|

|

|

Jan 18, 2012 19:06:17 GMT

|

|

As I'm quite new -Hi everyone.

I have a window louvre and was wondering what is the easiest/cheapest way to make up a mold to enable other louvres to be constructed.

any ideas ?

|

| |

|

|

|

|

RobinJI

Posted a lot

"Driven by the irony that only being shackled to the road could ever I be free"

"Driven by the irony that only being shackled to the road could ever I be free"

Posts: 2,995

|

|

Jan 18, 2012 19:19:42 GMT

|

|

I'd have thought that the easiest way would be to produce a fiberglass mould, although the shape of a louver may be a little intricate. Any pictures of it would help us give you some idea of the best way to go about it.

Oh, and welcome, with this talk of widow louvers and moulding it sounds like you'll fit right in here. ;D

|

| |

|

|

|

|

|

Jan 18, 2012 19:45:21 GMT

|

If it's particularly fiddly then thixotropic RTV for the mould and possibly two-part polyurethane resin for the copies with talc filler to bulk them out and make them less brittle. TOMPS have pretty reasonable prices for this sort of stuff, but depending on the size you'll be looking at probably £60 to get started. |

| |

|

|

sphinx

Part of things

Posts: 219

|

|

Jan 18, 2012 19:55:43 GMT

|

Self pimping here but check out my fiberglassing guide on my site: www.tckehoeonline.co.ukIf you do go down the fiberglass route then it may help you. |

| |

|

|

|

|

|

Jan 18, 2012 20:07:57 GMT

|

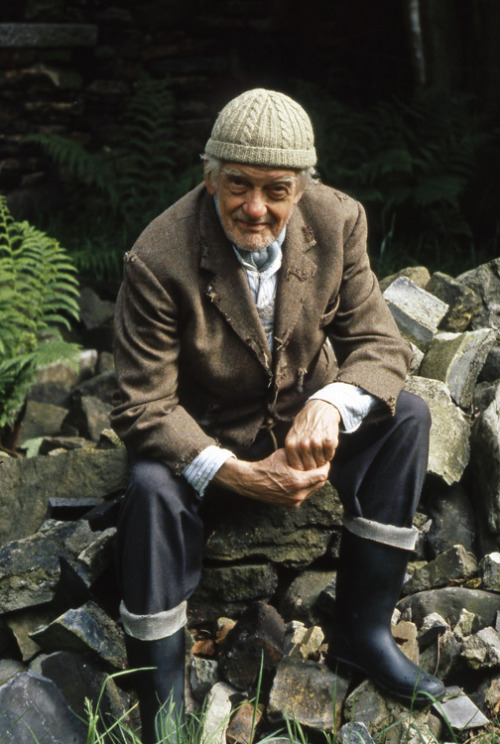

I'd have thought that the easiest way would be to produce a fiberglass mould, although the shape of a louver may be a little intricate. Any pictures of it would help us give you some idea of the best way to go about it. Oh, and welcome, with this talk of widow louvers and moulding it sounds like you'll fit right in here. ;D PIC...  stolen from other thread. If it's particularly fiddly then thixotropic RTV for the mould and possibly two-part polyurethane resin for the copies with talc filler to bulk them out and make them less brittle. TOMPS have pretty reasonable prices for this sort of stuff, but depending on the size you'll be looking at probably �60 to get started. Not sure about fibre glass, as you can see from the photo the louvre itself is only 2-3mm thick plastic/fibreglass- and making a mold with fibreglass..hmm it may not be flexible enough to hug the contours of original louvre. I'll look up thixotropic RTV and poly resin. I guess it needs somthing that will turn into a great big figure hugging rubber skin that could then be filled with resin. thanks Robinji and Calamity and Sphinx. and thanks for the welcome, I mess with old skodas n dubs so no stranger to the tech sections- just quite new on here. its a skoda rapid rear window louvre- so if in future i could get some made i know they are rare and i could get a few made for spares and swaps. |

| |

Last Edit: Jan 18, 2012 20:13:59 GMT by ambrose89

|

|

|

|

|

Jan 18, 2012 21:19:55 GMT

|

|

Sorry, I didn't read the OP properly and hadn't realized how big it was. That much RTV would cost quite a bit and I don't think powder filled polyurethane would be strong enough to support its own weight on something that size. An RTV mould might work ok for fibreglass, I've not tried it.

|

| |

|

|

RobinJI

Posted a lot

"Driven by the irony that only being shackled to the road could ever I be free"

"Driven by the irony that only being shackled to the road could ever I be free"

Posts: 2,995

|

|

Jan 18, 2012 22:17:03 GMT

|

|

It would be possible to do that in traditional fiberglass, both the mould and product, but it would be far from easy, not ideal for a first project, but possible.

|

| |

|

|

|

|

|

Jan 18, 2012 22:20:08 GMT

|

|

That would be seriously horrid to try and do in grp - it looks vacc formed originally.

Hand molded grp does not lend itself to sharp corners or intricate detail.

It's too big for a flexible mold.

Spray lamination may work but the kit is £££'s

If it was me, i'd mold the surround only, then carve a simpler smoother shape out of builders foam then mold over with tissue.

|

| |

'83 GTM Coupe. 4A-GE Powered

'00 GTM Libra Auto. Ick.

'71 Detomaso Pantera. Current Resto

'89 GMC Safari Tow/Kip bus

'05 SAAB 9-3 Daily

'71 Siva Moonbug. Not even contemplating resto yet.

|

|

|

|

|

Jan 18, 2012 22:36:07 GMT

|

|

yeah, I'm puzzled as to how to go about it, I'd be looking at getting it professionally done. I thought vacuum. wonder if you could push it into clay/wet sand/foam and layer up the impression with a spray then layer and trim/cut holes?

|

| |

|

|

|

|

|

Jan 18, 2012 22:39:09 GMT

|

I could recoup the costs by selling a couple, on skoda rapid forums. this is the skoda variant  |

| |

Last Edit: Jan 18, 2012 22:45:36 GMT by ambrose89

|

|

|

|

mikeymk

Part of things

'85 Polo Coupe S 1.6 16v

'85 Polo Coupe S 1.6 16v

Posts: 931

|

|

|

|

|

Vacuum molding, that. And there's your answer - fill the inside with fibreglass to replecate the original mold, then create more vacuum forms that way, should be as good as that one once you've cut the slats out.

Means finding a vacuum molder to do it - much as it'd be nice to have one in your garage, i bet you haven't..

|

| |

|

|

|

|

|

Jan 21, 2012 13:34:02 GMT

|

|

Alternatively find the original manufacturer and ask if they still have the moulds to produce further copies ?

Paul h

|

| |

|

|

|

|

|

Jan 24, 2012 19:42:36 GMT

|

|

Hi ambrose89. I'm also new to Retro Rides, I have been looking for a rear window louvre for my Rapid for ages. If you manage to get some done i would definately be interested. Good luck!

|

| |

|

|

RobinJI

Posted a lot

"Driven by the irony that only being shackled to the road could ever I be free"

"Driven by the irony that only being shackled to the road could ever I be free"

Posts: 2,995

|

|

|

|

|

For the production numbers you're talking about I really would say fiberglass is likely to be the best option. OK it's not the easiest of shapes, but it is 100% possible, it would even be a single piece mould. People regularly do a lot fiddlier shapes, I've done a couple of sets of small wheel arch louvers with a pretty decent success rate and they're a much more intricate shape. Even if you ballsed up a couple I expect it would still be cheaper than trying to do it any other way unless you're able to call in some big favors.

|

| |

|

|

mattestelle120

Club Retro Rides Member

oooooo shiney i must have

Posts: 390

Club RR Member Number: 27

|

molding - how?mattestelle120

@mattestelle120

Club Retro Rides Member 27

|

Apr 16, 2012 18:12:32 GMT

|

|

I want one for an Estelle :-)

|

| |

|

|

|

|

|

Apr 29, 2012 17:53:15 GMT

|

As said previously, it could be done in fibreglass but its far from easy! The way i would do it is to have 2 moulds, male and female. Gel and lay-up the outer part(female) as normal, then while its still wet, slide in the male mould. This way you`ll get a nice smooth finish on both sides and you shouldnt get any air in it. I made some side vents this way for a Porsche Spyder replica, and also the slats on a Ferrari Testerossa kit, while it was still on the car!!(but i wont go into that!!  ) Hope this helps  |

| |

|

|

stolen from other thread.

stolen from other thread.

) Hope this helps

) Hope this helps