|

|

|

|

|

Started on adjusting the roof to fit the door openings and the door gaps  Brain started to hurt trying to work out the best way to cut.  Gave up and attacked with the wheel of death  Turned out pretty well.  In the process of blending in.  Did the same on the driver's side but had to also take into account the wide door gap at the top. Use the same method and it worked out pretty well.   |

| |

Last Edit: Apr 9, 2020 8:08:50 GMT by nalesutol

|

|

|

|

|

|

|

|

|

Looking good! Alas I've come up to the poor fitment of fibreglass panels too now. The rear boot on my Spitfire has too shallow a curve on it so the middle ducks down below the level of the deck panel. Here's hoping that's the fibreglass one like it looks like, and not your new carbon one in disguise! Oh, and any luck on the wind tunnel? Still looking forward to seeing that in action  Thanks Yeah, aftermarket panels never seem to fit properly or are rather flimsy due to cost cutting. The hood is an original Lenham Top. It is worth a fair bit but I am still going to cut it up to make it fit :-) Once I am happy with the fit I can take a mould from it so I can produce the carbon version. I now have all the sensors for the tunnel but it has been put on the backburner while I get on with the doors and roof. Once they are out of the way I plan to get back to it. It should take more than a couple of days to complete. |

| |

|

|

|

|

|

|

|

Is the roof overhang uneven due to the roof, or the car being built wonky? Liking the remanufacturing of the roof for a different rear screen fitment tho  One side of the car is 30mm longer than the other, either due to manufacturing tolerances or the crash damage sustained prior to me owning thew car. Actually, there should be an overhang, I have discovered, but I will be removing it entirely as I have changed the door/window configuration. A work in progress. Once the roof pattern is to my satisfaction I will take a mould from it and make the real thing in carbon. |

| |

|

|

|

|

|

|

|

|

|

| |

Last Edit: Apr 8, 2020 8:06:47 GMT by nalesutol

|

|

|

|

|

|

|

Started working on the carbon fibre roof on my Elan. I am using an old Lenham top as the pattern from which I can take a mould. However, and I have known this for a while, one side of the car is 30mm longer than the other side! So when offering up the top it overhangs the door openings. It overhangs both sides but more on the passenger side. I am going to have to butcher the top in order to line it up, plus a lot of other mods to accommodate the Lexan rear screen and flush mounted side windows. First job is to secure it to the body and then shape it to suit.    |

| |

Last Edit: Apr 6, 2020 15:09:33 GMT by nalesutol

|

|

|

|

|

|

|

Don't you just love Lotus' door gaps :-) The front isn't too bad, but as for the back......   |

| |

|

|

|

|

|

|

|

In contrast to a lot of man caves and garages (and car wings for that matter) I only exhibit posters and stickers from manufactures that I have used on the car. However, most of the parts have come from one supplier, the one at the bottom of this list :-)  |

| |

|

|

|

|

|

|

|

A two day job stretched into three, but the mould is now finally ready for eight coats of release agent. Hopefully tomorrow will see the application of carbon. The finish on the mould won't produce a perfect, glass like, appearance on the finished product but it will be perfect for my needs.  |

| |

|

|

|

|

|

|

|

|

Door carcass should end up weighing between 1.5 and 2kg.

AND they will probably sprout a few holes so as not to feel left out :-)

|

| |

Last Edit: Apr 4, 2020 19:17:23 GMT by nalesutol

|

|

|

|

|

|

|

I have been preparing an old bonnet so I can experiment with the paint system I plan to use. To this end I sanded the bonnet and sprayed it black using rattle cans so as to not waste the real base paint. So far so good. Today I was going to add the colour and clear coats. However, my compressor decided not to play ball and started blowing fuses whenever I tried to start it. The On/Off plunger won't stay off so I am hoping that this is the issue and ordered a new one from Machine Mart. Now what to do? Ah, yes, I still need to repair the door mould. Got stuck into this and realised that there were more repairs needed than I first thought, in fact it is a bit of a pig's ear. Oh, well, the sooner I get started the sooner it will be ready for carbon.   |

| |

Last Edit: Apr 2, 2020 20:32:13 GMT by nalesutol

|

|

|

|

|

Mar 26, 2020 19:35:08 GMT

|

Why does stuff always seem to slightly exceed storage, no matter how much of one you have? One of nature's laws, stuff always expands to fill the available space :-) |

| |

|

|

|

|

|

Mar 26, 2020 16:47:15 GMT

|

|

The evolution of the seats for the Elan. Standard seats are way too heavy :-)

|

| |

Last Edit: Mar 26, 2020 16:48:53 GMT by nalesutol

|

|

|

|

|

Mar 25, 2020 20:46:50 GMT

|

Still sorting out the garage by moving stuff from the old barn that the Elan was kept in. Running out of space so looking at adding storage in the shallow roof area. Using the roof struts from an old bread van body we are dismantling and window cutouts from wall cladding I have made a couple of areas for storage. Lighting needs to be adjusted.   |

| |

|

|

|

|

|

Mar 16, 2020 18:57:21 GMT

|

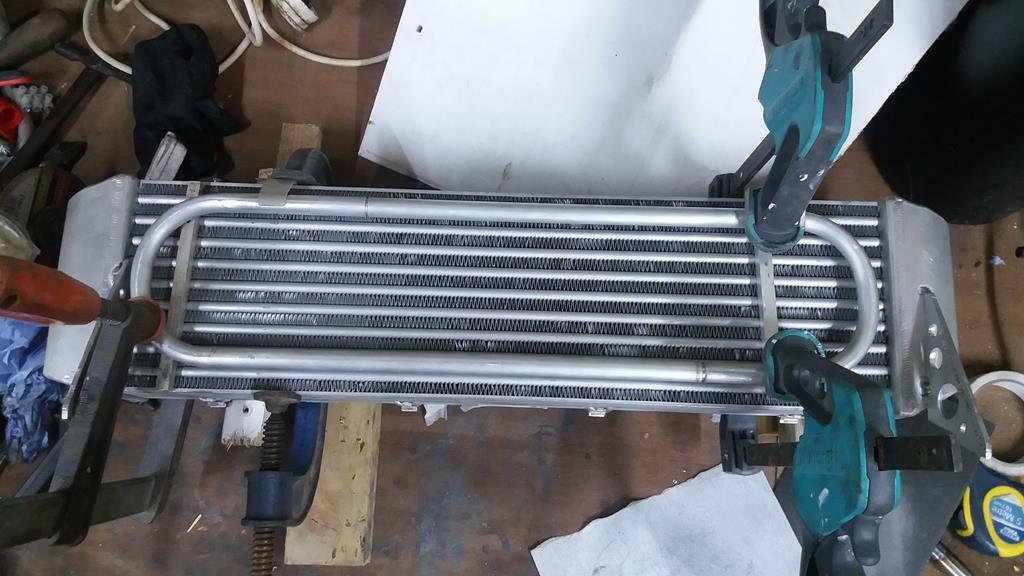

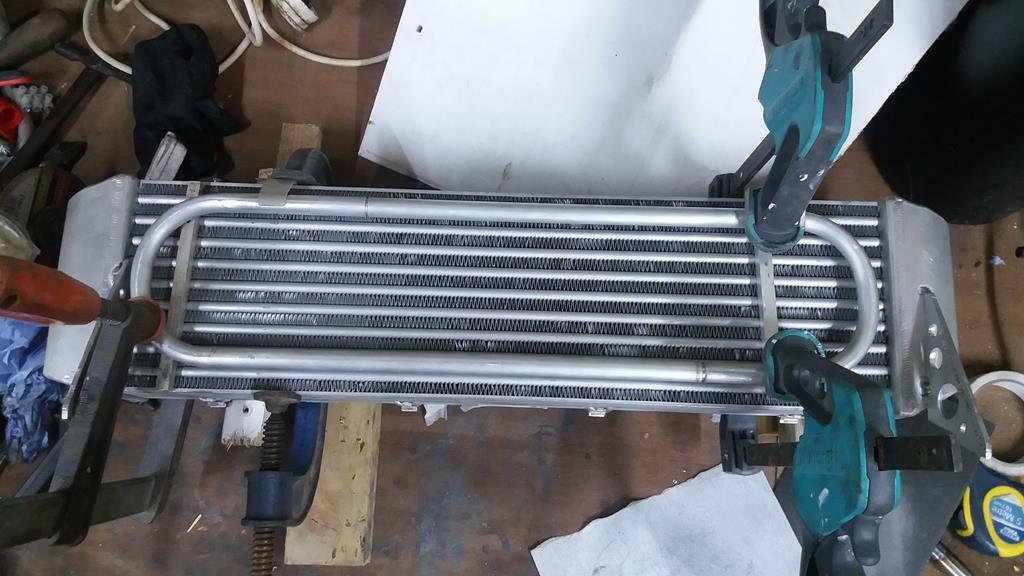

I doubt that very many of you will be at all surprised :-) Dimensions of intercooler dictated by available space rather than engine power requirements. Spray bar designed on CAD with holes (two rows) positioned (and drilled on the CNC Mill) so the whole of the intercooler is covered. Will use nitrous as that is already installed. Another part built not bought.  |

| |

|

|

|

|

|

|

|

|

I am now identifying as over 70 so that I can self isolate in the garage.

|

| |

|

|

|

|

|

Mar 14, 2020 22:19:38 GMT

|

well 5l of water weighs in at 5kg, plus the container and plumbing system. the weight gain probably wouldn't justify the "loss" in power from the cooling effect. just imagine how many more speed holes etc would be required for 5kg plus If I could remove another 5kg it would have already been removed :-) |

| |

Last Edit: Mar 15, 2020 7:28:58 GMT by nalesutol

|

|

|

|

|

Mar 14, 2020 22:17:56 GMT

|

Will you also have a water spray on the inter cooler? With water then gas spray it should have a huge temperature drop through it. No, adding water both adds extra weight and risks being pulled from the start line if the car dribbles on to the track (drag strip). |

| |

|

|

|

|

|

Mar 14, 2020 11:16:15 GMT

|

|

The reason for the intercooler cooler is that I am intercooler space restricted. Although the intercooler core is the best out there (wasn't cheap) apart from F1 spec It is still a little small. This cooler should make up for this. The coolant will be nitrous as this is already installed on the car.

|

| |

|

|

|

|

|

Mar 13, 2020 20:03:29 GMT

|

I recently got told off for posting too many videos, so I have reverted to the old fashioned still images :-) First bend worked fine but the next two sheared at one of the holes so I had a rethink. Ended up bending sans holes then drilling them by hand. Not as neat as CNC but they are hidden so no problem :-) There is a central spray bar still to be added. The holes have been angled so that the whole intercooler is covered.....hopefully.     |

| |

Last Edit: Mar 13, 2020 20:06:58 GMT by nalesutol

|

|

|

|

|

Mar 12, 2020 20:58:45 GMT

|

Noooo... not another thread going to video  It's been over 5 weeks - are you going to bother telling us the colour? No, just some things work better in video, like moving stuff :-) Err, no :-) You will have to wait for the reveal. Oooo, the tension :-) |

| |

Last Edit: Mar 12, 2020 20:59:36 GMT by nalesutol

|

|