|

|

|

|

|

Hi Dom, making good progress  That big orange monster is hilarious! I guess you can fit the whole engine in there? I need to look back through the thread again to see where you are, it has evolved so much! Wheels? Supercharger? (Lysholm?) Speak soon buddy  |

| |

|

|

|

|

|

|

|

Feb 26, 2015 21:57:27 GMT

|

LOL Cheers Fella  I cant wait to get it fired up and blasting now. A couple of other pics.... Finally got my lower wishbones blasted, epoxy primed and painted, along with the Front Springs. These have been plated on the bottom to stiffen them too    So Just the front Crossmember to finish welding now and that can be done. I need to find my Rack Mounting brackets and I`ll probably strip the rack again as well. That way I can get the body blasted and painted, and all the steel parts plated nicely  Other wise I will always regret it and not be happy with them. I still need to get the Uprights dipped / stripped / fettled a bit more before bead blasting and Plating those too. I will also get the Hubs cleaned up and plated with the uprights, then they can have new ARP long studs pressed in. Thanks for looking Cheers Dom |

| |

Last Edit: Feb 26, 2015 21:58:38 GMT by CR500Dom

|

|

|

|

|

|

|

NOt much actual work to report as I`ve been snowboarding  But I did make a detour on the way back to pick up another parts washer tank  The Fact the bench top one I brought about 2 years ago is still in its box is immaterial  I now have a "dirty" parts washer and a 2nd stage "Clean" parts washer. Nothing goes into the clean tank until its been through the dirty one, the larger floor standing one will be the dirty tank (so I can hang engines / gearboxes over it to clean before stripping) and then the bench top one will be the clean tank. most of the stuff that wants a second clean will be engine or transmission internals so will be smaller in size too. If it needs to be cleaner than that, then I have access to a decent Ultrasonic Bath too. Oh and while I was collecting the parts washer, he had a bench top blast cabinet at a "too good to pass up" price too So I figured it would be silly not to. I might keep this one with just fine glass bead or Walnut shell in it, similar principle, Garnet in the big cabinet, softer/gentler medium in this one for finer jobs. I`ll have to do a manifold for the cyclone extractor now so I can use that for both cabinets too Thanks for checking in as always Cheers Dom |

| |

|

|

Rob

Posted a lot

You know, for kids!

You know, for kids!

Posts: 2,515

|

|

|

|

|

Looking great Dom - just read through and saw my last comment on here was from 2007 back on page 5 :/

If it's ANY consolation at all I'm still working on the same car too haha.

|

| |

|

|

|

|

|

Mar 23, 2015 18:05:54 GMT

|

Well I actually managed to do some stuff, not much, but a little bit to keep it progressing Crossmember is nearly finished now. Full strengthening kit added and it just needs the Rack mounts Plating, and the original (removed) engine mounting positions plating over with a quick tidy up to the mounting ears too.    I Have also finished cleaning up / semi polishing the front Uprights too.   These will now go off for Zinc and Gold Passivated plating, so should look lovely when they come back later this week. I`ll get the hubs done the same as well. Quickrack needs stripping, cleaning and detailing to match, If I don't do it now I will always regret it So It wont be long hopefully, and I`ll have a complete front end to go back together  It`d be nice to have a shell finished to fit it to  As Always, thanks for looking ;o) |

| |

Last Edit: Mar 23, 2015 18:07:24 GMT by CR500Dom

|

|

Seth

South East

MorrisOxford TriumphMirald HillmanMinx BorgwardIsabellaCombi

Posts: 15,543

|

|

Mar 23, 2015 20:32:04 GMT

|

Crossmember is looking really good with all those mods  |

| |

Follow your dreams or you might as well be a vegetable. |

|

bstardchild

Club Retro Rides Member

Posts: 14,971

Club RR Member Number: 71

Member is Online

|

|

Mar 23, 2015 20:34:40 GMT

|

Well I actually managed to do some stuff, not much, but a little bit to keep it progressing Crossmember is nearly finished now. Full strengthening kit added and it just needs the Rack mounts Plating, and the original (removed) engine mounting positions plating over with a quick tidy up to the mounting ears too.  Looks great excuse the question but why not fully weld? I'm sure it's more than strong enough as it is but just wondered what reasons for not fully welding? |

| |

|

|

|

|

|

|

|

Cheers Guys  BC, as for Welding it doesn't need it, and by stitch / plug welding you minimise the distortion. I was always taught that on Body shells and additional gussets, stitching is better as it does allow some flex of the whole system without inducing cracks. (That's one of the reasons why down tube or top tube gussets on push bikes are always open on the end /welded down the sides) If its fully welded, there is no where for the stress to flex, so it will flex at the weakest point. Normally the heat affected zone of a weld, which then starts a crack, continued flexing propagates this crack. That's as I understand it / have always done it |

| |

|

|

PhoenixCapri

West Midlands

Posts: 2,685

Club RR Member Number: 91

|

|

|

|

Starting to come together very nicely this Dom - still can't wait to see it finished  |

| |

|

|

Rob

Posted a lot

You know, for kids!

You know, for kids!

Posts: 2,515

|

|

|

|

|

Crossmember looks great, love the strengthening.

|

| |

|

|

|

|

|

|

|

Mar 29, 2015 14:17:04 GMT

|

Cheers Guys !! Nice to know its still being followed, apologies for the Gentle feel of the updates, in comparison to some on here !! I did get the Uprights back from the Platers and a very nice job they made of them too  It was worth spending the couple of hours with die grinder and roloc discs to smooth everything out as the finished result should stay a lot cleaner for longer when fitted to the car.  In other news, I am hopefully getting some time today to do some stuff on the CAD, relating to the Bellhousing swap / reconstruction / new casting And I may even get my rear brake caliper mounting plates finished.... Still not sure whether to cut the ends of the axle casing off, and fit Group 4 fully floating ends. This would require the half shaft to be turned down and then re-splined at the outer end so I`d end up with a 2 piece half shaft. It would provide a bombproof rear axle, and means I could use the tried/tested and readily available Escort Gr4 solutions, all be it with a 4x100 stud pattern for this build. |

| |

|

|

bstardchild

Club Retro Rides Member

Posts: 14,971

Club RR Member Number: 71

Member is Online

|

|

Mar 31, 2015 20:05:14 GMT

|

|

Those front bits plated shouldn't be hidden.... Should have got an extra one done as a bookend.

Enjoying the updates however small (don't pretend to understand the rear axle/half shaft quandry but I just know you'll make the right choice and soon we'll see pictures of the shell on it's wheels and then I'll know it's close)

|

| |

|

|

|

|

|

Mar 31, 2015 20:49:59 GMT

|

|

Lol, they do look rather nice !

It's nice to be getting stuff back clean again at last, I'm sick of seeing all my nice, carefully chosen and crafted components, all covered in corrosion of one type or another.

It's only small stuff at the moment but psychologically it's very important.

Soon I will have a complete front end, all painted, plated and prepped, ready to refit.

I've dropped the 6 speed off with a mate tonight as well, he's going to have a look at the bellhousing issue as well.

The axle issue isn't an issue if I run 15" wheels, but I want to be able to run 13s.

That makes it harder to get the discs and calipers in the available space while still clearing the back of the wheels

Fully floating hubs make the whole issue somewhat easier to solve as it's been done that way for years on rally escorts.

But it does add a starting kit of bits at around £400-450, before I start welding / modifying again

Needs another proper looking at and some more measuring, I still can't properly see it at the moment.

Thanks again for looking

Cheers

Dom

|

| |

|

|

Rob

Posted a lot

You know, for kids!

You know, for kids!

Posts: 2,515

|

|

|

|

I'm sick of seeing all my nice, carefully chosen and crafted components, all covered in corrosion of one type or another. It's only small stuff at the moment but psychologically it's very important. I get this. By the time I'd got the rear suspension done my front disks, a-arms etc were all covered in the dreaded brown. Like painting the Fourth bridge when work slows down isn't it? |

| |

|

|

|

|

|

Apr 17, 2015 20:47:36 GMT

|

|

It is indeed Rob !!!

Well I have actually made some progress, and done a lot more thinking and working out.

Thinking first.

The rear discs are still a problem and will always be I think. The problem is I need a very deep bell to get the caliper mounts far enough away from the wheel bearings to not cause a problem when they are welded on, this also allows the caliper to sit inside a 13" wheel.

I have some really light, really nice AP Racing calipers which can be fitted with handbrake mechs and I'd like to use them if at all possible.

They are designed for thin solid discs on single seaters, and all single seaters run 13" wheels

So having exhausted all the options in the APEC catalogue for off the shelf discs with integral bells, the next logical step is going to be separate discs and alloy bells.

FF1600 cars ran some really nice solid discs with alloy bells on the later cars, some were even fully floating discs too, so I'm going to see if I can get a used disc to measure up from and see if I can then get that over the half shaft. If it clears then I have half a chance of designing some alloy bells to put the calipers where I need them to be.

So I'm feeling a bit happier about that, at least now I have a possible way forwards, without having to go fully floating "Atlas" ends and hubs etc.

|

| |

|

|

|

|

|

Apr 17, 2015 21:02:43 GMT

|

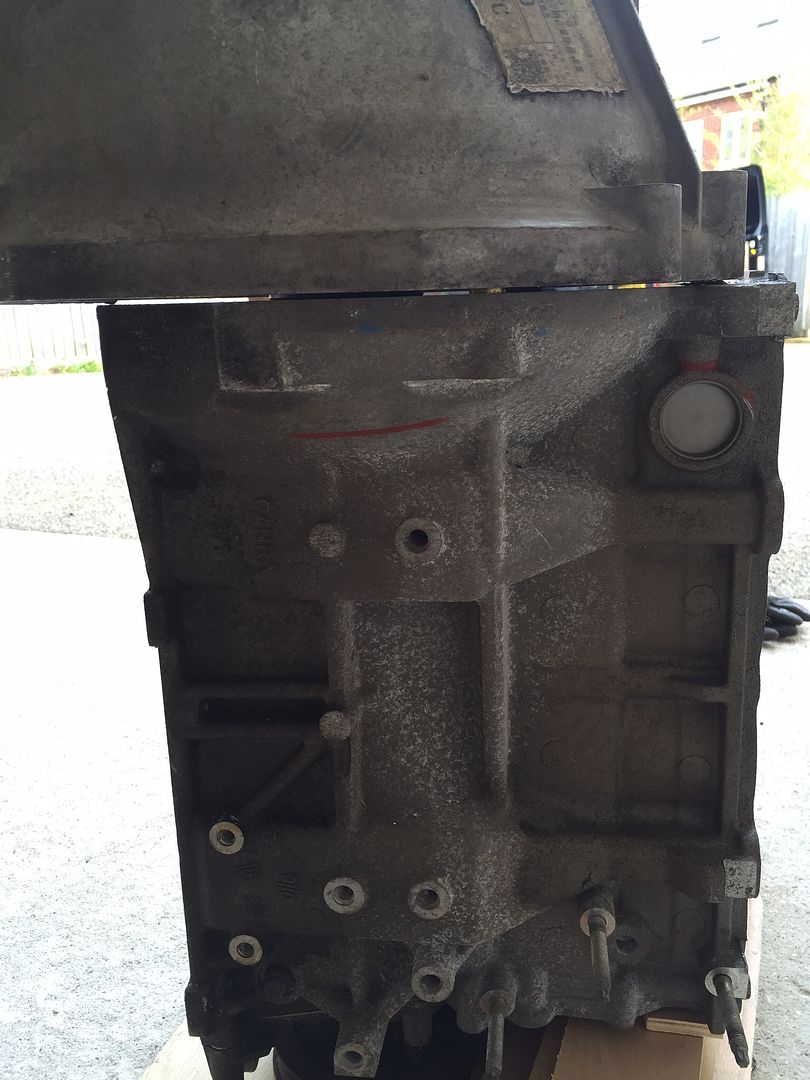

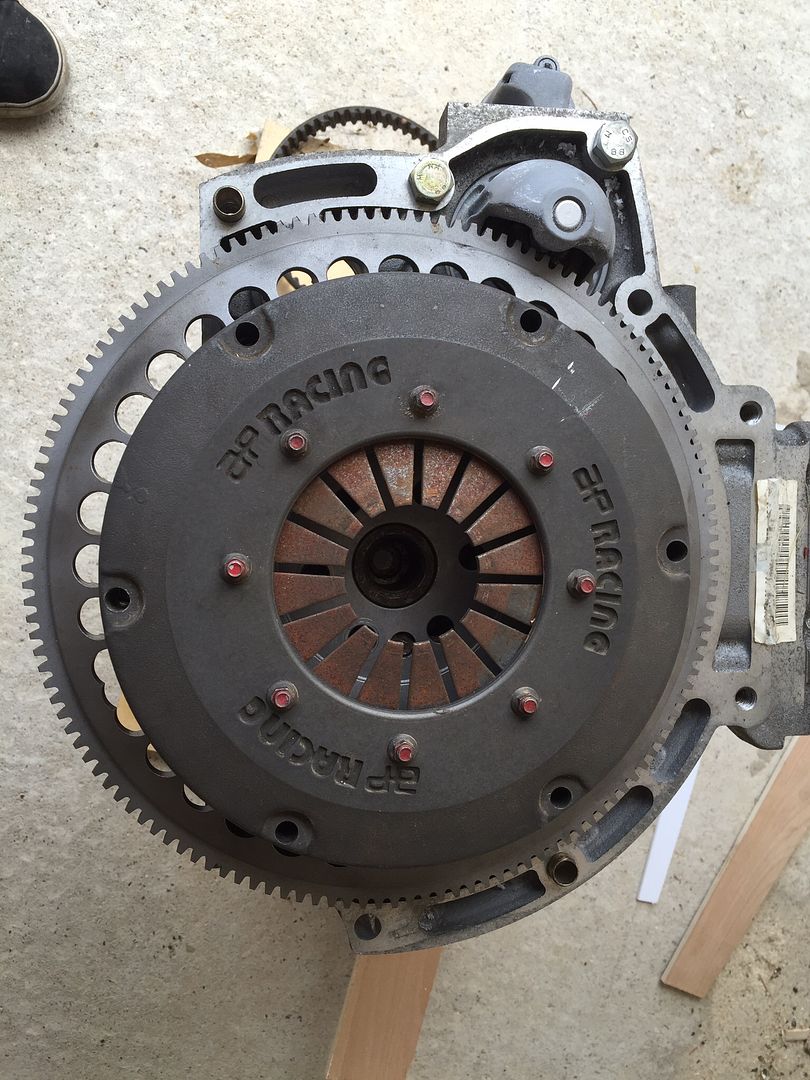

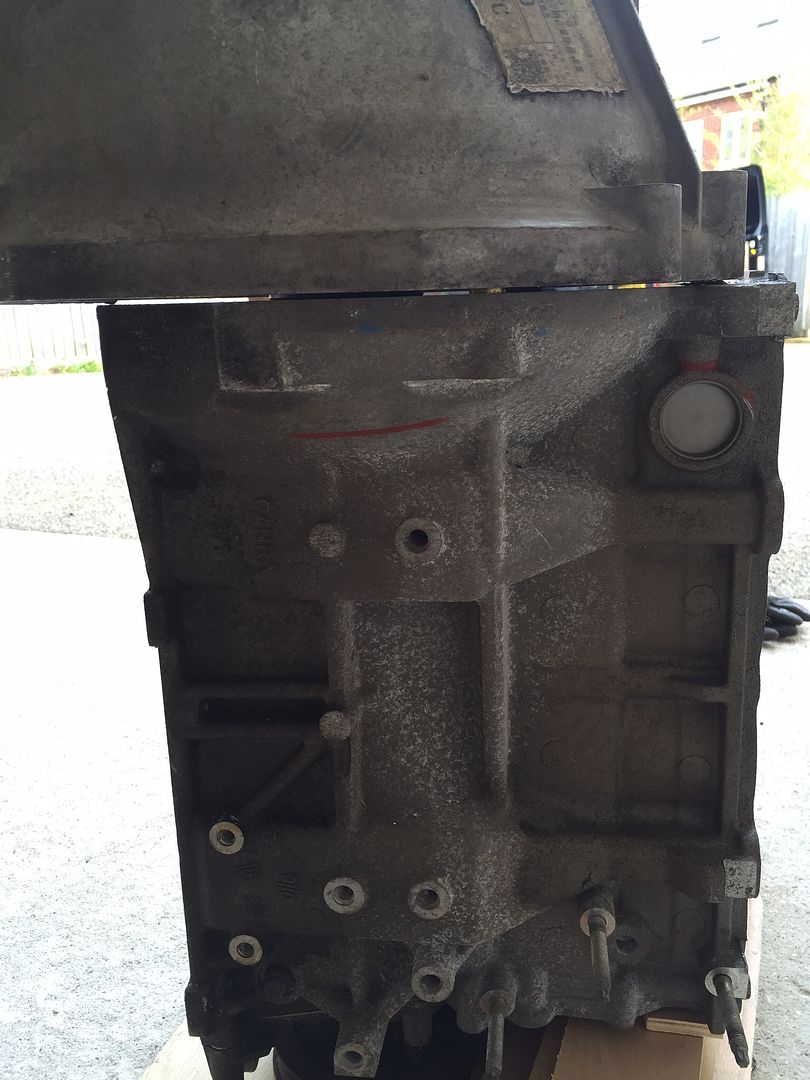

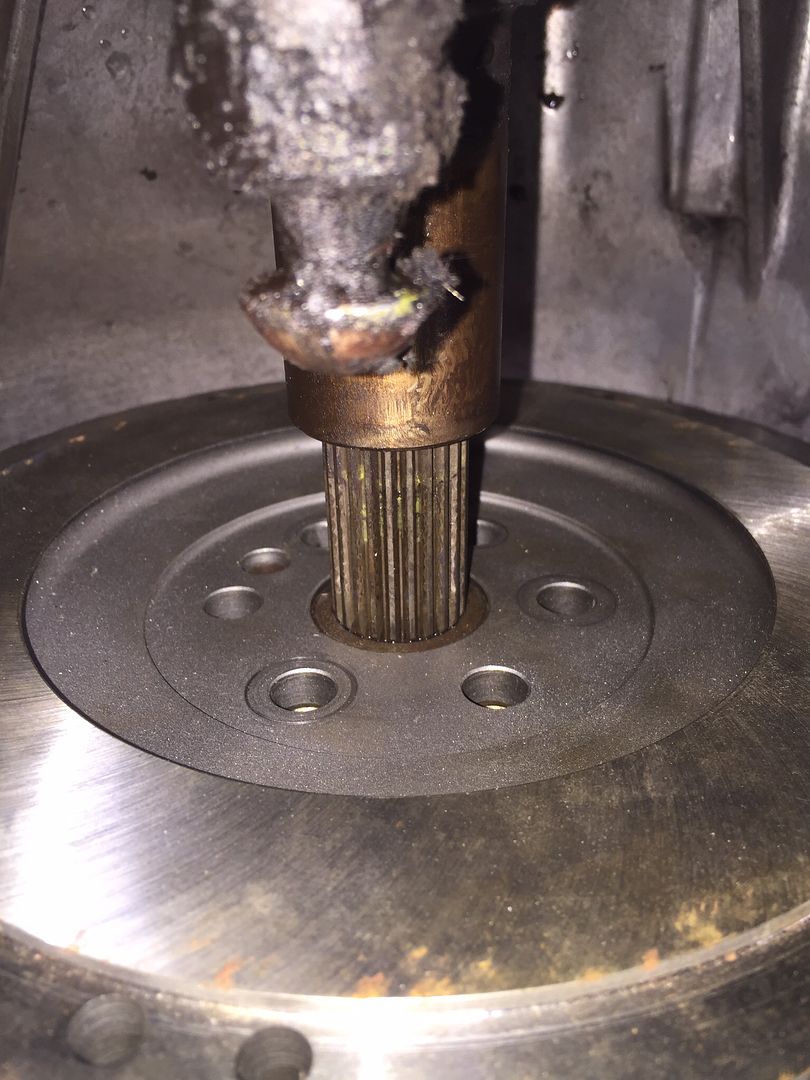

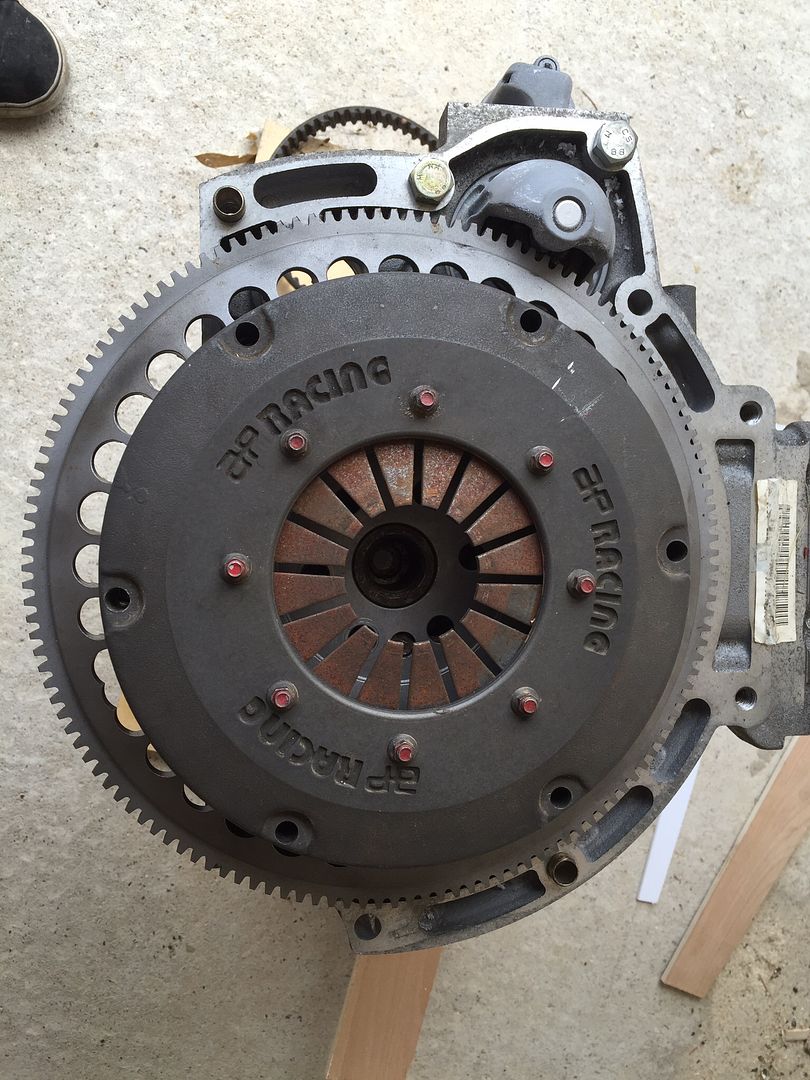

As for the progress, I have done some more gearbox playing and research. The original 6 speed I stripped, was from an IS200, which is a nice compact close ratio box, but would have required a custom clutch plate /pack and also quite a complicated adaptor plate in the first instance. This model of transmission is used in lots of cars, with different castings and shaft splines, but they are all basically the same Trans, just in a different case. So I read on another forum that there was another version that shared input splines with Ford !! This was quite handy. Considering I have an uprated sigma clutch to suit the standard type flywheel, and a billet steel lightened flywheel to go with it. But I also have in stock, another billet steel flywheel to suit a 7-1/4" race type clutch, and I picked up a very cheap AP Racing twin plate paddle clutch a while back too Now there are loads of Ford spline plates available for these in all different configurations, so I just need to decide what type of plates I want and then I can get those ordered too. So yesterday on the way home I picked up another 40,000 mile 6 speed box  £100 later, we are hopefully in business (that's 3 AZ6 transmissions I have now) Today I cleaned it and dragged out my spare dummy short engine too........ Pics in a bit  Thanks for looking as always ;-) |

| |

|

|

gn3dr

Part of things

Posts: 391

|

|

Apr 17, 2015 22:41:05 GMT

|

|

Want to share the secret of which box has Ford splines. I'm guessing Mazda MX5?

|

| |

|

|

|

|

|

|

|

Nope, RX8  And rumour has it, a type9 prop fits the output splines too, but you'll need a different seal as the OD is different |

| |

|

|

gn3dr

Part of things

Posts: 391

|

|

Apr 18, 2015 22:20:57 GMT

|

|

Good to know. Thanks

|

| |

|

|

|

|

|

Apr 23, 2015 10:03:23 GMT

|

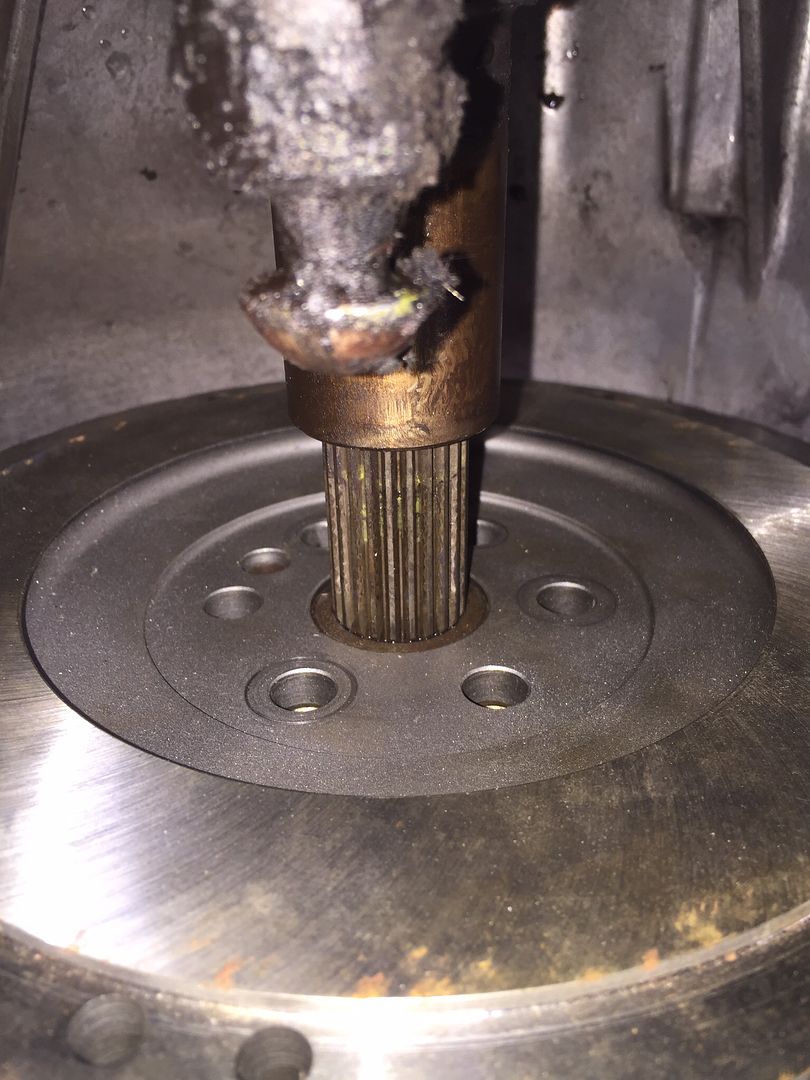

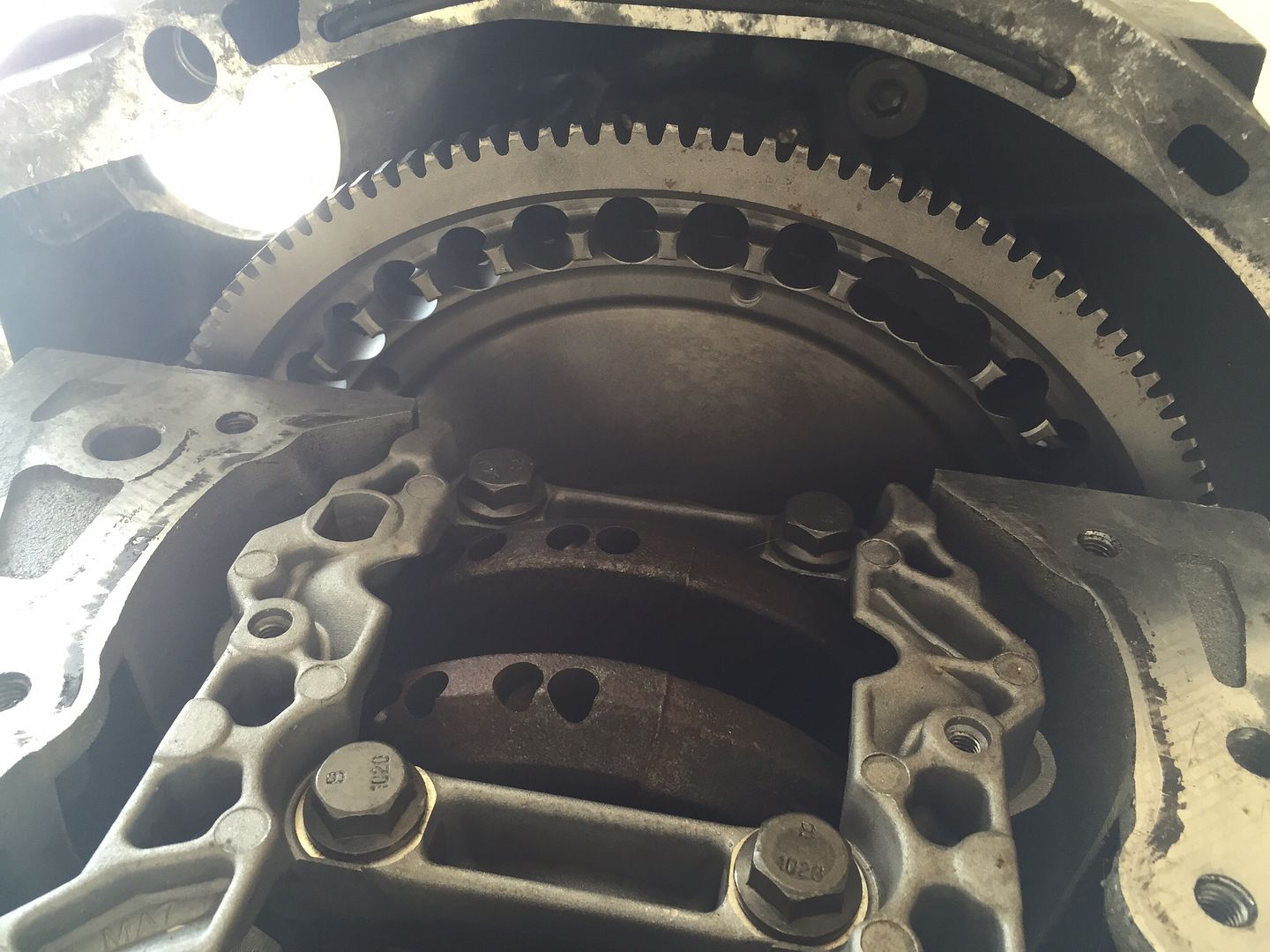

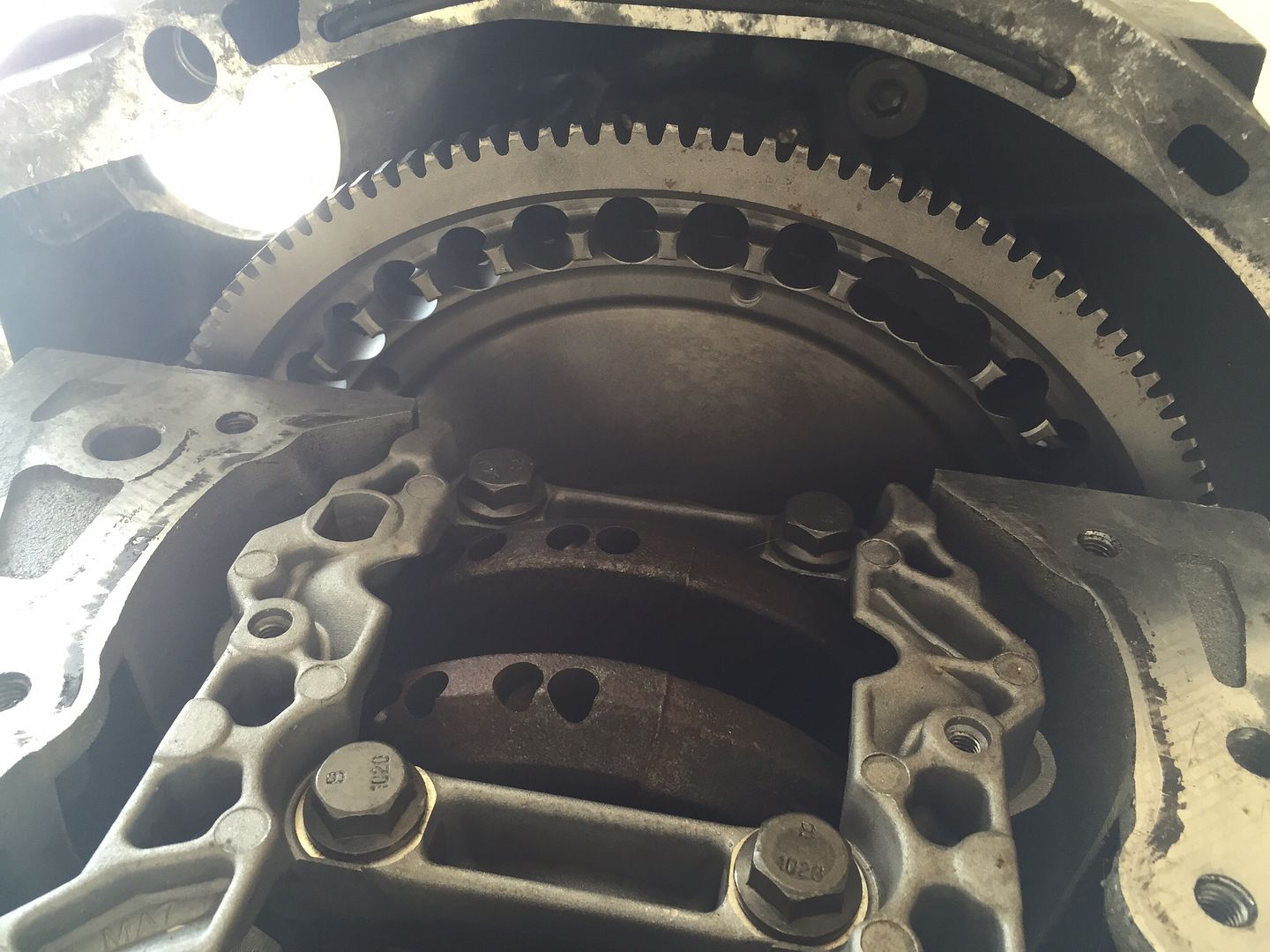

Sorry, I forgot to update with the Pictures  So, spare short block supported vertically with freshly cleaned RX8 transmission mocked up  Slight problem to overcome with the starter hole  Now I may try an RX8 Starter and see if that fits the flywheel ? as that would free up a lot of space for the Phase 2 supercharger set up (Bigger Lysholm charger from an AMG Merc  other side  Billet steel flywheel, no spigot bearing, input shaft bottomed out on the crank  Billet steel flywheel from sump, showing RX8 starter hole  Steel flywheel, AP Racing 7-1/4" twin plate clutch cover and std ford Starter in position   So A bit more work to do yet. I have schemed up an adaptor plate which I`m going to get laser cut at work to try it out But first look is promising Thanks for looking as always Cheers Dom |

| |

|

|

|

|

[*]

[*] [*]

[*]

£100 later, we are hopefully in business (that's 3 AZ6 transmissions I have now)

£100 later, we are hopefully in business (that's 3 AZ6 transmissions I have now)