|

|

|

|

|

|

Stew

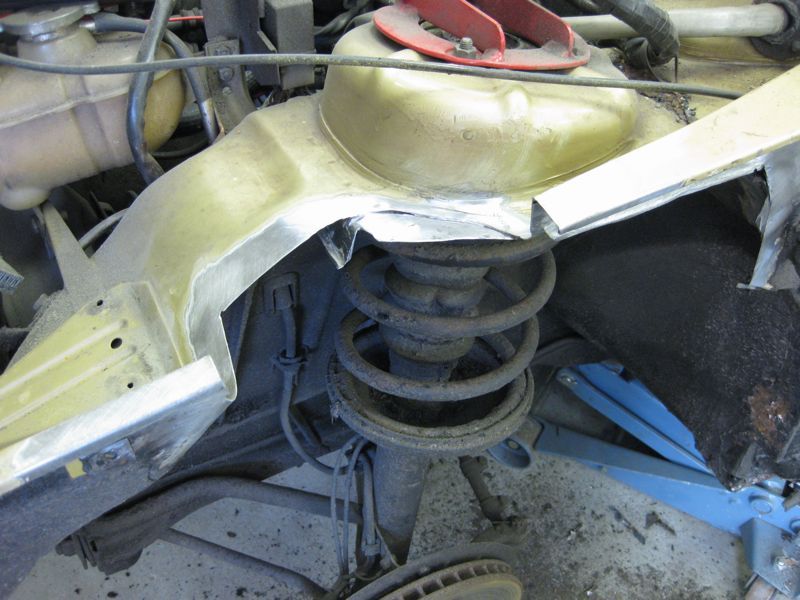

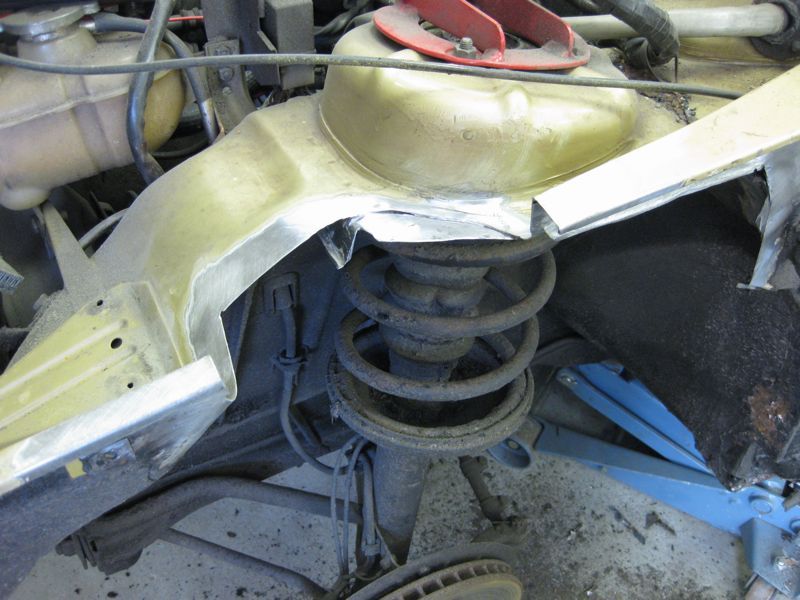

The only way to repair this properly is to cut back the inner wing to sound metal, clean up the chassis leg flange, and then piece back the inner wing, pool welding it onto the chassis leg where needed.

Tony

|

| |

|

|

|

|

|

|

|

|

|

|

Thanks Tony so if I use sheet metal to bend it to the shape and weld it into place will this be ok ?

|

| |

|

|

|

|

|

|

|

Seeing dubwarriors question reminded me of this thread. It can be a little slow to load because of the number of pictures, but the work is pretty impressive. vwrides.com/viewtopic.php?t=43(Sorry if it's a duplicate, I had a quick look up the thread and couldn't find it). |

| |

|

|

|

|

|

|

|

Thanks Tony so if I use sheet metal to bend it to the shape and weld it into place will this be ok ? Yes that sounds about right, just make sure that you weld all the way around where it joins the inner wing |

| |

|

|

|

|

|

|

|

Seeing dubwarriors question reminded me of this thread. It can be a little slow to load because of the number of pictures, but the work is pretty impressive. vwrides.com/viewtopic.php?t=43(Sorry if it's a duplicate, I had a quick look up the thread and couldn't find it). - I had not seen this before, those guys certainly take this to another level, But again a perfect example of what can be created with some basic tools and a bit of know how, although I am not sure I would ever want to hand beat one of those cargo bay floor panels. Dubwarrior, I see what your part is now, and those guys made it in 2 parts, I guess because of the little strengthening ribs that cross the large flange. I reckon you could weld in those ribs afterwards if you did it my way, or do as they did and make it in 2 pieces, I am sure either way would create the desired affect We still want to see photos if you attempt it |

| |

Last Edit: Feb 8, 2010 22:15:58 GMT by tonybmw

|

|

dubwarrior2

Part of things

"Open up, its the filth"

"Open up, its the filth"

Posts: 576

|

|

|

|

|

Thanks for all the advice so far.

First thing on my "TO DO" list is get length of 50mm angle and have a go at one of your patented benders. Just hope I can weld it all square.

I'm putting off work on the splitty til the weather improves a bit, but have got a big old work surface in the garage, so will attempt some bending/folding practice.

I am determined to master the black arts of steel this year.

|

| |

|

|

|

|

|

Feb 11, 2010 18:07:58 GMT

|

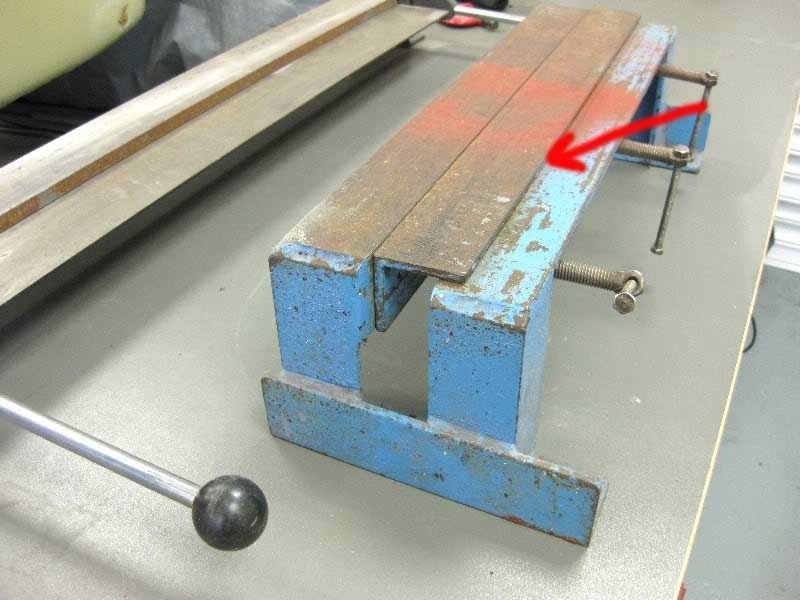

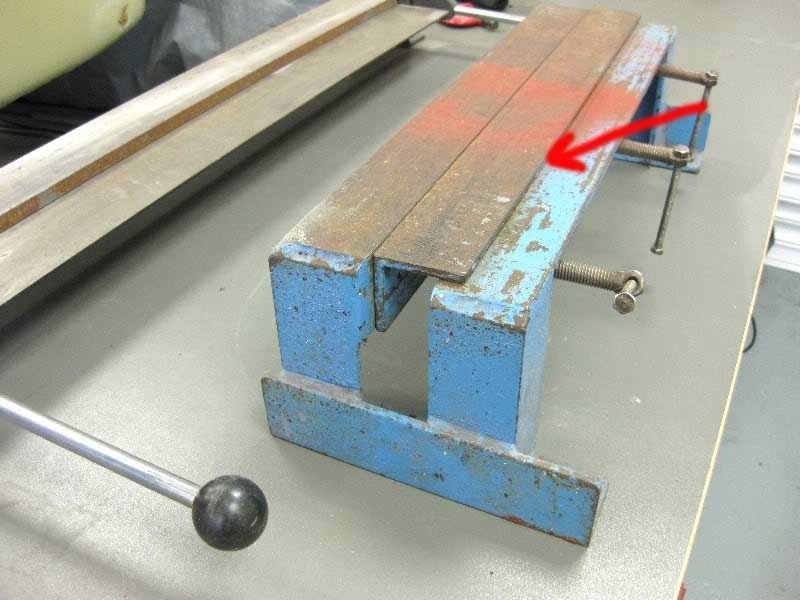

I can't believe I didn't spot this earlier, must be an old age thing, and the fact that I had stored it away, but you could use the Open source Bender to create the ribs that I just detailed. You could use the step in the 2 angles, as shown below as your working area  Its even more versatile than I thought   |

| |

Last Edit: Feb 11, 2010 18:09:14 GMT by tonybmw

|

|

DutyFreeSaviour

Europe

Back For More heartbreak and disappointment.....

Posts: 2,944

|

|

Feb 12, 2010 12:04:13 GMT

|

|

Tony,

How are the screws/bolts working on pushing the meeting face on your bender fella? Are they passing through captive nuts or something?

Grabbed an ancient bed frame of heavy duty angle so gonna try knocking up a folder myself too......

John

|

| |

Back from the dead..... kind of

|

|

|

|

|

Feb 12, 2010 18:43:27 GMT

|

|

John

Yes there are nuts welded to the outer angle and the bolts screw right through them to push against the loose angle

Tony

|

| |

|

|

|

|

|

Feb 13, 2010 17:14:26 GMT

|

|

Hi Tony, a couple of questions.

What thickness of steel is the bender made out of?

Also, i see you use plug welds and spot welds for a lot of the panels you add, my mot tester has always told me all repair panels must be fully seam welded. I can see that any mot tester looking at your car wouldn't even see the repair panel but having to seam weld has always caused me to lose the original finish to a lot of my repairs.

Cheers

Kev

|

| |

|

|

|

|

|

|

|

Feb 13, 2010 18:00:43 GMT

|

|

Kev

The bender is made from 50 x 50 x 6 thick angle

Where you are repairing a section in a panel, then it must be fully welded, but where that panel meets another panel, then spot welding or pool welding is fine, after all, this is exactly as they were when they were new.

I've certainly never had any problems come MOT time, and I would certainly challenge any MOT tester who said differently, not sure what anyone else's experiences have been.

|

| |

|

|

|

|

|

Feb 13, 2010 19:13:01 GMT

|

Tony, Ive just found more rot in the nova front turrets pic from top  pic from underneath  also the other side  how could i go about repairing this ? |

| |

|

|

|

|

|

|

|

|

Stew

Sorry I have just seen this post, for some reason I did not get a notification email

with repairs like this the only way to do it properly is to cut out the rotten metal, back to sound metal, if this involves cutting through 2 or 3 other panels, then that is what you have to do. I would however advise not to cut out any more than is needed, you don't want to make it any more difficult than it already is

But don't worry it always looks like you don't know where to start with stuff like this, but once you have it cut out and cleaned up then just start making each piece as needed, and soon it will much clearer.

I still have moments like this where it is just not clear how it is going to be fixed, but I know that the rot has got to come out, so that is where I start.

Tony

|

| |

|

|

wallopadonkey

Part of things

stunning grinder! curse word welder!

stunning grinder! curse word welder!

Posts: 234

|

|

May 16, 2010 19:40:22 GMT

|

|

I would like to say a big thanks to tony especially as his enthusiasm for old cars has got me to pull my finger out and get on with my first project.

I made one of your benders 457 mm wide and the steel to make one at standard size and one at 600mm wide cost less than £20 from the stockholder and I painted it red and silver so it can live outside

I used the rest of the steel to make a trailer which I completed this afternoon

thanks

again

dave

|

| |

1983 mini city e

1985 miny Mayfair

1997 Audi a4 tdi

2003 gsxf 750

|

|

|

|

|

May 16, 2010 20:19:05 GMT

|

Dave Hope you get as much use out of it as I have done from mine Just to prove that I have not been sitting on my backside over the last few months and to reiterate the point above, about cutting out 2 or 3 panels if needed to get rid of the rot. I am busy with a another BMW at the moment, This is the inconspicuous looking patch that had been put on previously, to pass an mot I assume  and here it is with the patch removed, not pretty  and another dodgy patch over the rot under the inner wing stiffener  so as I said earlier, the only way is to cut all the rot right out  new panel made and fitted.    and new inner wing stiffener made and fitted  so the moral of the story is, don't just patch over rust, as pretty soon afterwards it will be a hole all the way through, and no matter how daunting it might look, once you cut the rot out and take a methodical approach to repairing it, you will soon have a nice solid repair     |

| |

Last Edit: May 16, 2010 20:19:40 GMT by tonybmw

|

|

wallopadonkey

Part of things

stunning grinder! curse word welder!

stunning grinder! curse word welder!

Posts: 234

|

|

May 16, 2010 21:02:17 GMT

|

|

jesus h, i would have looked at that and had a rather large episode of the squits !

if i was doing it though the last thing i would do is cut the flange of the top of the wing out as i would not feel confident getting it back to where it should look

what gauge steel was the repair 20 g? i have both 22g and 20g zintec here at home mainly because it can live outside lol

cheers

dave

|

| |

1983 mini city e

1985 miny Mayfair

1997 Audi a4 tdi

2003 gsxf 750

|

|

|

|

|

May 16, 2010 21:12:56 GMT

|

|

Dave

Most of the body repairs are 20 swg, but I use 16swg for any chassis repairs

|

| |

|

|

wallopadonkey

Part of things

stunning grinder! curse word welder!

stunning grinder! curse word welder!

Posts: 234

|

|

May 16, 2010 21:34:31 GMT

|

|

gotta ask while you are on :-)

i'm doind an mx5 and the chassis rails (anti drum strengtheners on the floorpan) are very thin and they just remove noise really however they are mostly crushed and I wanted to make them bit stronger to give some jack points what would you use? and how

I thought just to make some -u- section with wings and over plate it to strengthen it all the sills are rotten but they are not structural and I have made them as strong as they were

now tempted to add some box section lol

|

| |

1983 mini city e

1985 miny Mayfair

1997 Audi a4 tdi

2003 gsxf 750

|

|

|

|

|

May 18, 2010 17:47:50 GMT

|

|

Dave

Not sure I can entirely picture what you mean, but 16swg U channels with wings, as you say, would certainly add stiffness, but I would not just cover a rotten chassis with them

|

| |

|

|

wallopadonkey

Part of things

stunning grinder! curse word welder!

stunning grinder! curse word welder!

Posts: 234

|

|

May 18, 2010 21:55:33 GMT

|

|

|

| |

1983 mini city e

1985 miny Mayfair

1997 Audi a4 tdi

2003 gsxf 750

|

|

|

|