|

|

|

Oct 13, 2020 12:00:07 GMT

|

|

|

| |

Last Edit: Oct 13, 2020 12:12:26 GMT by exuptoy

|

|

|

|

|

|

|

Oct 13, 2020 12:16:56 GMT

|

|

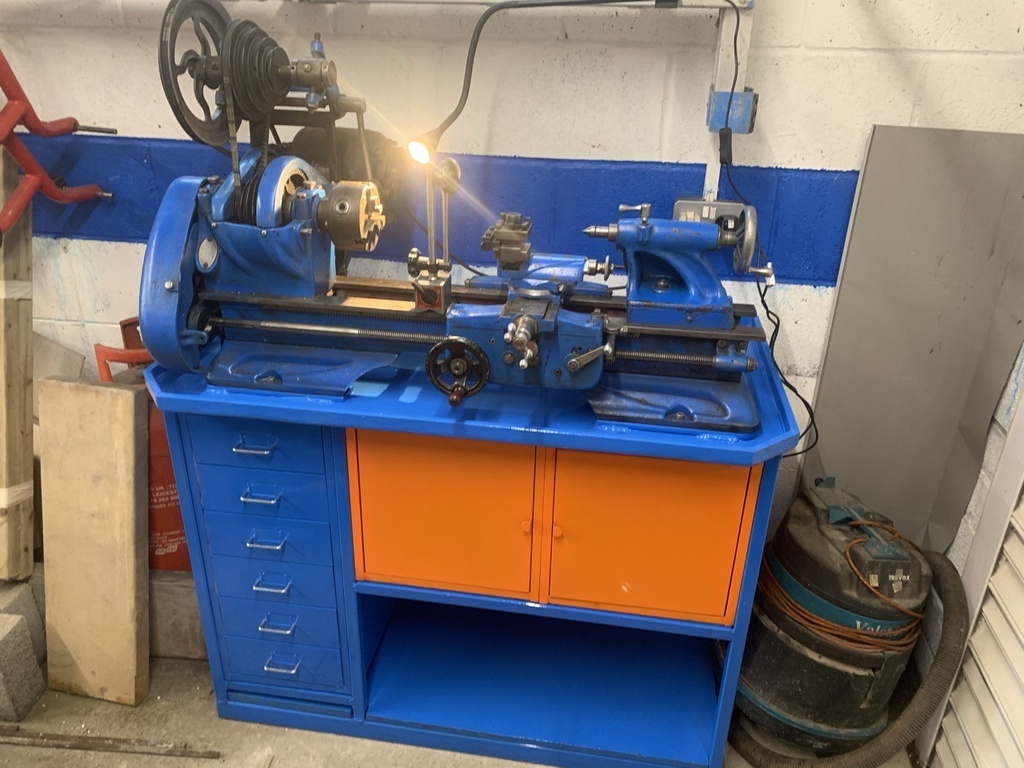

Very tidy end product. Now let the lads on mig-welding see it too!

Which parts came from IKEA? I haven't thought of them for steel items.

|

| |

|

|

|

|

|

Oct 13, 2020 12:37:07 GMT

|

It’s already on Mig-Welding, I’ve been on there a long time.  The two orange cupboards were about £20 each I think and the drawer unit was £29. |

| |

|

|

|

|

|

Oct 13, 2020 12:40:04 GMT

|

|

|

| |

|

|

|

|

|

Oct 13, 2020 14:41:42 GMT

|

|

What a bargain. And also a brilliant idea for the stand/tool cupboard. I may borrow that idea for mine.

|

| |

|

|

pptom

Part of things

Posts: 475

|

|

Oct 13, 2020 15:49:31 GMT

|

|

Nice, you'll wonder how you ever got on without it soon.

The old stuff really was built to last, they may have a little wear but I started out with a Chinese mini lathe and it was a bit rubbish for anything other than aluminium, now have a 60's Myford and between projects restored a 40's / 50's pillar drill and a couple of pre war vices.

Would love to upgrade the lathe to something more heavy duty and add a Milling Machine, be warned, it could be the tip of the old machine iceberg!

|

| |

|

|

|

|

|

Oct 13, 2020 16:44:14 GMT

|

|

|

| |

|

|

|

|

|

|

|

It’s already on Mig-Welding, I’ve been on there a long time.  The two orange cupboards were about £20 each I think and the drawer unit was £29. Er senior moment?

See user name.

I did check, but evidently didn't scroll far enough down the list of your posts.

Thanks for those IKEA links. I'll try to find a use for them.

|

| |

Last Edit: Oct 14, 2020 7:58:15 GMT by theoldman

|

|

pptom

Part of things

Posts: 475

|

|

Oct 14, 2020 11:46:39 GMT

|

|

Nice job on the torque arm, have a Milling slide for mine, but always found it a bit Mickey mouse, though it could be the operator!

If I attempted one of them I'd get to the last slot, the cutter would grab and I'd end up with a fancy corkscrew.

|

| |

|

|

|

|

|

Oct 14, 2020 13:49:00 GMT

|

|

nice purchase!

I have a Myford M type which is a similar age gathering dust, the plan is to sort the belt drive as it's misaligned and sounds like the bearings are worn.

the lathe bed and the main bearings are all in good order so it should be fairly straight forward to fix.

Thanks for the mojo to do it

|

| |

1966 Ford Cortina GT

2018 Ford Fiesta ST

Full time engineer, part time waffler on Youtube - see Jim_Builds

|

|

|

|

|

|

|

Oct 14, 2020 22:30:37 GMT

|

|

Haha,that's quite alright.

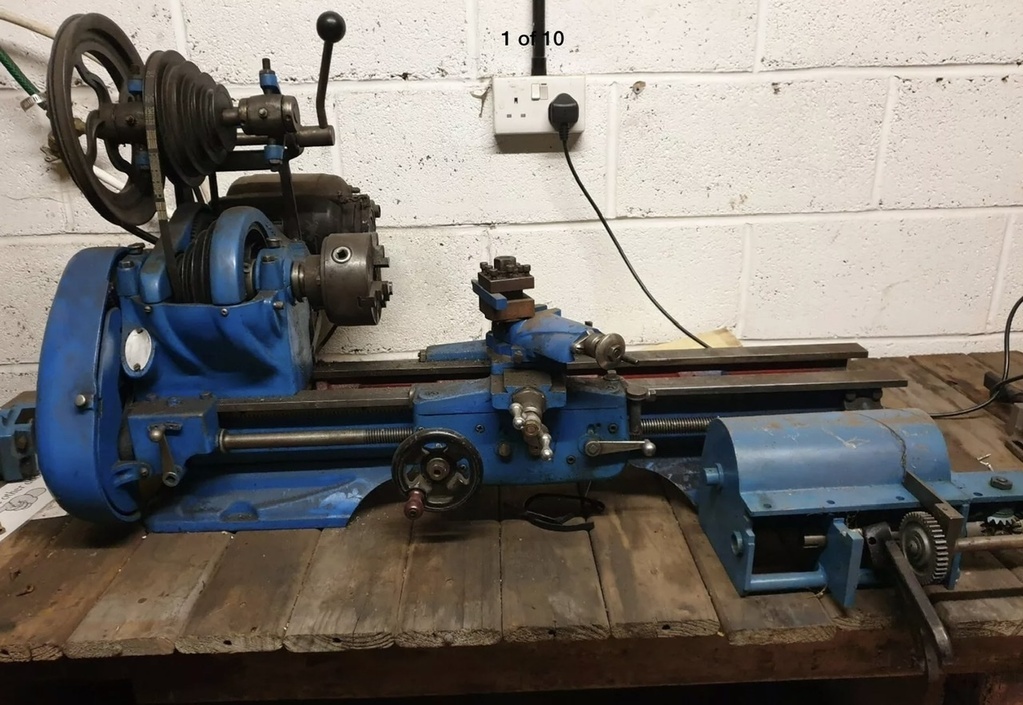

Mine isn't actually a TV36, the bed is a TV36 but it has the babbit bearings not the Timken tapers but it works just fine providing you keep the oil pots full otherwise it slows down as it gets warm. As long as you're aware it's fine and puts out work that's more than acceptable.

|

| |

Last Edit: Oct 15, 2020 7:19:42 GMT by exuptoy

|

|

elfman

Part of things

Posts: 399

|

|

Oct 15, 2020 22:21:10 GMT

|

|

That looks great £300 well spent and the bench looks fantastic..

|

| |

|

|

oldisbetter

Part of things

If it has a ECU it's complicated :)

If it has a ECU it's complicated :)

Posts: 478

|

|

Oct 15, 2020 23:01:05 GMT

|

Nice lathe set up exuptoy i keep looking at lathes in the hobby sized range but it is more i want one than need one lol |

| |

|

|

|

|

|

Oct 16, 2020 15:45:55 GMT

|

|

I know but at £300 it really was a no brainer! It now owes me double that with the steel,cupboards, paint and tooling but I really am far from frugal when doing something I want. Ido waste some money! 😂

|

| |

|

|

elfman

Part of things

Posts: 399

|

|

Oct 16, 2020 16:53:25 GMT

|

|

Yes i've spent mine on cars, beer, holidays and women, wasted the rest ...lol

Keep up the good work its a great link to follow..

|

| |

|

|