It was nearing the end of the holiday period, and a little Marina waited patiently for some attention.

Now that the Alto was up and running again, I could focus some time on the Marina and check off another item on the pre-WOF list.

One of the main things I needed to sort, that I had everything for, was to fix the wipers and washers.

I removed the whole wiper system a couple of years ago because it was seized and didn't work. The motor didn't function, one of the wiper boxes was jammed solid and the washers didn't respond to the button.

I started with the washer system. The Aus spec Marina uses a bespoke washer bottle with an integrated pump.

I removed the bottle, removed the pump, and found it full of rust. Trash.

There were a couple of options for a replacement pump, but in my eyes the easiest option was to convert the system to the UK spec bottle and remote pump. It's not as tidy, but easier to get parts for.

I started by scrounging up a good used bottle and cap, some new hose, a new pump and a used mounting plate for the firewall as the bracket is different.

The bracket is spot welded to the mounting plate, so I carefully drilled out the spot welds and removed the bracket. Here I had also prepped it for welding.

I considered using rivnuts to mount the bracket, but it's flat on the back so has no space for the bolt heads once the bottle is fitted. The only option was to weld it to the original mounting plate (or paint the replacement one, drill out the rivets and swap the whole plates over).

I marked it out and cleaned the paint off the weld points

And gave it a quick tickle with the sparky glue. I also welded up the lower hole for the Aus spec bracket as this had been letting water in.

A quick prime and a flick of paint and it didn't stick out so much

A test fit with the new bottle

I pulled out all the old perished washer hose and ran all new 4mm hose. Unfortunately during this one of the washer jets crumbled to bits.

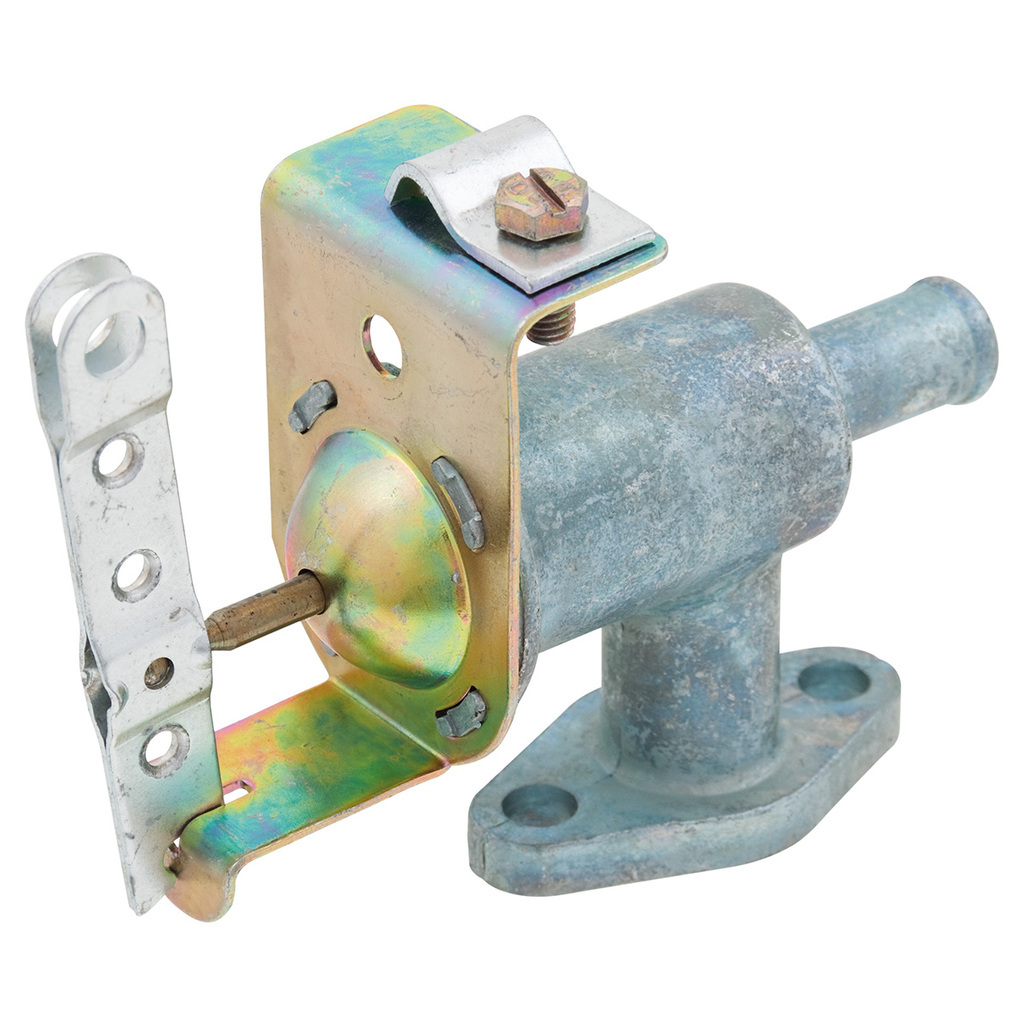

With the bottle and hoses in place, I just needed to adapt and install the pump. The connectors are slightly different, so I had to change the wiring to a pair of female spade terminals, but other than that it just plugged straight into the pump and worked. Dark green was positive, and it grounded through the switch.

I drilled a couple of small holes and used a pair of new self-tappers to mount the pump. Also note the nice new hoses to and from the pump, including a one-way valve inside the bottle.

A quick test with some water in the bottle and we finally had water outside the car, albeit in a stream, not a jet

A quick trip to Supercheap resulted in a pair of generic twin jet washers, which I quickly set about fitting

They looked ok and didn't stand out too much

And they worked a treat. Ignore the spoiler regarding the wipers....

Next on the list was to sort the wipers. When I originally removed everything I had to remove one of the spindles with the rack as it was seized solid and you normally slide the cable through it to remove it.

A bit of brute force got the cable out without damage.

The wiper system is quite interesting really. Instead of linkages like cars have these days, it was operated by a motor pushing and pulling on a spiral wound cable through some steel tubes. This cable engaged teeth on the wheels in the spindles, which caused them to rotate back and forth, thus moving the wipers.

It's quite simple, with not many places to go wrong.

Except mine had. The motor was dead and one of the spindles was seized solid. I also discovered that one of the steel tubes had been bent to get around a bracket (which it should have passed though) which was causing huge resistance on the cable.

I removed the motor which is done by removing the mounting screw and bracket, removing the wiring and then flipping the motor over.

Unless you can/want to remove the whole cable with the motor, you need to disengage it from the motor. This is done by removing the circlip from the arm, remove the small washer and then the arm comes free. The cable is attached to this arm on a pin.

A quick bench test showed that although dirty, the motor was working correctly. Even the park function worked.

I removed and cleaned the park switch too. It's worn, but still functioning. I have a spare for the future, if needed.

Everything got a thorough clean and then regreased.

I started by grabbing a pair of good working wiper spindles and fitting them to the cowling panel. This wasn't a job I enjoyed, so there are no photos of it. It involves having to hold the spindle up under the dash with one hand, while pushing on the rubber seal, washer and screw on the nut with your other hand. Next was fitting all the steel tubes (including a replacement one between the spindles to replace the bent one) and attaching the gear covers, mostly with one hand due to space. Good fun.

Once all that was in place I greased the cable up, attached it to the motor and threaded it into the tubes, watching as the spindles rotated as it went through. The motor was then refitted to the inner guard, and plugged in.

A quick test showed everything worked correctly, so I installed the original wiper arms and blades. Note the correct side parking position, which was reversed on the later Marina for whatever reason.

For the first time in a couple of years, the Marina had wipers.

To celebrate, I poured some water on the windscreen (since the washers didn't have jets yet) and turned them on

Hmm, something wasn't quite right. It wiped well (ignoring the ancient rubbers smearing the glass), the wipers had plenty of speed and parked perfectly, but the sweep was.... tiny. It barely cleared the drivers vision.

I tried adjusting the position of the arm up the screen, but by the time I could get enough sweep on the glass, the arm was basically in the middle of my vision.

At best I got this much wipe

I ruminated on it for a bit and came to realisation that I had cocked up. Ages ago, knowing one of my spindles was seized, I bought a couple of second hand replacements. What I had ended up doing, was fitting UK spec spindles, to the AUS spec motor. This had created a mismatch in the gearing, meaning the wipers didn't move as far as they needed to.

I confirmed this by checking my photos taken when I removed the spindles, as to which type were fitted originally

The remedy? I needed to swap the drivers side spindle out for my one remaining good Aus spec spindle with the correct gearing. It means the passengers side doesn't wipe as far as it should, but the drivers side is the one that matters.

Thankfully the drivers side is the easier one to get to. I removed the wiper arm, dismounted the motor and pulled the cable out enough that it disengaged the spindle.

I then removed the back cover so I could remove the tubes from the spindle. It's obvious in this photo, compared to the one above, that the gear on the spindle is bigger and has a different design.

Once removed I put them side by side and you can see the difference here. Aus spec on the left with the smaller gear.

With the Aus spindle installed, how was it?

MUCH better. It now cleared right up to the A pillar, from the arm being horizontal.

The Triangle of Doom is horrific though, Hubnut would not be impressed.

The ultimate solution would be to source another Aus spec spindle and replace the passengers side one too, but this will do for now. It will get me through a WOF inspection anyway, well, once the new blades arrive to replace these smeary old things. This is a good-weather car anyway.

One last thing for the week was to sort out the source of jokes from my wife

I had previously tested the wiring, so knew the issue was the headlight itself and being a sealed beam unit where the whole light is essentially the bulb (not a lens and reflector with the bulb in it) the only option was complete replacement.

This one was an ancient GE unit (ignore the upside down photo...)

I bought a pair of sweet NOS Hella H4 units a couple of years ago and have been waiting to fit them

Date stamped 1996, about a year after this car was last on the road

These are a lens and reflector unit with a replaceable H4 bulb

They were a direct drop-in replacement. The Hella, on the right of this photo, has a slightly whiter shade

My only real issue with them is they don't have the nice pronounced curve in the lens like the old lights (and other new replacements available)

Old

New

I'll use them for now, but will look to replace them again in the future with curved lens units, which is a shame because the Hella ones are really nice quality and really expensive to buy new now. They don't quite look right though with the flat lens.

They do light up really well though

Since I have changed the ride height of the car and levelled it out some, I had to adjust the lights to bring them back to level. This is done with the adjustment screws on the light bowl.

With the grille panel refitted. It somehow changed the face of the car not having curved lenses. It looks surprised.

We're one step closer to a WOF and about three more things crossed off the list. The pre-WOF list is getting pretty small now. I need to reinstall the rear quarter glass, install some carpet, reinstall the seats, install the seatbelts, make a door card and have the exhaust rear section replaced and we should be good to give it a try.

Now that the Alto was up and running again, I could focus some time on the Marina and check off another item on the pre-WOF list.

One of the main things I needed to sort, that I had everything for, was to fix the wipers and washers.

I removed the whole wiper system a couple of years ago because it was seized and didn't work. The motor didn't function, one of the wiper boxes was jammed solid and the washers didn't respond to the button.

I started with the washer system. The Aus spec Marina uses a bespoke washer bottle with an integrated pump.

I removed the bottle, removed the pump, and found it full of rust. Trash.

There were a couple of options for a replacement pump, but in my eyes the easiest option was to convert the system to the UK spec bottle and remote pump. It's not as tidy, but easier to get parts for.

I started by scrounging up a good used bottle and cap, some new hose, a new pump and a used mounting plate for the firewall as the bracket is different.

The bracket is spot welded to the mounting plate, so I carefully drilled out the spot welds and removed the bracket. Here I had also prepped it for welding.

I considered using rivnuts to mount the bracket, but it's flat on the back so has no space for the bolt heads once the bottle is fitted. The only option was to weld it to the original mounting plate (or paint the replacement one, drill out the rivets and swap the whole plates over).

I marked it out and cleaned the paint off the weld points

And gave it a quick tickle with the sparky glue. I also welded up the lower hole for the Aus spec bracket as this had been letting water in.

A quick prime and a flick of paint and it didn't stick out so much

A test fit with the new bottle

I pulled out all the old perished washer hose and ran all new 4mm hose. Unfortunately during this one of the washer jets crumbled to bits.

With the bottle and hoses in place, I just needed to adapt and install the pump. The connectors are slightly different, so I had to change the wiring to a pair of female spade terminals, but other than that it just plugged straight into the pump and worked. Dark green was positive, and it grounded through the switch.

I drilled a couple of small holes and used a pair of new self-tappers to mount the pump. Also note the nice new hoses to and from the pump, including a one-way valve inside the bottle.

A quick test with some water in the bottle and we finally had water outside the car, albeit in a stream, not a jet

A quick trip to Supercheap resulted in a pair of generic twin jet washers, which I quickly set about fitting

They looked ok and didn't stand out too much

And they worked a treat. Ignore the spoiler regarding the wipers....

Next on the list was to sort the wipers. When I originally removed everything I had to remove one of the spindles with the rack as it was seized solid and you normally slide the cable through it to remove it.

A bit of brute force got the cable out without damage.

The wiper system is quite interesting really. Instead of linkages like cars have these days, it was operated by a motor pushing and pulling on a spiral wound cable through some steel tubes. This cable engaged teeth on the wheels in the spindles, which caused them to rotate back and forth, thus moving the wipers.

It's quite simple, with not many places to go wrong.

Except mine had. The motor was dead and one of the spindles was seized solid. I also discovered that one of the steel tubes had been bent to get around a bracket (which it should have passed though) which was causing huge resistance on the cable.

I removed the motor which is done by removing the mounting screw and bracket, removing the wiring and then flipping the motor over.

Unless you can/want to remove the whole cable with the motor, you need to disengage it from the motor. This is done by removing the circlip from the arm, remove the small washer and then the arm comes free. The cable is attached to this arm on a pin.

A quick bench test showed that although dirty, the motor was working correctly. Even the park function worked.

I removed and cleaned the park switch too. It's worn, but still functioning. I have a spare for the future, if needed.

Everything got a thorough clean and then regreased.

I started by grabbing a pair of good working wiper spindles and fitting them to the cowling panel. This wasn't a job I enjoyed, so there are no photos of it. It involves having to hold the spindle up under the dash with one hand, while pushing on the rubber seal, washer and screw on the nut with your other hand. Next was fitting all the steel tubes (including a replacement one between the spindles to replace the bent one) and attaching the gear covers, mostly with one hand due to space. Good fun.

Once all that was in place I greased the cable up, attached it to the motor and threaded it into the tubes, watching as the spindles rotated as it went through. The motor was then refitted to the inner guard, and plugged in.

A quick test showed everything worked correctly, so I installed the original wiper arms and blades. Note the correct side parking position, which was reversed on the later Marina for whatever reason.

For the first time in a couple of years, the Marina had wipers.

To celebrate, I poured some water on the windscreen (since the washers didn't have jets yet) and turned them on

Hmm, something wasn't quite right. It wiped well (ignoring the ancient rubbers smearing the glass), the wipers had plenty of speed and parked perfectly, but the sweep was.... tiny. It barely cleared the drivers vision.

I tried adjusting the position of the arm up the screen, but by the time I could get enough sweep on the glass, the arm was basically in the middle of my vision.

At best I got this much wipe

I ruminated on it for a bit and came to realisation that I had cocked up. Ages ago, knowing one of my spindles was seized, I bought a couple of second hand replacements. What I had ended up doing, was fitting UK spec spindles, to the AUS spec motor. This had created a mismatch in the gearing, meaning the wipers didn't move as far as they needed to.

I confirmed this by checking my photos taken when I removed the spindles, as to which type were fitted originally

The remedy? I needed to swap the drivers side spindle out for my one remaining good Aus spec spindle with the correct gearing. It means the passengers side doesn't wipe as far as it should, but the drivers side is the one that matters.

Thankfully the drivers side is the easier one to get to. I removed the wiper arm, dismounted the motor and pulled the cable out enough that it disengaged the spindle.

I then removed the back cover so I could remove the tubes from the spindle. It's obvious in this photo, compared to the one above, that the gear on the spindle is bigger and has a different design.

Once removed I put them side by side and you can see the difference here. Aus spec on the left with the smaller gear.

With the Aus spindle installed, how was it?

MUCH better. It now cleared right up to the A pillar, from the arm being horizontal.

The Triangle of Doom is horrific though, Hubnut would not be impressed.

The ultimate solution would be to source another Aus spec spindle and replace the passengers side one too, but this will do for now. It will get me through a WOF inspection anyway, well, once the new blades arrive to replace these smeary old things. This is a good-weather car anyway.

One last thing for the week was to sort out the source of jokes from my wife

I had previously tested the wiring, so knew the issue was the headlight itself and being a sealed beam unit where the whole light is essentially the bulb (not a lens and reflector with the bulb in it) the only option was complete replacement.

This one was an ancient GE unit (ignore the upside down photo...)

I bought a pair of sweet NOS Hella H4 units a couple of years ago and have been waiting to fit them

Date stamped 1996, about a year after this car was last on the road

These are a lens and reflector unit with a replaceable H4 bulb

They were a direct drop-in replacement. The Hella, on the right of this photo, has a slightly whiter shade

My only real issue with them is they don't have the nice pronounced curve in the lens like the old lights (and other new replacements available)

Old

New

I'll use them for now, but will look to replace them again in the future with curved lens units, which is a shame because the Hella ones are really nice quality and really expensive to buy new now. They don't quite look right though with the flat lens.

They do light up really well though

Since I have changed the ride height of the car and levelled it out some, I had to adjust the lights to bring them back to level. This is done with the adjustment screws on the light bowl.

With the grille panel refitted. It somehow changed the face of the car not having curved lenses. It looks surprised.

We're one step closer to a WOF and about three more things crossed off the list. The pre-WOF list is getting pretty small now. I need to reinstall the rear quarter glass, install some carpet, reinstall the seats, install the seatbelts, make a door card and have the exhaust rear section replaced and we should be good to give it a try.