|

|

|

|

|

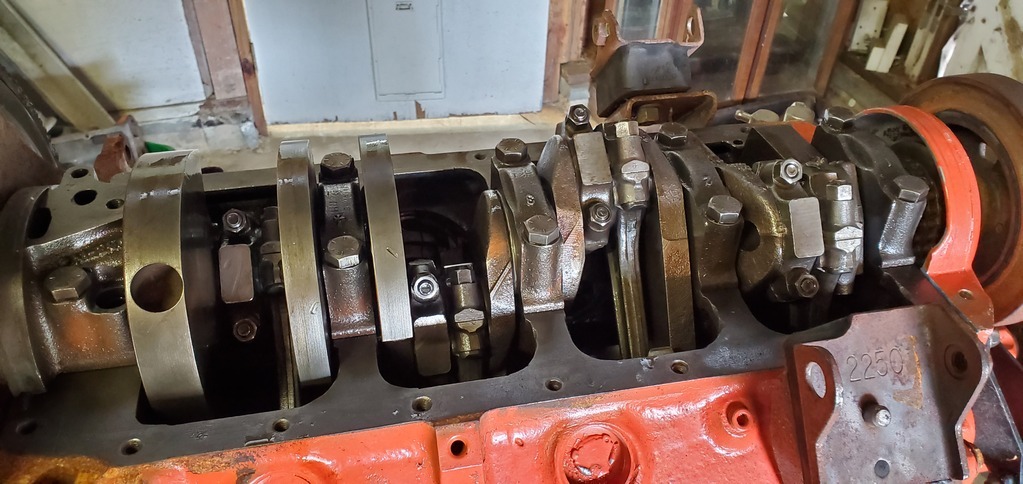

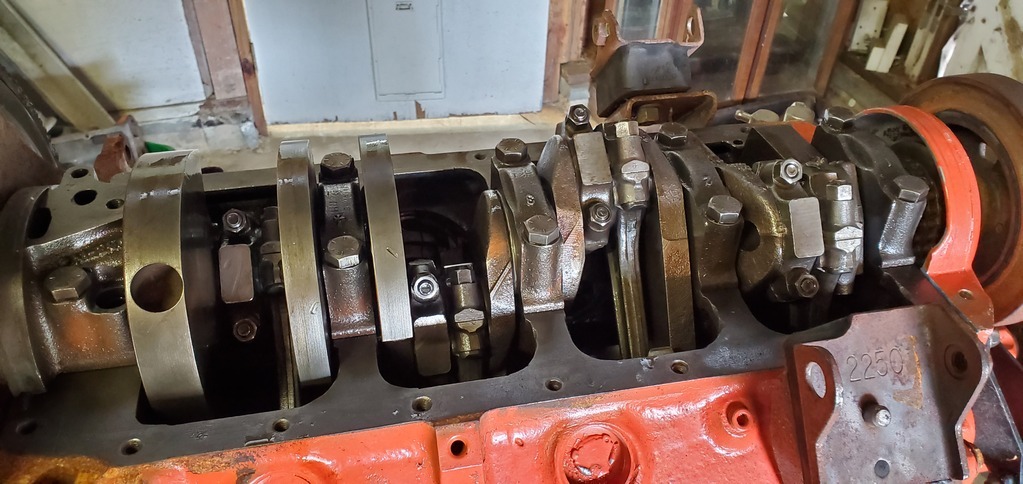

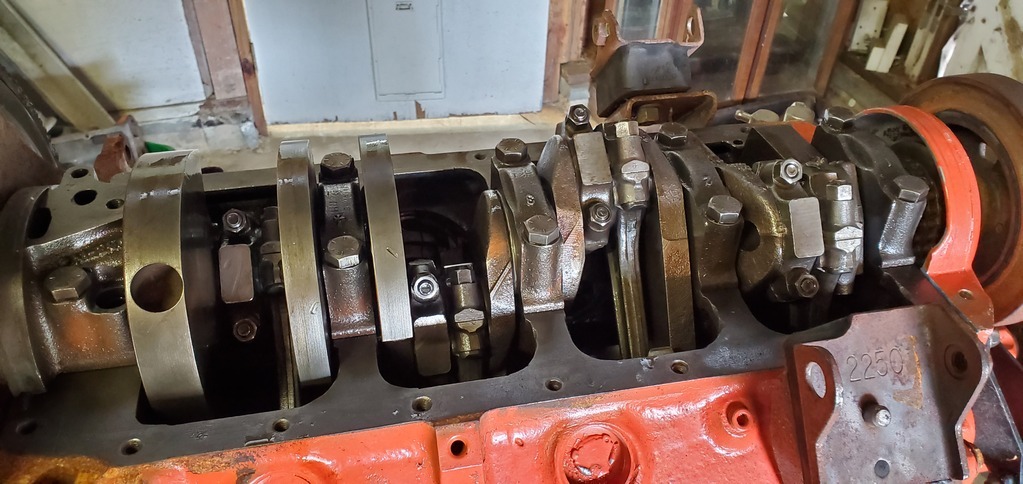

A little garage time this afternoon.  Got all the pistons cleaned up and back in, torqued up.  Heads on.  Manifold on, torqued down. Need to get some bolts for the lifting chains. I'll put some oil in and get it timed up, hook up the gearbox (starter attaches to the gearbox bell-housing, not the engine). I need to clean the carburetor and then I might see if it fires. Phil |

| |

|

|

|

|

|

|

|

|

|

|

|

I'm trying to do a little when I can. This past week and weekend were hell on wheels and significantly more stressful than I wanted to ever be. I'm hoping things will pick up a bit, and I can get back to something resembling normal. |

| |

|

|

jamesd1972

Club Retro Rides Member

Posts: 2,921  Club RR Member Number: 40

Club RR Member Number: 40

|

1966 Plymouth Fury 3jamesd1972

@jamesd1972

Club Retro Rides Member 40

|

|

|

|

Hope whatever is causing the stress eases and you have more time to play and share what you are up to on some interesting cars.

Life has a habit of catching up on you sometimes doesn’t it?

James

|

| |

|

|

|

|

|

|

|

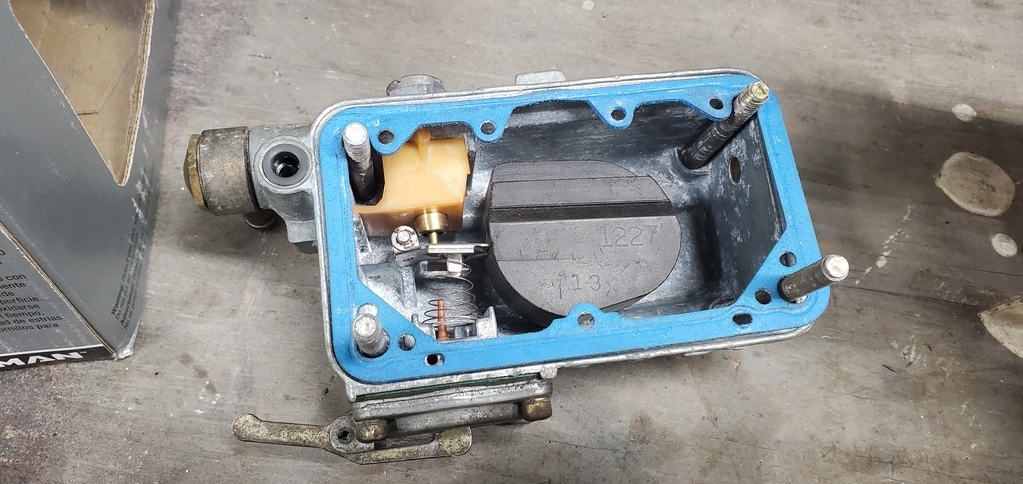

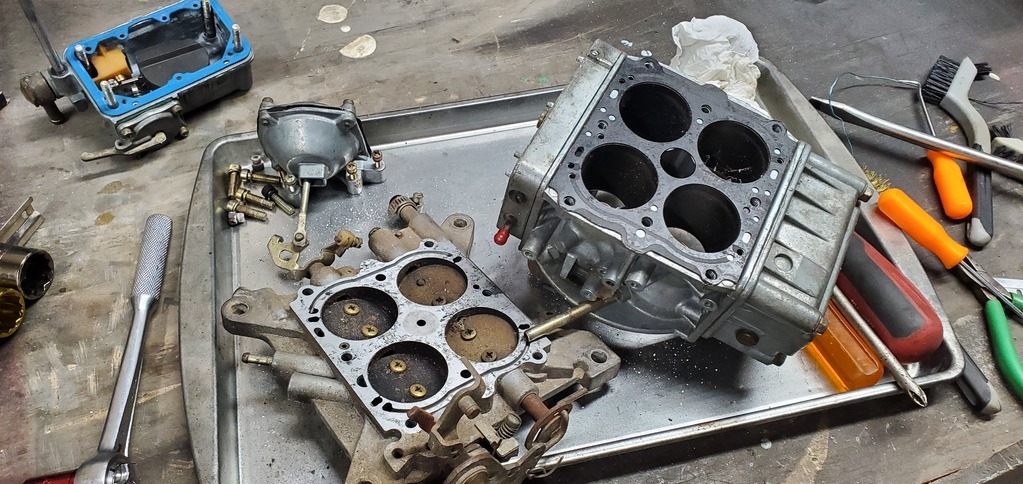

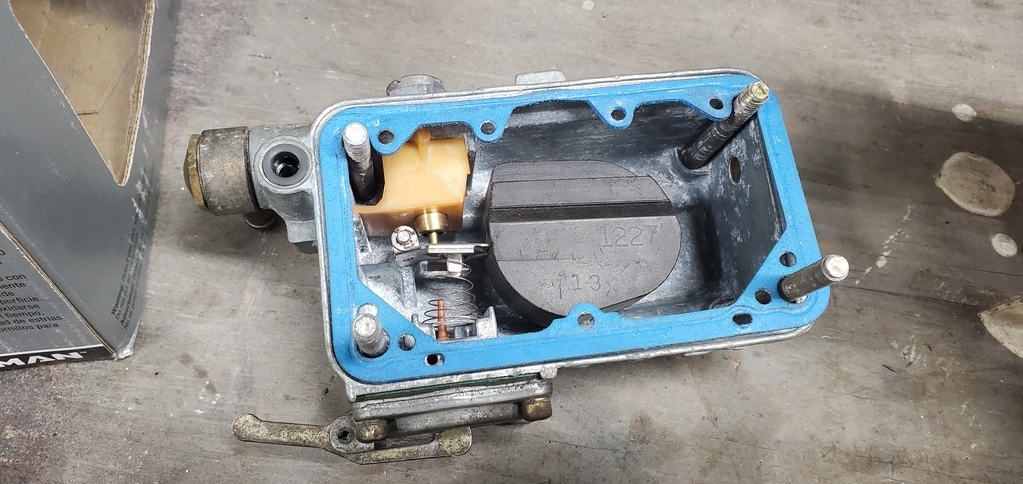

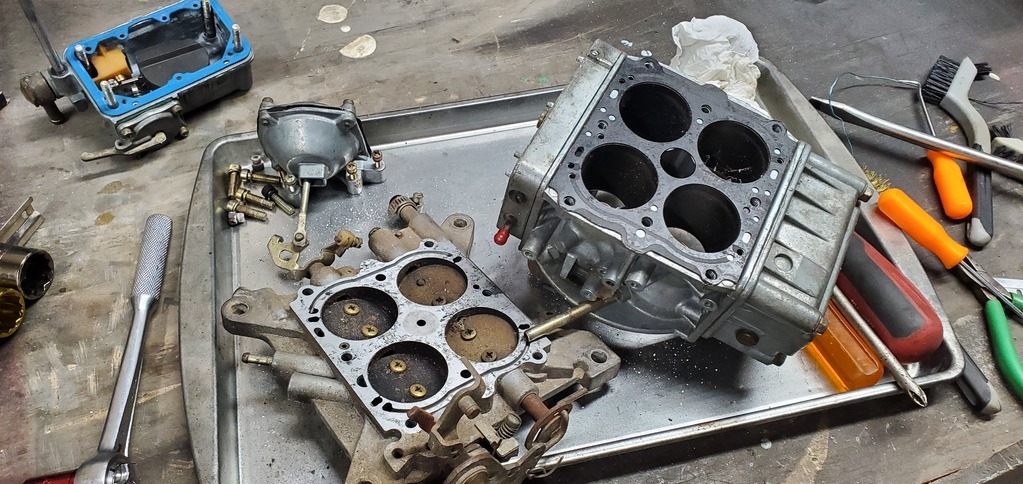

Hopefully so. Yesterday I was passing by the hardware store so I stopped in and picked up some stainless screws for the rocker covers and studs/bolts for the exhaust.  I thought I had the gaskets for the valve covers in a box that came with, bit it turns out to be for the oil pan. Useful in its own right but not helpful here. So, I need a new top-end gasket set. There's also an odd question-mark shaped bypass hose that is not as inaccessible as that on an A-series but still just as stupid in design because you cannot use a standard piece of hose to repair it.  I remembered after the fact that I also needed to get some rod stock from the hardware store to make an impromptu oil pump drive shaft. So, I measured the drive shaft, which is just under 3/8" hexagon. I can file a 3/8" round bar down to size so I can use my drill to spin the oil pump and get the system primed with oil pressure before starting it.  I couldn't resist mocking it up. Mojo boost! I need to get some studs for the carburetor (they're a Holley particular thing) from the auto parts store, plus the spacer gasket- someone's taken an angle grinder to the intake manifold to clear the vacuum secondary mechanism. I am pretty sure that there's enough overhead room to have the 1/2" thick phenolic spacer between the carb and the manifold, which negates that issue. Still, progress is progress. Phil |

| |

|

|

|

|

|

|

|

Stop, carburate and listen.  This is definitely not a brand new invention.  Will it ever stop? I don't know.  Word to your mother. |

| |

|

|

|

|

1966 Plymouth Fury 3peteh1969

@peteh1969

Club Retro Rides Member 107

|

|

|

|

Great work Phill

What are you going to do if the Converter has a problem as it's has the ring gear as part of it.

|

| |

|

|

|

|

|

|

|

Great work Phill What are you going to do if the Converter has a problem as it's has the ring gear as part of it. I have a spare, luckily. They might both be bad, but this one still has some fluid in so there's a possibility it's not totally bad. |

| |

|

|

|

|

|

|

|

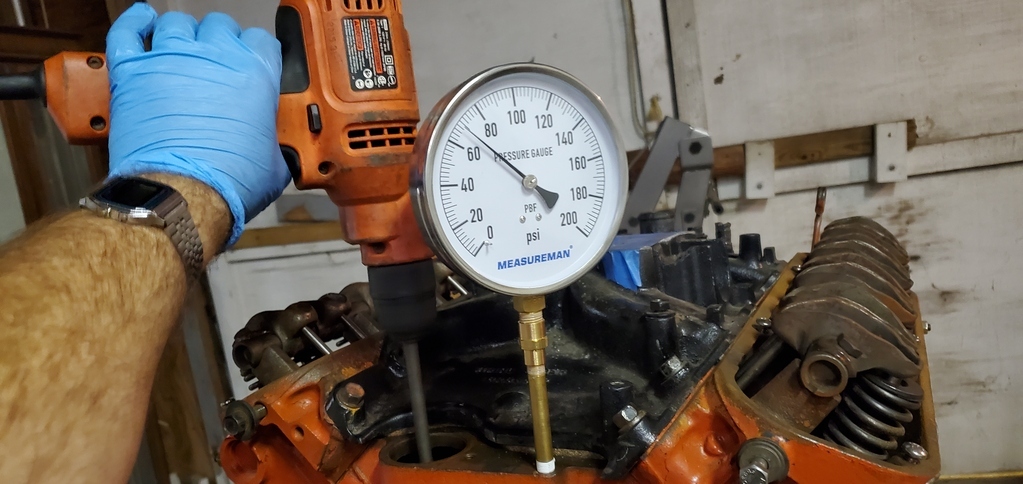

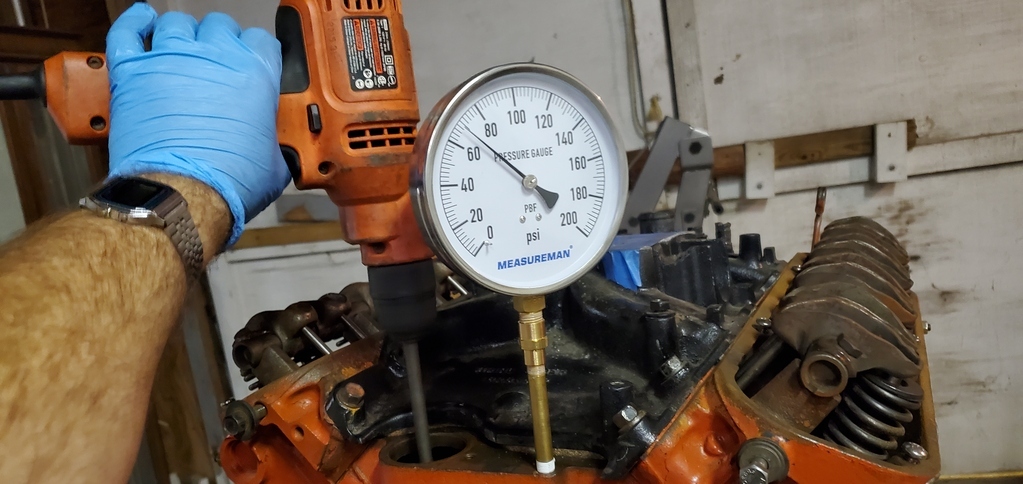

Lubricate.  I bought a length of 3/8" bar and filed the end down to match the oil pump drive.  I then fitted my big oil pressure gauge to the position the oil pressure warning light switch lives, and slotted the drill in place.  I spun the drill over a little and immediately it primed up and barfed out of the filter holes. I then made a quick trip to AutoZone and bought a filter for it.  I ran the drill, I got HORK BLOIP and then Exxon Valdez from the adapter plate. Swapped the plate from the other engine and tried again- better (needs a new seal but it'll work for now).  With that solved, a steady 68 psi on relief is achieved quite easily. The tappets all pumped up but I'm not getting any oil at the top end so I need to check into why before I go much further. Might end up taking the heads off again- could be something stupidly simple as the gaskets are upside down and the oil gallery is obscured. I didn't think to check that before I put it together... But best discovered now rather than later. I know I said I was going to do bodywork first, but that demands a spend; right now that's on hold. So far I'm in $17 on the engine (bolts, oil filter) and the oil I had already. So, progress on the oily bits. Plus, it might actually run. That's always fun. Phil |

| |

Last Edit: May 6, 2021 3:00:20 GMT by PhilA

|

|

|

|

|

|

|

|

Just thought, the rocker arm bars could also be handed, I'll have to check I don't have them on backwards or something stupid like that.

Phil

|

| |

|

|

|

|

|

|

|

|

Phil, oil to the top end in LA engines is timed by the delivery ports in the cam. The top end gets two shots of oil for each crankshaft rotation (one for each head).

If you turn the engine over you should get oil.

|

| |

Proton Jumbuck-deceased :-(

2005 Kia Sorento the parts hauling heap

V8 Humber Hawk

1948 Standard12 pickup SOLD

1953 Pop build (wifey's BIVA build).

|

|

|

|

|

|

|

Phil, oil to the top end in LA engines is timed by the delivery ports in the cam. The top end gets two shots of oil for each crankshaft rotation (one for each head). If you turn the engine over you should get oil. Okay, that is handy to know, thank you. I guess that saves flooding the top end with oil. |

| |

|

|

|

|

|

|

|

|

I was about to also add - on Chevy engines it relies on the dizzy seal at the bottom to oil the top - so the drill wont get pressure to rockers on Chevy's either.

|

| |

|

|

|

|

|

|

|

I was about to also add - on Chevy engines it relies on the dizzy seal at the bottom to oil the top - so the drill wont get pressure to rockers on Chevy's either. Distributor on this doesn't have the oilway like the Chevy, it's just a plugged seal and it's clamped in a "table" in the valley. The drive itself is misted by oil from the cam. The feed comes up through the block to the heads on this one. |

| |

|

|

|

|

|

|

|

Clocked.  That was it; just needed to be brought round to the correct position for the oil to be delivered to the top end. That's everything primed now, which I'm happy about. Phil |

| |

|

|

|

|

|

|

|

I got carried away.   Can thieve the battery from the Pontiac and see if that starter is any good later. Phil |

| |

|

|

Paul Y

Posted a lot

Posts: 1,951

|

|

|

|

I got carried away.   Can thieve the battery from the Pontiac and see if that starter is any good later... Phil ...and throw a carb on it and fire it up on the floor.... I knew that was what you meant Phil... P.  |

| |

|

|

|

|

|

|

|

...and throw a carb on it and fire it up on the floor.... I knew that was what you meant Phil... P.  Well the carb is still in pieces. First check is if the ignition still works, it looks like an MSD system, coil-in-cap which is a first for me- it's a really neat solution. Just attach power and it does everything else. Phil Edit: It's made by A-Team, and the service pack (cap, coil, rotor arm, pickup module) is $29.95 so that's actually not bad. The current cap is cracked so at least replacements aren't stupid cost. |

| |

Last Edit: May 7, 2021 13:13:02 GMT by PhilA

|

|

|

|

|

|

|

|

One starter is bad and tries to arc weld itself internally when power is applied.

The other one is lazy.

Plus the battery isn't doing so well.

Great!

Phil

|

| |

|

|

|

|

|

|

|

|

I only have spark on one plug. Battery is taking a charge, I've been hammering it.

Phil

|

| |

|

|