|

|

|

|

|

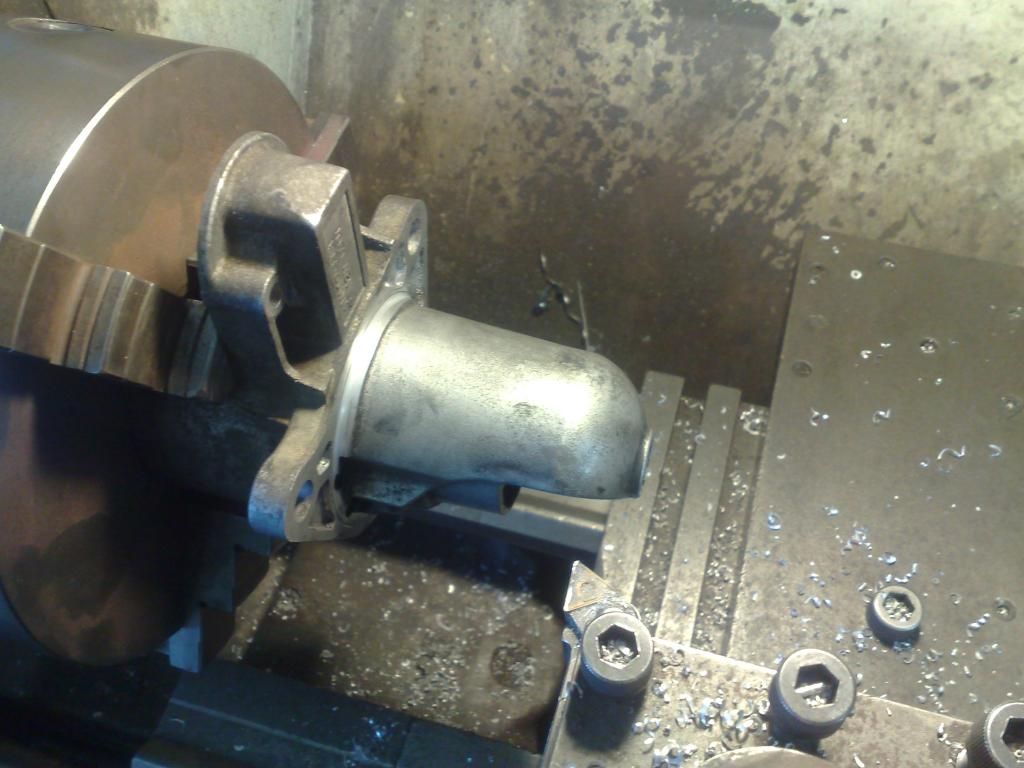

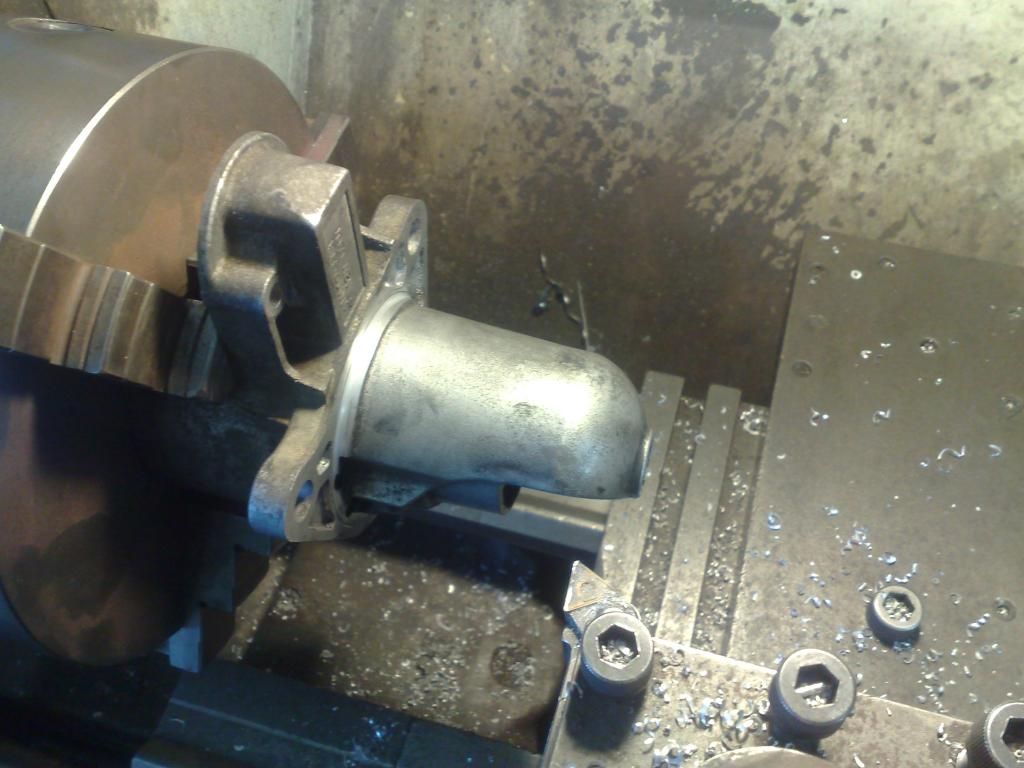

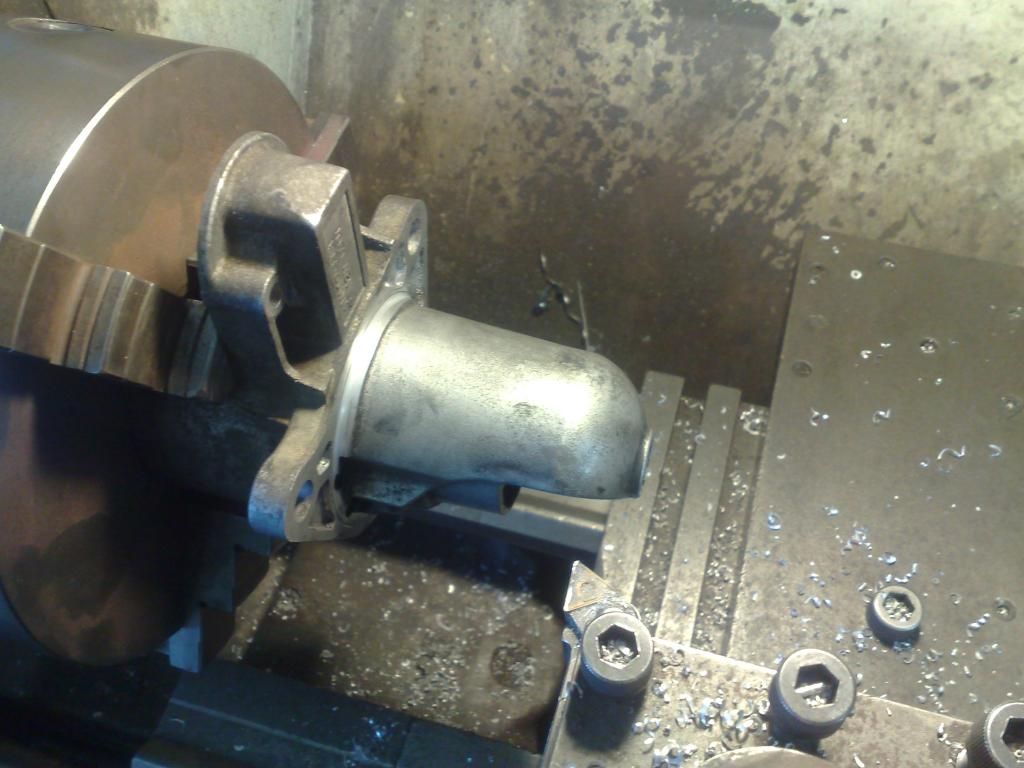

I have not done as much work on this as planned as I am trying to get as much bike riding in- I have a mtb race in March that I really want to do well in- beat my previous best time (of 18 years ago..) :-) And then any spare time at work recently I have been using to build a welding bench for my new welder. Anyway- on Saturday I marked up and drilled the 10mm thick adaptor plate. It was a bit of a mission as I wanted to get it spot on.  I made a spacer to hold the input shaft tight and central and then a little bit on the end with a centre that I could measure off...  I was originally going to use 16mm, then decided on 12mm but that wa almost the same price as 16mm. Going to 10mm saved me $85! And it means I don't need to space the flywheel back so much. I decided to make steel inserts for the bellhousing bolts though rather than rely on 10mm of alloy to screw into. The plate locates and centralises on two dowels in the bellhousing and two in the block. tonight i finshed the last insert and checked that it all worked. I have yet to finish cutting down outside of the plate.  I then set to working through the starter pinion/ring gear problem. As the V6 ring gear is 10mm smaller dia I was going to have to move the rx7 starter inwards 5mm. I originally discounted using the V6 starter as the locating tabs were wrong and the solenoid sticks outwards. But I checked the room in my Viva around the starter and there is still enough room for exhaust pipes. The V6 starter was too big in diameter by only 5mm and it also has a bigger pinion- 9mm bigger. Almost the difference I need. Plus its a later high torque unit.  I spun it down to fit.  And its almost perfect for mesh.  I would like it in a further 1mm to take up the back lash so I might turn down the other one I have but do it in the 4 jaw chuck and offset it by 1mm. Now I need to move the starter forwards by as much as I can- I need about 8mm. This photo is as it is with out any spacer to take in account of the 10mm plate I have added.  I cant just space the flywheel back all the way as I fear I then wont have enough room for the clutch release bearing to clear engagement. I will take some off the starter - maybe 2.5mm. Then hopefully mill the flat that the starter sits against - but not till I get my box out of the Viva. ( remember this current box is on loan) I would like to borrow a release bearing and clutch fork so I can see what I can get away with. Hopefully I can get these locally. I'm bloody relieved that the pinion to ring gear diameter problem is sorted anyway- it would have been a mission to try and move the starter inwards. |

| |

|

|

|

|

|

|

|

Nov 28, 2012 20:27:57 GMT

|

|

What a terrible place to work, all those expensives tools just laying around....

You must hate it!

So how heavy is the Viva?

|

| |

Koos

|

|

1mzmk1

Part of things

Posts: 205

|

|

Nov 28, 2012 21:57:40 GMT

|

|

I'm also interested to know the weight!

I have just bought an HB myself so I will be following this with interest...

|

| |

|

|

|

|

|

Nov 29, 2012 17:04:15 GMT

|

Chunky little car. Still very light compared to moderns though I suppose. |

| |

|

|

|

|

|

|

|

|

A mk2 Elise is 910kg and a mk1 mx5 is 940kg....

Viva is a skinny little thing. She's gonna fly with the V6!

|

| |

Koos

|

|

|

|

|

|

|

Its still quite a bit heavier than i thought. but it does have 4 seats, full carpet, underlay etc... Anyway.. This is not a huge update full of massive steps forwards but I am very happy indeed to discover that with only a small amount of modifying the sexy fraser inlet manifold will fit facing forwards. sweet!    I promise to get some real work done this weekend.... and soon the rotor will have to be pulled out... sad times but thats evolution. |

| |

|

|

|

|

|

|

|

|

My '97 Mitsubishi Lancer CK1A weighs a lot more 1205Kgs and only has 75BHP to make him 'running'...

Yours with a rotary turbo or like know with a V6 twin camed should go like a small rocket...

They say that the old ones are slow maybe some, maybe some... heheheh

Nice project... Keep it up...

|

| |

|

|

|

|

|

|

|

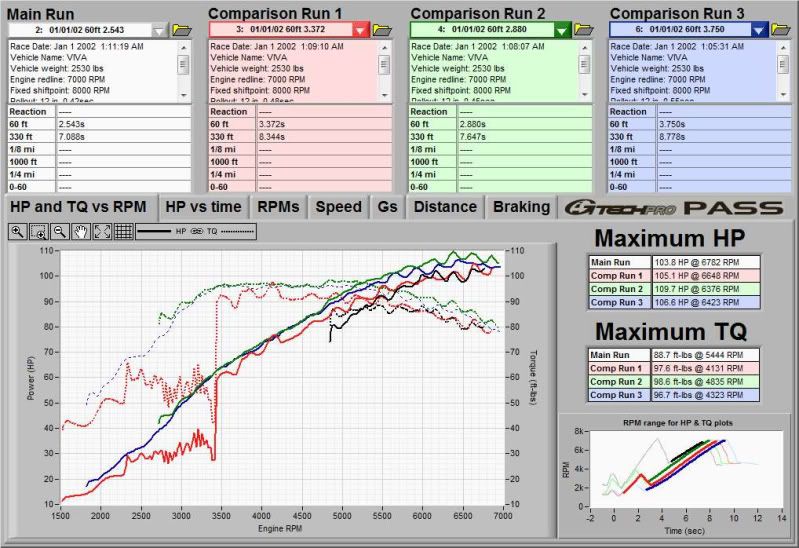

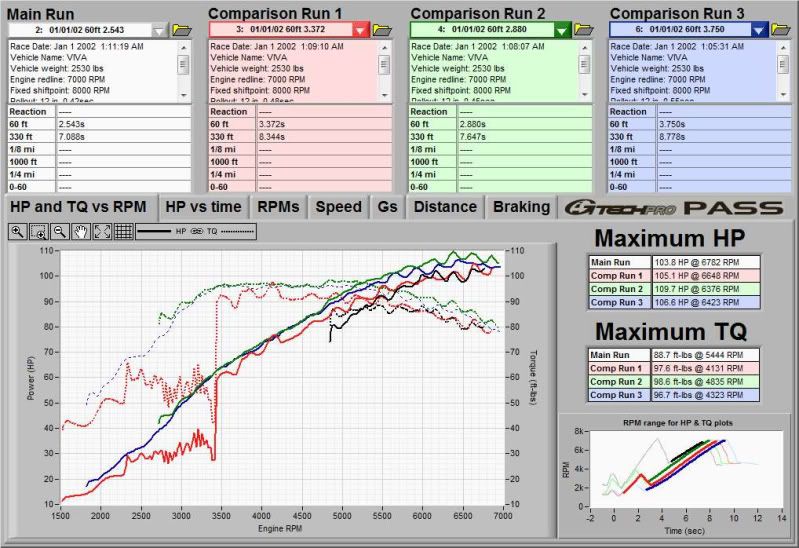

Wow- 1200 kg with 75 bhp! Ouch. Yeah I spose the viva still ain't that heavy. But it's still heavier than I thought and I have always based my power to weight on a much lighter weight. To make matters worse (or even better with respect to swapping the engine) last week a friend set his gtech device up in the viva and we entered the now confirmed weight then did some acceleration tests. He uses it against cars he sets up on dynos and it's actually very accurate so long as you enter the right data. Rather than the expected roughly 130 bhp at the wheels it only has 105 which equates to about 132 bhp at the fly. (using the guesstimate of 20% losses through drivetrain)  So it's quite peppy with that but I can't wait to have a lot more ...along with the v6 soundtrack!  I might add that the turbo is not putting in the full boost of 6 psi.  I think the waste gate is creeping or getting blowby- possibly my mild steel waste gate seat I made is receding  . I need to adjust the waste gate actuator rod. So with this in mind the above test is possibly a tad low. Not worried either way as I'm doing the swap anyhow. ;D One day it may sound like this.... |

| |

Last Edit: Dec 7, 2012 19:36:34 GMT by yoeddynz

|

|

|

|

|

|

|

|

That's pretty low on power huh? I was thinking the old wankel turbo had around 200....

|

| |

Koos

|

|

|

|

|

|

|

|

standard 12a turbo- the first turbo'd rotary was 160 ish. but very thirsty compared to mine!

The later 100cc bigger 13b turbo engines started at 200 and worked up from there over the years.

I think i am losing a fair bit due to not getting full boost. but not really worried as it still feels quick enough and engine is to come out soon.

|

| |

|

|

|

|

|

Dec 18, 2012 23:57:58 GMT

|

|

I'm a bit surprised by that weight too, would have though more 850-900kgs. Still good to see you getting on with it and loving the V6 noise. I'd never thought much about V6s until I ran into a mate that put a VR6 in a 1L badged Polo. I don't know if the engine was played with or what exhaust he had but my god did it sound amazing. I'd love a 6 cylinder but can't bring myself to get rid of the Viva yet (and it's currently worthless) and the Saab Turbo and it's tune-ability is too good to get rid of too, so it'll have to wait.

|

| |

Project Diary1975 Viva / 1988 T25 Camper / 1989 Mini / 1991 MX5 / 1992 Mini / 1994 Saab 9000 / 1997 Saab 9000 / 2008 Saab 9-5

|

|

|

|

|

|

|

|

Just put a v6 into your viva. Simples. Wait till I have finished mine and learn from my mistakes. Your hc has a longer engine bay too.

Tonight after work I machined the spacer to go between the crank and flywheel. I have also offset another starter motor in the lathe and machined it down. Now the starter meshes neatly with the ring gear. So it's all pretty much ready to bolt together and with that I will remove the engine from the viva. Work is closed for two weeks so I will spend much time there fitting the engine in place and making the most of the workshop.

I'll post up a pretty photo of my spacer soon. Not that exciting but we all like shiny things.

Oh- I have now got a ac/dc tig welder. I have been practising now and then out in the shed and it's so much fun. I bought 5kgs of alloy filler rods to crack on with practice. Looking forwards to building some things! Maybe a new inlet manifold.

|

| |

|

|

|

|

|

|

|

This weekend should be the last weekend that the Viva will be propelled forwards by two softened triangles spinning away merrily. I will miss it but I'm positive the V6 will be even better (certainly sound better) and I have very itchy engine swappy fingers. Last night I finished off the spacer that moves the flywheel back 13.5mm. Its a good fit and with that done the conversion of the V6 into RWD configuration is all finished. I now just need to sling it in place and build some engine mounts. I have been playing with our new ac/dc tig welder. Its top fun! lots to learn but boy its gonna be handy! My first alloy welds, just practicing running beads. My control still isn't there to blend two thin bits together yet but with practice. The messy welds were when a gas hose brass fitting worked loose by the welder. I was wondering what was happening all of a sudden and the heard the argon escaping. ha.  I then thought why not see how the welder handles 10mm thick alloy. I veed the gap out first and then set too. things got pretty hot by the end of it, including me on what was already a hot summer night in the shed. BUt the welder was fine and it almost looks neat. It wont actually be seen anyway but at least now the plate doesn't have a big gap.   I bought a $35 chunk of alloy to make my spacer and then found a chunk big enough behind my tool box. Typical. I had to work carefully with the old lathe as its quite worn out and I don't want any throwout at all with the flywheel.  the spacer all finished.  When I have finished lunch its off to work for the afternoon to finish getting the last things ready before I pull the Rotary out. I have many many things to make and do once the V6 is sitting in place but it will still be a cool place to be just having it mounted there. |

| |

|

|

|

|

|

Dec 22, 2012 12:22:48 GMT

|

|

Nice looking welding mate. My best welding looks like your messy one!

Will that Ali plate not fret when clamped between two big heavy bits of steel?

|

| |

Koos

|

|

|

|

|

Dec 22, 2012 20:45:39 GMT

|

|

Fret? Not sure what you mean but the spacer will be fine. It's a nice tight fit and has 8 lovely bolts holding it all together. I'm glad I managed to get the width down to only 13.5mm because some others doing the similar conversions have used up to 25mm! That's too much distance to sling the flywheel out in my opinion and would put extra stress on the rear main.

|

| |

|

|

|

|

|

Dec 22, 2012 21:55:36 GMT

|

|

Fret, as in gall due to tiny movements between flywheel and crank....

|

| |

Koos

|

|

sowen

Club Retro Rides Member

Posts: 2,245

Club RR Member Number: 24

|

|

|

|

Just read through this from the start, amazing work you're doing  Good luck with swapping the swap ;D |

| |

|

|

|

|

|

Dec 23, 2012 19:28:15 GMT

|

So took the Viva out for last (rotary powered) spin yesterday evening. Met up with Andre who brought out his genuine GT. Had a couple of little races here and there just to confirm to Andre that my little rice powered engine still beats his boat anchor 2.3 slant 4 with big ol' webbers..... :-) Got some pretty photos.    I'll miss this little engine- it has done 8652 kms completely fault free and never failed to start since last october. Nothing amazing for a modern engine but for a cobbled together old 12A being fed by a carbie turbo its not bad. Still uses curse word all oil. I think its next home may well be Shane's little Ford Anglia- he's the painter at work. Will go bloody well in that!  Today the Viva goes under the knife. |

| |

|

|

|

|

|

Dec 23, 2012 22:33:50 GMT

|

|

If there's gonna be blood, I'll look away....

Tell me when it's safe to look!

Be interesting to see what th GT weighed - porky I bet!

|

| |

Koos

|

|

|

|

|

|

|

And its out...  Then in with this.. except I had only loosely done the clutch cover bolts so the input shaft moved the disc so they wouldn't mate up, it was bloody hot, properly bloody sweating wet through hot with a beach only 3 mins drive away and we were running late to look after the olds dogs for xmas. But anyway- it fits without touching the servo- so thats nice.  Oh and looking after the new maine coon girl called Molly- who has the biggest tail I have ever seen on a cat..  |

| |

|

|

I think the waste gate is creeping or getting blowby- possibly my mild steel waste gate seat I made is receding

I think the waste gate is creeping or getting blowby- possibly my mild steel waste gate seat I made is receding  . I need to adjust the waste gate actuator rod. So with this in mind the above test is possibly a tad low. Not worried either way as I'm doing the swap anyhow. ;D

. I need to adjust the waste gate actuator rod. So with this in mind the above test is possibly a tad low. Not worried either way as I'm doing the swap anyhow. ;D