|

|

|

Mar 11, 2022 10:18:54 GMT

|

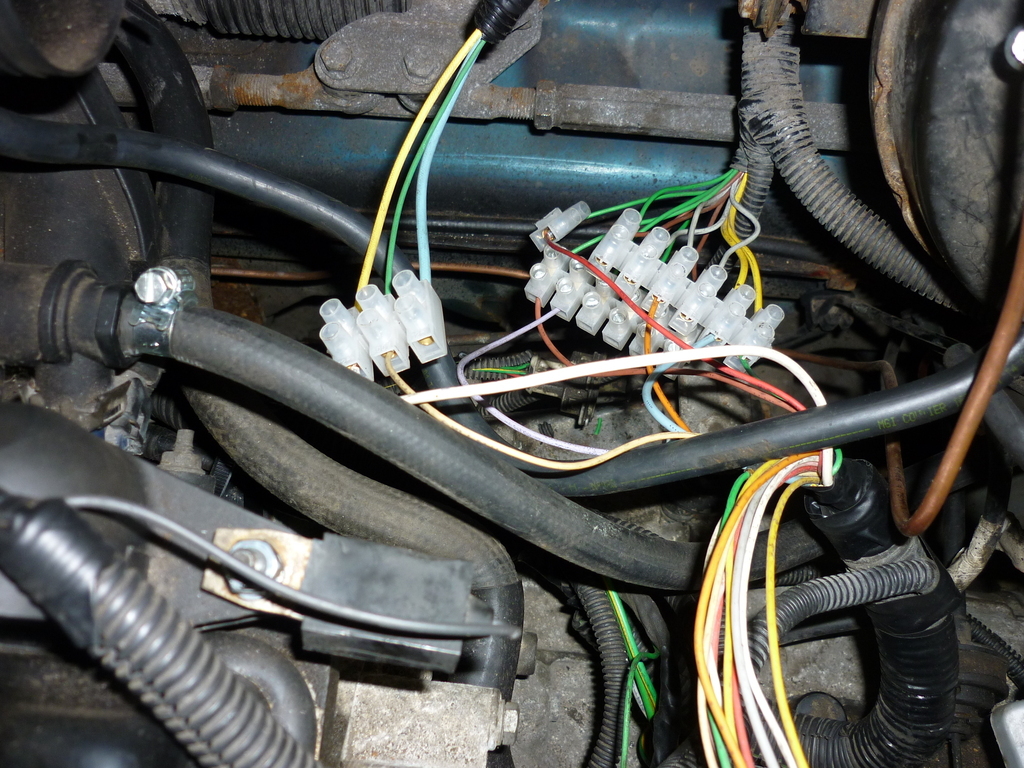

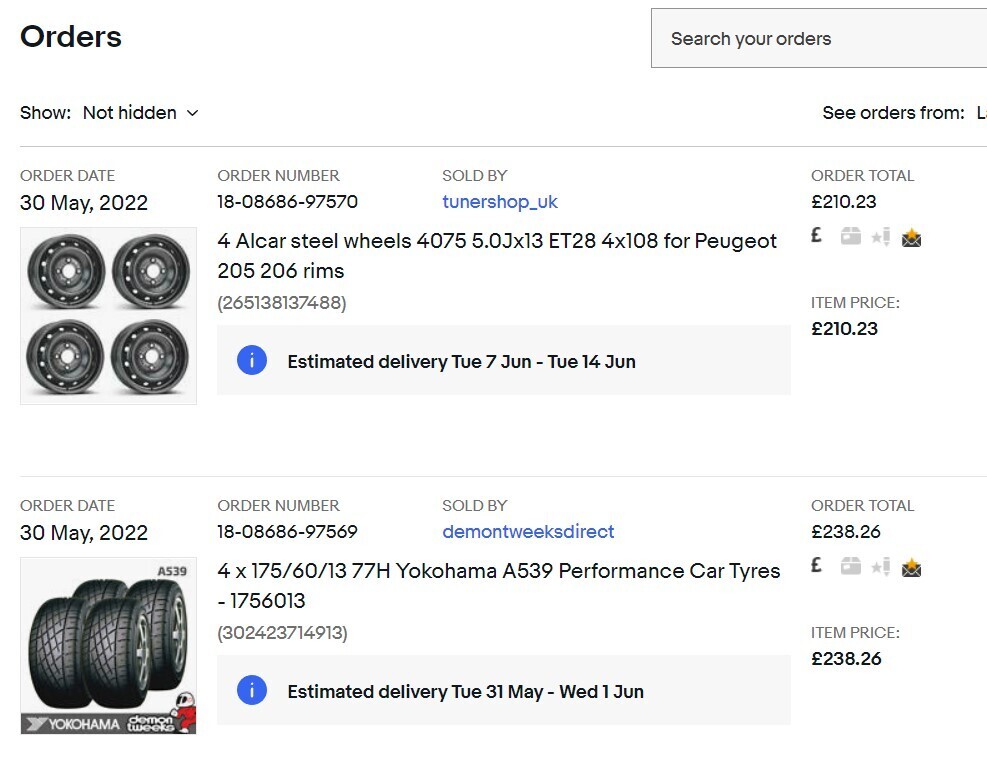

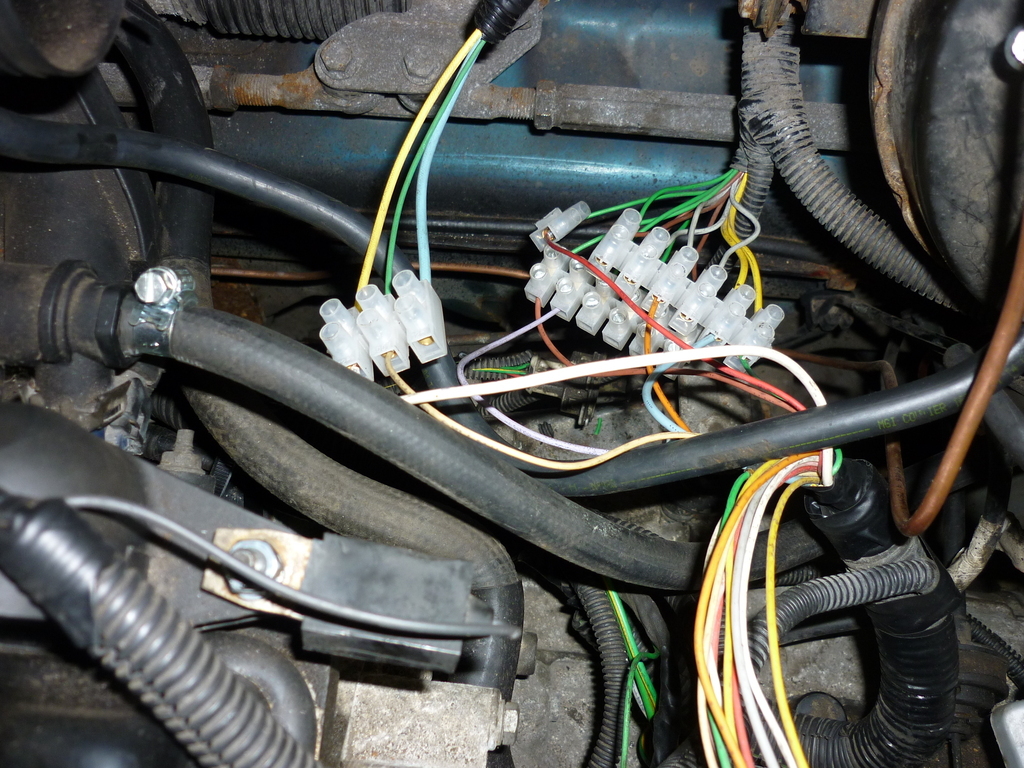

Having worked out what all the wires did, I temporarily hooked everything up using choccie blocks. (Note to self: this IS temporary and not how the car will still be wired up five years from now.) The switched ignition feed (pin 1 on the VTR loom multiplug) was nice and thick at the plug end but spliced into a much thinner wire further down which bothered me as I thought it looked far too feeble to power the ECU and fuel pump. I then realised that the system draws power from the main starter connection via the double relay, so the power circuit is internal to the engine loom and the ignition feed only carries a relay switching load.  Switched the ignition on, all the dash lights came on, engine turned over but no fuel pump. It worked fine when I powered it direct from the battery. After a bit of thought I realised that the Saxo has an inertia switch, which explains the spare two pin plug that I couldn't find a home for. Bridged the contacts and I now have power to the fuel pump.  So close to a running engine now. |

| |

|

|

|

|

|

|

|

Mar 11, 2022 17:43:04 GMT

|

|

It runs! Despite not having a cooling system that holds water, or any kind of exhaust, I just couldn't resist tipping a gallon of petrol in to see what happened. I powered up the pump manually to purge the system and check for leaks, and after a bit of cranking the beast coughed and farted a couple of times, then barked into life.

I couldn't run it for long due to lack of coolant, enough to establish that it's not entirely happy yet. Throttle response is very erratic and the engine management light is on. I think I have worked out how to wire up an OBD2 port so that once I have the cooling system and exhaust on it I can clear the fault codes, start it up and see how many codes come back again.

For now, just having the oil and charge lights go out is enough for me. With the engine running, fuel pressure holds steady at 3.0 bar, slightly higher than the manual suggests for a Mk2 VTR, but I can adjust that if needed.

Now I really need to get on and finish the suspension, also do the couple of little bits of welding so I can refit the interior.

|

| |

|

|

|

|

|

Mar 19, 2022 15:02:53 GMT

|

Another milestone. I sorted out the cooling system: there was a blanking cap missing from the new radiator (possibly where a coolant level sensor would go on high-spec AXs). I couldn't find anything suitable so I got hold of a threaded plastic plug, attacked the radiator with a thread tap, then screwed the plug in with RTV sealant. I also got the AX cooling fan to fit after I shaved a bit of metal off the frame.  I then hung the old AX 1.0 exhaust off the 4-1 downpipe to give me a bit of silencing. Earlier in the week I had got the OBDII port working, despite a rather misleading Citroen wiring diagram which doesn't show the power feed or earth, so I cleared all the fault codes. One of the codes was PO443 "purge control valve" which needed a bit of thought.  I discovered that there should be a solenoid valve between the inlet manifold and the charcoal canister under the offside front wing. There was probably one attached to the old engine which I sold. The missing pipework explained the throttle response issues when I first ran the engine. I have ordered a replacement valve, and blanked the stub on the manifold for now. So I ran the engine for about 15 minutes, no problem other than the usual PSA one of trying to get all the air out of the cooling system. It sounded sweet and there were no obvious issues: the only fault code which returned was PO443 due to the missing purge valve. But then I noticed this pool of oil and water which had been blown out of the exhaust:  Horrible sinking feeling - blown head gasket? I whipped all the plugs out and did a compression test. Result - 225-230 psi across all four cylinders. So I suspect it has just blown out a load of oily muck from the old exhaust, and the water was just condensed vapour from a cold start. At least I hope so. Now waiting for a new set of terminal crimpers to do Econoseal connectors and then I can tidy up the engine bay and finish off various odds and ends. Slow progress, but at least it's progress. |

| |

|

|

|

|

|

|

|

Another useful Saturday morning's work. During the week I asked a mate to do the last couple of bits of welding as I was busy. Lee spends most of his time welding old Japanese cars so this wasn't too much of a challenge for him - a plate in one of the front chassis legs and a bit of new metal around the nearside front jacking point and sill end. With all the welding done I could refit the interior which I managed without breaking anything.  Next job was to adjust the tracking. I bought a Track Ace a couple of years ago. It's a bit slow and cumbersome to use compared to a proper professional alignment tool but I have found it gives very accurate results. According to the Haynes book of misleading words, ordinary AXs have a bit of toe-in, GTis have a bit of toe-out. So I compromised somewhere in the middle.  The solenoid valve for the vapour trap turned up in the post so I cleared the fault codes, started the engine and the check engine light went out and stayed out. Cool. I downloaded a factory parts book which shows all the pipework for the vapour system, so I should be able to put the system together again.  But first I have to sort out the fuel filler. The neck has cracked around the mounting screws. I brazed some new metal into the badly rusted cap retainer, then epoxied it to the filler neck and have left it to cure over the weekend with lots of clamps attached. If this doesn't work I will have to hunt around for another filler assembly: not many AXs in scrapyards these days and I suspect these mounting attachments are a weak spot on all of them.  I haven't had much success with my new crimping pliers: they crimp the connectors OK but not as strong and neat as a factory crimp, so I think I might have to solder them just to make sure they don't fail. A job for a quiet couple of hours when there is no-one around to disturb me. Front brake pads on my 106 are wearing a bit thin and it has a sticking caliper, which makes me wonder whether to upgrade it to the VTR all disc setup. This would free up a 4-stud drum rear axle for the AX: the standard diesel 106 brakes can fade under heavy use and it's my daily driver so better brakes would be worth having. Front body panels should be going on shortly and the little blue box will start to look like a viable car again. Or is it a little green box? The V5 says it is green, but it looks blue to me. Maybe I'm colourblind. |

| |

|

|

|

|

|

|

|

|

Superb, I followed your link from PH (thanks for posting it up) as I wanted to see what had been done. Looks like you’re nearly there, and I think it will be a hoot to drive when done.

When I had my AX engine issues and was looking at engine swaps from the 1.1 that was in there, it was the differing driveshaft lengths and 4 stud hub conversions that made me reconsider. Hat is well and truly off to you for taking it on.

I did go the 4 branch manifold route though for a similar price and have been impressed so far. Similarly, the new driveshafts I fitted were from a motorsport specialist on eBay (I was enormously sceptical) but again, so far so good…. Better than the ones from the motor factors at twice the price anyway!

Keep up the good work, and let me know if you want any photos from the book of lies for the AX.

|

| |

|

|

|

|

|

|

|

|

Fantastic work and project, really impressive how you have "enginerred" solutions to the problems as they have arisen,

Always liked the little AX's, bought a little 1 ltr model years ago with a totally kn*ckered engine, (sellers words,) 1 new piston and my wife ran it trouble free for a few years,

Looking forward to seeing future updates on this thread,

Nigel

|

| |

BMW E39 525i Sport

BMW E46 320d Sport Touring (now sold on.)

BMW E30 325 Touring (now sold on.)

BMW E30 320 Cabriolet (Project car - currently for sale.)

|

|

Neil

Posted a lot

Posts: 2,485

|

|

May 14, 2022 13:13:50 GMT

|

|

y0! Any updates?

Don't tell me you've pushed it into a corner of the workshop only to dig it out in 5 years and sell it as an unfinished project?! 😂

|

| |

|

|

|

|

|

May 22, 2022 20:49:29 GMT

|

|

Can't believe it is two months since the last update. I got all the wiring connectors finished, but workload for paying customers got a bit out of hand so the poor little boxy blue car got dumped in the corner and covered in dust. This is simply Not Good Enough.

One of the reasons the project stalled was that I needed a few big metal bits, namely a 4 bolt rear axle with drum brakes and a Saxo VTR anti roll bar. Last week I had a quiet day and fancied a run out so I hitched a trailer to my long-suffering diesel Pug 106 (it's retro, it just doesn't know it yet) and headed across to Adam Wiacek over near Evesham, who breaks little French cars for a living and was the guy I bought the engine and gearbox from. He sorted me out with the bits I needed, plus a set of 106 clocks with a rev counter which I am hoping I can transplant into the AX instrument pack.

Back at base I tried fitting the new anti roll bar and learned a couple of things. I was a bit worried that the VTR/VTS ARB mounts on the floorpan are totally different to the standard AX GTi ones but my AX shell turned out to have the correct mounting slot and captive nut. Unfortunately I now know why the wishbones on the Saxo VTR look different to the normal AX/Saxo/106 cast ones: the rear mounting is totally different to give enough clearance for the ARB. Never mind, the wishbones I bought will do as spares for the 106.

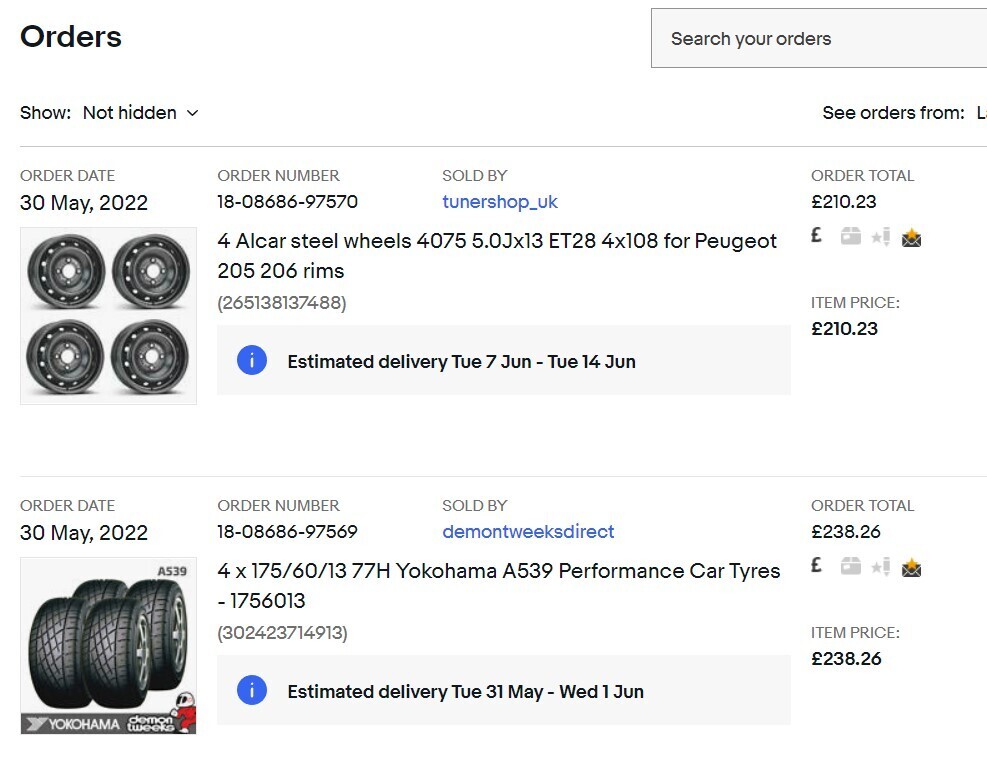

I'm now having a big spending splurge to get together all the bits I need to make this car drivable next weekend: wishbones, ARB links, rear drum/hub assemblies, shoes and cylinders, plus a nearside headlight to replace the one that fell on the floor and broke. I'm wondering whether to really push the boat out and get an exhaust custom-made but funds are limited so I may have to go with a stock AX GTi system for now, especially as I still have to sort out some decent wheels and tyres. I'm thinking gloss black steelies with chromed bolts, subtle but anyone who knows AXs will spot the extra wheel bolt straight away.

Big weekend coming up, wish me luck.

|

| |

|

|

|

|

|

May 28, 2022 20:28:31 GMT

|

A day and a half of hard work and I now have (I think) all the heavy stuff done. This afternoon the little AX drove out of the workshop, the first time it has moved under its own power since I started taking out the 1.0 engine back in January. I gave it a quick jetwash to get all the dust off it.  I started yesterday by removing the Saxo VTR rear axle and bolting in the bare AX beam instead. I had already knocked the stub axles out of the donor drum Saxo axle, but I had to use the hydraulic press to get them into the AX axle . I could have used a bigger hammer but I didn't want to risk damaging the trailing arm bearings, and if you know anything about small PSA cars you will understand why. There then followed a series of minor aggravations of various kinds: - The NOS drums I bought turned out to be too big. I reckon they might be for a 206. Luckily the bearings were the same size as the Saxo/106 4-stud hubs so I just used one of them to replace a duff bearing in one of the hubs from the donor axle. The drums are a bit worn and ridged (drums and hubs are cast in one piece on these cars) but will do for now. - The AX handbrake cables fit into a steel tube spacer attached to the backplate. 106/Saxo cables plug straight into the backplate. I salvaged the spacers from the old AX backplates and welded them to the Saxo ones. This worked perfectly. - For some French reason, 106/Saxo 4-stud rear brake cylinders have absolutely huge unions. I discovered this after I had made up new brake pipes with the normal metric unions that every other manufacturer in the world uses. I salvaged one union off the donor axle (the other had been binned with the old cylinder) and found one new one in my box of weird random sized unions. With everything together and the new Bilstein shocks on I dropped it back on its wheels and found I had plenty of wheelarch clearance on side and only just enough on the other. I loosened the axle bolts and gave the body a good shove sideways which gained me a couple more mm, got Lee to sit in the back seat and there is definitely enough clearance without having to tit around with rolling the arches etc. Happy days. Front end was dead easy with the right bits. Here are the two types of wishbone compared: note how the rear bush sits further forward relative to the two studs. The ARB runs behind this bush and that few extra mm clearance is the difference between "fits" and "doesn't fit".  Summary for anyone else doing this conversion: use AX springs, spring seats and top mounts. Everything else is Saxo VTR/VTS. To be continued... |

| |

|

|

|

|

|

May 28, 2022 21:17:13 GMT

|

Exhaust next. I went for the full AX GTi system which I thought would bolt straight on. Not quite: the front end of the cat was a slightly larger diameter tube than the 4-1 front pipe was designed to take. I just cut the front end off the old AX cat, the tube was exactly the right diameter to slot neatly inside the new cat and I just had to weld round it. I rotated the flange position about 30 degrees as it was a bit close to the engine stabiliser mount. The GTi back box tucks neatly behind the rear bumper like the 1.0 system, no mods needed.   Suddenly I realised I had a drivable car, so I started it up, drove out of the workshop and found I had no brakes. Not yet sure why, I spent ages bleeding them but either there is still air in the system or the new master cylinder is duff. Still, I was able to drive up and down the yard a couple of times. There is a clonk from the front end which I hope is just the front wishbone bolts. I haven't tightened them fully yet as I wanted to settle the car to its normal ride height first. Other than that it all seems happy enough. Final job for today was the headlights which have broken clips, a common AX problem. The headlights attach at three points: the outer one is no problem, but the inner two are clips which push over ball-ended adjusters, and the lugs on the clips always snap. I tried looking around for suitable replacements but couldn't find any. In the end I used s spring to hold the headlights in place (actually salvaged from the old AX rear brakes). I drilled a small hole in the back of each headlight close to the edge, another hole in the front panel and hooked the spring between the two. It works.   I'm now at the point where I can make a list of the jobs left without being plunged into black despair: - Get the brakes working - Deal with a minor blow where the manifold joins the front pipe - Fit the front bumper and repair a broken clip on the back bumper - Horn and screenwash not working And of course wheels and tyres. I was going to go 165/65R13 but the choice available isn't huge, so I might look at 165/70R13 which is what it is sitting on at the moment. (Tyres look OK in photos, but I took them off my 106 for a reason.) I have loads of steel rims in two different patterns so I will choose the best four matching ones and get them blasted and painted. Once the little blue box is MoT'd I'll look at instrumentation - trying to fit the 106 rev counter, plus a separate water temp and oil pressure gauge. I like to have some warning when things are about to go horribly wrong under the bonnet. Then drive it around for a bit before I get the paint tidied up. Nice to have items include an AX GTi front bumper with driving lights, and possibly an original Saxo VTR airbox to replace the K&N on a bit of old rubber hose that is fitted at the moment. |

| |

|

|

|

|

|

|

|

May 28, 2022 21:42:18 GMT

|

|

Tyre sizes: it seems impossible to find anything other than budget Chinese or "eco" tyres in 165-13 sizes. However I have just found that Yokohama A539s are available in 175/60R13, which will fit 5J rims. Slightly worried about that rear arch clearance but I really like A539s, had them as wet weather tyres on my old trackday Mk1 Golf. Not too expensive either.

|

| |

|

|

|

|

|

|

|

|

Now trying hard to resist the temptation to go up to the workshop. It's 40 minutes away but I'm desperate to see how much clearance there is between the rear tyres and the boot floor outer edge. Reason? I've found that Peugeot 205 steel wheels are ET28 (Saxo/106 rims are ET20) and available brand new. That would solve the outer edge clearance issue with 175 tyres but I need to check it there is enough room behind them. Those AX enclosed rear arches are tiny.

Question: what would be the most durable gloss black finish for steel wheels? I've never been much impressed with powder coating, but I want something that won't chip easily.

|

| |

|

|

|

|

|

|

|

Little blue box is just a money sponge now.  Managed to get the brakes bled this morning with a bit of help, once James worked out the offset pedals and realised he had his foot on the accelerator pedal instead of the brake. AXs are a bit strange like that. You get used to it. |

| |

|

|

|

|

|

May 30, 2022 11:53:44 GMT

|

|

loving this, it's giving me the inspo to tear into my 106 Rallye this winter! Thanks for sharing!

|

| |

1971 Triumph Toledo 1500 Road/rally

1998 Peugeot 106 Rallye

2007 Volvo V50 T5 AWD "Sensible Daily"

1978 BMW R100RS Cafe Racer "Jägerbomb"

1979 Harley Davidson SXT trials bike

2018 Black Lab/Alsatian cross "Rocky"

|

|

|

|

|

May 31, 2022 17:02:04 GMT

|

I think the little blue box might actually be ready for MoT. Seems hard to believe, I'm sure I've missed something but all the important bits seem to work. A couple of last minute dramas. My joy at having the headlights stay in place was premature. The plastic on the nearside unit has gone super brittle with age: I tried removing the headlight to make the bumper easier to fit, and a big chunk of reflector broke away where I had attached the spring. No worries, I glued it back in with epoxy and came up with a better idea. Each headlight now has a 100mm piece of angle steel bolted across where the clips used to be, using M8 Allen screws whose heads seat nicely on the adjuster balls. A long M6 bolt passes through the steel strip and headlight panel, with a spring (Land Rover gearbox detent spring) to keep the adjusters located in their sockets. Much stronger than my first attempt.   The front bumper isn't in great shape, and the indicators are slightly more scruffy than they were before, as I chipped the edges trying to get everything to fit together. I suspect the car has suffered a bit from "touch parking" in its earlier life. But it all went back on and seems to be staying on. Apart from the wheels and tyres, the only other thing I need to sort fairly urgently is the fuel rail connectors. The inlet as mentioned above is just 8mm hose Jubilee clipped onto a smooth plastic pipe stub: it should hold 2 bar OK but I don't trust it. Need to see what is out there by way of high pressure fuel connectors. At the other end, the threads on the Schrader valve cut through the hose I had clamped over it, which could have had bad consequences if it had let go completely. As a very temporary fix I have slid a bit of heatshrink over the threads but I need an adapter which screws on and will take 8mm ID hose. There must be something suitable out there, an airline connector of some kind maybe. I doubt I'll get the AX MOT'd tomorrow before the Bank Holiday shutdown but I'll ring the test station in the morning and see what they can do.  |

| |

|

|

|

|

|

|

|

What happened to the little blue box? Well, I decided there was no point in getting it MoT'd until I had the proper wheels and tyres for it. A mate offered to paint the wheels for me but then ran into problems with his business and ended up going bust. Happily he returned the wheels and tyres before he lost his workshop and I found someone else who could do the job, although it took a while. This afternoon I bolted the wheels on. Clearance on the fronts is very tight on the calipers which hadn't even occurred to me as a possible issue. The wheels were balanced with self adhesive weights and one of them was catching on the offside front caliper so I had to put that wheel on the back axle. But they fit, with a finger's width clearance on the rear arches, inner and outer. The cooling system was almost impossible to bleed because French, but I think I have the air out of it now. The heater seems to work anyway. Occasionally it starts running rough and then cuts out for no obvious reason, although it then restarts and idles as if nothing had happened. It is throwing up a fault code PO110 for intake air temperature sensor which the VTR engine doesn't seem to have, unless it is built into the MAP sensor. The fault isn't putting the EML on so I'll cross my fingers and hope it doesn't happen during the emissions test. I can't see any reason not to put it in for an MoT this week, then I'll see about having the paintwork sorted while the weather is miserable. At least the little blue box is back in my workshop for now, nice and snug with the battery on charge.   |

| |

|

|

|

|

|

|

|

|

Little blue box failed the MoT on emissions, and not just a little bit. This didn't surprise me as it ran like a pig on the way to the MoT station and back. Looking on the positive side, everything else was fine, gearbox is smooth and quiet and the engine pulls hard on full throttle. As soon as I ease off it starts misfiring and if I dip the clutch it cuts out. But it then restarts and runs fine until the next time.

I still have the same three codes: P0110 (stored) and P0711/P1B00 (pending). The last two relate to automatic transmission which I obviously don't have. I read somewhere that Citroen either screwed up or deliberately sabotaged OBDII implementation, so that if you use a generic code reader (as opposed to a Citroen dealer one) you get fault codes which tell you nothing useful.

The fault appears to be triggered by large throttle openings and / or high revs. Back in the workshop I found that if I booted the throttle a couple of times I could then feel the engine start to die, and trying to keep the revs up gave me a crackly uneven misfire. My wife's old E36 328i coupe did that when the crank position sensor started to fail. So if I can only work out which is the correct sensor for this particular engine, I'll try swapping it.

|

| |

|

|

|

|

|

Dec 20, 2022 17:28:21 GMT

|

|

Quick update: I changed the crank sensor and manifold pressure sensor: don't know which one was causing the problem but new electrical bits seem to have cured it.I also backed off the fuel pressure slightly: Saxo VTR engines are supposed to run 2.0 - 2.5 bar (regulated) according to the Haynes book of comforting lies, but my Chinese pressure regulator won't go below 2.6 bar. It seems to idle a bit more smoothly now, but if HC emissions are still a problem I might have to get a better regulator.

It could really do with a quick blast at high revs before it goes for retest but not much scope for that on the route to the MoT station. Given how badly it was running before and how much better it is now, I'm faintly hopeful that it might scrape through the emissions test this time round.

|

| |

|

|

|

|

|

Dec 21, 2022 10:20:44 GMT

|

|

It can be surprising what an "Italian tune up" can cure, 😁😁

Nigel

|

| |

BMW E39 525i Sport

BMW E46 320d Sport Touring (now sold on.)

BMW E30 325 Touring (now sold on.)

BMW E30 320 Cabriolet (Project car - currently for sale.)

|

|

|

|

|

Dec 21, 2022 19:34:28 GMT

|

|

Still a little way short of an MoT. HC, CO, Lambda: it seems I can have any two but not all three. At idle, CO and HC are within limits but lambda is around 1.4. At about 2000 rpm, lambda value comes back down to 1.03 or less, but CO goes up to 0.7%. My MoT tester has no suggestions for what to try next.

I have a strong suspicion that the problem relates to how I fitted the oxygen sensors. The later VTR engine has a "close coupled" cat attached to the exhaust manifold, with O2 sensors immediately before and after it. I junked this (too bulky for the AX bay, and the manifold was cracked) and instead I have a 4-1 stainless manifold and an AX GTi cat underneath the vehicle. The 4-1 has two threaded bosses for O2 sensors, but one of them is only fed by one cylinder, and the other one by two. Both my O2 sensors are upstream of the cat. That was the easiest way to plumb in the O2 sensors but I think I might have to do it properly, with threaded bosses welded in either side of the cat, and new sensors with longer leads.

The drive to and from the test station was fun, now the engine is running properly. It is a good bit quicker than I expected, sounds great and I was getting wheelspin in 3rd gear (admittedly on a wet and mucky road). I think the little blue box and I are going to have a lot of fun together, if only I can get it through an MoT.

|

| |

|

|

|

|