appearance.

It will be nice to see it continuing to make steady progress.... even if life often gets in the way for many of us these days.

|

| |

|

|

v8ian

Posted a lot

Posts: 3,832

|

|

Dec 19, 2013 18:06:41 GMT

|

|

I'm liking this, I wonder which is going to be lower, Your 8, or My 7

|

| |

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

|

|