nze12

Part of things

Posts: 193

|

|

|

|

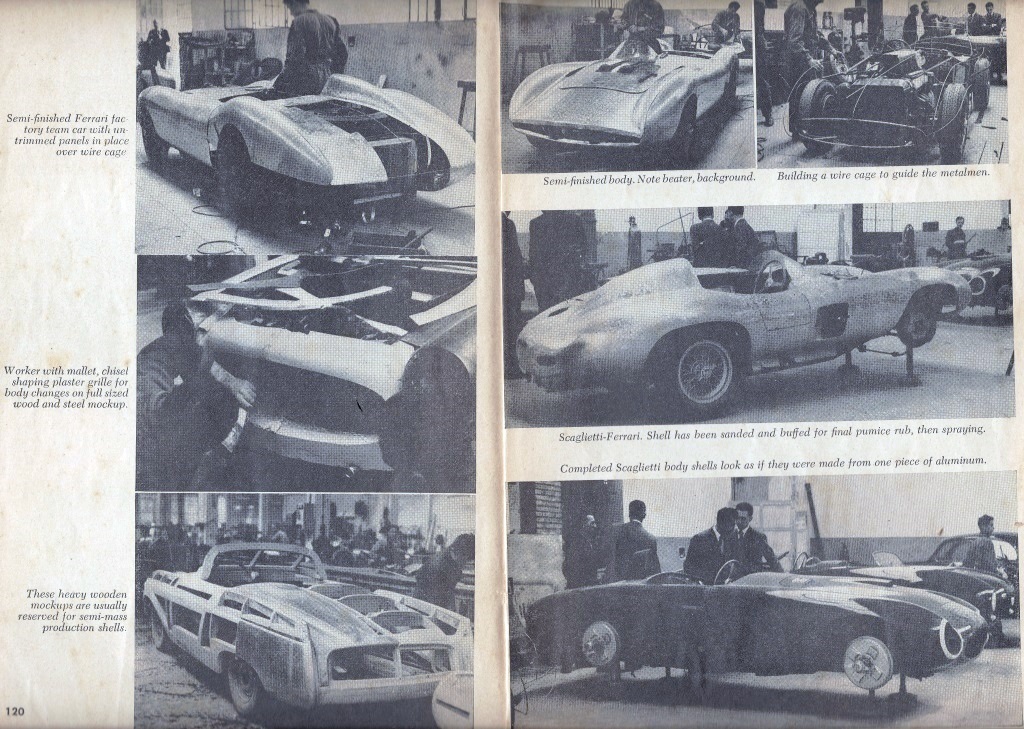

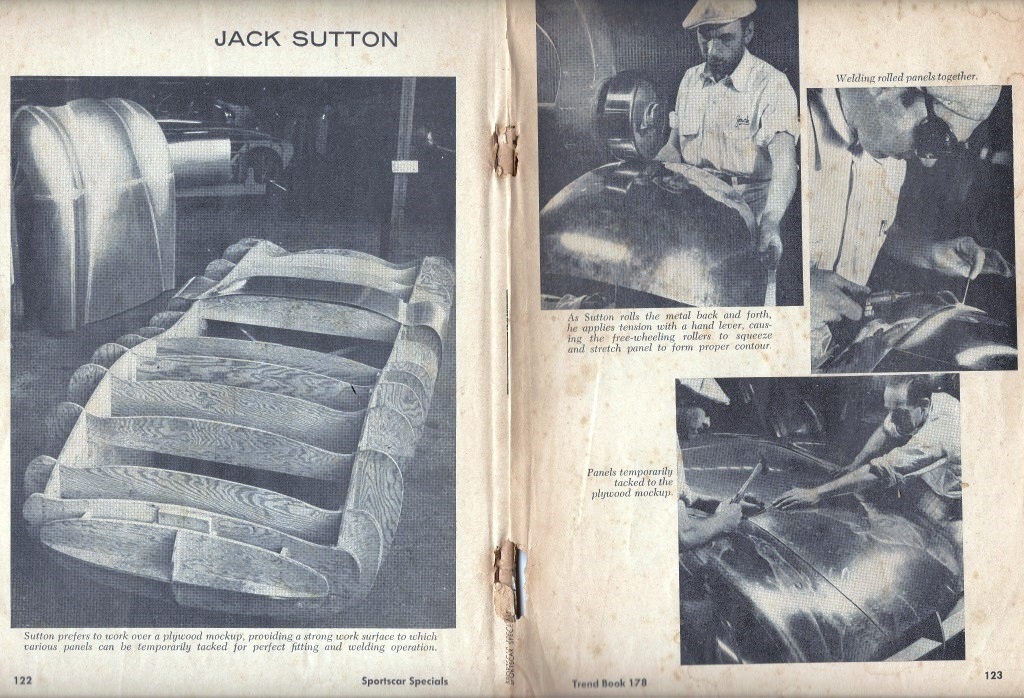

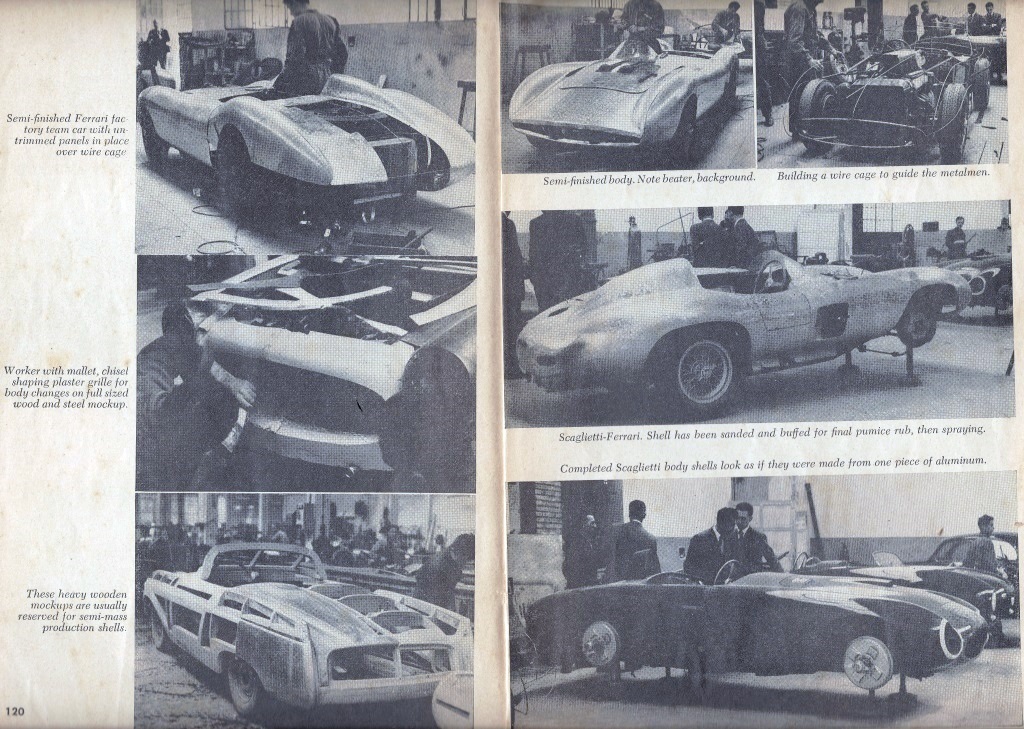

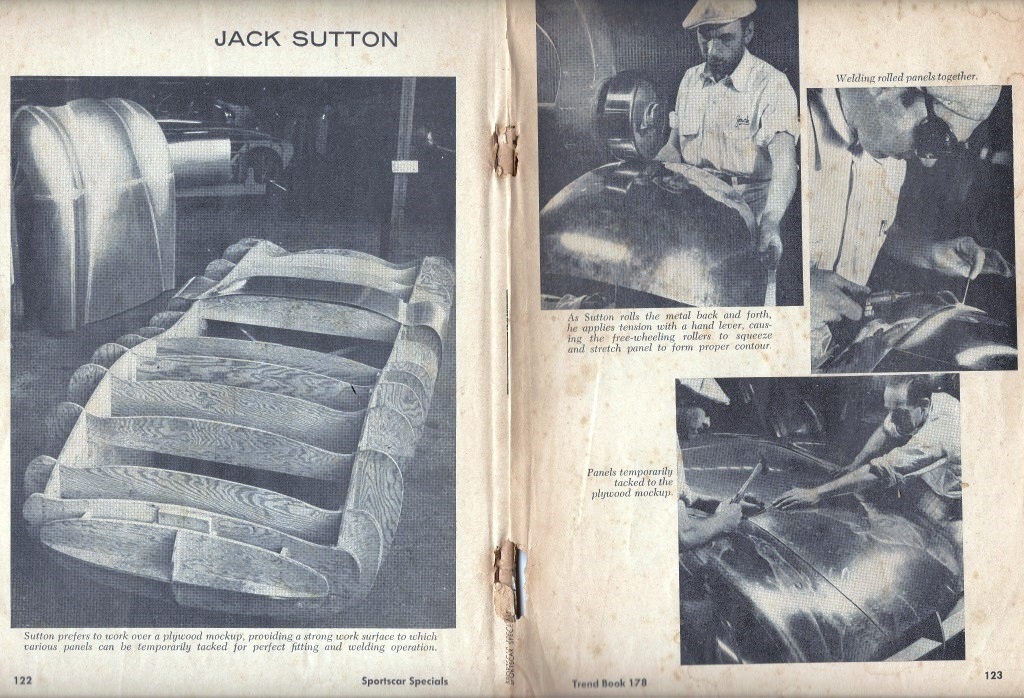

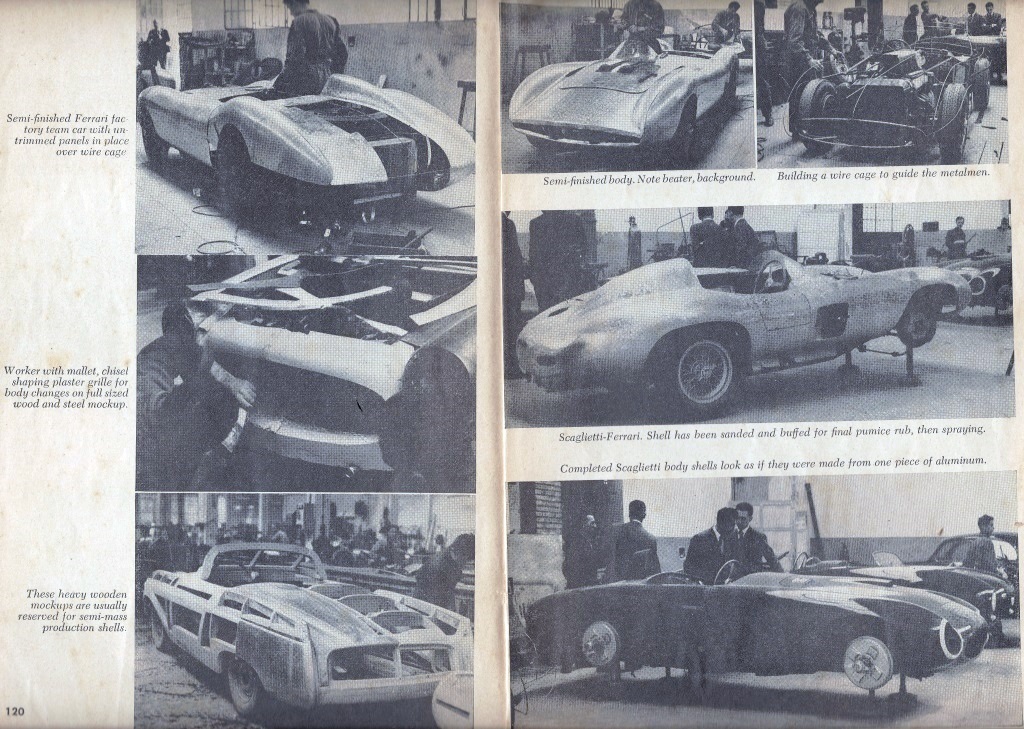

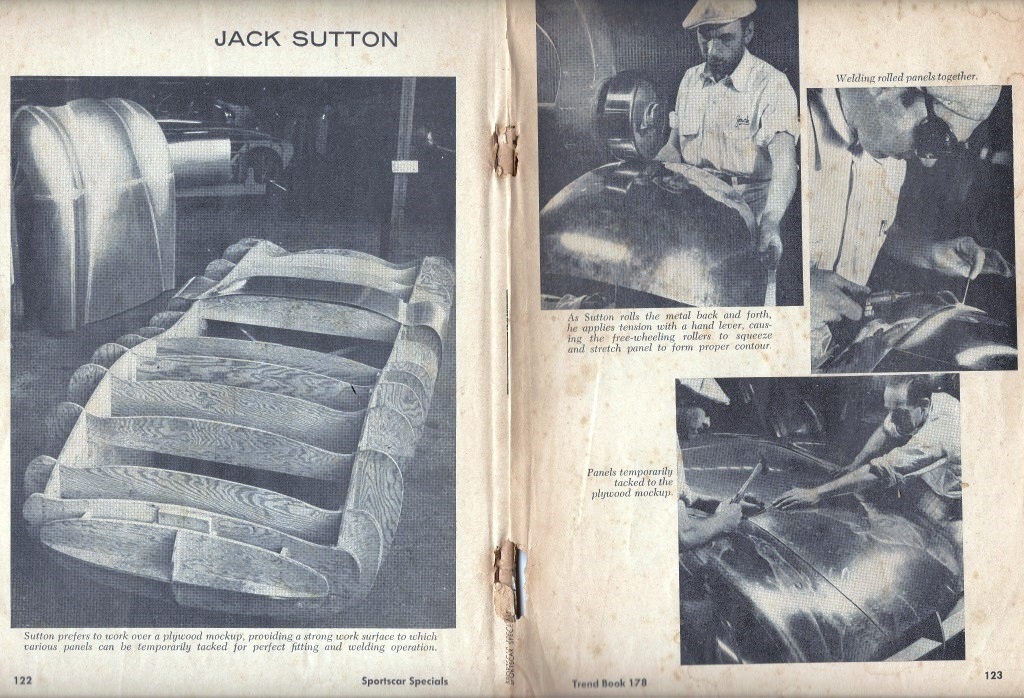

Hi John Been following this with great interest as aluminium forming is such an exotic subject. Your thread jogged my memory about an article in a book entitled "Sportscar Specials - Trend Book 178", published in 1958. Anyway, I dug it out of my collection, here is some interesting aluminium history:    Keep up the great work! Regards Ken. |

| |

1986 BMW E30 refreshed to original spec

1973 BMW E12 520 converting to Motorsport 530

1982 XJS V12 converting to 5 speed manual

Many landscaping projects overriding above!

Cogito cogito ergo cogito sum!

|

|

|

|

|

|

|

Feb 22, 2024 19:37:30 GMT

|

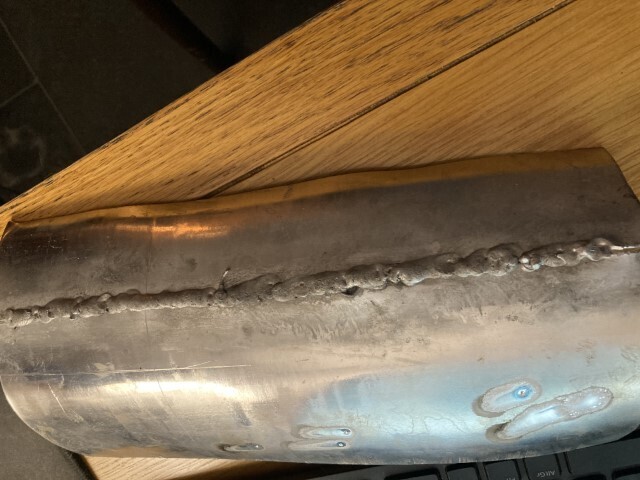

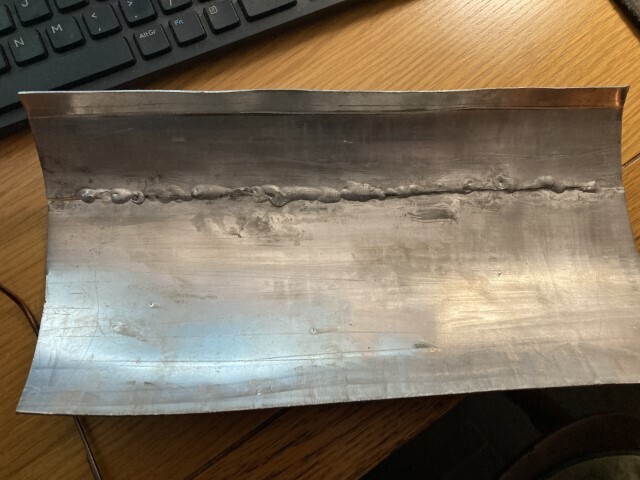

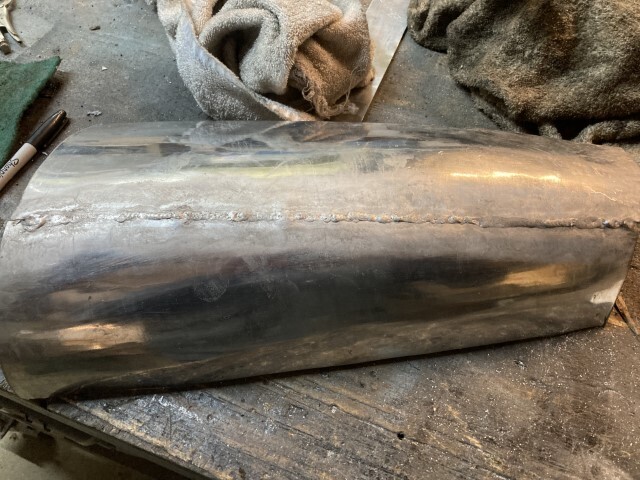

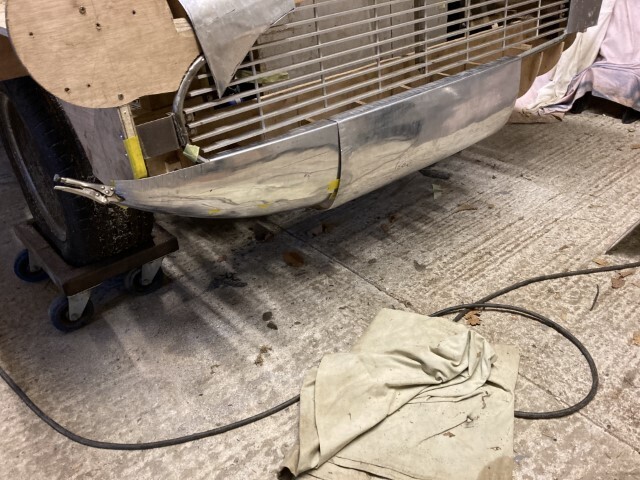

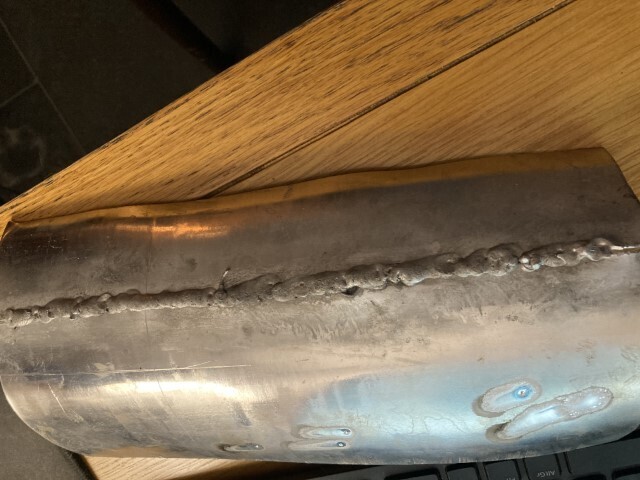

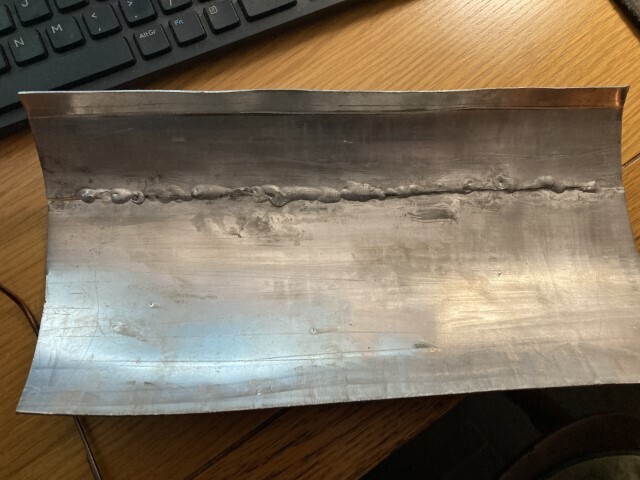

Ken, Thank you for that. I apologise for taking so long to respond. It is interesting that the Italian coach builders always hammered in the shape either manually or with power hammers but never with an English wheel. It just shows that there is always more than one route to the same destination. The one thing that they all have in common is their skill which can only come with training and years of experience of which I have neither. You may recall that I have been having trouble with cracking in the areas to the side of the TIG weld bead on one of the front wings and I'm so fed up with it that I have made the decision to gas weld the panels from here on in. Gas welding has the advantage of producing a malleable weld bead and a fully annealed band either side of the weld allowing the weld to be hammered wheels and generally worked without much chance of any cracking. The factor that encouraged me to TIG weld is the high cost of acetylene but I have bitten the bullet and resurrected my BOC Saffire torch together with new hoses. Ron Fournier said in one of his videos that gas welding aluminium isn't difficult, it's just different and he's right but it is a technique that has to be acquired and for me, that wasn't done overnight. In fact, there was a time when i thought I would never be able to master it until one day I found I could weld aluminium without burning holes in it. Both of my previous two projects were gas welded but that was a long time ago and I was under no delusion that I could go straight back into it and weld up panels without any trouble. And how right I was.  But like the time when I was learning it came back and this test piece was better      With a bit more practice I was ready to risk welding two actual panels together   I think the most critical component is adjusting the flame which has to be neutral to the correct heat. Too little and the aluminium won't melt and too hot it just runs away with you and large holes are formed. The cone of the flame also needs to be almost touching the aluminium and if it is too far away the result is a huge hole. The two pieces I welded together form part of the front lower valance. Filing and planishing the weld was so much easier than with TIG and the metal finished panel has come out really well. |

| |

|

|

|

|

|

Mar 19, 2024 12:59:06 GMT

|

|

|

| |

|

|

gazzam

Part of things

Posts: 747

|

|

|

|

|

Very pleased to read that you’re enjoying the process again.

And to see that it’s coming along nicely.

Always a pleasure to read your posts, you have a nice way of putting things.

Cheers.

|

| |

|

|

|

|

|

|

|

That's really kind of you, thank you and very nice to hear from you. I've just got to wondering whether people are getting bored with this thread and perhaps it might be the time, not to wrap it up, but rather just report when large chunks of the build have been completed. What I'm doing is hugely satisfying and interesting to me but I can appreciate that it is very specialised and just sending photos of pieces of a jigsaw puzzle of formed sub-panels might not be to everyone's taste and Ican quite understand if they don't share my childlike glee with each new part . It is the nature of the beast that progress is always going to be painfully slow and I can imagine the eye rolling when the piece the size of a postage stamp is proudly displayed  Please do let me know what you think and I'll fit in with you. thank you. John |

| |

|

|

|

|

|

|

|

|

its all fascinating john .

|

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,362

Club RR Member Number: 64

Member is Online

|

|

|

|

|

I enjoy watching people progress with stuff that I lack either the skills or patience to do myself. I learn things, even if I am not likely to put them into practice. Similarly, I post my own trials and tribulations, regardless of the fact that there’s very few people like me with my own very narrow field of vehicles. It’s the sharing of techniques and strategies that matters. I have learned things from so many people via this forum, very few of whom have demonstrated those lessons with vehicles I’m ever likely to want to own.

So carry on, please. 😃👍

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

Mar 20, 2024 11:28:09 GMT

|

I enjoy reading every post on this great build. Please keep going, John.  |

| |

|

|

mk2cossie

Club Retro Rides Member

Posts: 3,063  Club RR Member Number: 77

Club RR Member Number: 77

|

|

Mar 20, 2024 13:25:01 GMT

|

Amazing work johnbonnett  Always pleased to see updates on many peoples projects, but I do understand your point entirely. I get seemingly few replies on my vehicle build thread, but appreciate the fact that it has had as many views and likes on posts as it has. (And I'm also terrible for not photographing things as I go, and updating little and often) Sometimes I seeks like no one is liking or appreciates the effort that has gone in to the work you have done, but I can assure you it is  Keep up with the updates, no matter how large or small they seem to yourself. The Retro Rides collective loves this sort of thing  |

| |

|

|

|

|

|

Mar 20, 2024 13:28:02 GMT

|

|

It's the case with every build thread that the poster feels that no-one is interested.

People are though - look how many 'likes' you get to each post.

Remember, forums are an archive like a library (unlike facebook etc) people will be looking at your thread 20 years from now & learning something that may well be lost in time otherwise.

|

| |

|

|

|

|

|

Mar 20, 2024 13:59:51 GMT

|

|

Keep doing what you're doing John, this is one of my favourite projects on RR. Youre an inspiration!

|

| |

1971 Triumph Toledo 1500 Road/rally

1998 Peugeot 106 Rallye

2007 Volvo V50 T5 AWD "Sensible Daily"

1978 BMW R100RS Cafe Racer "Jägerbomb"

1979 Harley Davidson SXT trials bike

2018 Black Lab/Alsatian cross "Rocky"

|

|

jimi

Club Retro Rides Member

Posts: 2,240

|

|

Mar 20, 2024 14:31:04 GMT

|

Just to echo what glenanderson and mk2cossie and others have said ! Please definitely keep going with the updates as you have been. Lack of comments may well be down to peeps being speechless at the skills on show  |

| |

Last Edit: Mar 20, 2024 14:32:46 GMT by jimi

Black is not a colour ! .... Its the absence of colour

|

|

|

|

|

Mar 20, 2024 15:21:58 GMT

|

Crumbs, that's amazing encouragement to keep the posts going, thank you all. The last thing I want to do is to bore the pants off everyone but if you are okay with it, I'll keep the thread updated as often as there is progress. Once the valence is complete I'm going to take a break from panel work and turn my attention to the tubular frame that is going to support the bonnet skin. I'm making this from 15mm round steel tube with front mounted hinges that will enable the whole front to open similar to a Spitfire arrangement. I'm not sure whether the inner wings will form part of it and move with the bonnet or if they will remain in situ as they do on a Sprite. I'm favouring the former not only for accessibility but for the practical reason that there isn't much to anchor them to otherwise.The frame is the reason I opted for a wooden buck at the front in preference to the wireframe I used on the rest of the body. I can notch out the stations to allow the tubes to sit flush and be assured of a nice fit with the skin. I have sourced some BMW hinges which are both light and compact and I'm sure they will do a good job. Some of you may be following fanatek's YouTube channel and he has used the same hinges on his amazing GT6 project. I believe the lad is Canadian and he comes over so well, quite manic and very entertaining. His work is top notch and, unbelievably, he is doing everything in a small garage with the minimum of tools. Well worth a gander if you haven't come across it. www.youtube.com/@fanatikbuilds |

| |

|

|

redratbike

Posted a lot

Posts: 1,827

Member is Online

|

|

Mar 20, 2024 19:47:18 GMT

|

|

please keep the updates coming

i’m hoping to have a little play with some aluminium soon so watching your methods etc really helps

|

| |

|

|

|

|

|

|

|

please keep the updates coming i’m hoping to have a little play with some aluminium soon so watching your methods etc really helps If I have, through my modest efforts encouraged you to have a go then I'm really pleased. |

| |

|

|

|

|

|

|

|

|

Bit late to the party but as all the other posts have said, keep going with the updates. I find them very interesting.

|

| |

Proton Jumbuck-deceased :-(

2005 Kia Sorento the parts hauling heap

V8 Humber Hawk

1948 Standard12 pickup SOLD

1953 Pop build (wifey's BIVA build).

|

|

logicaluk

Posted a lot

Every days a school day round here

Every days a school day round here

Posts: 1,373

|

|

|

|

|

I too am fascinated by this project, some projects I read every post every time I come here, others like this one, I catch up when I have free time so I can better digest the information. As long as you are happy to, keep doing what you are doing. Looking forward to the flip front.

Dan

|

| |

|

|

maf260

Part of things

Posts: 534

|

|

|

|

|

Please keep the updates going, John. The work you do is way beyond my comprehension and even further from my skills; it's fascinating to watch an entire car body materialise out of sheet metal. Your enthusiasm in creating and joy at completing each element is a very pleasurable read. Don't worry about the lack of comments - I have nothing to add, so say nothing.

|

| |

|

|

|

|

|

Mar 21, 2024 20:01:14 GMT

|

|

Great updates. Love this thread. I'm going to have to have a go at alloy wishing with my oxycet. Not that I need to but would be fun to learn.

|

| |

|

|

|

|

|

Mar 21, 2024 20:21:05 GMT

|

I had turned 60 when I decided to take up metal shaping and at that time Frosts were offering a series of instructional videos made by Ron Fournier and I bought the whole set which covered bucks and patterns, blocking and smoothing, gas welding etc. I found Ron to be an inspirational teacher and using his videos as a basis, I had a go. I was fortunate to have been able to buy an Edwards wheeling machine from a local firm who restored Lola cars and I also bought a shrinker stretcher along with shot bag and mallets from Frost. Frost no longer offer the videos which is a shame but I believe they are available as CDs from Fournier Enterprises in the States. www.fournierenterprises.com/6m3/books-dvds/dvds/fournier-titles.htmlI bought a BOC Saffire welding torch and hired bottles of acetylene and oxygen also from BOC. Despite my best efforts and the video I was unable to master gas welding of aluminium at home so I enrolled at Exeter college for a welding course, one evening a week and after several frustrating weeks when all I could do was burn holes, all of a sudden, I managed to join two pieces of aluminium together without blowing holes everywhere. With more practice it became easier and easier to the point where I wondered why I had found it so difficult. But it's like any skill, once you are proficient it's not a problem anymore and you wonder why it took so long to get to that point. Project 1 was a strange looking vehicle which I built to compete in Class 8 in MCC Classic trials. It had and still has a 1.9 litre Peugeot GTI engine mounted in the rear. The body could easily have been a traditional trials car shape but I wanted to explore the world of metal shaping and double curvature panels which is the reason it looks like it does. I think architects and maybe some clothes designers take off on their own to produce unorthodox and in some people's eyes, downright ugly creations just because they can and to please nobody else but themselves. Exercises in creating something unique you might say. In my case, I just wanted to copy Ron's examples and forming techniques, particularly the rear wings and the nose cone which relate directly to projects that he covered. The front wings gave a strong nod to Dellow and also provided good experience. The fact that when all the panels were fitted together to make a complete body, the whole effect was a complete and utter mismatch and that mattered not a jot to me. The important thing was that I had been able to put into practice many of the techniques Ron taught in his videos which stood my in good stead for Project 2, the Lightweight. In fact, despite its appearance, the car did very well in my hands and my son Chris and did win a coveted Gold on a Lands End. As far as I know, the car is still competing which is heartening. A few photos of the car and my very first foray into metal shaping. The reason for mentioning this is that it is example of what can be achieved, even by a geriatric, if you really want to do something and put your mind to it. I hope this may encourage others who have been thinking about having a go to Just Do It!!       |

| |

|

|