jonomisfit

Club Retro Rides Member

Posts: 1,787

Club RR Member Number: 49

|

|

|

|

|

Do you have any chandlers/ boat spares and repair places near you?

They may have all sorts of polyesters and epoxy resins / repair kits.

I wish I had your patience for bodywork detail. This is all a superb piece of work.

|

| |

|

|

|

|

|

|

|

|

|

|

Maybe, but my Daily is in for MOT tomorrow so that might need some attention - or not hopefully!

I could use the David's Isopon from Halfrauds, but I prefer to get all my supplies from CFS Fibreglass in Cornwall as I know it's good stuff and will keep the same characteristics to all the other glass.

|

| |

|

|

|

|

|

|

|

|

I was forced to use the little tins they sell during lock down, seemed surprisingly good quality.

I had to do the same on my Elan's bootlid to get it to sit flush, even with it supposedly coming out of an original mould

|

| |

|

|

|

|

|

|

|

As I could not do any fibreglassing** today I got on with a few other jobs instead.

** more on that later in the post.

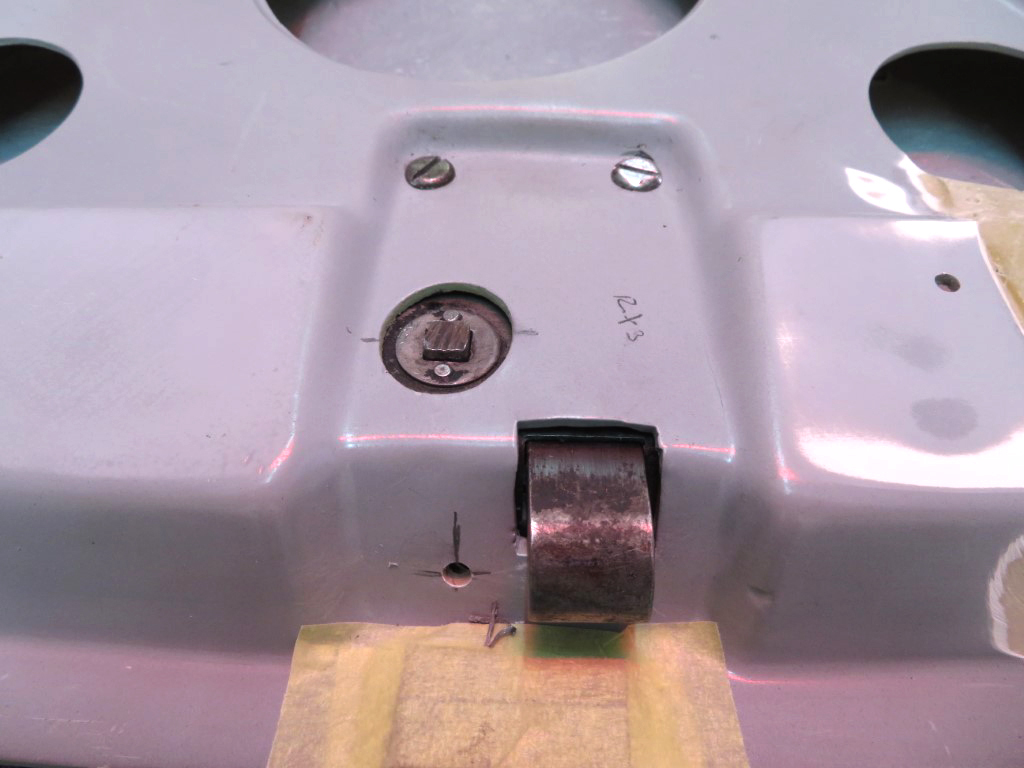

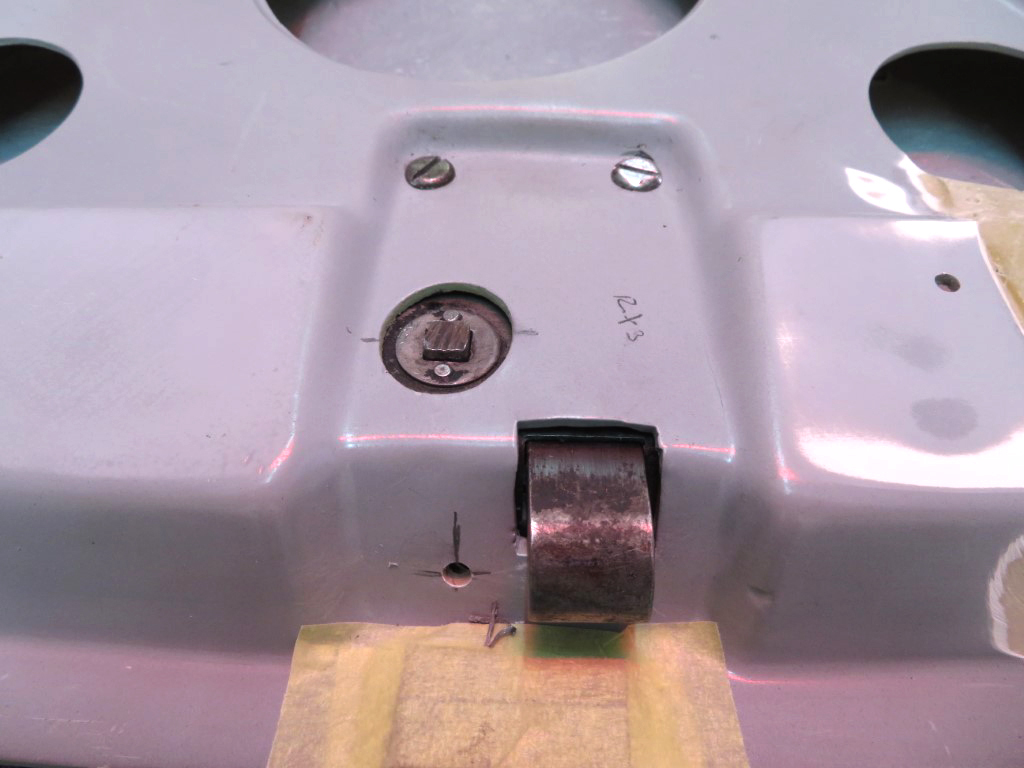

The boot lock should be held in with 4 bolts, as you can see Phils is only held in with the lower two. There should be two more - one either side of the tongue latch. As these are very near the edge of the bootlid (they were designed for steel bootlids) I decided that one bolt would be sufficient so drilled a new fixing hole.  This had a 5mm rivnut fitted - you can see the original fixings in this photo.  And fitted back with a stainless flanged button head bolt.  I then started on the doors. I knew they were generally excellent and are 95% ready for topcoat, but I had spotted swollen returns on the bottom of the doorskins so I wanted to open them up and get rid of loose rust & treat them. Thety were a little worse than I expected  Drivers door was the worst, outer skin is actually very good, the inner skin is a bit non existant in places. I'm not going to repair it, just treat it and fold the skins back again. They will be fully seam sealed inside & out before paint so properly treated should last quite a few years or longer without issue.

Passenger door a lot better; They were all cleaned out and the inside of the doors also cleaned along the seam edge. A liberal coat of Hydrate 80 was then applied.  I have started on the filler work over the repaired glass so far as well;

And now I'm feeling a bit smug  I retrieved the resin tin from the bin and had a look inside - there was still a little resin in the bottom. So I punched a hole in the bottom of the tin & left it to drain over the mxing tub while I was doing the door repairs. 20 minutes later there was nearly 50ML of resin in the tub  yay! Just enough to repair the bootlid, I got a couple of layers on the inside of the repairs as well. 613.5 hours.

|

| |

|

|

|

|

|

|

|

I took my pop out to the Bagshot breakfast meet this morning, nice to give it a run as it's not been out for ages. This afternoon it was back on Phils' car. I inspected the doors and carefully dressed the door skins back down. All went well on the passenger door, not so well on the drivers door. The inner skin on that one disintegrated when I dressed the outer skin down leaving a 10" strip of door flapping in the wind....oh dear. I said I was not going to repair the doors...well that escalated fast, lol   A while later it was all welded up and dressed back carefully. Nice & strong now.  I had got the passenger door fully smooth & flat a few months back but the drivers door was only 90% done as it was still on the car at the time. It was mostly there but a bit more filler work is needed to remove the last of the low spots.  While that was curing I blocked back the filler on the bootlid repairs - now ready for primer again;

Last job of the day was to give the bottom of the doors another dose of Hydrate 80, working it really well into the seams of the door skins on the inside and along the bottom of the doors, I want to make sure any rust is fully treated & encapsulated before I seal the seams up.

617.5 hours.

|

| |

|

|

|

|

|

|

|

|

I keep looking in and just shaking my head at your work mate.

Amazing progress and finishing off.

What a build, what a thread.

Thank you.

|

| |

Last Edit: Jan 11, 2022 7:40:56 GMT by grizz

|

|

|

|

|

Jan 10, 2022 23:05:00 GMT

|

Three companies/products I am happy to recommend in this post.

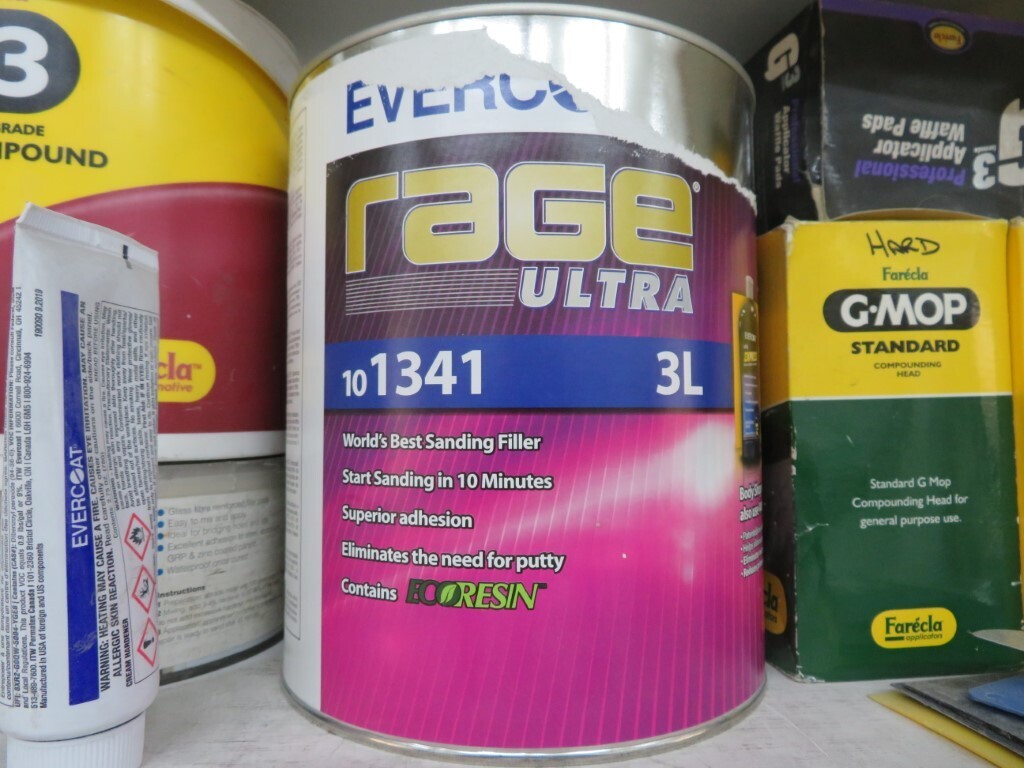

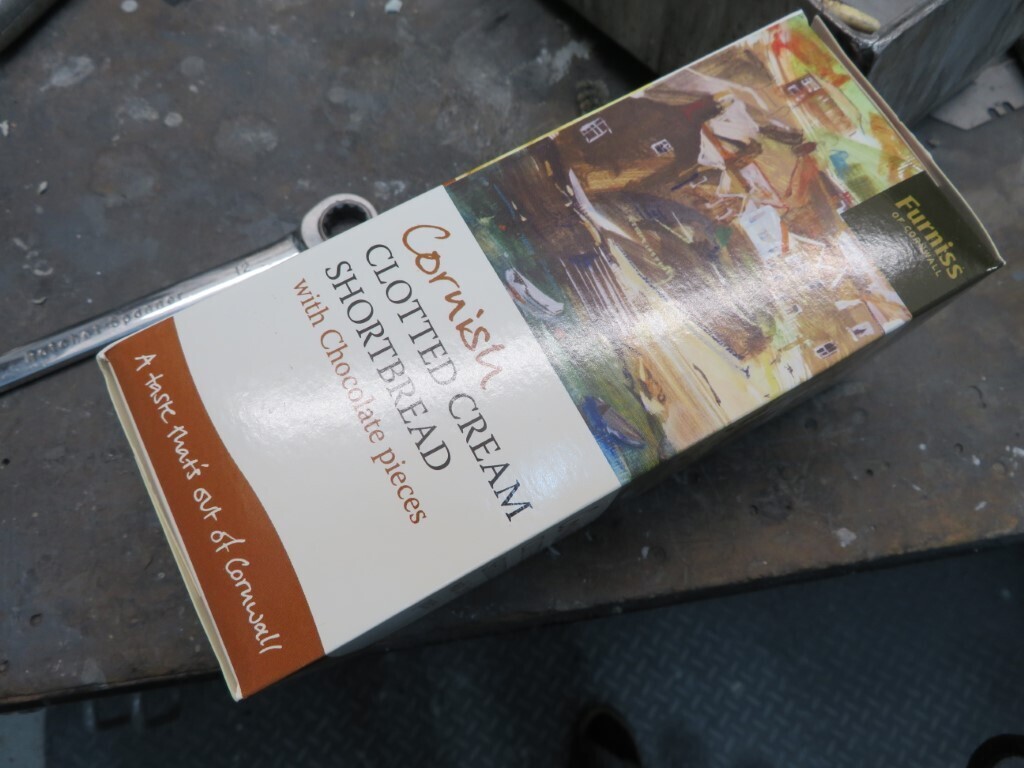

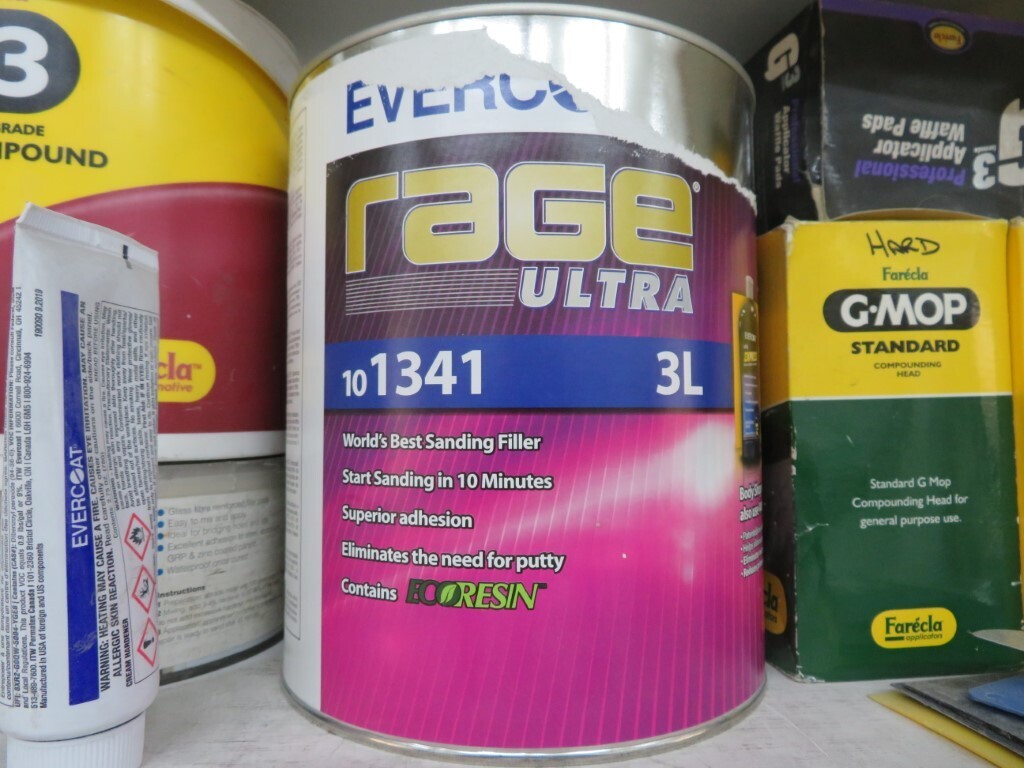

Deliveries arrived today, the fibreglass resin arrived early from CFS fibreglass, so good service there and a nice suprise in the box as well, a box of Clotted cream shortbread, nom,noms   More paint arrived from CC Paints who I can highly recommend, good service and I really like the paint as well. They even phoned me today to check all was ok and that I was happy with their service. With the filler sanded back on the door it was time for a bit more primer. I have been using this filler - Evercoat Rage Ultra, I bought it in error as I was after Evercoat Gold self levelling (the green filler in earlier posts) but I have to say I absolutely love it, its super smooth and it sands like a dream, absolutely no clogging of the paper at all. It really does what it says on the tin, including the sanding in 10 minutes (in a 20 degree workshop).  The drivers door is primed over the filler, looks pretty good but has some minor areas that will need a little more work.  Bootlid is primed over the repaired areas as well and the ground back bootlid gutter was also done.  Repaired section of door looking a lot better as well.

619 hours.

|

| |

|

|

|

|

|

|

|

|

Nothing exciting to report tonight, sanded some primer, did a bit of filling, cleaned up some bits for paint and painted the inside bottom of the doors with a brush bent to 45 degrees and a mirror so I could paint the back edge where you cant see normally.

621 hours.

|

| |

|

|

75swb

Beta Tester

Posts: 1,052

Club RR Member Number: 181

|

|

|

|

painted the inside bottom of th doors with a brush bent to 45 degrees and a mirror That's some level of fit and finish. Great dedication |

| |

|

|

|

|

|

Jan 12, 2022 10:46:17 GMT

|

|

Has to be done though as these are 'wet' doors (water runs through them) and there is pretty well no paint at all on the back edge on the doors - no point in painting the bits you can see if it's bare steel on the bits you can't.

Tedious but necessary.

|

| |

|

|

Norman

Part of things

Posts: 449  Member is Online

Member is Online

|

|

Jan 12, 2022 11:02:43 GMT

|

|

Great work Mark, i did wonder about the bottom of the doors. It’s always worse than you think, should last for years with the repairs you have done. All the best, Norman

|

| |

|

|

|

|

|

Jan 13, 2022 23:33:22 GMT

|

Thanks Norman. Night off last night as it was our club meet, nice to go to a pub again. Back on it tonight though with a bit more Mojo back again. I made these plates up at work with 5mm clinch nuts in them for the bootlid strap saddles.  Which will go here;

fixed behind the fibreglass with a countersunk rivet;

It makes bolting the saddles on a nice simple job.

Up inside the bootlid area got the same treatment;

together with the centre bar, this has had a big hole drilled in it as well. The rivnuts here (and the saddle ones in the previous photo) will hold an aluminium panel across the top of the boot (the same as my Pop) which will house two boot lamps. The hole is for the lamp switch to go through.

I started to seam seal the bottom of the doors, but ran out of Tiger seal so will need to pick a tube up tomorrow. It's a bit untidy as it's really difficult to get the gun in the door and some areas I just can't get the nozzle into so it's got to be applied with a narrow spatula.

Last job was to flat off most of the bootlid in readiness for topcoat this weekend hopefully.

623 hours.

|

| |

|

|

|

|

|

Jan 15, 2022 19:18:55 GMT

|

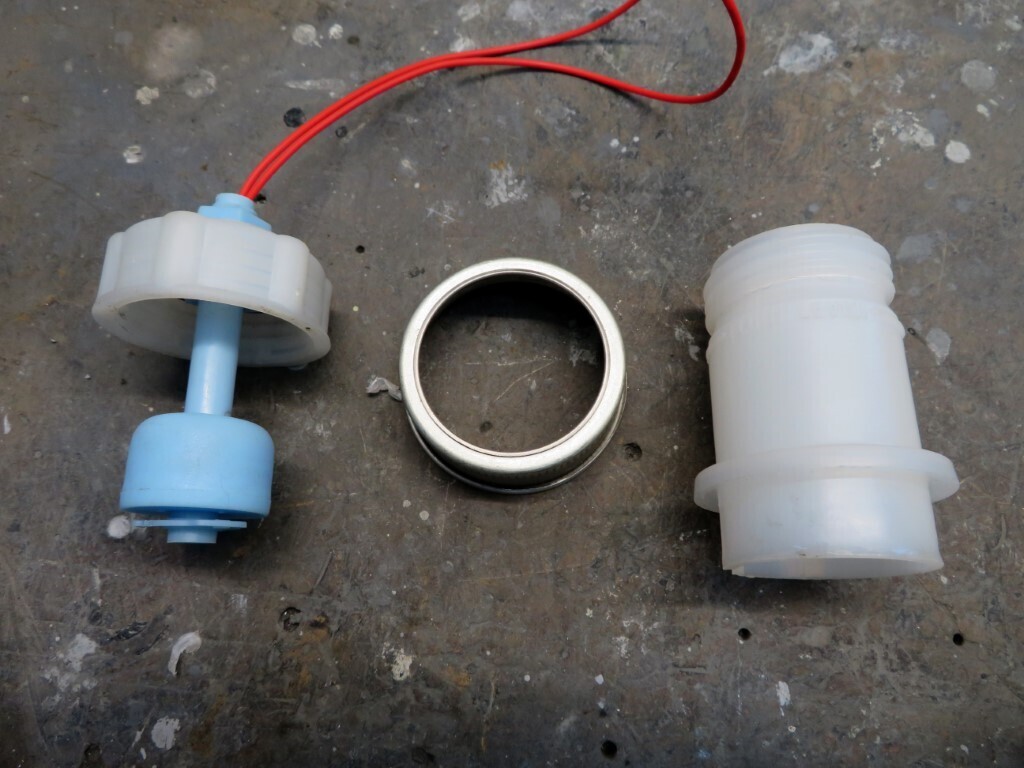

Phil came over today and sanded both doors down for me. We also ate nearly all of the clotted cream shortbreads shown earlier in the thread  yum. While Phil was sanding I made another retainer plate for the bootlid handle, this was bonded into the inside of the bootlid with some Tiger Seal.  Part of the brakes upgrade (I wanted to go tandem master cylinder, but it is not practical without a lot of work so we will go with refining the current system which has worked perfectly for the last 40 years) was to fit the extension reservoir which doubles the amount of fluid in the brakes.  I was sanding down all of the window apertures in readiness of painting the inside of the car, and also adapting the trim around the doorframe that the door seals nail into so it sat flatter around the door locks. Last job before we packed up was to finish off sealing the insides of the doors and we made a start sealing up the edges of the door skins on the outside.  627.5 hours. |

| |

|

|

gazzam

Part of things

Posts: 735  Member is Online

Member is Online

|

|

Jan 15, 2022 20:45:14 GMT

|

|

I hope you swept the floor!

|

| |

|

|

|

|

|

Jan 15, 2022 22:26:34 GMT

|

I hope you swept the floor!     not yet, living life on the edge! will do it tomorrow whe I finish sanding the doors. |

| |

|

|

|

|

|

Jan 16, 2022 21:41:10 GMT

|

Progress for today. Garage and car had a good clean out and then I started masking up the body to put more primer the insides of the window frames. Many other holes got masked in preparation of painting the rest of the inside of the car as well. Today was getting a decent thickness of primer on the inner window frames, door shuts and bootlid guttering.

And with the primer applied;  They will got scotchbrite'd back tomorrow and I'm hoping to get the inside of the car in gloss tomorrow night. Many other small parts got primed as well for the bonnet locks.

Before I did the primer I did a bit more filler work on the doors so they will be ready for primer later in the week. Last job for today was the pedal assembly. Thr brake pedal has been hacked around in its life - re-shaped & probably shortened. Its shorter than the clutch pedal so that won't do. Cleaned up here ready for being cut up.

And after a bit of surgery with the angle grinder and some 3mm plate steel it's now a bit longer and lines up with the clutch pedal.  632 hours.

|

| |

|

|

|

|

|

Jan 17, 2022 23:45:47 GMT

|

Tonight I have been making cardboard templates.  Which are now stuck in the car;   I really wanted to get some gloss on the inside of the car this week, but thinking on it I realised that I can't do that until the outside of the car is fully primed (it's only a light coat at present to seal it from moisture). So these boards in the window holes make it easy to seal the car off. Door apertures might be more of a challenge though. The filler on the doors was then blocked back and primer applied over the filled areas on the drivers door and the whole outer passenger door to cover the black primer.  634.5 hours. |

| |

|

|

|

|

|

Jan 18, 2022 10:11:28 GMT

|

I like the glass fluid reservoir's. Gingham is a bold choice for lids too!  |

| |

|

|

|

|

|

Jan 22, 2022 20:40:06 GMT

|

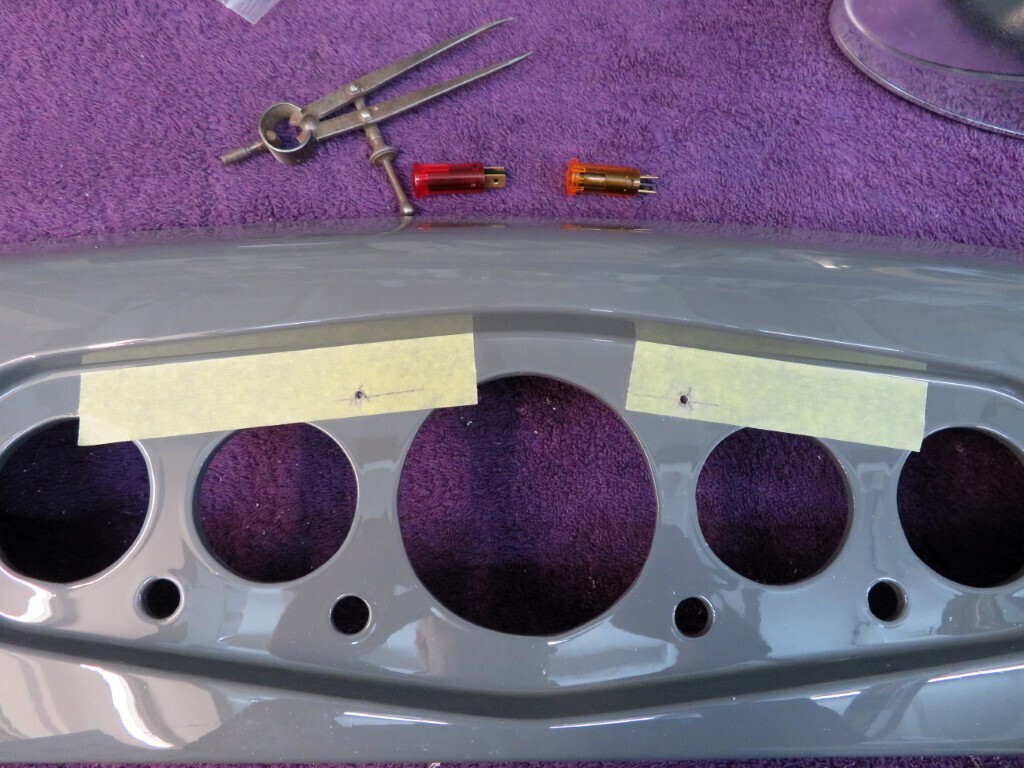

No progress this week as work has been very busy and I've just been too tired to do anything on it. My friend Geoff came over Tuesday night (he's building a Pop as well) and had a look at progress. Unfortunately when we were looking over the body together we spotted a crack in the filler in the roof  We are not sure why this has cracked as it's not an area with a joint or anything so it's a bit of a mystery. It has been ground back out to metal and inspected but I cannot see any reason for the crack. It's all been cleaned out and re filled so I'll just have to hope it was a one off problem.  Back on to the doors, all of the inner trim panel fixing holes have been drilled in both doors and both fully seam sealed on all of the panel edges.  Door hinges were also sealed to the door skins.  One small job I did do during the week was modifying the brake fluid reservoir to take the fluid level sensor that I got from Car Builder Solutions. This led on to altering the dashboard for the extra warnimg lights, one for the brake fluid level warning and one for the rear foglamp. Carefully marked out for drilling;

And with the new lamps fitted (they match the 4 in the bottom of the dashboard).  The rest of today was the boring but necessary rubbing down of bodywork (& finding some areas that still needed a thin skim of filler) in readiness for the proper coats of primer. Last job before packing up for the day was to give the workshop a good clean so I could paint the bootlid. First two coats on today, next 2 tomorrow.

Looks a good shine so far;

640 hours.

|

| |

|

|

|

|

|

Jan 23, 2022 21:32:42 GMT

|

An excellent day on the car today. Phil came over and we spent the day rubbing the entire body down. I was intending to get the next two coats of paint on the bootlid, but after rubbing it all down, on inspection the top edge of the bootlid was not quite as smooth as I thought and it was a bit shy of paint thickness. Edges are always difficult to get enough paint on. So that was sanded down to remove the blemishes and then I carefully painted the edge in with a small artists brush. This was done twice so the bootlid will get prepped again tomorrow and painted then. When rubbing the body down there was one bit bugging me, the bonnet latch bars. It's impossible to paint behind them and difficult to sand around so on the spur of the moment the drill came out and the rivets were drilled out to reveal the metal behind. Not as bad as we expected as there was never any paint behind them from the factory. A little bit of rust but not much. We did find a few areas that required a little more filler as well - one is in this photo.  When we had finished rubbing down we did a big garage clean to get all of the dust removed and then started masking the car up. The whole of the painted section of the underneath is fully masked;  And so is the entire body, windows were done previously, but now the doors are done as well;  And finishing off we had to crawl out of the bootlid and then mask that up with cardboard around the edges and some masking sheet in the middle - difficult masking the inside from the outside, it was like the Cheshire cat licking itself invisible in Alice in Wonderland!  Tomorrow I will finish masking the rear wheel arches up to the arch bolt line as they are glossed to that point. The plan then is to spot prime the few areas that we broke through to bare steel on the body and then gloss the bootlid and various small parts I have lined up. Hopefully on Tuesday I can do two coats of primer on the body, if all goes well I'm planning on getting the front of the underbody in gloss including the front chassis rails, and getting the bulkhead glossed completely up to the body flange before I go Skiing next weekend. That will be another milestone if I can achieve that. 645.5 hours. |

| |

|

|

I retrieved the resin tin from the bin and had a look inside - there was still a little resin in the bottom. So I punched a hole in the bottom of the tin & left it to drain over the mxing tub while I was doing the door repairs. 20 minutes later there was nearly 50ML of resin in the tub

I retrieved the resin tin from the bin and had a look inside - there was still a little resin in the bottom. So I punched a hole in the bottom of the tin & left it to drain over the mxing tub while I was doing the door repairs. 20 minutes later there was nearly 50ML of resin in the tub

yum.

yum.