andyborris

Posted a lot

Freedom is just another word for nothing left to lose.

Freedom is just another word for nothing left to lose.

Posts: 2,218

|

|

Jan 23, 2012 19:30:50 GMT

|

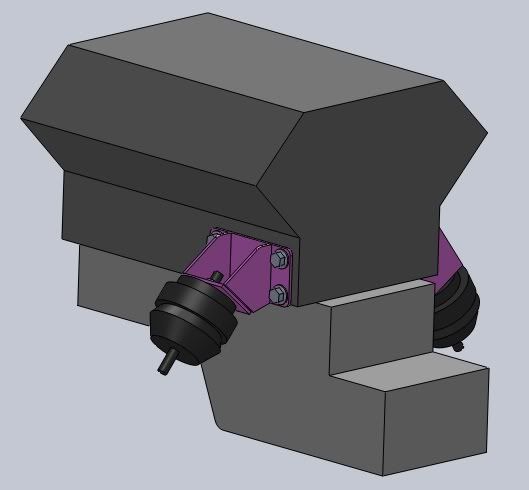

Got some ideas on the mounts for my engine swap, but would like to see others! So any non factory engine mounts please, esp. ones used in engine swaps. Thanks and as a reward take a couple of engine swap pics.   |

| |

|

|

|

|

Dez

Club Retro Rides Member

And I won't sit down. And I won't shut up. And most of all I will not grow up.

Posts: 11,790

Club RR Member Number: 34

|

|

Jan 23, 2012 19:49:20 GMT

|

|

|

| |

Last Edit: Jan 23, 2012 19:50:43 GMT by Dez

|

|

sphinx

Part of things

Posts: 219

|

|

Jan 23, 2012 19:55:27 GMT

|

|

Some nice work there Dez!

|

| |

|

|

|

|

|

Jan 23, 2012 20:00:29 GMT

|

|

Very impressed dez. You definitely have skills. Very inspirational

|

| |

|

|

andyborris

Posted a lot

Freedom is just another word for nothing left to lose.

Freedom is just another word for nothing left to lose.

Posts: 2,218

|

|

Jan 23, 2012 21:04:40 GMT

|

Thanks, interesting that these ones don't have a lot of bracing on them. I think maybe I'm trying to overbuild.........? |

| |

|

|

|

|

|

Jan 23, 2012 21:20:32 GMT

|

|

Thats not a engine mount Dez thats Pure Art.

|

| |

Peace,Max signature height = 80px

|

|

|

|

|

Jan 23, 2012 21:40:50 GMT

|

|

|

| |

Last Edit: Jan 23, 2012 21:42:47 GMT by Deleted

|

|

|

|

|

Jan 23, 2012 21:53:32 GMT

|

|

|

| |

|

|

fogey

Posted a lot

Posts: 1,620

|

|

Jan 23, 2012 22:46:23 GMT

|

|

|

| |

Last Edit: Jan 23, 2012 22:50:36 GMT by fogey

|

|

andyborris

Posted a lot

Freedom is just another word for nothing left to lose.

Freedom is just another word for nothing left to lose.

Posts: 2,218

|

|

Jan 24, 2012 14:14:32 GMT

|

It looks like the mount positions on the engine block will be level (or slightly lower)with my chassis rails. To my untrained eye, this looks wrong, it puts the stress into the wrong place, i.e. the bolts that go into the aluminum engine block? Mounts that angle down onto the chassis rails place the stress down through the arms and into the rails? I was hoping to use mounts like these  but fear that the stress from being mounted horizontal will damage something or worse, pull the bolts out of the block! Am I worrying about this too much? |

| |

Last Edit: Jan 24, 2012 14:15:44 GMT by andyborris

|

|

|

|

|

|

|

Jan 24, 2012 15:42:31 GMT

|

if that's what I think it is - that looks more like a steady-bar, to stop the engine rolling around as much. Usually used in conjunction with normal mounts, to increase the life of the engine mounts Here's mine - used to fit a FWD engine, in RWD layout   Nowhere near as pretty as Dez's (I think we can all say his work is amazing!) but it worked rather well  |

| |

You're like a crazy backyard genius! |

|

andyborris

Posted a lot

Freedom is just another word for nothing left to lose.

Freedom is just another word for nothing left to lose.

Posts: 2,218

|

|

Jan 24, 2012 16:16:30 GMT

|

|

|

| |

|

|

|

|

|

Jan 24, 2012 18:16:00 GMT

|

not gonna lie... this one looks RIDICULOUSLY weak!!!  with that style of mount holding up an engine, barely any of it is actually supporting the weight of the engine (like, maybe 1/4 of it?) so it'll destroy it within a rather short space of time |

| |

You're like a crazy backyard genius! |

|

Dez

Club Retro Rides Member

And I won't sit down. And I won't shut up. And most of all I will not grow up.

Posts: 11,790

Club RR Member Number: 34

|

|

Jan 24, 2012 18:42:14 GMT

|

|

either of those mounts are absolutely fine for a v8 (and that tube one looks like its on a SBC). you have to understand how the engine is trying to move to understand why. the flat plate one is actually much better than the tube one, itterms of the angles of the forces applied to it. as each cyl fires, the engine basically wants to kick to the opposite way to the other side of the engine bay, at the same angle as the cylinder- equal and opposite reaction and all that. as 99% of v8s, especially american ones are a 90deg vee, this means the force will be pushing down into the opposite chassis rail at a 45deg angle. thats why if youre using bobbin mounts, they should be at 45degrees rather than straight (like the ones I posted third from last pic up there^) so they actually work mostly in compression, rather than the engine trying to pull or twist them about.

the other factor is the torque of the engine will basically try to twist it out of the car radially as you lay the power down- compressing one mount and pulling on the other. this is where the tube one above could do with some triangulation, as a plain pipe that long could potentially bend, whereas the flat plate one is already trangulated in the right direction.

so on the flat plate mount above, the forces involved only travel through the plane of the flat piece of steel- there is no fore-aft movement whatsoever on this mount. an engine actually trys to move front to back very little on its mounts, and even then it only really treid to do it if its tried going a different direction first and been denied. the fore-aft movement is taken car of solely by the gearbox tailshaft mount on most american v8s- indeed, a lot of em specifically designed to be able to rock side to side here, but not backwards and forwards. earlier engines like Y-blocks (a favourite of mine) actually had twin 45-degree bellhousing mounts, and then only a single mount at the front under the pulley. it doesnt matter either way, it still works the same.

granted, with enough horsepower you could maybe bend one- but were talking high hundreds if not thousands, and by that point you'd have already gone to motor plates anyway like marks car up above, cos no rubber mount can take that kind of power reliably. and a motor plate is just that- a flat plate, with no triangulation as you can see.

engine mounts on a inline engine are a different kettle of fish though, as the two forces (cylinder opposition and radial torque) are always in different directions- downwards for the opposition if its mounted upright, or just opposed to the slant if its mounted at an angle, but then the torque will always be radial.

car manufacturers used to like to use horizontal mounts, often with an extra steady-bar at the top of the engine(like in a mini for example) but quite a few also use the 'best compromise with least amount of parts' method of going for 45degs to handle the torque and relying on both engine mounts being in good order to handle the opposition.

|

| |

Last Edit: Jan 24, 2012 18:54:04 GMT by Dez

|

|

andyborris

Posted a lot

Freedom is just another word for nothing left to lose.

Freedom is just another word for nothing left to lose.

Posts: 2,218

|

|

Jan 24, 2012 19:04:58 GMT

|

|

So a inclined BMW 6 cylinder engine will try to "stand up straight" as it fires and the torque will try to twist the engine around in the engine bay?

Or have I misunderstood?

|

| |

|

|

andyborris

Posted a lot

Freedom is just another word for nothing left to lose.

Freedom is just another word for nothing left to lose.

Posts: 2,218

|

|

Jan 24, 2012 19:10:08 GMT

|

|

Re-read and I have got it wrong!

My BMW inclined 6 will try to stand up as it fires, but the torque will try to to turn it the other way?

Pistons go down at angle, which makes the engine want twist upright, but the torque reaction is in the opposite direction?

|

| |

|

|

RobinJI

Posted a lot

"Driven by the irony that only being shackled to the road could ever I be free"

"Driven by the irony that only being shackled to the road could ever I be free"

Posts: 2,995

|

|

Jan 24, 2012 22:48:59 GMT

|

|

Dez, there is no force placed on the engine mounts directly from the firing of the cylinders as you describe. You said it your self, equal and opposite forces, for every newton put into the piston CROWN, pushing the engine down, an equal amount of force is placed on the cylinder head's combustion chamber, pushing the engine up. The forces cancel out and place all the force into tension in the cylinder head bolts as well as moving the piston, which creates the torque. If what you say was true, then if you ran an inline engine upside down it would try and take off, and BMW motorbikes with all 4 cylinders firing horizontally in the same direction would try and slide sideways as you accelerated.

There will be a very high frequency force in the direction you describe, caused by the piston, gudgeon and little ends acceleration, but these again equal each other out on average, and on most engines almost cancel each other instantaneously. (eg, in a 4 pot you've got 2 pistons accelerating downwards and 2 upwards, but the swing of the conrod creates higher acceleration at TDC than BDC, so they're not quite even.) These are only a relatively small vibration though.

It is just the engines weight, and the torque reaction, which in most cases will try and twist the block anti-clockwise (viewed from the front), so compress the left mount and pull on the right mount.

You're completely right of course about that flat mount being perfectly strong in the direction it actually has to deal with forces in though, (assuming the engine's got decent fore-aft location elseware) and the tube one not being ideal, but the mount design doesn't need to vary depending on engine's cylinder arrangement. The mounts tend to be angled for the exact reason you mentioned, the 'best compromise with least amount of parts'.

There is some concern about for-aft mounting though, think about under braking, with a sticky set of tyres it's not un-common to manage 1G of deceleration, that's the same force the engines weight normally places downwards on the mounts being placed on them trying to pull the engine out forwards. The same goes for rearwards force during acceleration in a drag car too.

|

| |

|

|

|

|

andyborris

Posted a lot

Freedom is just another word for nothing left to lose.

Freedom is just another word for nothing left to lose.

Posts: 2,218

|

|

Jan 26, 2012 12:09:04 GMT

|

|

Nice mounts, wish I had CAD skills!

I'll be chopping mine up with a grinder as I go!

Did they fit up to the original chassis mounts? Or did you have to add chassis mounts in a new position?

|

| |

|

|

|

|

|

Jan 26, 2012 14:01:57 GMT

|

Poor picture, sorry, but you can just see 'em.  Engine 'swap' pic comes free  |

| |

Last Edit: Jan 26, 2012 14:02:54 GMT by phillipm

|

|

|

|

but fear that the stress from being mounted horizontal will damage something or worse, pull the bolts out of the block!

but fear that the stress from being mounted horizontal will damage something or worse, pull the bolts out of the block!

[*]

[*]