|

|

|

|

|

Thanks homersimpson, I've put the shims back as they were and was intending to do the setup when it's all back together and on the car, or do you think it is better to go with your suggestion now? When I had the springs reset I asked for them to be compressed by and inch and a half as I liked the stance of goldenrust's when he did his. Does the fact that the Jag is somewhat heavier make a difference? I would suggest doing it when its all back on the floor and been driven to settle it.

It will be interesting to see what its like on the dropped springs, 1" 1/2 sounds a lot when you take into account the springs being inboard of the hubs and so it will be more at the wheel. You could probably drop it with standard springs by putting spacers and longer bolts between the spring pan and bottom arm.

If you haven't already I would recommend bending the wheel arch lip in at the top to stop the tyre rubbing, adding negative camber will help with this too.

|

| |

|

|

|

|

|

|

|

|

|

So far I have left the back axle in the too hard/expensive basket, but as it's been sitting for 5 years now i expect I really should do that also. (plus the fuel tank will certainly need a flush etc.) I remember following someone's blog having great difficulties extracting the back axles - did you find that hard? - and what else should I look for? If the brakes are half as bad as the front was I'm in for an expense there as well.   Getting the half shafts out tends to be a mission, you need the proper puller really as the universal type don't tend to do it (unless you are lucky).

I did the first MK2 by cutting the rear brake discs off, unbolting the bearing retainer and extracting the hub and shaft as one and then putting it in a press (leave the nut on but loose as when it goes there is a lot of force involved). I required a 30 ton press as the 15 ton one I had access to just wouldn't do it.

The second MK2 I was lucky as I bought a home made puller that worked in the same way as the original. I'm not exactly sure what the reason is but I suspect that it might be because the original puller pulls from inside the wheel stud line and most aftermarket ones put on the outer edge and the minor difference in deflection is enough to break it loose (or not!)

For the rear brakes you can use the later XJ6 callipers, they bolt straight up although you do need slightly longer bolts and a spacer or a couple of washers to centralise them. You still need to use the MK2 handbrake callipers and they bolt straight on.

The XJ6 callipers have the conventional seal in the body with the pistons moving against the seal, they are easy to rebuild and not expensive new compared to MK2 ones.

For the front I understand you can use Volvo callipers although there are some mods required which I understand are to drill out the mounting holes from 12mm to 12.5mm, modify the pipes for single circuit use and turn the discs down slightly. I think the suitable callipers were off a Volvo 240 and you need the solid not vented disc ones.

Alternatively what I did on Econojag was fit 3 pot callipers from a Jag 420 but you also need the suspension uprights as the calliper bolt spacings are different, these callipers again are the more conventional design and cheaper to rebuild and provide better stopping power.

|

| |

|

|

jehu

Part of things

Posts: 98

|

|

Oct 27, 2024 11:23:46 GMT

|

|

Actually, i cant remember exactly how much i asked for it to be dropped - it may have been only an inch. At the time I was impressed with some before and after photos and discussion on goldnrust's blog August 2022. I certainly don't want it to be overly obvious that it's lowered.

|

| |

2016 Audi Q3

1976 MGB

1968 Daimler 250 V8

|

|

jehu

Part of things

Posts: 98

|

|

|

|

|

|

| |

2016 Audi Q3

1976 MGB

1968 Daimler 250 V8

|

|

|

|

goldnrust

West Midlands

Minimalist

Posts: 1,887

|

|

Oct 28, 2024 11:15:46 GMT

|

Good to see this build back again 🙂 I was really happy with how my car sat, and was more than happy that I'd not ruined the ride quality and overall 'Daimlerness'. Others (including the chap who bought it from me  ) may disagree! My front springs were around 1.5" shorter than standard. As you say homersimpson, the spring is inboard of the hubs, about halfway along the distance from lower arm mount to hub face, so any height reduction in spring is doubled at the wheel. But also the spring is heavily compressed when fitted. I calculated that to get a 2" drop in ride height, that means 1" shorter at the spring pan, and the spring is compressed to about 2/3rd it's full length when fitted to the car so a 1.5" shorter spring is what I needed. It came out about right. I used E-type s2 callipers on the rear of mine, as far as I can tell it's the same part numbers as those XJ callipers anyway! Jaguar were good like that, I was always surprised about the number of parts, things like front suspension bushes, that were labelled as suitable from 50s Xks through to 90s XJ6! I did need to add a couple of spacing washers to align them to the disc correctly and but other than that it was a straight bolt on as far as I remember. Removing rear axels, I used a puller, of of this kind of design (first link I found on google, not an endorsement of this particular model!) www.amazon.co.uk/WilTec-Universal-puller-extractor-automobile/dp/B01H8SM2HK?source=ps-sl-shoppingads-lpcontext&ref_=fplfs&psc=1&smid=ATW9UHJ0SMTBMLoaded it up, added a bit of heat, bit of tapping and it popped free. I think I was lucky though, mine didn't put up half as much fight as my Triumph Spitfire ones did, and those were much smaller axels. So I'm sure they can be stuck hard if you're unlucky! |

| |

Last Edit: Oct 28, 2024 11:20:06 GMT by goldnrust

|

|

jehu

Part of things

Posts: 98

|

|

|

|

|

Thanks homersimpson, they look a reasonable price. NZ are only doing recon exchange brakes which is not worth my while with freight.

|

| |

2016 Audi Q3

1976 MGB

1968 Daimler 250 V8

|

|

jehu

Part of things

Posts: 98

|

|

|

|

|

I have really appreciated your detailed blog goldnrust and the Fiat 500 looks like a lot of fun.

|

| |

2016 Audi Q3

1976 MGB

1968 Daimler 250 V8

|

|

|

|

|

Oct 29, 2024 10:27:35 GMT

|

|

I think you will be either lucky or unlucky regarding the back axle, some people have pulled the bearings off themselves but I broke a brand new puller that a bought for the job and had to take mine to a local jag engineer to do it.

|

| |

Last Edit: Oct 29, 2024 10:36:38 GMT by pollystag

|

|

jehu

Part of things

Posts: 98

|

|

Oct 29, 2024 12:19:53 GMT

|

|

Yes i was wondering whether to go to the expense of buying a puller or just taking it straight to someone with the right equipment. as you point out I might end up with a broken puller and the cost of getting it done.

|

| |

2016 Audi Q3

1976 MGB

1968 Daimler 250 V8

|

|

|

|

jehu

Part of things

Posts: 98

|

|

Oct 29, 2024 21:07:42 GMT

|

I bought my first tool kit 55 years ago as a first-year apprentice fitter and turner. Relatively speaking tools are so much cheaper and varied these days. I had never even heard of bearing grease packer until recently and for $10 what a useful tool - saves so much mess and does the job better.  )   |

| |

Last Edit: Oct 29, 2024 22:15:53 GMT by jehu

2016 Audi Q3

1976 MGB

1968 Daimler 250 V8

|

|

jehu

Part of things

Posts: 98

|

|

|

|

Making Good progress.  |

| |

2016 Audi Q3

1976 MGB

1968 Daimler 250 V8

|

|

jehu

Part of things

Posts: 98

|

|

|

|

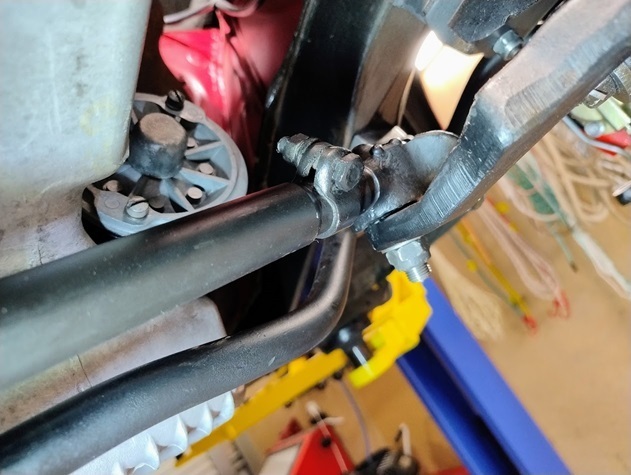

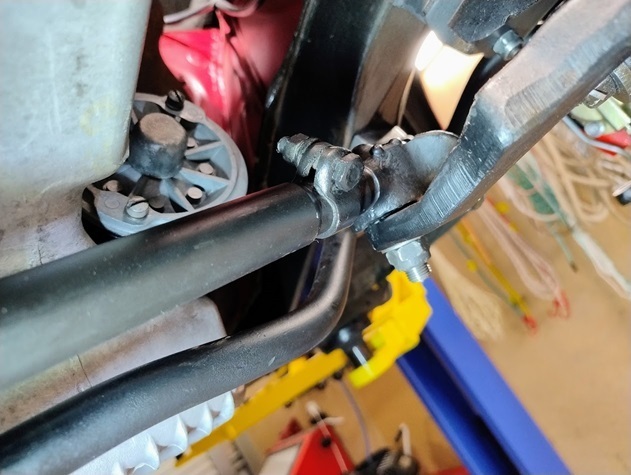

Any idea why there is no clearance between the idler arm and track rod knuckle? It's the same on the steering arm knuckle (and I never took that apart) although it's not quite as tight. The idler knuckle is not locked up but I cant see what I can do but let it rub.   |

| |

Last Edit: Nov 13, 2024 9:42:59 GMT by jehu

2016 Audi Q3

1976 MGB

1968 Daimler 250 V8

|

|

jehu

Part of things

Posts: 98

|

|

|

|

Engine back in.   |

| |

2016 Audi Q3

1976 MGB

1968 Daimler 250 V8

|

|

jehu

Part of things

Posts: 98

|

|

|

|

|

|

| |

2016 Audi Q3

1976 MGB

1968 Daimler 250 V8

|

|

|

|

|

Nov 13, 2024 10:32:46 GMT

|

Any idea why there is no clearance between the idler arm and track rod knuckle? It's the same on the steering arm knuckle (and I never took that apart) although it's not quite as tight. The idler knuckle is not locked up but I cant see what I can do but let it rub.   Certainly doesn't look right. Could you not insert some spacing washer between the knuckle and the arm? I suppose another option would be to grind away some of the metal on the knuckle... |

| |

|

|

jehu

Part of things

Posts: 98

|

|

|

|

|

Thanks Waxoyling Lyrical,

I cant put a spacer in there or it won't pull up on the taper. I think I will take your suggestion and grind a bit off the side of the track rod head.

|

| |

2016 Audi Q3

1976 MGB

1968 Daimler 250 V8

|

|

goldnrust

West Midlands

Minimalist

Posts: 1,887

|

|

Nov 14, 2024 11:38:00 GMT

|

|

I suspect either the taper has stretched, or the rubber in the tie rod worn/sagged? Looking at pictures, my tie rod was close, as it is on your steering box, but not touching.

With the brakes, I'm not an expert of this design, as mine were rusted to bits and didn't take much notice before binning them! But... as far as I can see, it's essentially the same set-up as factory, just with the wheel cylinders swapped left to right? So it should work and bleed just fine. It means a slightly longer and more messy hard line routing, but with the benefit of being able to bleed the brakes with the wheel still on? In the original line routing you'd have to remove the wheel to access the bleed nipple.

|

| |

|

|

jehu

Part of things

Posts: 98

|

|

Nov 14, 2024 11:48:30 GMT

|

Thanks, as I am making new pipes it will be easier to bend them for the standard setup. I am just curious as to why someone would go to the trouble to design and bend them that way just to be able to bleed them with the wheels on. Australian regulations will not allow copper pipes and bending steel into tight shapes is tricky.  |

| |

Last Edit: Nov 14, 2024 11:52:45 GMT by jehu

2016 Audi Q3

1976 MGB

1968 Daimler 250 V8

|

|

jehu

Part of things

Posts: 98

|

|

|

|

ground a bit away on the track rod knuckle and now have clearance.  |

| |

2016 Audi Q3

1976 MGB

1968 Daimler 250 V8

|

|

|

|

) may disagree!

) may disagree!  )

)