|

|

|

|

|

|

It looks like the front could easily be lowered 3 or 4 inches by bolting the subframe through the chassis rather than on brackets hanging underneath.

for the back the chassis could be raised (technically not allowed but I don't suppose anyone has a record of how they were done in the fist place anyway) but obviously all the load area floor would have to be cut out..

Some sort of semi trailing arm set up such as a sierra could be used to lower it by only adding brackets to the chassis for the subframe spring seats dampers etc (or welding the subframe to the chassis). That said it looks like the rear springs are also on brackets hanging below the chassis and it could go a long way down with the chassis and axle as it is. if you want to go further add a length of the same square tube on top of the chassis over the axle then notch the original chassis to clear the axle, this would only need a couple of slots in the load are floor to be cut.

|

| |

Last Edit: Aug 24, 2021 7:51:51 GMT by kevins

|

|

|

|

|

|

|

|

|

Are you going to be doing any cutting/modifying of the chassis to achieve your desired running height? If so, it might be worth doing it before you get carried away with the blasting and painting. Personally, if I were going to be using that frame, I’d be adding some triangular gussets and braces to stiffen it up while everything is so accessible. Anyway, great work so far. Just goes to show how sound the base vehicle was under all the grot and filth. 👍😃 Morning Glen, Sorry, been a busy week, account plans and presentations. All a load of borroxx but its what we need to do to keep the mortgage paid. I cannot go mad cutting etc. But without doubt, a fair amount of gusseting everywhere I go with it. And yes, only one bit of chassis rust to deal with as shown before. I also have a few mounting points to revise as bolts were cut off in the frame as they were rusted off, out of shape, or brow when trying to undo them, despite repeated applications of Duck oil. I am hoping that I will be able to buy either a full set of Ford mounting bolts n nuts for the front and rear subframe and axle. As a kit. Also……… FORD OR KIT CAR GUYS: CAN ONE BUY A FULL SET OF BUSHES FOR THE FRONT AND REAR, RUBBER OR POLYURETHANE AS A COMPLETE KIT? Thanks |

| |

|

|

|

|

|

|

|

Making good progress, make sure you seal the breather on the axle before you go near it with a sand blaster though. One way to really stiffen the front up and lower it at the same time would be to weld the subframe in. Morning mate. Thanks for that reminder. I need to find the breather first, but would merrily hve filled it with disappearing media, without thinking. I think I will avoid the welding in, as it needs to be reversible, or at least editable in case it becomes too much fun and requires a re-edit of the front end. I really do not want this to spiral out of control (says the guy now getting ready to blast the stripped out frame) |

| |

|

|

|

|

|

|

|

Like glenanderson says I’d consider adding some gussets to the front end, especially having seen the Eagle chassis my neighbour had. That had some added as the front kick up one side had tweaked after a bump. Also while I think of it re the ‘rag joint’ or steering coupling. On Cortinas, Escorts etc they tend to be replaced as an assembly rather than just replacing the rubber. That said, Edd ( bodieanddoyle ) fitted a polyurethane one to his 2002, and a friend of ours found it was spot on to replace the rubber in the coupling on his Capri. Also, and I will say they may well be a different length, the coupling looks similar to the one used on mk3 / smiley face Transits. Looks to have the same fittings but has a UJ rather than a rubber coupling. Might be worth a look 🙂 Gussets yes. And any other strengthening it may need. Once the body goes back on, I really do not want to go back in. Unless it is to play naughty like LivingMyBoostLife has done in his awesome builds. Though that is waaaay ot of my league, however the MX5 seems to like a bit of boost too, and maybe I could be taught all that on here. Regarding the steering, I am happy to go with whatever works, Ford part or drill out the rivets nd replace with poly or whatever. |

| |

|

|

|

|

|

|

|

If I could get away with it ( depending on the rules in your neck of the woods ) I'd drop the middle part of the chassis ( or raise the front & rear ) to get some more clearance for lowered suspension. For stiffness, and it looks like it really needs it , I'd add a 8 point cage.  All good ideas. But as you say…… The Rules…… and it will be getting an MOT and the days of a mate passing your build knowing it is over engineered but not to MOT standard is drawing to a close, and I have no such mates, sadly. I like the idea of dropping the tub, but like with so many things, it goes hand in hand with rerouting and re-engineering a load of stuff too. Regarding a cage, I personally want as little as possible cage, mainly for aesthetic reasons. Despite what everyone will tell me. |

| |

|

|

|

|

|

|

|

It looks like the front could easily be lowered 3 or 4 inches by bolting the subframe through the chassis rather than on brackets hanging underneath. for the back the chassis could be raised (technically not allowed but I don't suppose anyone has a record of how they were done in the fist place anyway) but obviously all the load area floor would have to be cut out.. Some sort of semi trailing arm set up such as a sierra could be used to lower it by only adding brackets to the chassis for the subframe spring seats dampers etc (or welding the subframe to the chassis). That said it looks like the rear springs are also on brackets hanging below the chassis and it could go a long way down with the chassis and axle as it is. if you want to go further add a length of the same square tube on top of the chassis over the axle then notch the original chassis to clear the axle, this would only need a couple of slots in the load are floor to be cut. I think that you are right with most of your observations Kevin. I need about 8 inches drop to get the look I want, so it will be interesting. However, getting into breaking or finding another car to find a different rear end from etc is not going to happen. Right now, I am thinking cheap, affordable, fun and not a hillclimb monster, despite the temptation always being in our minds. In the mean time, I have taken Friday off to redo Sallys bathroom and free up most of the rest of the weekend for the chassis blasting and painting. And some payback time with her….. |

| |

|

|

|

|

|

Aug 26, 2021 10:18:27 GMT

|

Having taken Friday off, in order to get going on the blasting the frame and cross member and axle plus their bits…… I decided to listen to Paul Y and the rest of you. I hope these two items will be worth the £31.00 paid for them, mask and goggles are hopefully correct and decent spec. I do not often do this part of the job right.  Maybe even a hoody and overall to try keep the sand out of my crack. |

| |

|

|

|

|

|

Aug 26, 2021 12:10:36 GMT

|

|

What blast media are you using Grizz?

and I trust you have a compressor of enormity to run the blaster.

|

| |

Take the Next slot right coming up on the left.

|

|

|

|

|

Aug 26, 2021 12:17:48 GMT

|

What blast media are you using Grizz? and I trust you have a compressor of enormity to run the blaster. Glass media. Compressor will probably keep me frustrated. |

| |

|

|

|

|

|

Aug 26, 2021 13:44:27 GMT

|

|

|

| |

|

|

|

|

|

Aug 26, 2021 13:50:03 GMT

|

|

I think get the replacement bush. At least it's the right bit. Otherwise you'll have an unknown quantity in your steering, and you will have to modify it to fit.

That's the way I would do it.

|

| |

|

|

|

|

|

Aug 26, 2021 13:59:27 GMT

|

|

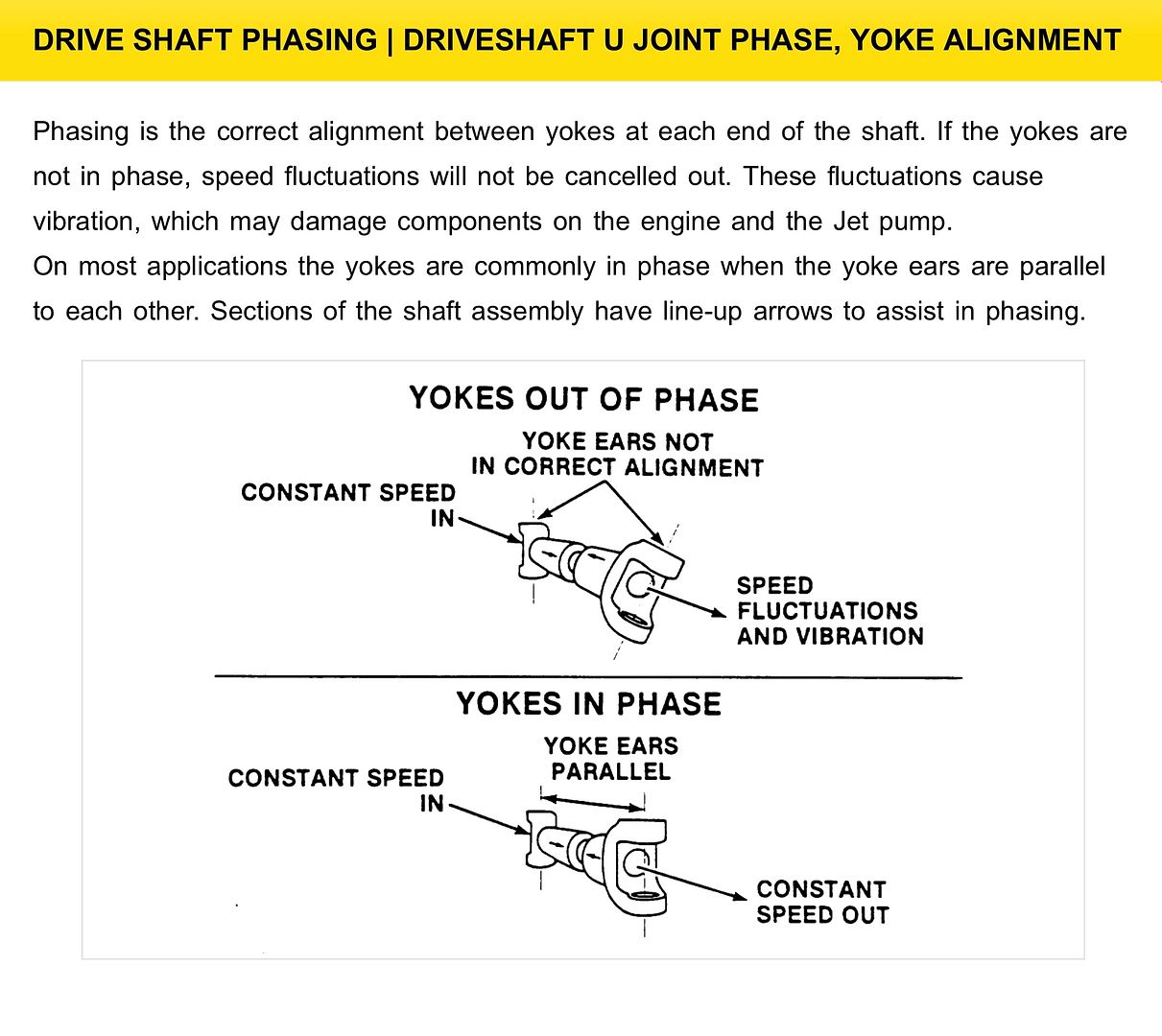

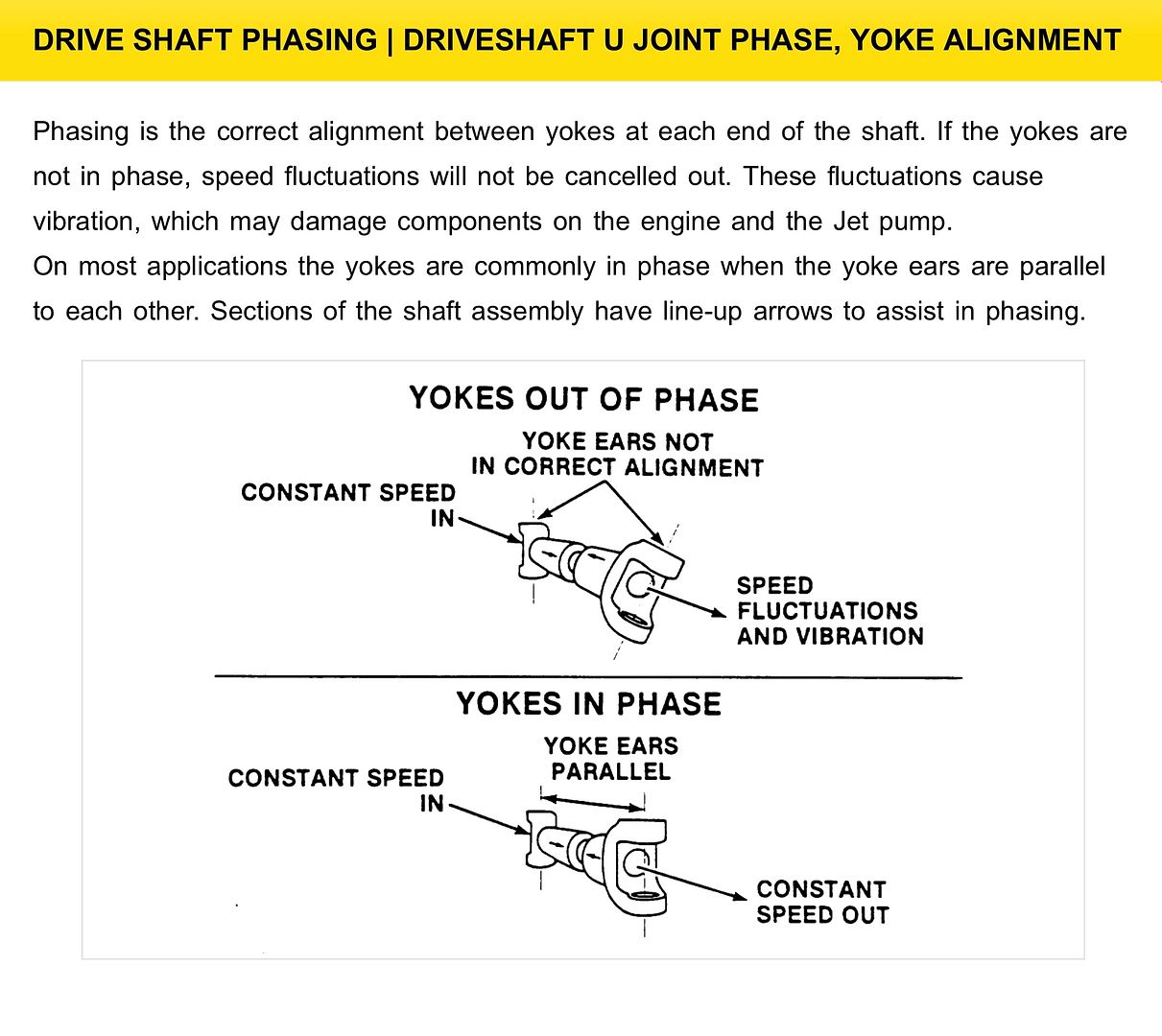

If you went the route of using the u/j you would have to be careful to get the phasing with the joint on the other end right otherwise it will feel lumpy.

|

| |

|

|

|

|

|

Aug 26, 2021 14:07:49 GMT

|

I think get the replacement bush. At least it's the right bit. Otherwise you'll have an unknown quantity in your steering, and you will have to modify it to fit. That's the way I would do it. Cheap enough, relative to the build I guess. If you went the route of using the u/j you would have to be careful to get the phasing with the joint on the other end right otherwise it will feel lumpy. Good call on the phasing, another bit of good advice from mate Edd. Well I'd personally order a rubber, less chance to slip with the grinder. But if you do cut it, read this www.drivelinesnw.com/part-trouble-shooting/vibration-analysis/phasing/ |

| |

Last Edit: Aug 26, 2021 14:08:54 GMT by grizz

|

|

|

|

|

Aug 26, 2021 20:15:19 GMT

|

|

I need a running, complete, possibly MOT failure, Mazda MX5 Mk2 or Mk2.5 for under £500.00 as a donor.

Whatcha got?

Of point me in the right direction.

I am in Kent.

Thanks.

|

| |

|

|

|

|

|

Aug 26, 2021 20:33:14 GMT

|

Are you going to be doing any cutting/modifying of the chassis to achieve your desired running height? If so, it might be worth doing it before you get carried away with the blasting and painting. Personally, if I were going to be using that frame, I’d be adding some triangular gussets and braces to stiffen it up while everything is so accessible. Anyway, great work so far. Just goes to show how sound the base vehicle was under all the grot and filth. 👍😃 Morning Glen, Sorry, been a busy week, account plans and presentations. All a load of borroxx but its what we need to do to keep the mortgage paid. I cannot go mad cutting etc. But without doubt, a fair amount of gusseting everywhere I go with it. And yes, only one bit of chassis rust to deal with as shown before. I also have a few mounting points to revise as bolts were cut off in the frame as they were rusted off, out of shape, or brow when trying to undo them, despite repeated applications of Duck oil. I am hoping that I will be able to buy either a full set of Ford mounting bolts n nuts for the front and rear subframe and axle. As a kit. Also……… FORD OR KIT CAR GUYS: CAN ONE BUY A FULL SET OF BUSHES FOR THE FRONT AND REAR, RUBBER OR POLYURETHANE AS A COMPLETE KIT? Thanks These guys in Wrexham have complete kits, and have been very helpful in the past. www.polybush.co.uk/ |

| |

|

|

|

|

|

|

|

Morning Glen, Sorry, been a busy week, account plans and presentations. All a load of borroxx but its what we need to do to keep the mortgage paid. I cannot go mad cutting etc. But without doubt, a fair amount of gusseting everywhere I go with it. And yes, only one bit of chassis rust to deal with as shown before. I also have a few mounting points to revise as bolts were cut off in the frame as they were rusted off, out of shape, or brow when trying to undo them, despite repeated applications of Duck oil. I am hoping that I will be able to buy either a full set of Ford mounting bolts n nuts for the front and rear subframe and axle. As a kit. Also……… FORD OR KIT CAR GUYS: CAN ONE BUY A FULL SET OF BUSHES FOR THE FRONT AND REAR, RUBBER OR POLYURETHANE AS A COMPLETE KIT? Thanks These guys in Wrexham have complete kits, and have been very helpful in the past. www.polybush.co.uk/Brilliant, Thank you. I will contact them. Any advice from the FORD GUYS on redoing these? I guess a big hammer, Duck Oil and patience. When you look at their range, the have three grades, I suspect the stiffest one will be for people who racing competitively. HOWEVER - Comfort or Dynamic ??To me, Comfort implies family car, and Dynamic more weekend warrior. What say those of you that have replaced bushes with polyurethane parts?? Looking at the website, it is all Escort that they seem to supply. I have been told that this is Cortina up front and Escort out back. I have no clue as it is just not my backyard, so any clever people, please speak up. Thanks. |

| |

Last Edit: Aug 27, 2021 7:16:03 GMT by grizz

|

|

|

|

|

|

|

|

Its Cortina front and rear , RWD escorts all had leaf springs on the rear.

The top ones at the back in the axle always used to be a bit of a mare to get out without the special tool the rest were pretty conventional and could be done in a press.

If the ones in there aren't cracked I would just leave them though.

|

| |

Last Edit: Aug 27, 2021 8:19:45 GMT by kevins

|

|

|

|

|

|

|

Any advice from the FORD GUYS on redoing these? I guess a big hammer, Duck Oil and patience. You'll be there for ever if you try a hammer to remove rubber bushes  The metal outer sleeves will be nicely rusted in place too. Either: holesaw the rubber portion out and cut the sleeve with a hacksaw blade, which is properly tedious when you have the whole car to do or press them out like you would a wheel bearing with a long bolt, drive piece and receiving cup   |

| |

|

|

|

|

|

|

|

|

Grizz. Polybush Wrexham have an extensive range, they mix and match for kit car builders they will also supply you with a comprehensive list of their "off the shelf" bushes listed by size. Kit car set ups may not be listed on the web site aa long as you know the origin of the components used or have measurements they will be able to assist.

|

| |

|

|

|

|

|

|

|

Its Cortina front and rear , RWD escorts all had leaf springs on the rear. The top ones at the back in the axle always used to be a bit of a mare to get out without the special tool the rest were pretty conventional and could be done in a press. If the ones in there aren't cracked I would just leave them though. Morning Kevin, Thanks for the reply. Good to know its all the same donor for starters. I take it you are talking of a void-bush puller , thankfully I have one a guy in Norfolk sent me to use when he saw what I had. So once used, I will post it back to him. I will hopefully be able to use mate paulf ‘s press that we used before. As far as cracking is concerned, again, I am happy to follow your advice, however, would a complete new set of bushes not be a better move in the longer term? Keep in mind, this thing lived a rough life, outside I suspect mostly. |

| |

|

|