Going back in time now.

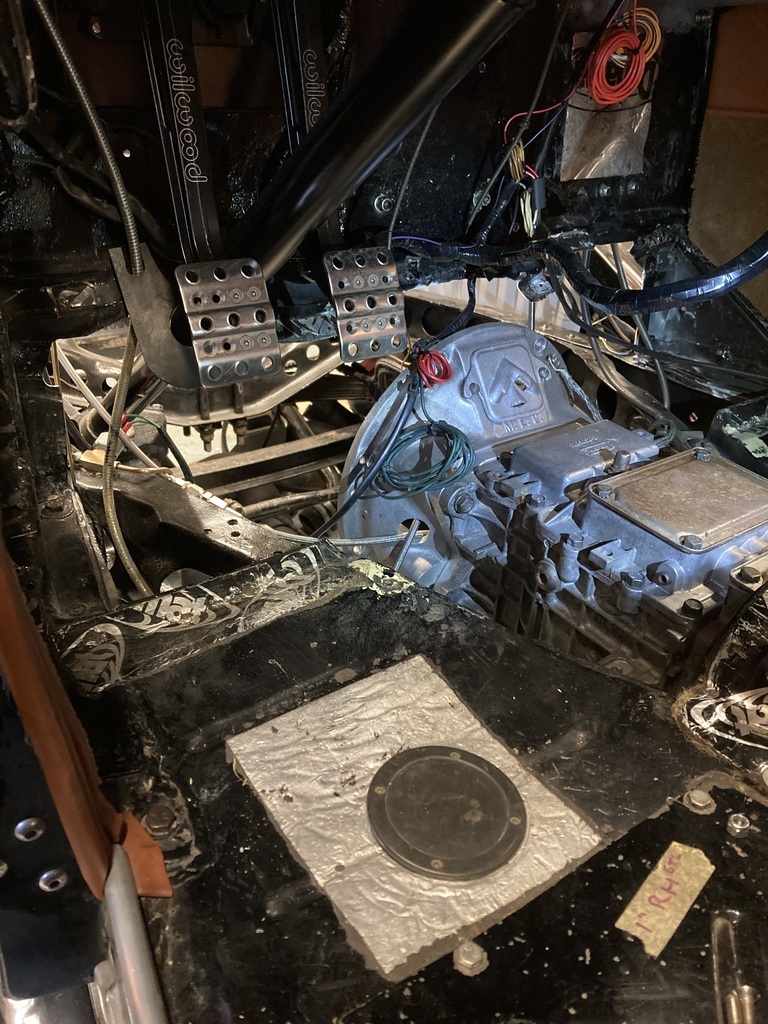

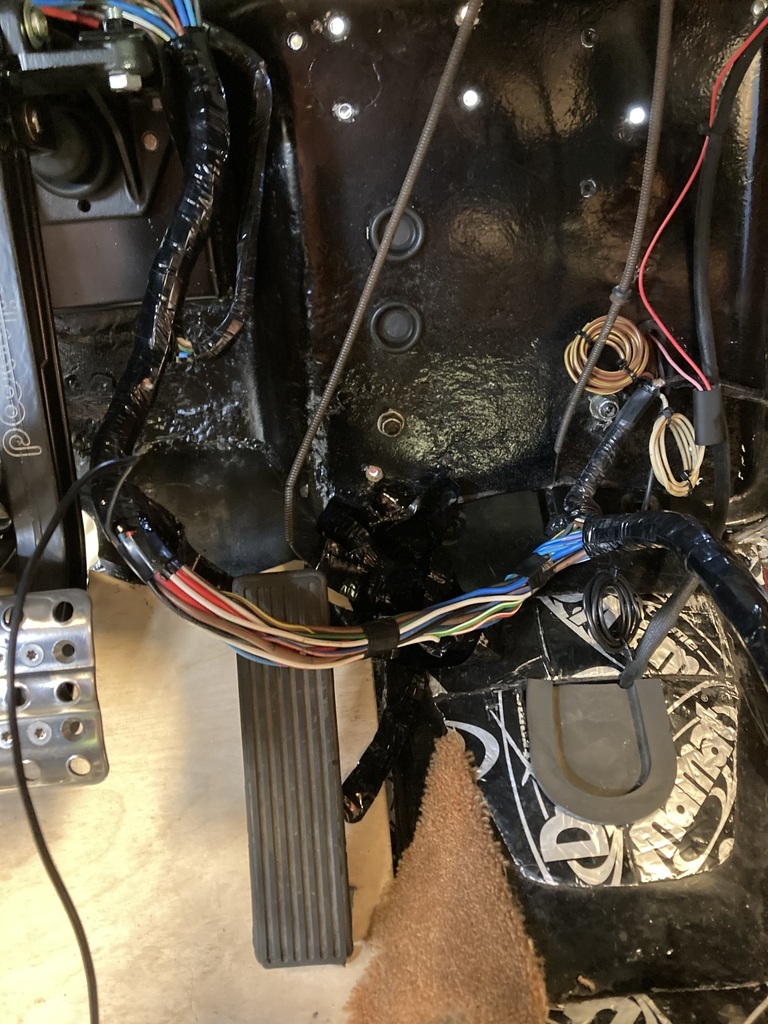

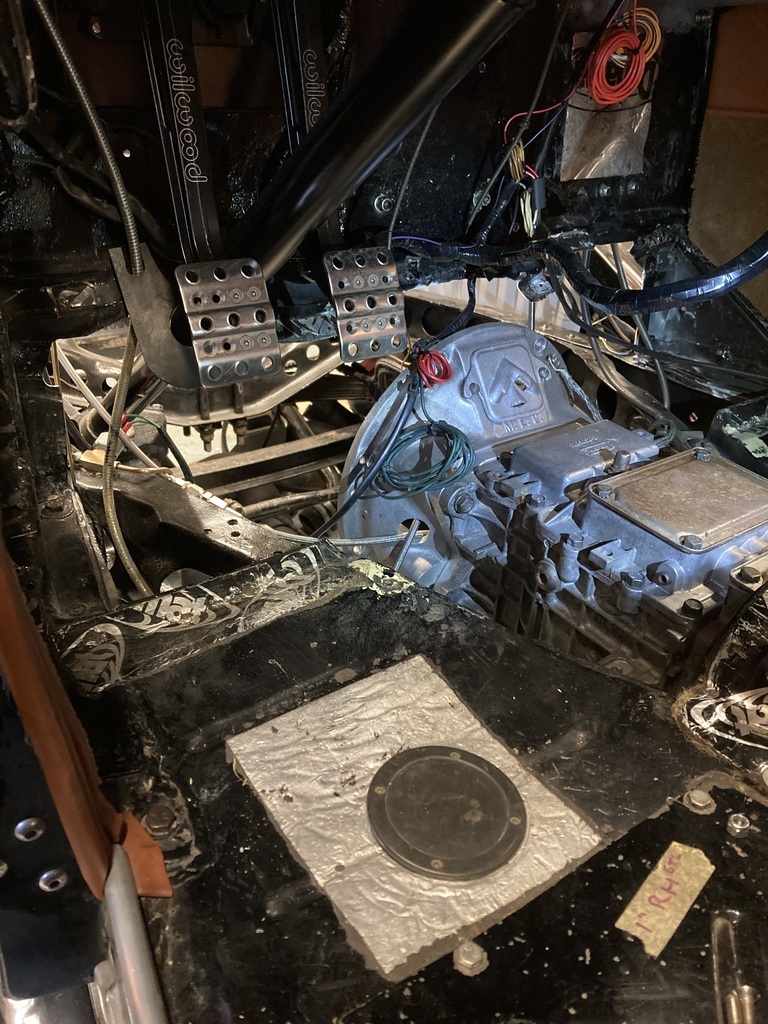

When I moved over to swing pedals and built the mounting box I was very conscious of having flex in the pedal mount which is all too easy to achieve as it’s easy to underestimate the leverage and forces being applied when you stamp on a brake pedal.

When I did the final buildup of the pedal mount I had a wobble that even though I’d made a good attempt at bracing things I’d only really braced the pedals to themself rather than to the car.

The pedals were fitted and time moved on. The brakes and clutch eventually got plumbed so the pedals now had a load behind them and the pedal mount flexed bad… really bad.

By this point the firewall and everything around it was finished and freshly painted.

I left it again for a period of time as I wasn’t really sure what to do with the situation.

Tackling the issue head on, I noticed the flexing wasn’t localised to the pedal mount but it was actually flexing the whole firewall across the car.

It then occurred to me that the firewall on these is actually quite a weak point as it isn’t a very well supported panel.

The firewall is only half depth and the floor is set back leaving a big hole between the two.

The hole is filled with a bolt-in trans tunnel and individual floor boards.

I bolted these floor panels in, probably for the first time since the pedal were fitted, just to see how much rigidity they added.

Well luckily quite a lot it seems as I’d say it took a good 80% of the flexing out.

Things weren’t as catastrophic as they first seemed but I still wanted it better.

The pedals still had this slight downward twist motion/flex that I wanted to eliminate completely.

I needed a brace or strut acting from above but this was the underside of the cowl so bolting or welding was out and I didn’t really want any more holes, mounts or complication under the dash either.

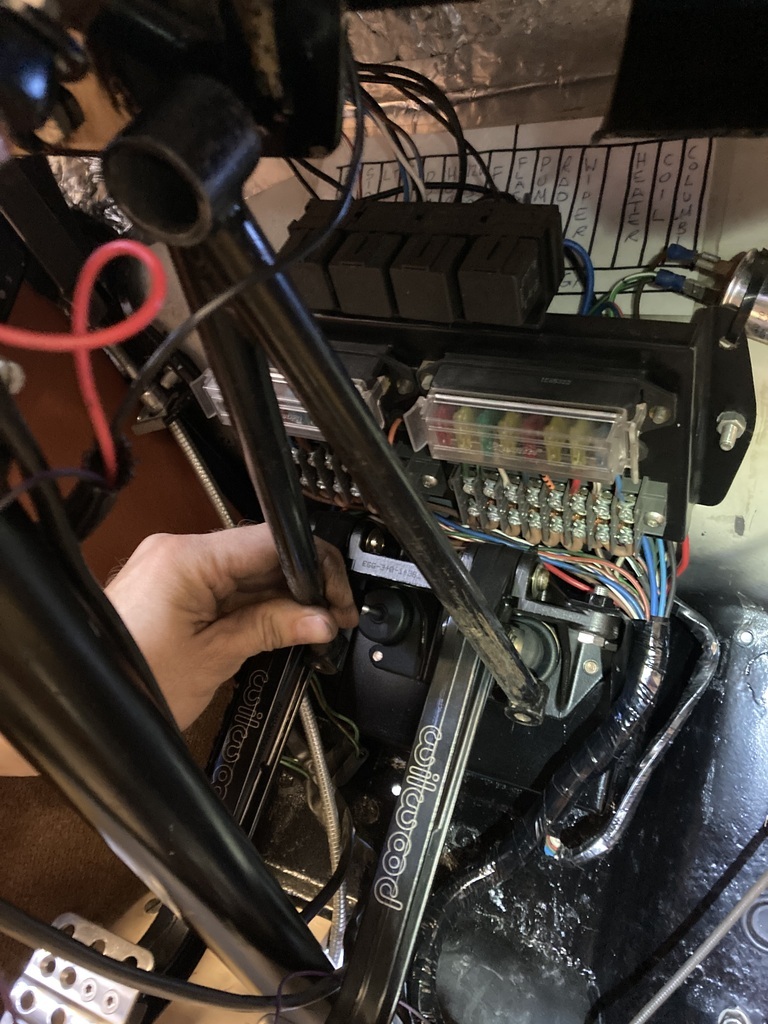

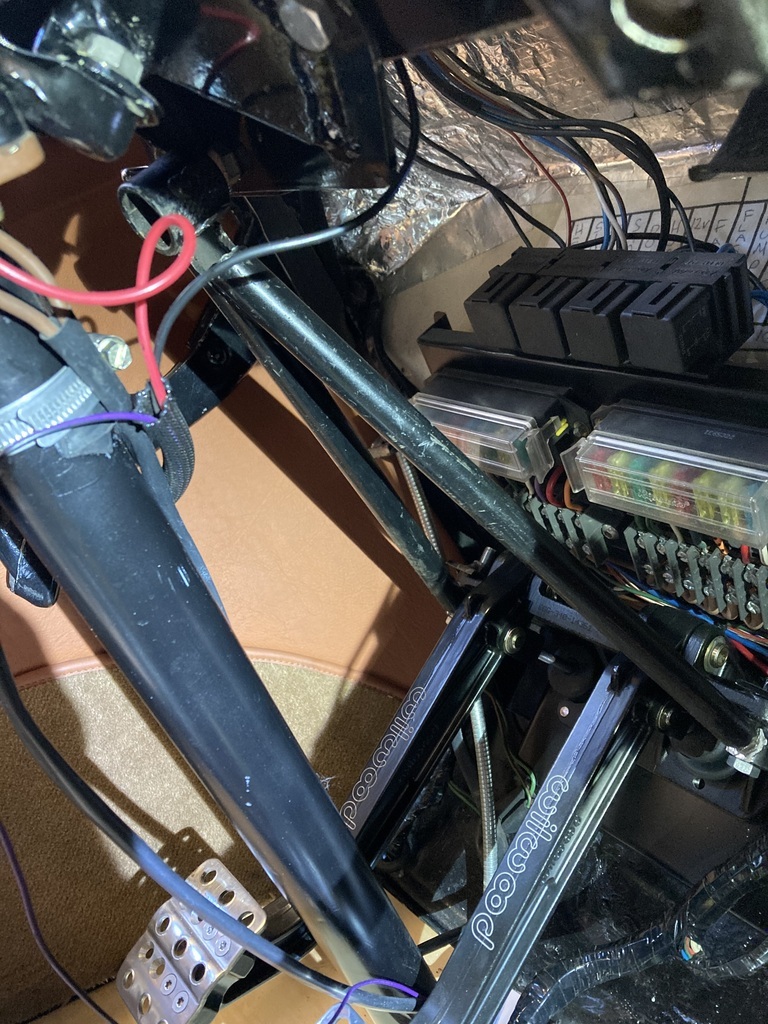

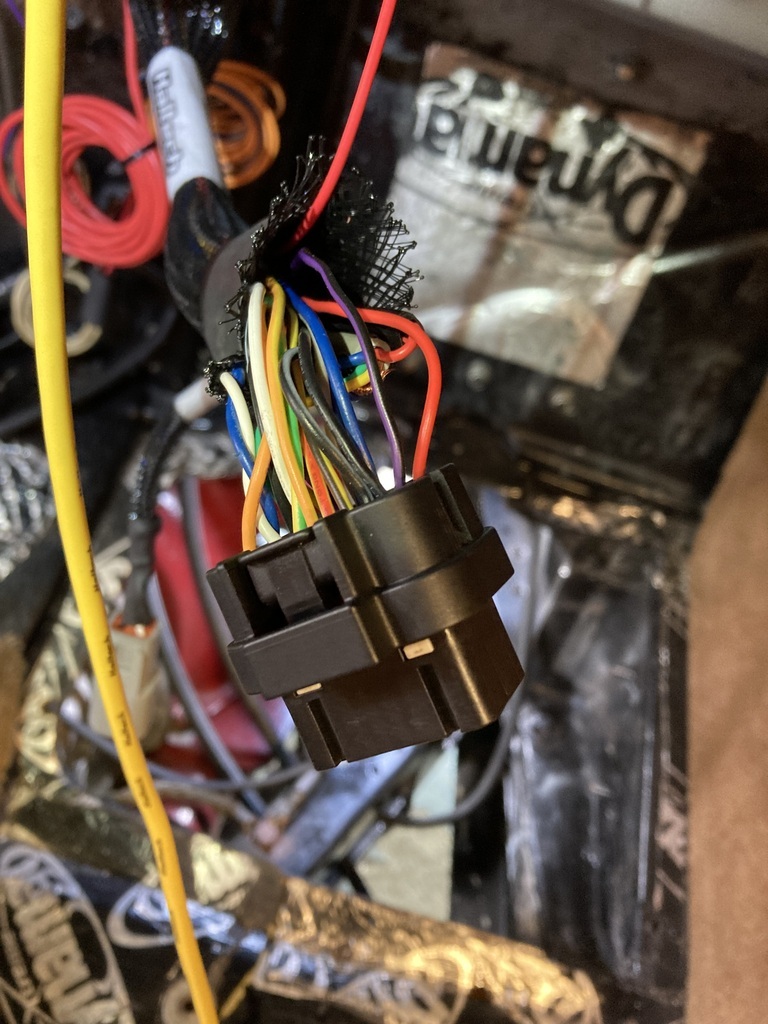

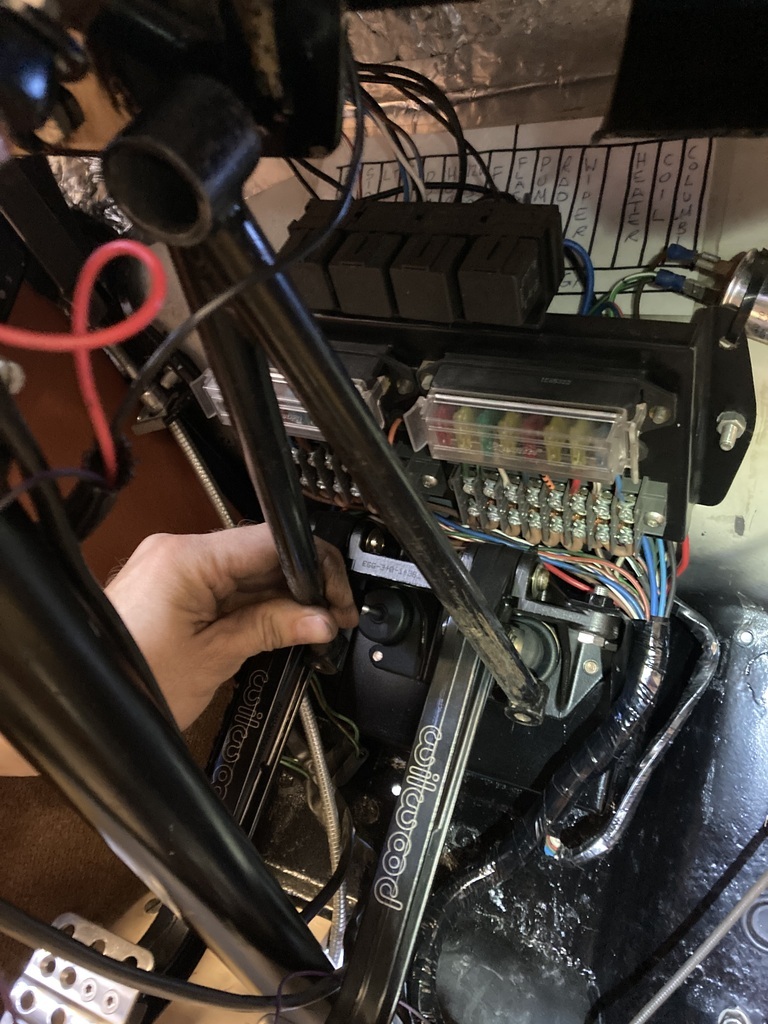

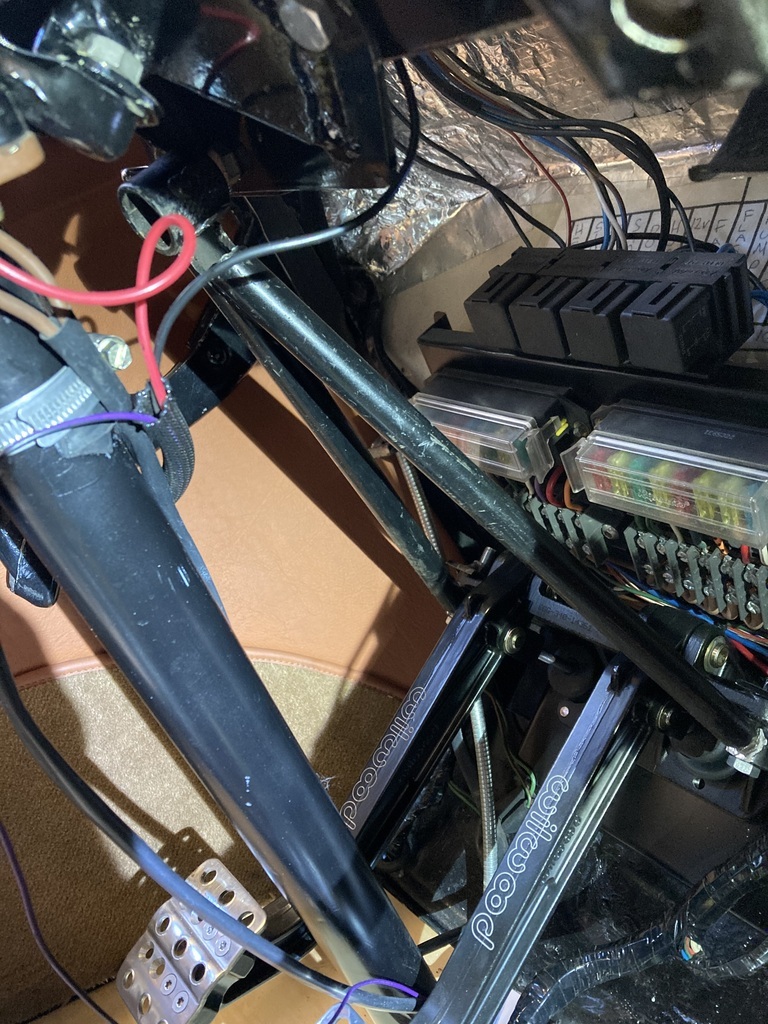

I noticed the steering column mount which is part of the dashboard stamping and is a pretty substantial piece could well be a good point to brace off.

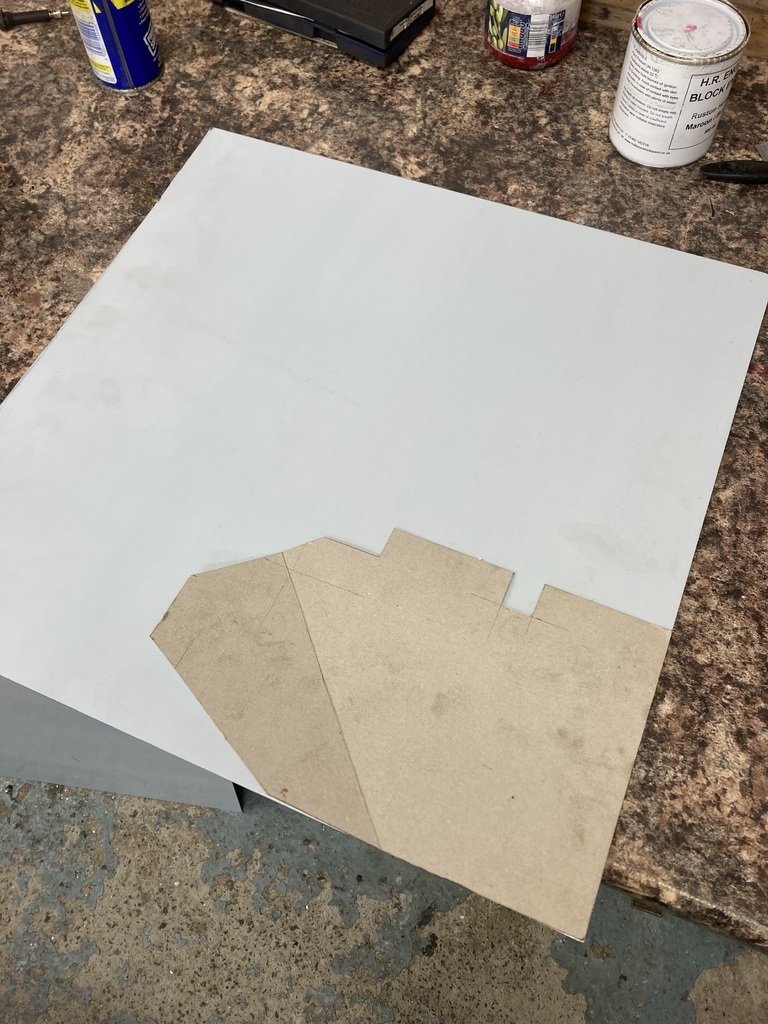

Rummaging through the scrap pile for something suitable I found this.

It’s a brace, for what I don’t know, from a newish Formula Ford racer.

A friend did a season with a Formula Ford team a few years back and had some random bits left over that he passed onto me.

It steel, probably chromoly and weights absolutely nothing.

Even has a part number printed in it.

A quick try out and it was almost a perfect fit!

I cut halfway through the welds so I could pull the legs out and tweak the mounting angles.

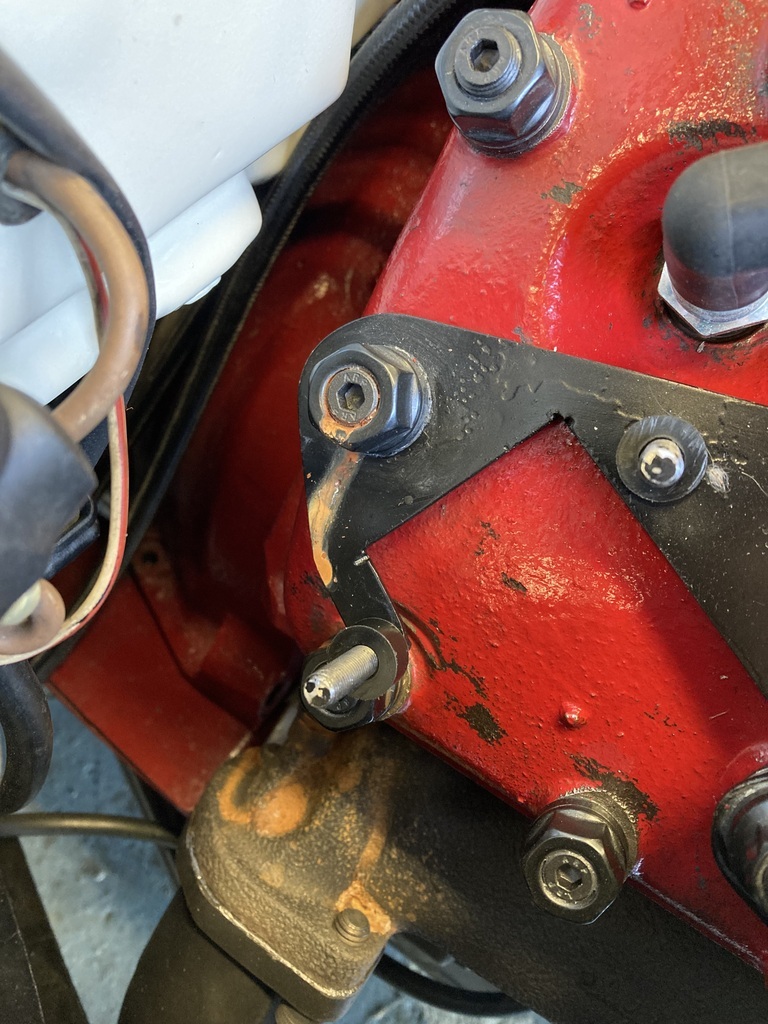

Mocked up in position for tacking using already existing mounting points.

I had to dismantle the steering column bracket so I could clearance it on one side.

How it ended up for final welding. The gaps got plated over with filler pieces.

Final bolt up.

No more flex. No added holes or hardware and even the fuse box is still accessible.

Well happy with that.

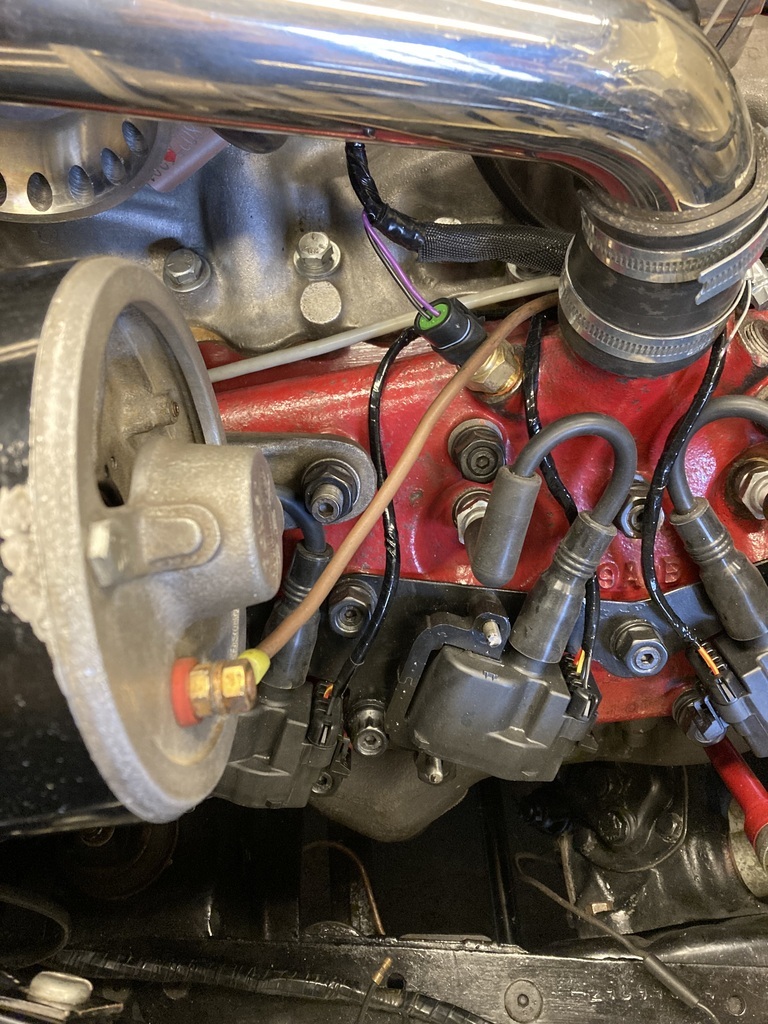

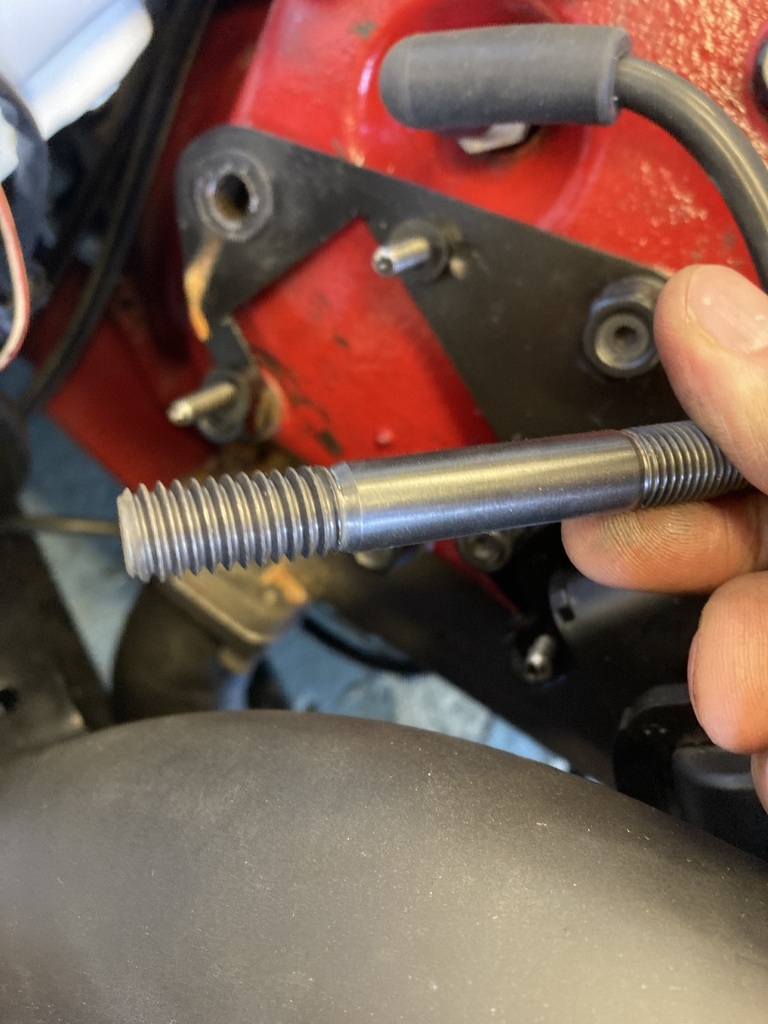

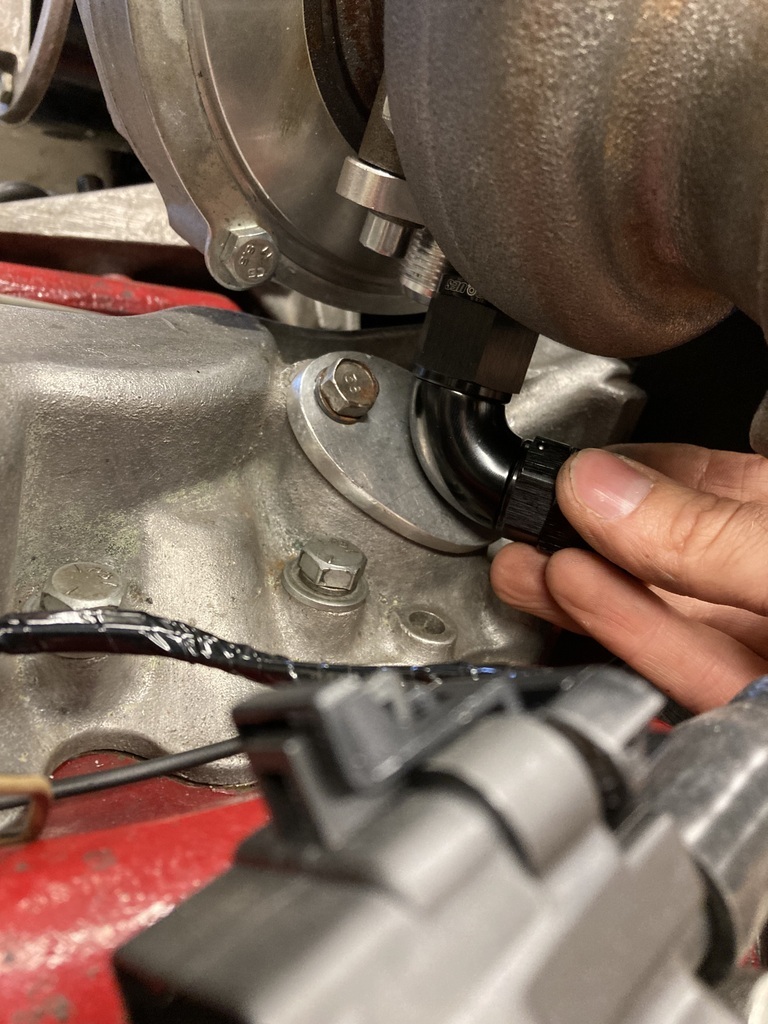

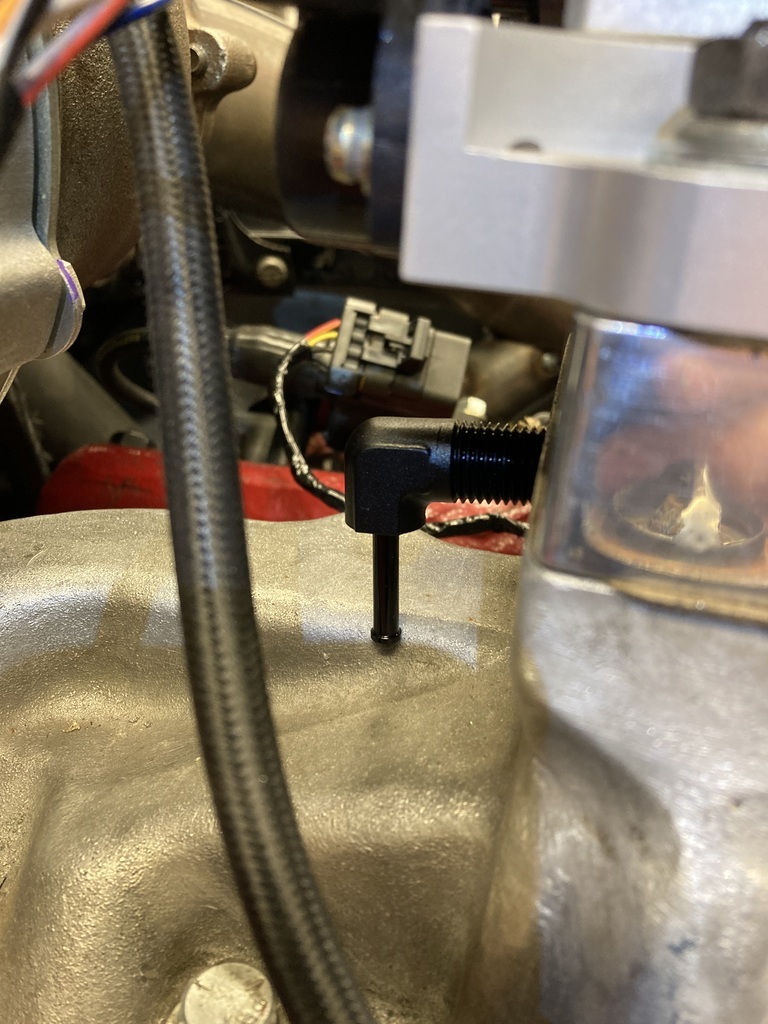

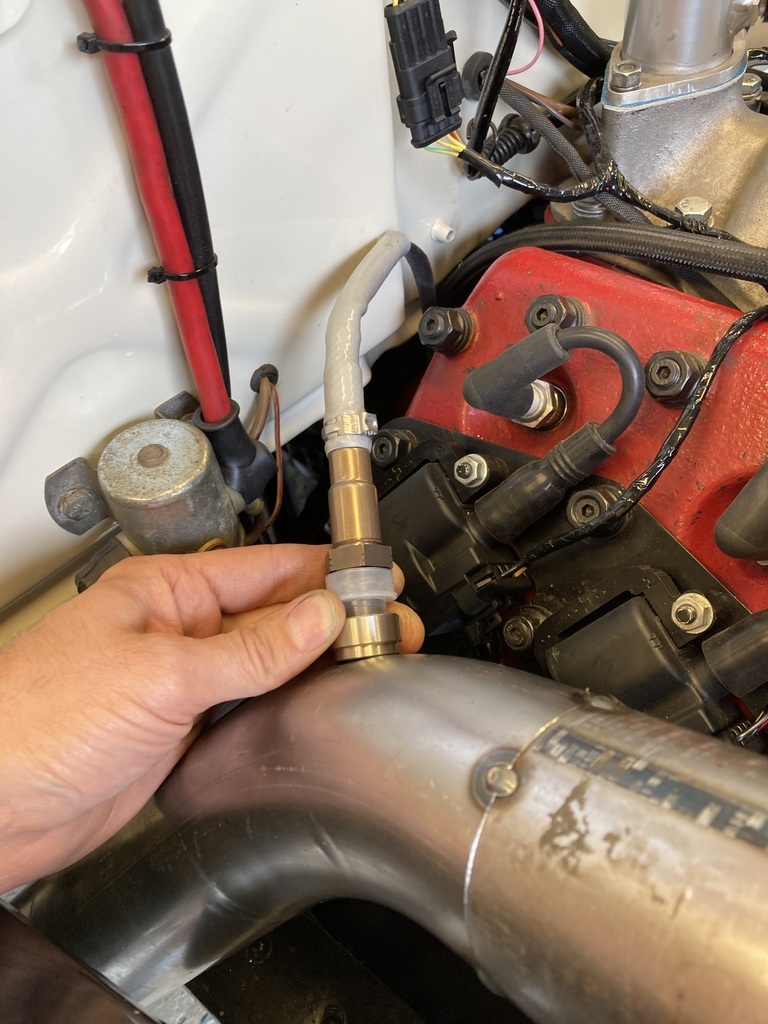

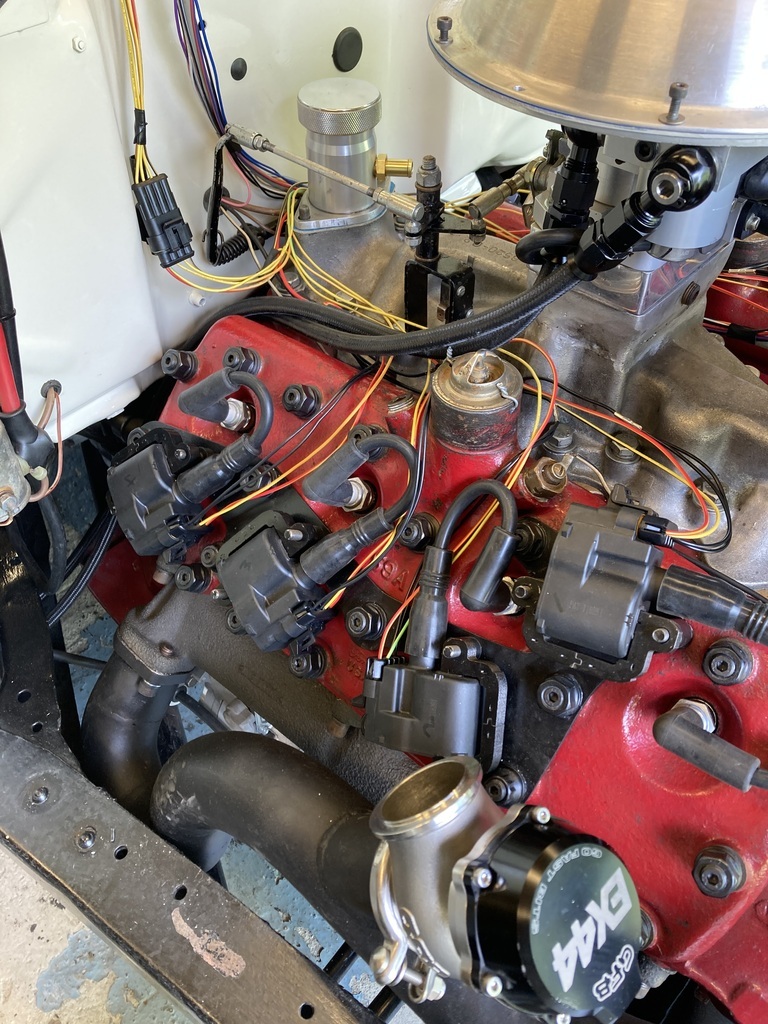

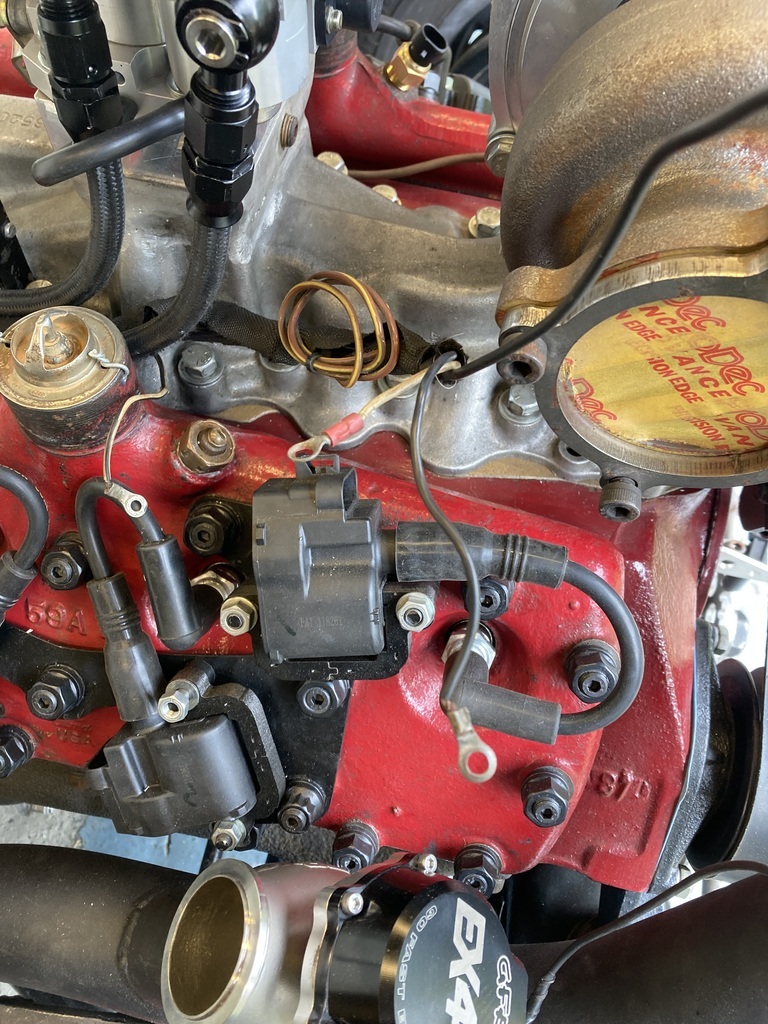

Another quick job was spacing the accessory belt idler out as the belt was running flush with the outside of the roller.

A 5mm spacer got the belt running in the centre.

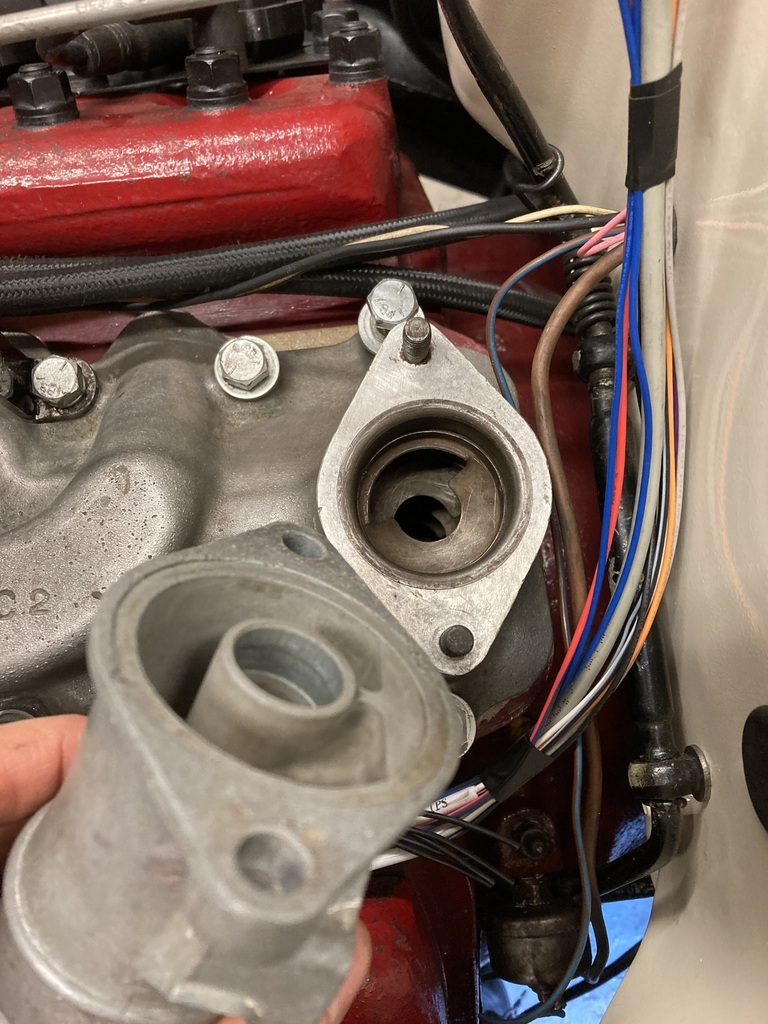

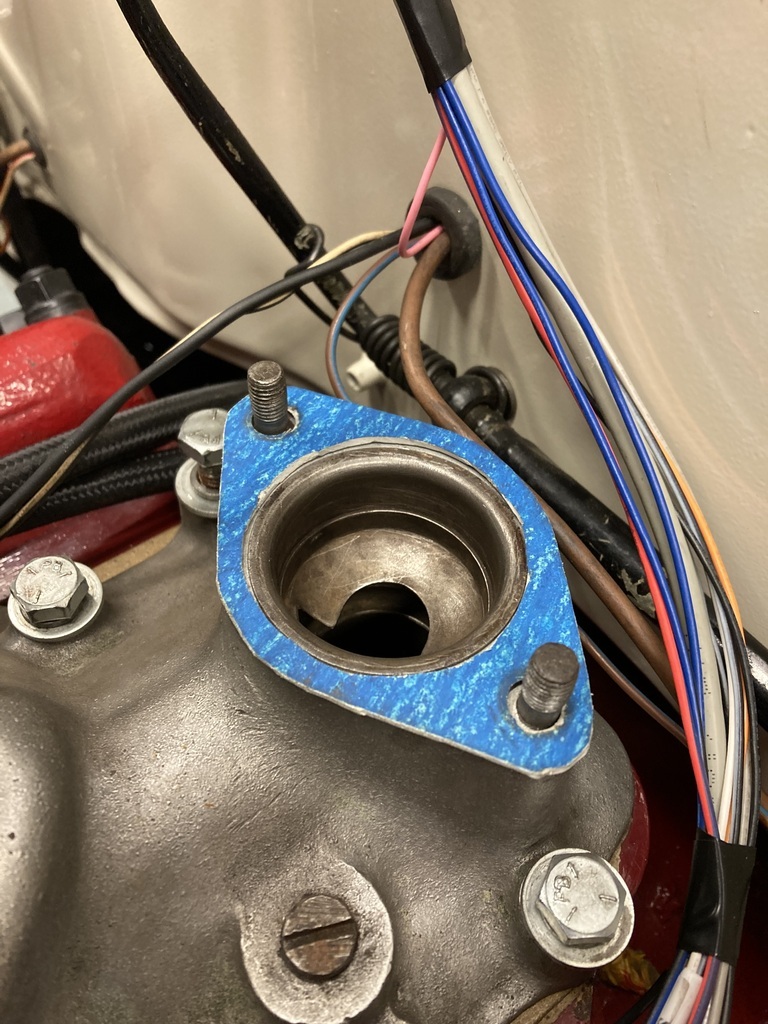

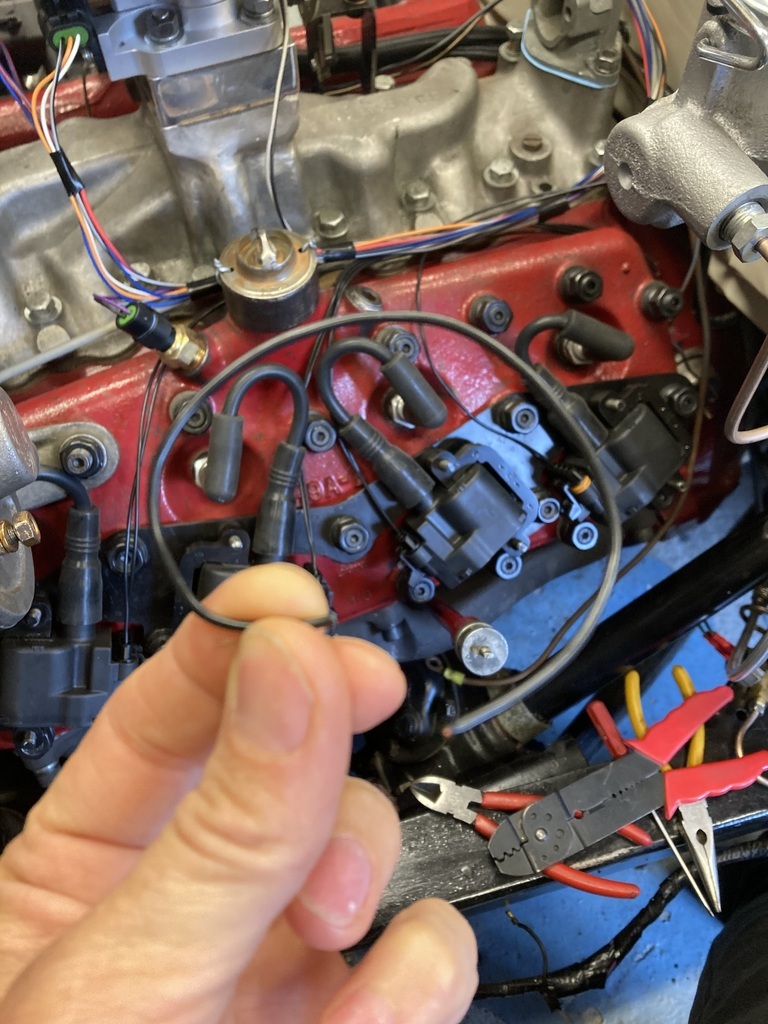

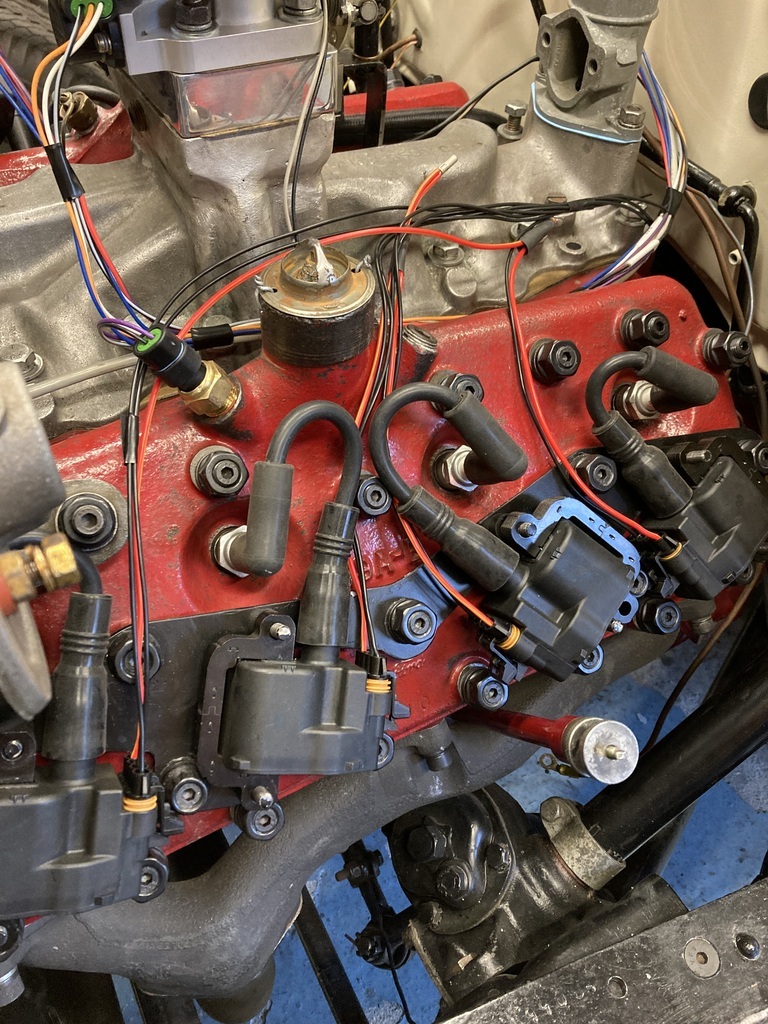

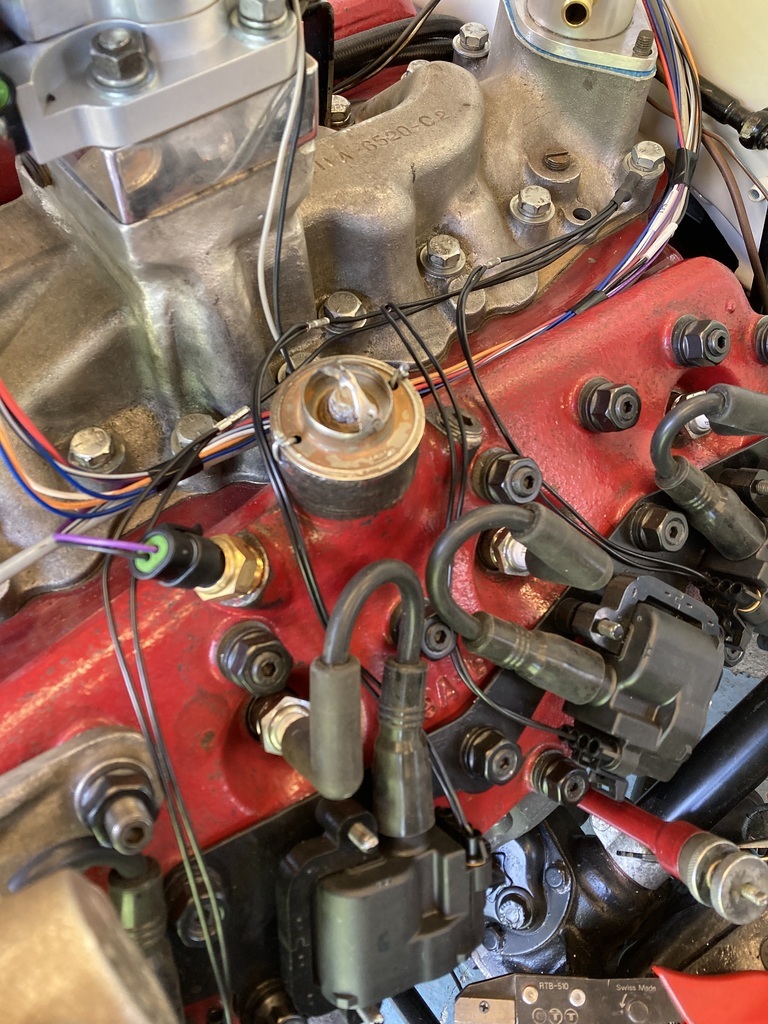

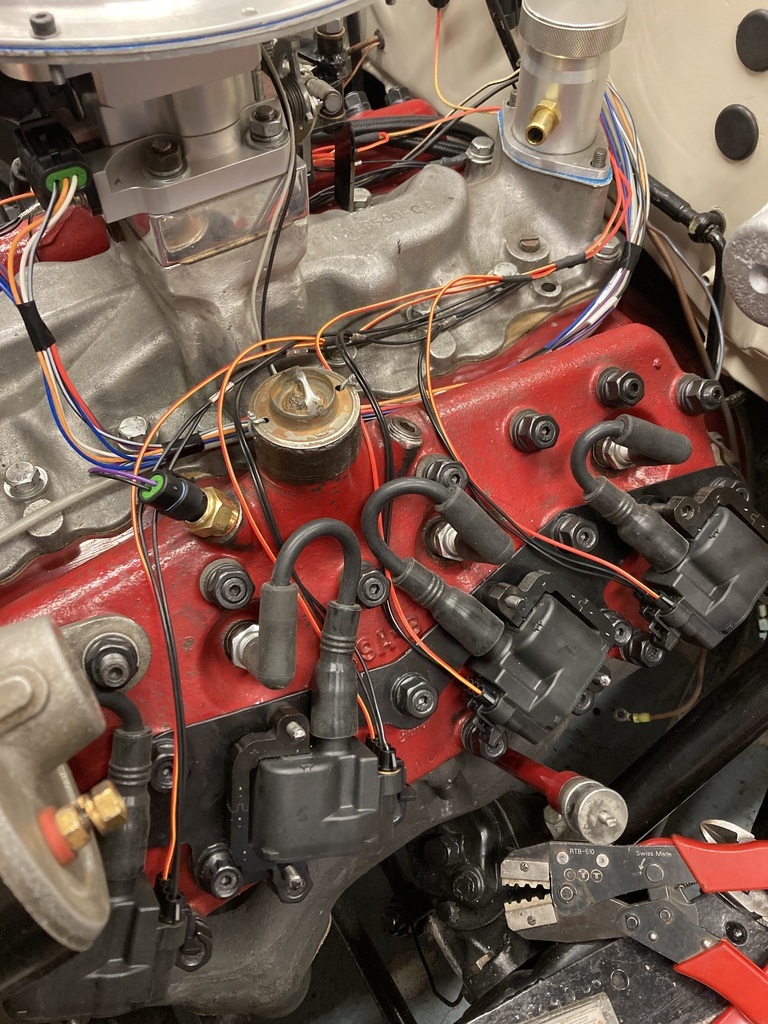

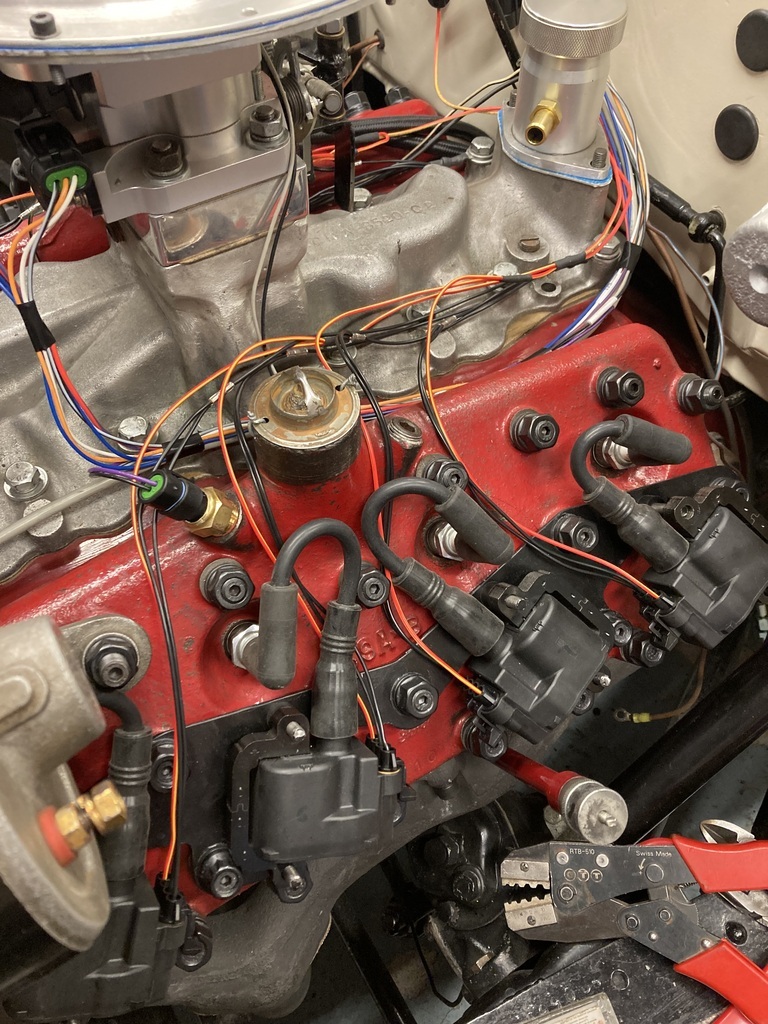

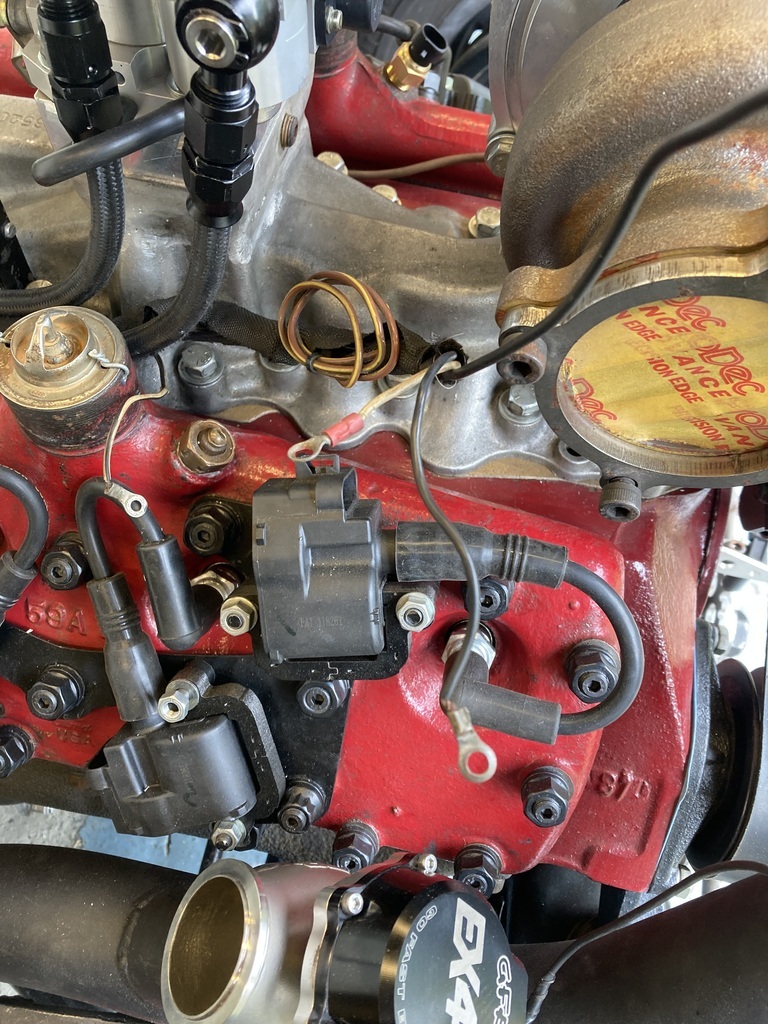

Running the turbo would potentially mean a colder plug compared to NA.

General consensus is one number colder when going from NA to a boosted application.

The go to NGK plug for the Flatty is a B6L. This is abit of a one size fits all plug and, as far as I’m aware, not available in any other heat ranges.

The closest NGK I could find in a ‘7’ (colder) heat range to the original was a B7HS.

It’s pretty much identical apart from the thread being a 1/16” (1.5mm) longer. Not a lot in the grand scheme of things but just to be on the safe side I ordered a set of 1.5mm copper washers to bring back to the same thread reach.

I might not even need them but I’ve got them.

Noticed the NGK packaging had changed a little and then spotted made in Thailand not Japan. ☹️

I mentioned before how the bumpers get pulled on and off regularly but I usually tire of the bumperless look pretty quickly.

Having the car in the garage for year with no bumpers had me wanting the bumpers back on so they did.

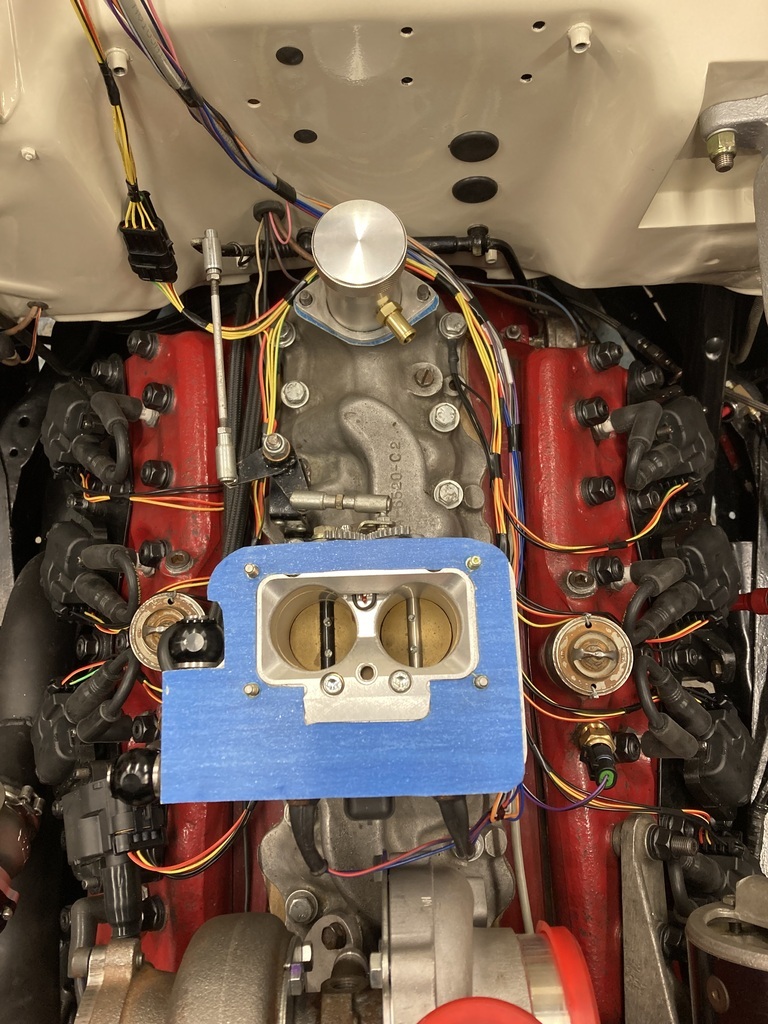

The day came to get on the rollers.

Help sorted. Van sorted. Trailer sorted. Much nervousness and anxiety!

We rolled through the gates to be told the dyno operator hadn’t turned up. ☹️

He’s in his 70’s and been suffering from poor health recently so its just one of those things.

We trailered back home and I drove the car back into the garage.😢

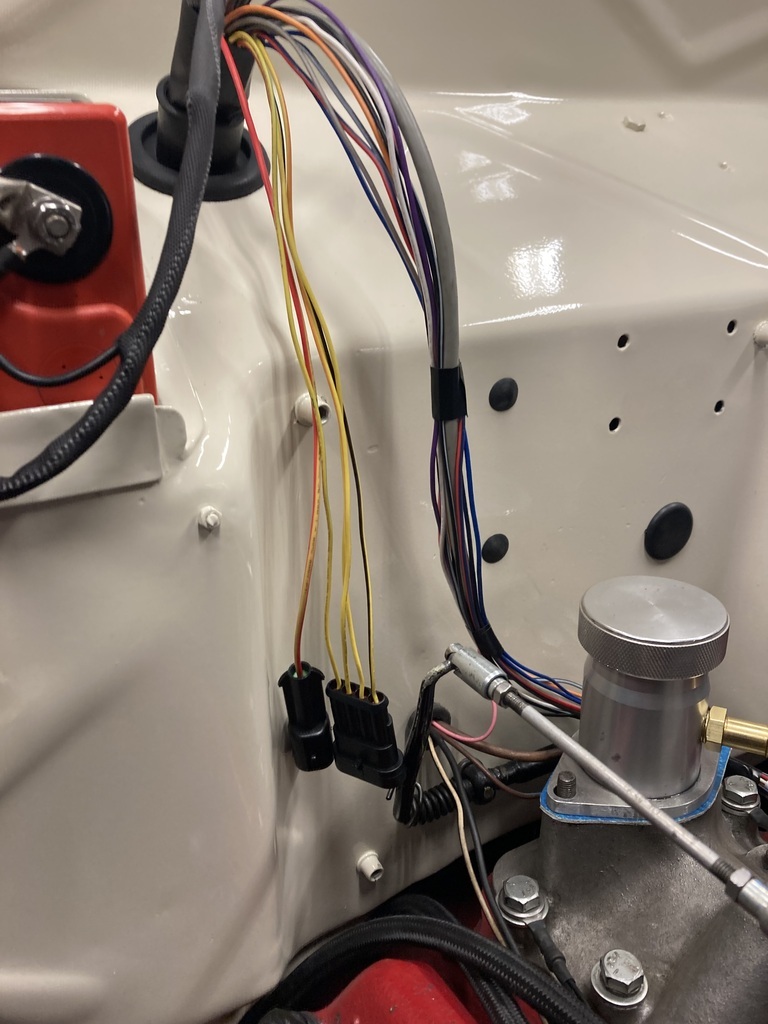

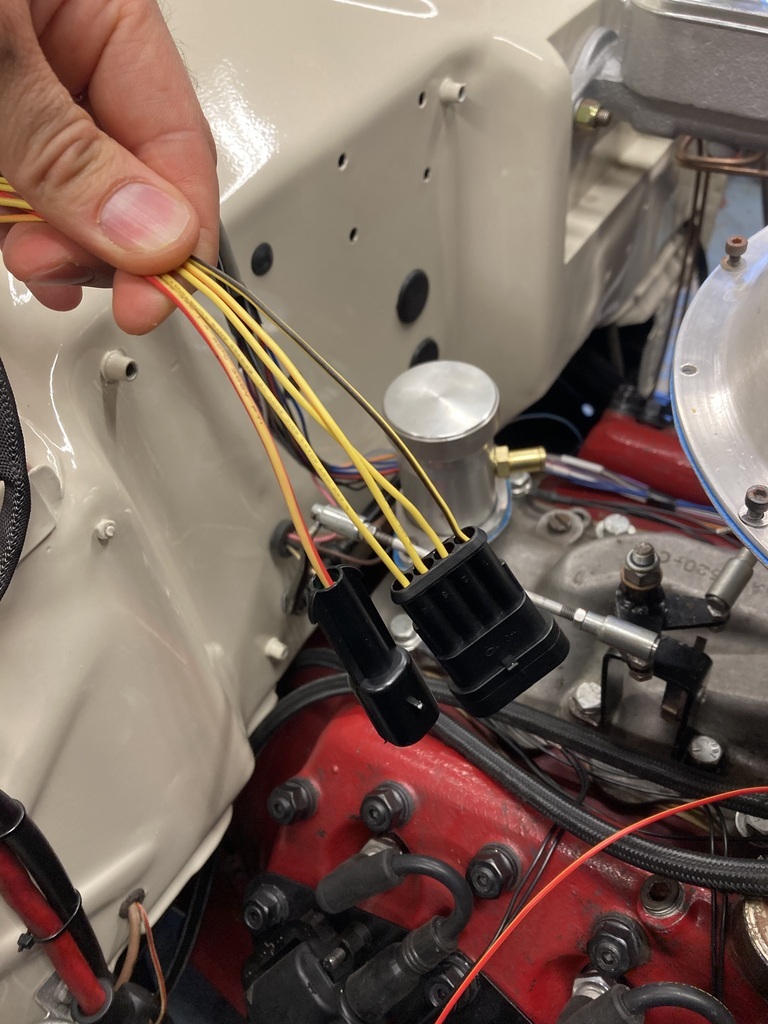

The following few days I started messing around with the tune myself just because and then this happened…

I love it 👌

I love it 👌