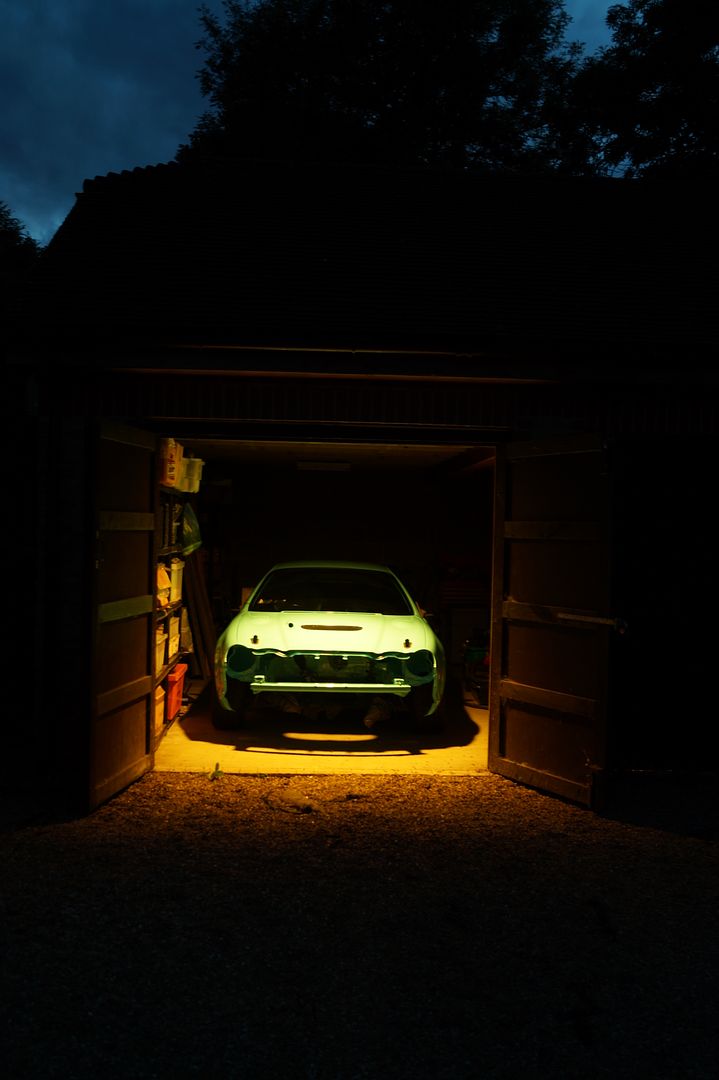

Ok, well I got home this weekend rather than staying away and it turned into a rather productive one

It was a savage week up to this point, I did two days at the Climatic Wind Tunnel for a client, working to sign off some new designs under very high load and temperatures. Got up at 4am and drove to the south coast then worked three ten hour days. By the end of the week I was shattered!

However there was time between things to order some bits from TCB, as usual they came up trumps and delivered everything I needed in double fast time with excellent packaging. I cannot recommend them highly enough!

The parts arrived and I opened my little present

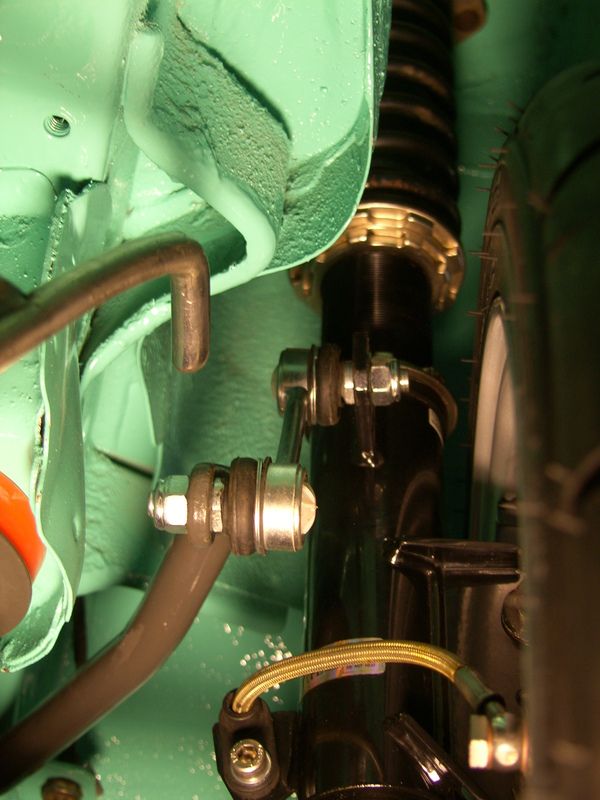

I got started, all new front brake lines, I do love working with OEM components especially Toyota parts, everything is so well resolved, with no loose ends left untied.

The Toyota lines are much more flexible than the braided items that were fitted, this means that the short length and high articulation is taken care of properly.

I also replaced the front drop links, that is the last of the bolt on items at the front. I just need some new calipers bolts and the wheels on, then it can be lowered to the ground

Also in the new package was a new fuel pump bracket, the old was was beyond repair at the top, frustrating because the portion inside the tank was literally in new condition. I will hold on to it for a while, if I need to go to upgraded lines I may be able to use it.

This bracket came with a new gasket, but all the others were NLA unless you buy the associated component. I did some research and came up with nitrile rubber bonded cork as the best solution, nitrile is oil and fuel resistant and the cork makes it very compliant. I cut the shapes out using a craft knife and scissors, then the bolt holes were popped out using a little bit of tube and a hammer.

It was fitted with all new bolts and washers

One little point of interest, did you know that washers have a way up? They are pressed out of sheet and so have a rounded side and a sharp side. It is detail parts like this that I love, every one on my car is put in rounded side up

All done and ready to fit

Whilst the sun was out, the girls came out and helped me to clean and wax the wheels, ready for valves and tyres over the coming week or two.

Before I fitted the tank, the little hose that goes between the hard lines needed cleaning up. I looked to get a new one, but at £55 quid it seemed like it should made from quality materials, so I gave it a go.

Came up alright!

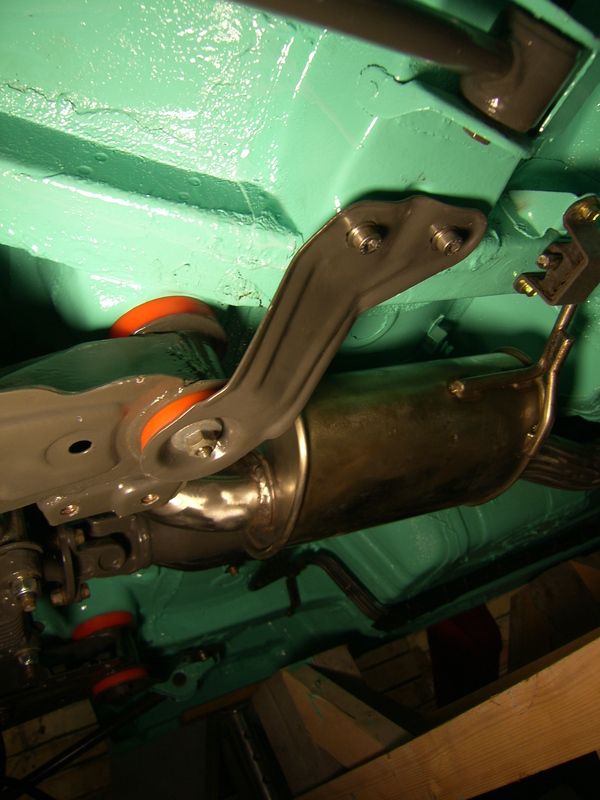

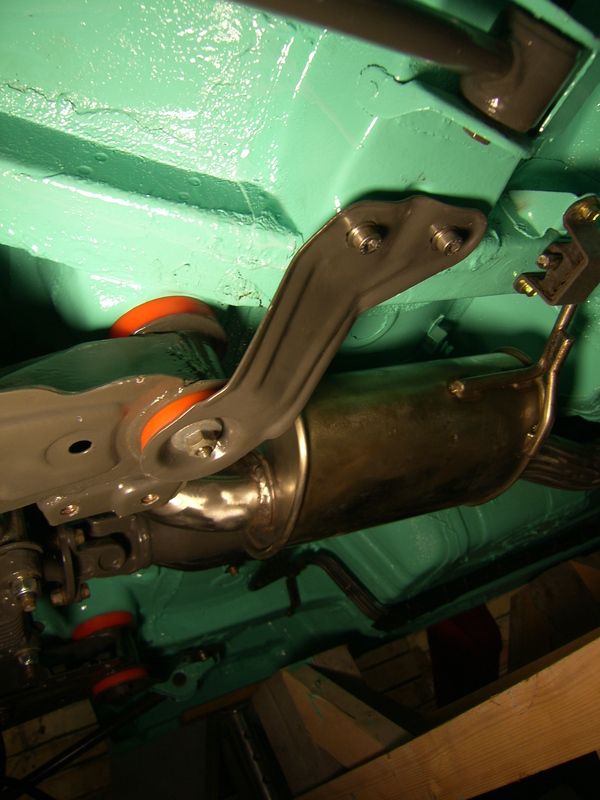

With the threads cleaned up on the hard lines under the car, it was fitted, along with the tank. This took ages to be honest, loads of faffing around to clean threads up, work out how the lines fitted and get all the bolts lined up.

Got there in the end though.

Finally ended finished up with putting on a couple more of the reinforcement parts on the rear subframe. You can see why these cars can take some abuse, talk about overbuilt.

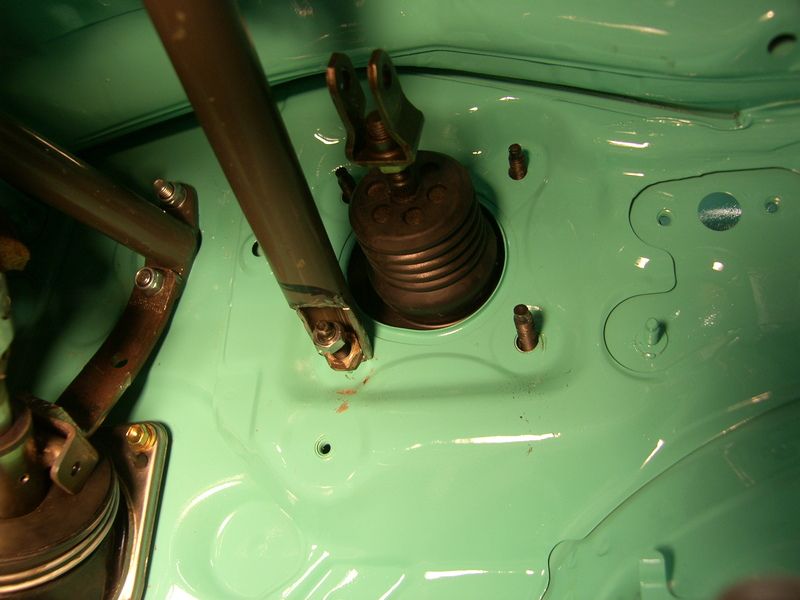

Finally a little look at one of the modifications that will make my life a little easier, and the reason I have not fitted a pump to the bracket yet

It was a savage week up to this point, I did two days at the Climatic Wind Tunnel for a client, working to sign off some new designs under very high load and temperatures. Got up at 4am and drove to the south coast then worked three ten hour days. By the end of the week I was shattered!

However there was time between things to order some bits from TCB, as usual they came up trumps and delivered everything I needed in double fast time with excellent packaging. I cannot recommend them highly enough!

The parts arrived and I opened my little present

I got started, all new front brake lines, I do love working with OEM components especially Toyota parts, everything is so well resolved, with no loose ends left untied.

The Toyota lines are much more flexible than the braided items that were fitted, this means that the short length and high articulation is taken care of properly.

I also replaced the front drop links, that is the last of the bolt on items at the front. I just need some new calipers bolts and the wheels on, then it can be lowered to the ground

Also in the new package was a new fuel pump bracket, the old was was beyond repair at the top, frustrating because the portion inside the tank was literally in new condition. I will hold on to it for a while, if I need to go to upgraded lines I may be able to use it.

This bracket came with a new gasket, but all the others were NLA unless you buy the associated component. I did some research and came up with nitrile rubber bonded cork as the best solution, nitrile is oil and fuel resistant and the cork makes it very compliant. I cut the shapes out using a craft knife and scissors, then the bolt holes were popped out using a little bit of tube and a hammer.

It was fitted with all new bolts and washers

One little point of interest, did you know that washers have a way up? They are pressed out of sheet and so have a rounded side and a sharp side. It is detail parts like this that I love, every one on my car is put in rounded side up

All done and ready to fit

Whilst the sun was out, the girls came out and helped me to clean and wax the wheels, ready for valves and tyres over the coming week or two.

Before I fitted the tank, the little hose that goes between the hard lines needed cleaning up. I looked to get a new one, but at £55 quid it seemed like it should made from quality materials, so I gave it a go.

Came up alright!

With the threads cleaned up on the hard lines under the car, it was fitted, along with the tank. This took ages to be honest, loads of faffing around to clean threads up, work out how the lines fitted and get all the bolts lined up.

Got there in the end though.

Finally ended finished up with putting on a couple more of the reinforcement parts on the rear subframe. You can see why these cars can take some abuse, talk about overbuilt.

Finally a little look at one of the modifications that will make my life a little easier, and the reason I have not fitted a pump to the bracket yet

[*]

[*] [*]

[*]

the rain ruined the finish. I did what I could and waited for today, when it would have hardened off enough to wet sand, my only hope at this point.

the rain ruined the finish. I did what I could and waited for today, when it would have hardened off enough to wet sand, my only hope at this point.