So had this little job fall into my lap, family car bought a few years ago as a cheap runaround, galactic miles and a 4 door mean the price was very keen and it was astoundingly original. All factory hardware and all original paint, quite rare to find one so straight for so cheap.

used for two years or so as a daily driver without a single issue, then we had a rocker failure, stranding my brother on the m25 for a few hours late at night...

Head was rebuilt with new parts and it was motoring again, then we got the horrible sign of mayonnaise death. blast. so assumed headgasket failure we decided it'd be more kind to the car to replace the whole 200k engine with a lower mileage donor, straight swap should've been the easiest solution.

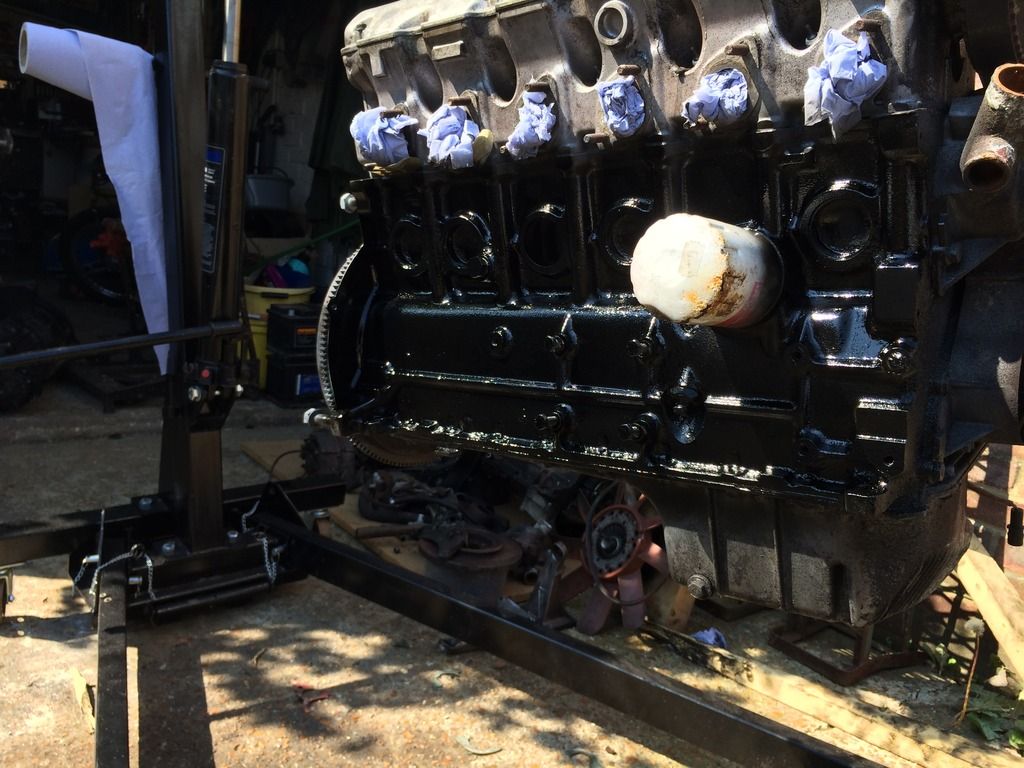

The dying engine getting ready to be removed

and the bonnet removed for easier work

Little stuff off first (amp not standard equipment!)

And the transplant organs arrive!

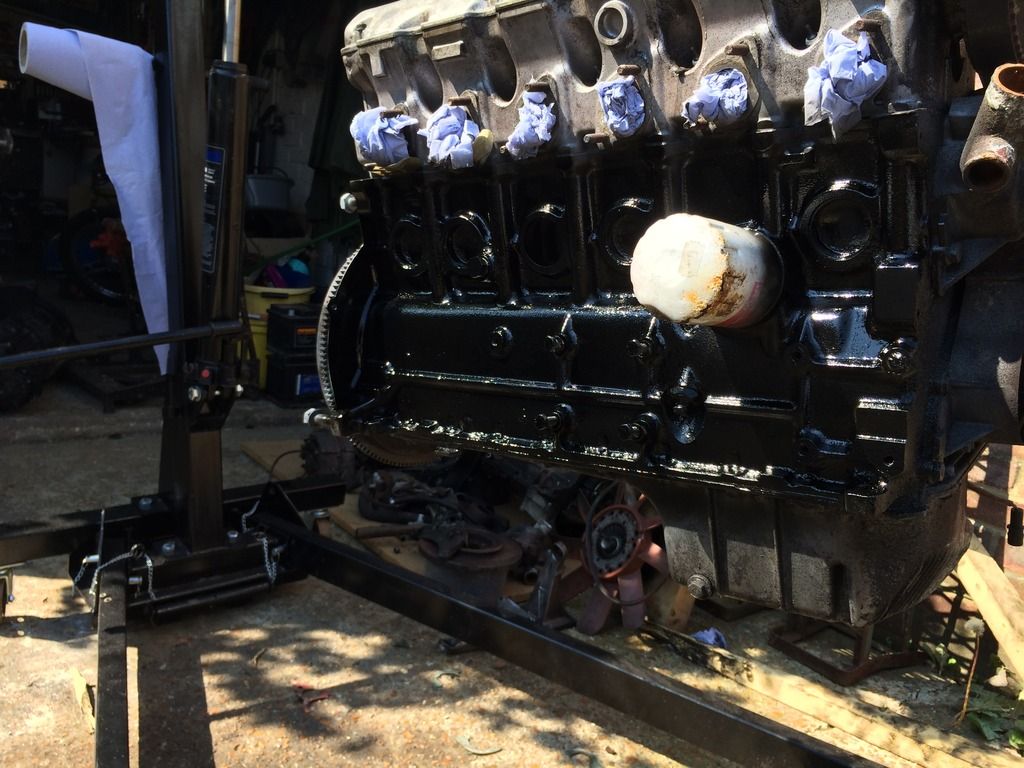

So as the story goes it's an early 2.3 with a very small port head (yuck) distributor ignition, covered about 50k miles before being rebuilt (checks out after looking inside) and after covering about 1000 miles it got swapped out for a bigger engine and sat in the garage for 6 years. at which point we snapped it up as a donor block.

Borrowed a mates engine crane

Stripped back a little more you can see the filth that was lurking just under the surface

Wiring loom removed and a fight with the injector plug later it's out!

Grim

So i started by stripping off the ancillaries on the new motor, got it down to a basic block and head

Fought the box off the old engine

Cleaned and painted the new engine

cleaned up the pulleys and cam belt covers

Whipped the bumpers off to get them painted as i'm not a fan of the black plastic

Struggled to get the distributor blank out of the old block, turns out it was just jammed in with years of crud!

Bit more tarting on the new engine and a new water pump installed

intake cleaned and painted

injector rail cleaned and rebuilt

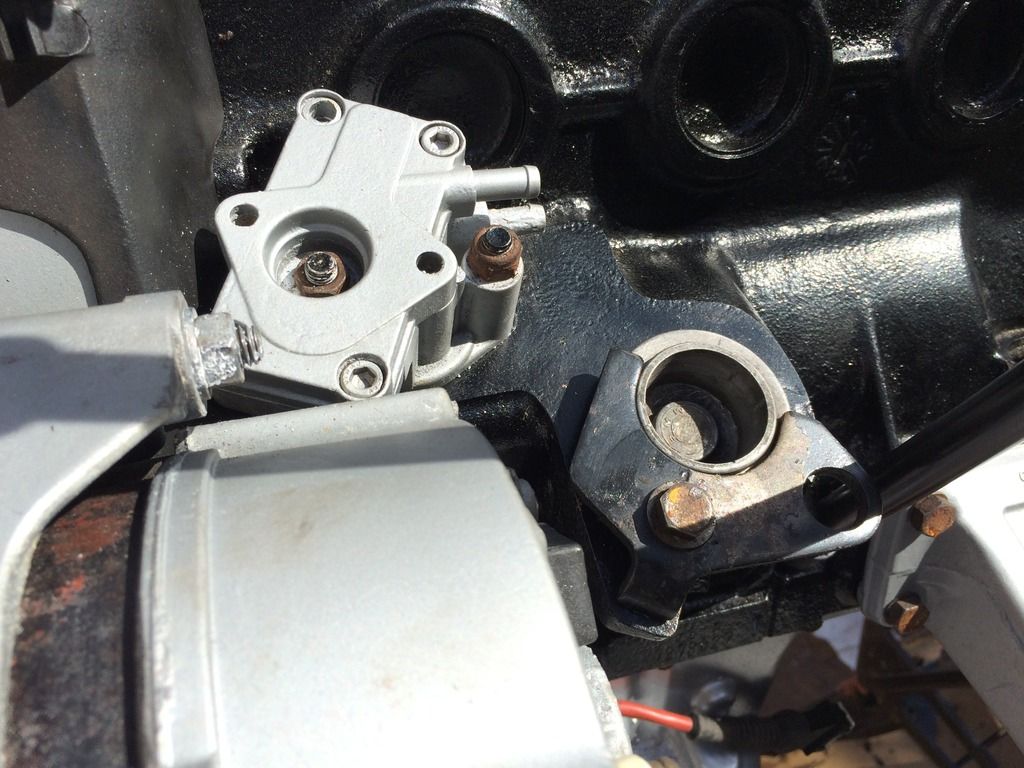

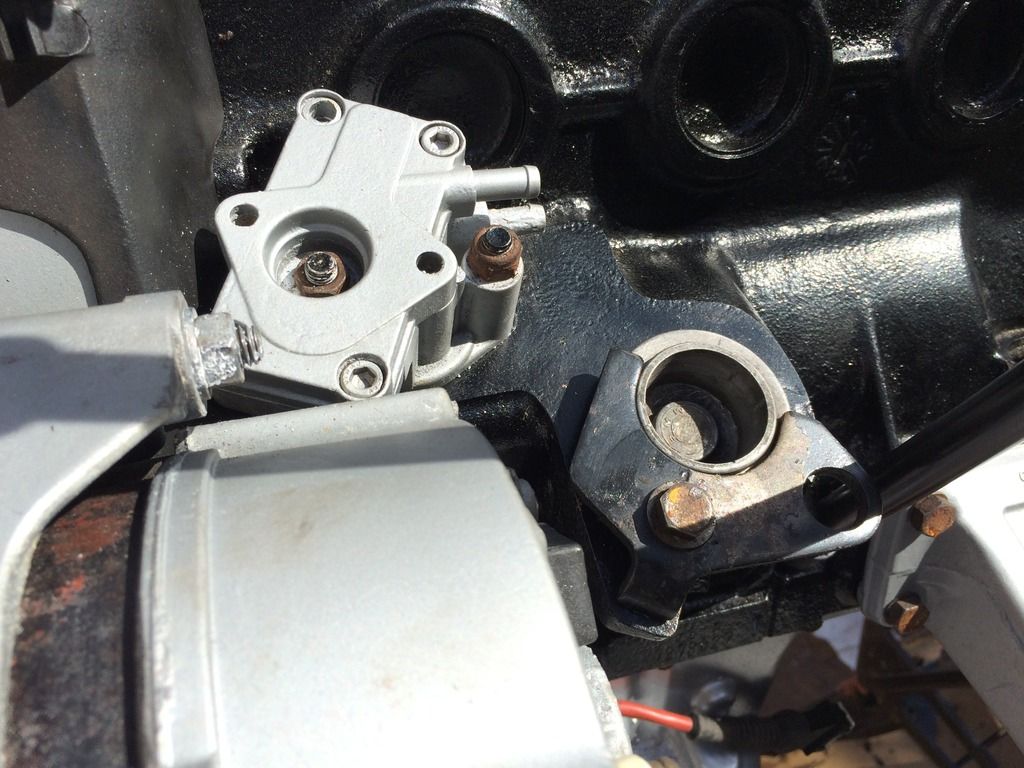

Not really sure what the little water block on the side is there for but we had to refit it to block of the hole into the crankcase, no moving parts inside so it was just aesthetic

Starting to look the part

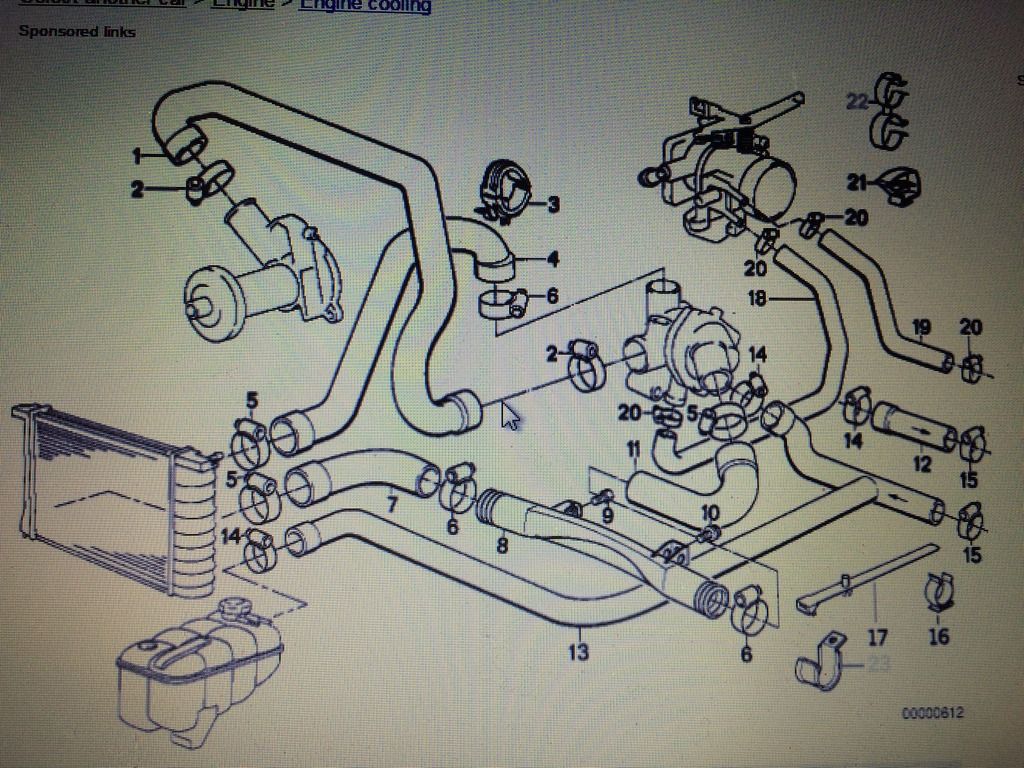

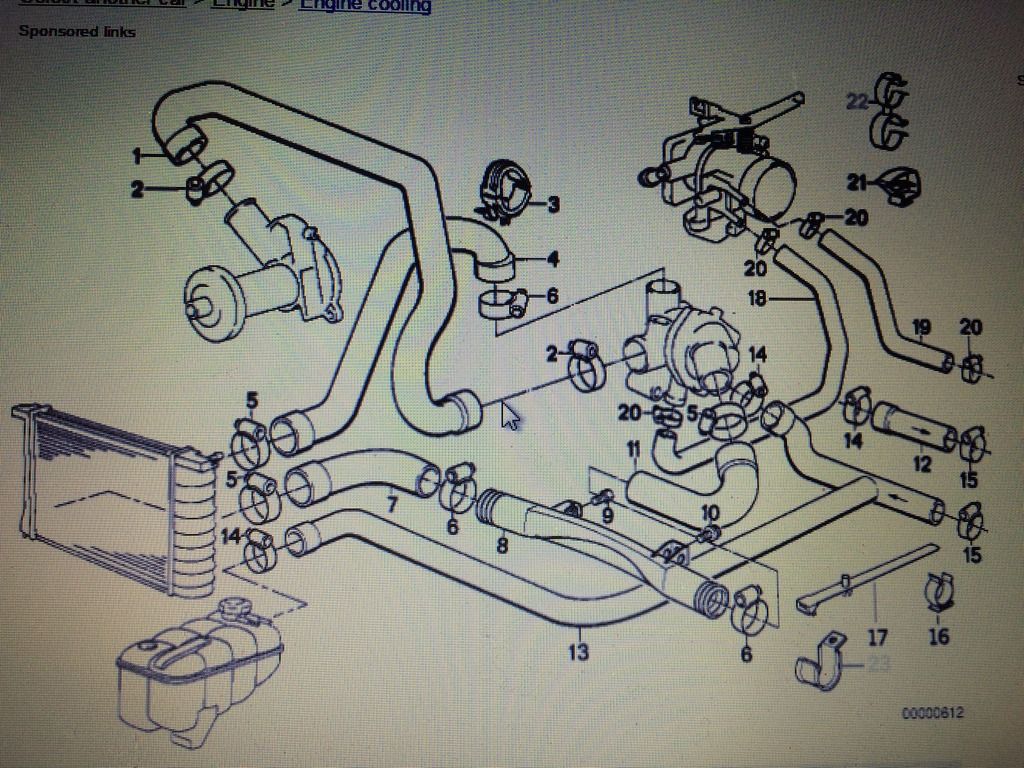

Had to check the coolant pipe routing as i'd forgotten the location of most of the pipes!

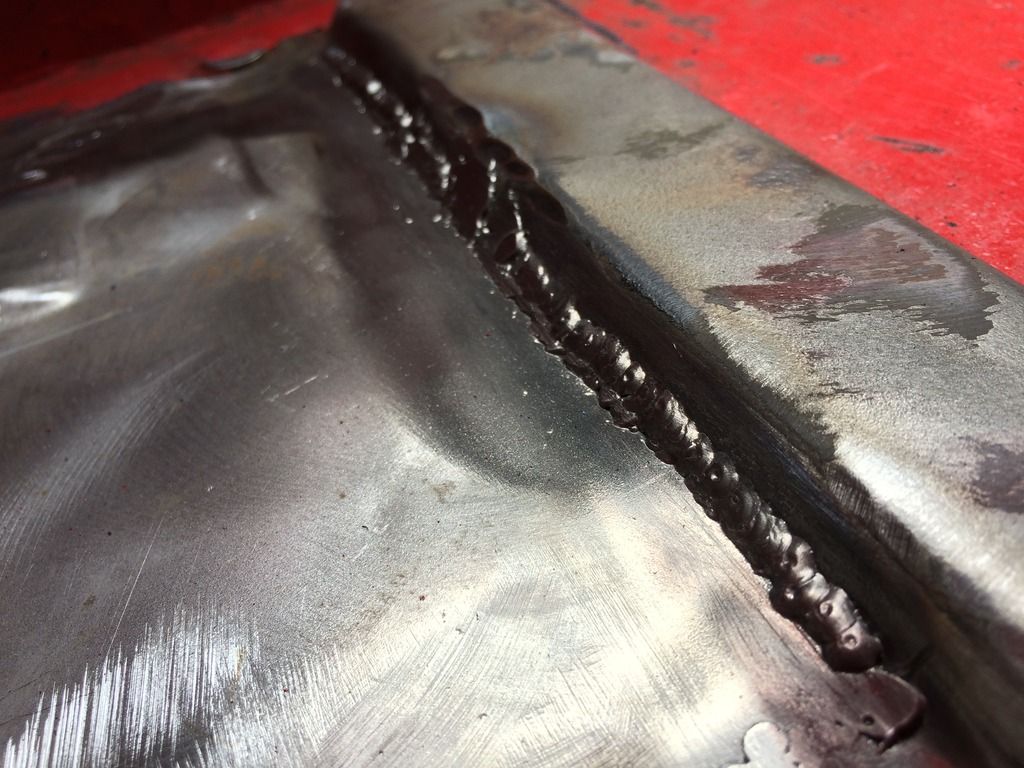

Bit of welding needed in the engine bay where a brake pipe mount had collected water and rotted through, as a side note bmw seemed to love their seam sealer haha

Painted bumpers go back on

used for two years or so as a daily driver without a single issue, then we had a rocker failure, stranding my brother on the m25 for a few hours late at night...

Head was rebuilt with new parts and it was motoring again, then we got the horrible sign of mayonnaise death. blast. so assumed headgasket failure we decided it'd be more kind to the car to replace the whole 200k engine with a lower mileage donor, straight swap should've been the easiest solution.

The dying engine getting ready to be removed

and the bonnet removed for easier work

Little stuff off first (amp not standard equipment!)

And the transplant organs arrive!

So as the story goes it's an early 2.3 with a very small port head (yuck) distributor ignition, covered about 50k miles before being rebuilt (checks out after looking inside) and after covering about 1000 miles it got swapped out for a bigger engine and sat in the garage for 6 years. at which point we snapped it up as a donor block.

Borrowed a mates engine crane

Stripped back a little more you can see the filth that was lurking just under the surface

Wiring loom removed and a fight with the injector plug later it's out!

Grim

So i started by stripping off the ancillaries on the new motor, got it down to a basic block and head

Fought the box off the old engine

Cleaned and painted the new engine

cleaned up the pulleys and cam belt covers

Whipped the bumpers off to get them painted as i'm not a fan of the black plastic

Struggled to get the distributor blank out of the old block, turns out it was just jammed in with years of crud!

Bit more tarting on the new engine and a new water pump installed

intake cleaned and painted

injector rail cleaned and rebuilt

Not really sure what the little water block on the side is there for but we had to refit it to block of the hole into the crankcase, no moving parts inside so it was just aesthetic

Starting to look the part

Had to check the coolant pipe routing as i'd forgotten the location of most of the pipes!

Bit of welding needed in the engine bay where a brake pipe mount had collected water and rotted through, as a side note bmw seemed to love their seam sealer haha

Painted bumpers go back on