stinkey

Part of things

Always rodding and chopping

Always rodding and chopping

Posts: 42

|

|

|

|

|

Hey mark,I know how you feel about communication,I personally love looking at people's builds, I miss the days when you actually went to SEE and crawl around other guys projects rather than going on the bloody internet? 🙄

Plus I'm useless with modern technology and also don't like to intrude into others comments especially if it's too geeky/nerdy/way above my knowledge? 😄 and obviously life gets in the way

|

| |

|

|

|

|

|

|

|

Apr 24, 2022 20:00:56 GMT

|

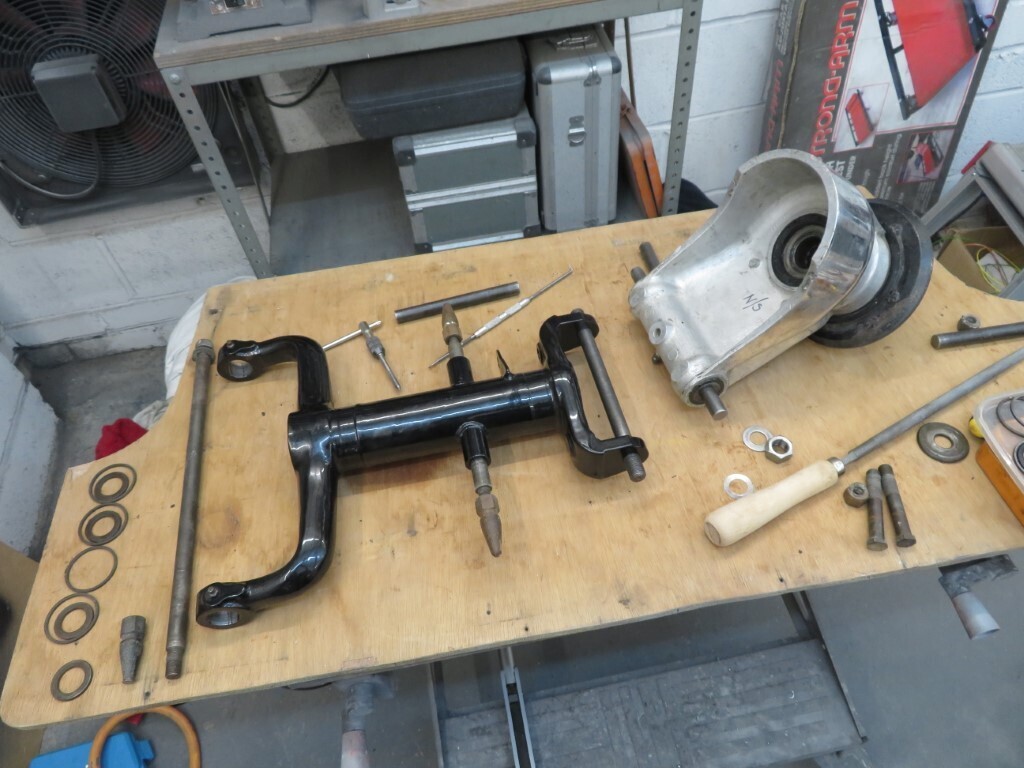

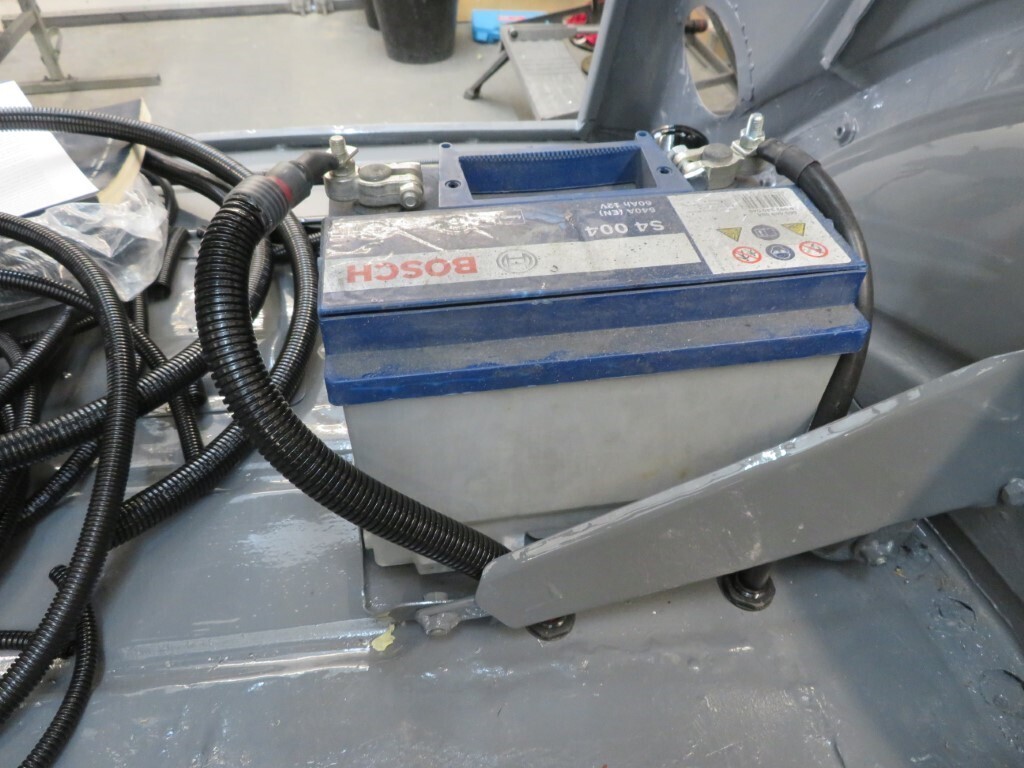

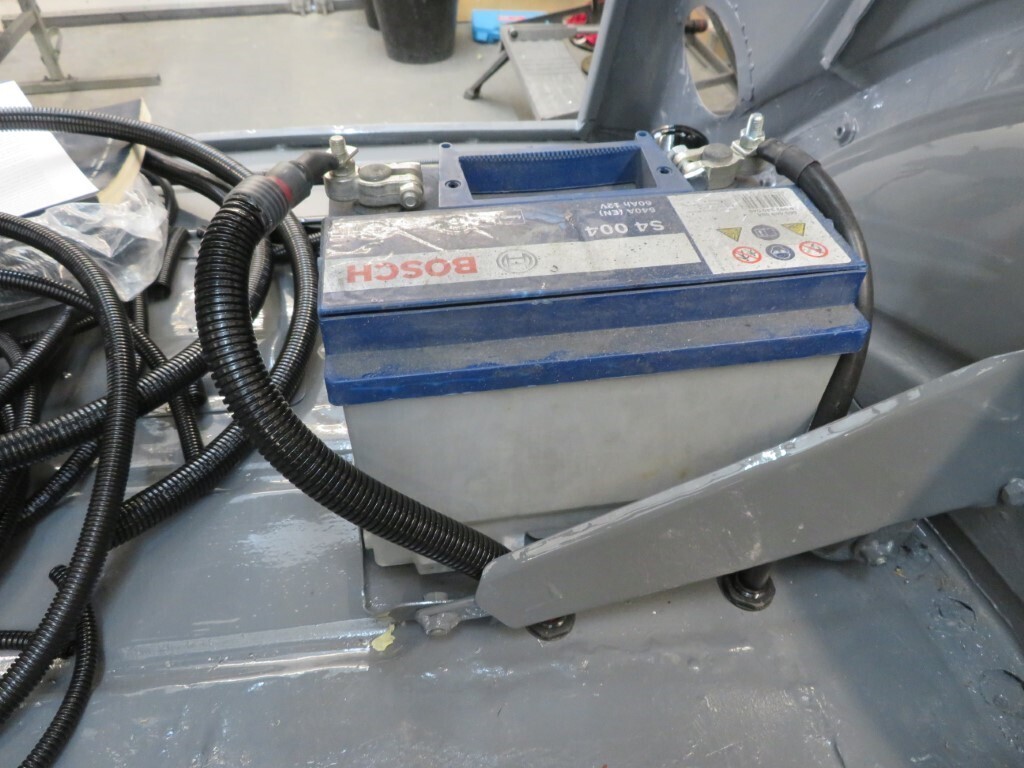

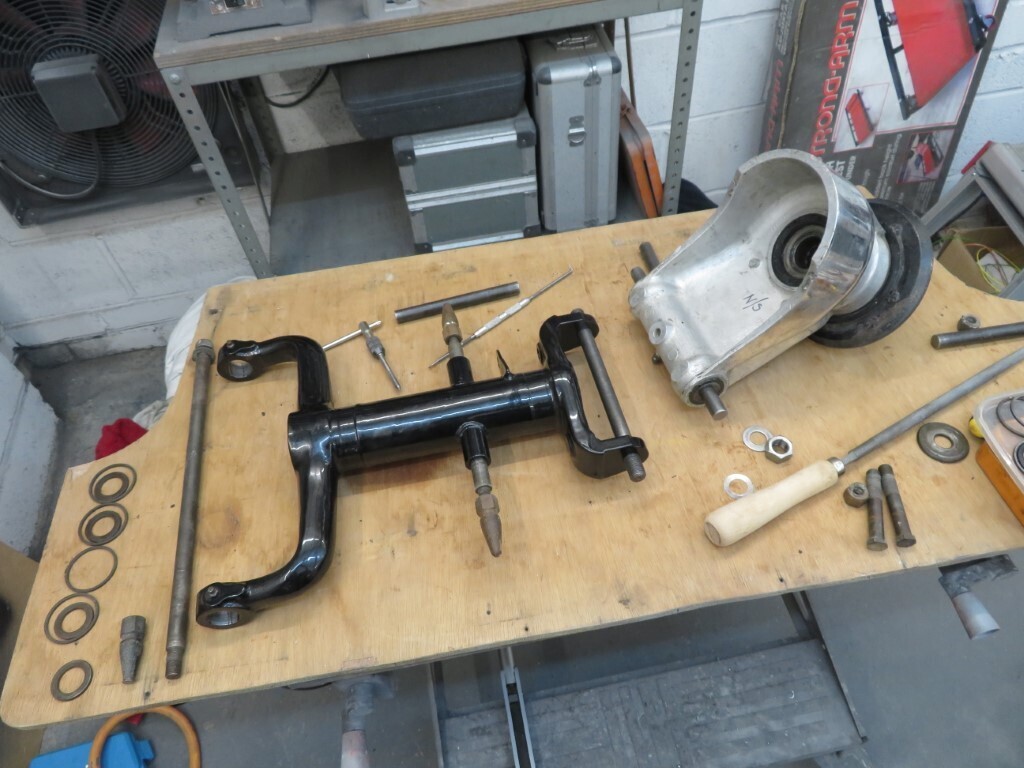

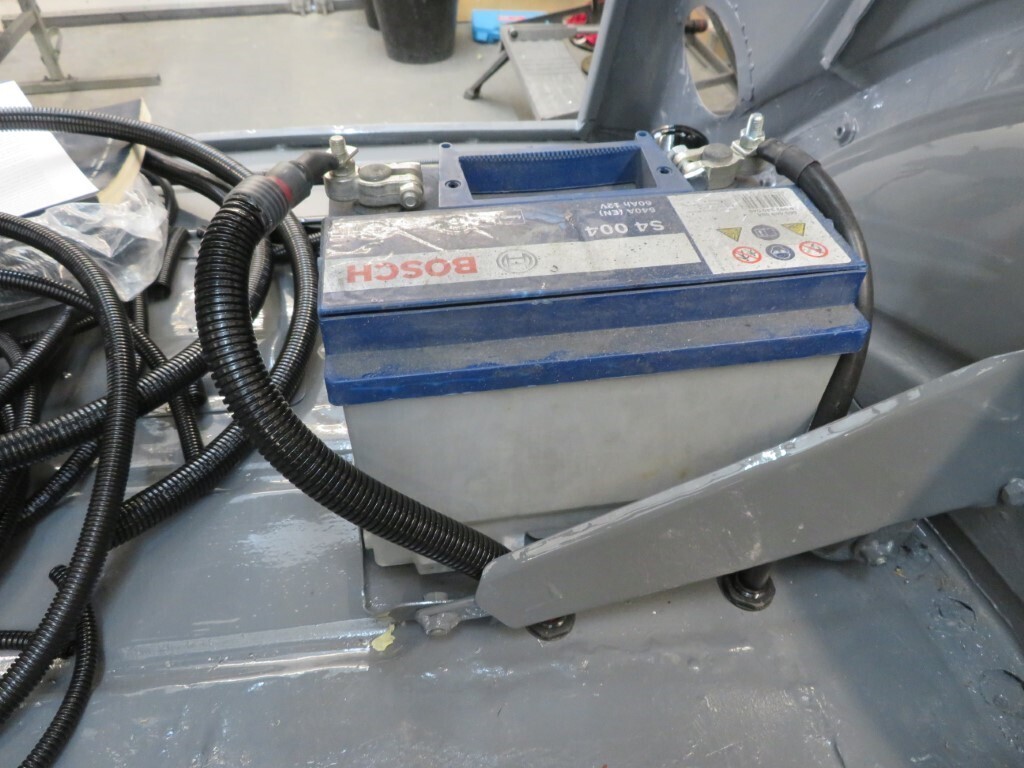

I took my Pop to the Aylesbury meet this morning - there were a good bunch of very nice Pops there amongst all of the other cars, it was a good morning out meeting up with friends and the weather was perfect. I left my phone at work otherwise I would have taken some photos. In the afternoon Phil came over and with the tools that we have been lent by our friend Mike I started on the rear axle assembly. The wishbone mounts are now shimmed properly and bolted up tight. The bolts and a few small areas have been touched in with primer again and once topcoated the bolts will be wired together.  I made a start on shimming the bearings in the hub carriers, one side is done but I need more shims for the other side - these should arrive tomorrow so with luck I can sort those tomorrow and get on with the rest of the reassembly. Some other parts of the axle (washers) were primed with a few small parts of the car that needed doing, one of which was the exposed threads on the pedal assembly where it exits the bulkhead. These will be glossed tomorrow.  Battery cables are now terminated.  Phil had finished sanding the door so I have now mopped it to the first first stage polish, looks pretty good so we are happy with that. It will get mopped to a high shine later when we start to reassemble the car.

In the meanime while I was polishing the door Phil was trying to use up all of his sound deadening sheets  and has covered most of the inside of the car with it. I had to hold him back from covering the seats as well    The second last job of the day was fitting the rear window trim - I suspected it did not fit very well and I was correct - none of the lower screws are anywhere near the metal of the car and exit into fresh air. Some small metal tabs will need to be added to the window frame to provide something for the screws to go into. The last job was templating the rear panel between the car & the boot, I'll try to cut a new panel at work tomorrow if I have time which can then be test fitted at home and tweaked where needed before I machine the speaker holes in it.  839 hours.

|

| |

|

|

jimi

Club Retro Rides Member

Posts: 2,148

|

|

Apr 24, 2022 20:07:44 GMT

|

Nice to see the battery leads are properly crimped and sleeved.   |

| |

Black is not a colour ! .... Its the absence of colour

|

|

stinkey

Part of things

Always rodding and chopping

Always rodding and chopping

Posts: 42

|

|

Apr 24, 2022 21:56:09 GMT

|

|

I am surprised you didn't clean the battery before fitting it 😄

|

| |

|

|

|

|

|

Apr 25, 2022 12:28:52 GMT

|

That's because its my old dummy battery  Phils battery is at his house. |

| |

|

|

stinkey

Part of things

Always rodding and chopping

Always rodding and chopping

Posts: 42

|

|

Apr 25, 2022 13:22:13 GMT

|

That's because its my old dummy battery  Phils battery is at his house. I think I'd come under that heading of being a dumb battery 😂 |

| |

|

|

|

|

|

Apr 25, 2022 15:14:18 GMT

|

|

Its getting very close to being finished, have you got a date to aim for or is it ready when its ready?

|

| |

|

|

|

|

|

Apr 25, 2022 18:36:05 GMT

|

It has to be fully drivable by 11th June as thats the date we are doing a 1000 mile drive around the lake district! No pressure then  It will be ready but it won't be finished. |

| |

|

|

stinkey

Part of things

Always rodding and chopping

Always rodding and chopping

Posts: 42

|

|

Apr 25, 2022 19:19:52 GMT

|

|

Take your umbrellas and raincoats mate 😄👍

|

| |

|

|

|

|

|

Apr 25, 2022 23:11:24 GMT

|

Tonight was a bit frustrating as I hoped to get a bit further that I have. It all started well with the new rear panel I cut at work almost fitting perfectly first time. Some minor trimming and sanding the edges saw it in place and I then drilled the fixings where it bolts to the parcel shelf. I will install rivnuts tomorrow when I borrow the tool from work.  Then it was back on the rear axle. I had the delivery of the shims today so armed with those I got the other bearing carrier lower bearings shimmed correctly. Once that was done I greased all of the bearings up and also the felt washers and installed all of the relevant parts for assembly. Where it got a bit frustrating was when I realised that I cannot assemble the bearing carrier to the lower wishbone until its all fitted to the car. Also the powder coating had to be carefully filed off the inside of the bolt holes as they had not masked all of them off. The same went for the grease nipples, I had to run a tap through the holes before twiddling the nipples for some time to get them in.  So it looks like the next job will be getting the calipers reassembled & fitted to the diff with the handbrake parts and getting that back under the car. The gearbox crossmember will need to be refitted so the radius arms can fit to the lower wishbones as the bolt for those has to be installed before the hub carriers go back on. 841 hours. |

| |

|

|

stinkey

Part of things

Always rodding and chopping

Always rodding and chopping

Posts: 42

|

|

|

|

|

Can't have been all bad because you got to twiddle some nipples 🙄?

I'd definitely suggest fitting the diff unit first, because has you know these things get heavier has you add the components..I love these axles and over the years have fitted many to different vehicles, thoroughly enjoying this build process mate..

|

| |

|

|

|

|

|

Apr 26, 2022 12:18:22 GMT

|

Yeah playing with some nipples is always top of my fun list    I was just hoping to get the hubs on the lower arms and then fit them to the diff later. |

| |

|

|

stinkey

Part of things

Always rodding and chopping

Always rodding and chopping

Posts: 42

|

|

Apr 26, 2022 19:09:57 GMT

|

|

Unless you have some sort of heavy duty lift which you could fit the complete axle, definitely better one piece at a time?

|

| |

|

|

|

|

|

Apr 26, 2022 22:47:00 GMT

|

Another frustrating evening. I started fitting the wishbone inner bearings - these are the ones given to us recently that have only been used for about 200 miles. First pair went in fine, second pair and the sleeve was binding in the bearing. Pressed them out again and inspected them carefully...........oh dear  When they were removed by the previous owner they must have been punched out with a drift rather than pressed out, the sides of the casing are damaged & split on 3 of them. I carefully inspected all of them and the other 5 are fine.  Another shipment from David Manners is now in order. I also bloody hate powder coating. So called professional job and it's all flaking off with no adhesion.  People ask me why I bother painting parts - well thats why. Paint may chip easier but it does not fall off in sheets. Water will creep under that and rust fron the inside. I'll have to grind it back and paint that section now. The rest of the evening was cleaning parts for reassembly and reaming out shaft holes of debris so the cleaned up shafts fit smoothly. 843 hours. |

| |

|

|

gazzam

Part of things

Posts: 718

|

|

|

|

|

Looking good.

What’s the rear panel made from?

Powder coating is for fences, not cars in my view. Paint is much better.

|

| |

|

|

|

|

|

|

|

|

Great progress Mark.

Re powder coating, I've never seen any that lasted. Once chipped it's worse than useless.

|

| |

Proton Jumbuck-deceased :-(

2005 Kia Sorento the parts hauling heap

V8 Humber Hawk

1948 Standard12 pickup SOLD

1953 Pop build (wifey's BIVA build).

|

|

|

|

|

Apr 27, 2022 10:29:13 GMT

|

Great progress Mark. Re powder coating, I've never seen any that lasted. Once chipped it's worse than useless. Great progress Mark!

I am a fan of powdercoating. Did all the suspension parts and even brake calipers on my Rover and MGB V8. MGB V8 is on the road for 15 years now and it still looks like new. The compagny that does my powdercaiting sprays on a primer before the powdercoating and advises to do a double coat of powdercoating. Still much cheaper then getting things painted.

I travel 125km to this powder coating firm. Have tried compagnys nearer to me but was never really happy.

Peter

|

| |

|

|

|

|

|

Apr 27, 2022 12:39:34 GMT

|

gazzam the panel is 10mm Birch ply with a pvc coating on both sides. We use it for making flight cases at work. Paul & Peter, We were seduced by the guy who narrowed the rear axle as he said they would be sandblasted, primed and then coated. It seems they were just coated over the cleaned part. The coating is very thick, so at least that part is ok but now I wish I'd just painted them.

|

| |

|

|

|

|

|

Apr 27, 2022 22:46:24 GMT

|

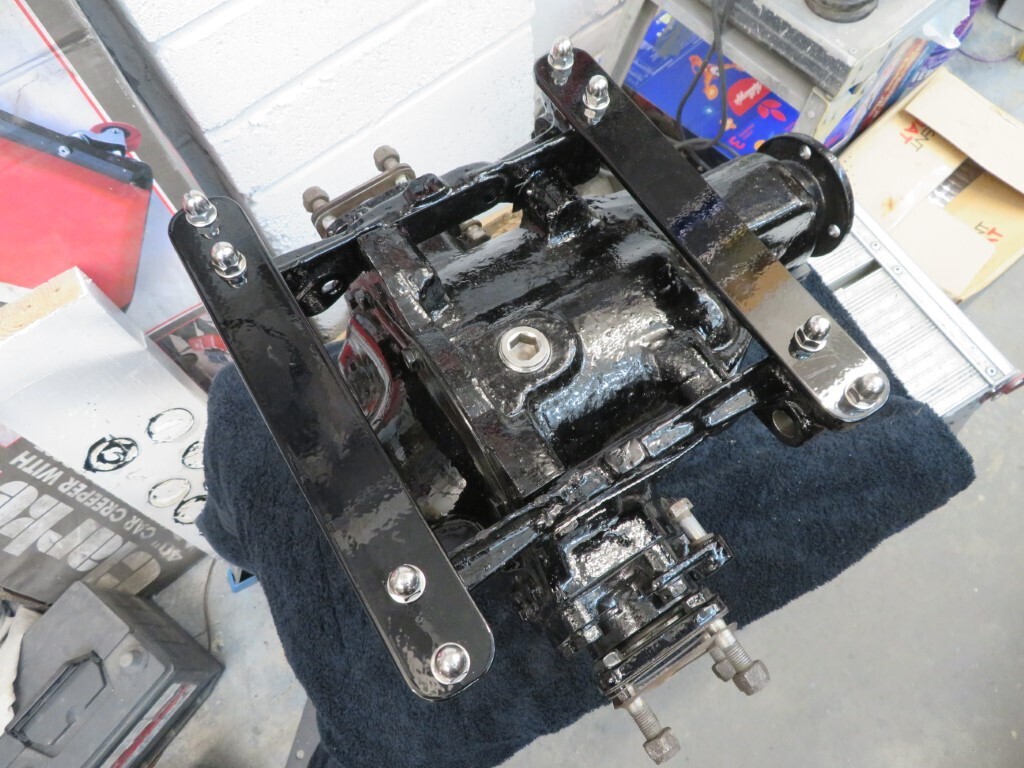

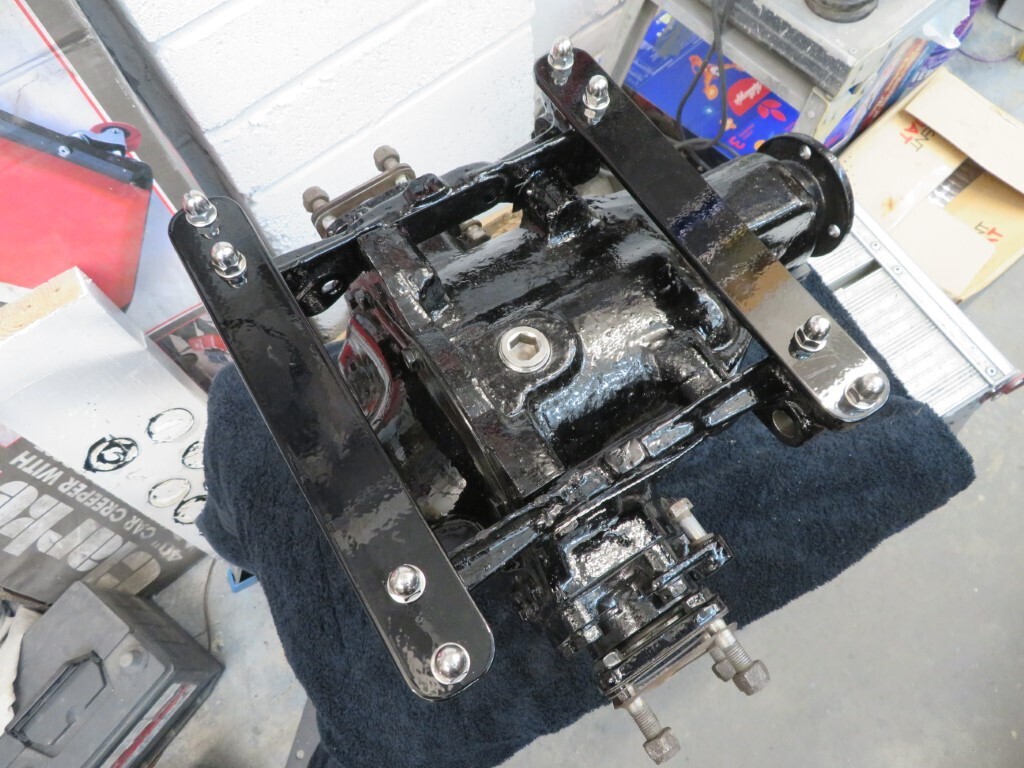

Well tonight was slow going. The panel in the car was removed so the 5mm rivnuts could be fitted in the parcel shelf. Then it went back in for marking out where the rear speakers will fit. Then it came out again for a bit more trimming and to go to work where I will machine the holes for the speakers. Then it was back on to the rear axle. Bottom brace bars are now bolted back on the diff with low strength loctite & torqued up.  Bolts start to get lockwired;  And then it was a case of turning a heavy chunk of metal into a really heavy chunk of metal. I can honestly say I don't like Jag rear ends. Heavy, overcomplicated and difficult to work on units. Really, who designs a caliper fixing that you can only get an open ended spanner on and only tighten 1/6th of a turn at a time?? No wonder lockwire is needed as you cant tighten them very much. I'm halfway through here, handbrake mechanism is loosely fitted but needs lubricating properly before proper fitment.  I reckon we might need the engine hoist to get it back down on the floor, lol. 845 hours. |

| |

|

|

stinkey

Part of things

Always rodding and chopping

Always rodding and chopping

Posts: 42

|

|

|

|

|

Tbh I prefer to use different handbrake calipers if possible for jag rear axle? And yes most definitely heavy but super strong and should last for years especially if you're mate keeps it maintained 😄👍

|

| |

|

|

and has covered most of the inside of the car with it. I had to hold him back from covering the seats as well

and has covered most of the inside of the car with it. I had to hold him back from covering the seats as well

Phils battery is at his house.

Phils battery is at his house.