bricol

Part of things

Posts: 290

|

|

May 25, 2022 12:57:14 GMT

|

|

Have to say there's a lot of doom and gloom about tapping that and then using a tapered BPS fitting . . . from the pictures, and the knowledge of my own MX5 engine transplant into a Dutton trials car, there's a lot of unnecessary worrying.

Cut the bit of steel pipe off flush, countersink it, and then "go at it with an 8.5mm drill" but maybe with a bit of care and attention rather than "wing and a prayer".

Tap it and wind in your PTFE taped fitting (although I would use Loctite pipe sealant) and stop when its close enough to what you want - add more tape if it stops past, less if you worry it might strip out.

It's a decent bit of cast aluminium - it won't simply fall apart unless you are so kak-handed with tool and not knowing when to stop tightening you really ought to step away from any tool related task. Not everything needs to be tightened to full on F.T. settings, with a bit more for luck . . .

|

| |

|

|

|

|

|

|

|

May 25, 2022 14:02:33 GMT

|

my own MX5 engine transplant into a Dutton trials car Please post a build thread link! |

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,345

Club RR Member Number: 64

|

|

May 26, 2022 14:53:30 GMT

|

|

Personally, I'd whack the casting in the lathe (or the mill), machine the old fitting out and the end of the casting flat, tap it appropriately and then use a banjo fitting to get the 90 degree outlet in such a way as it cn go exactly where you need it.

But the methods listed so far will all work fine.

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

|

|

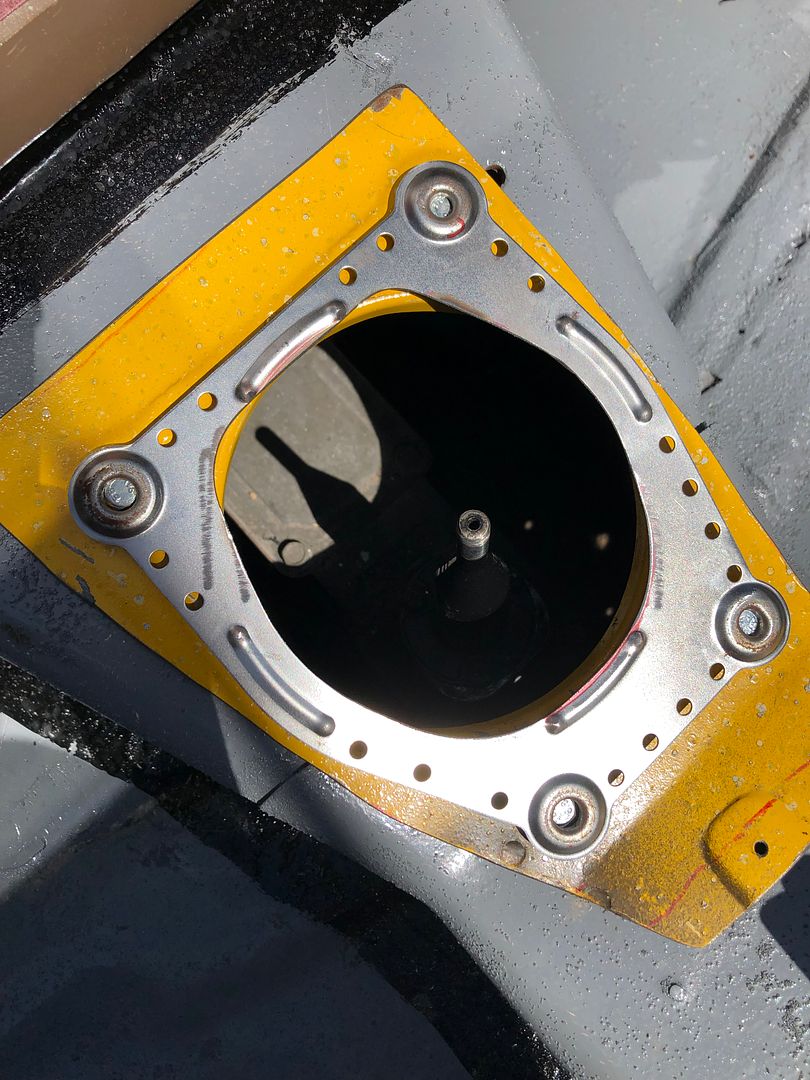

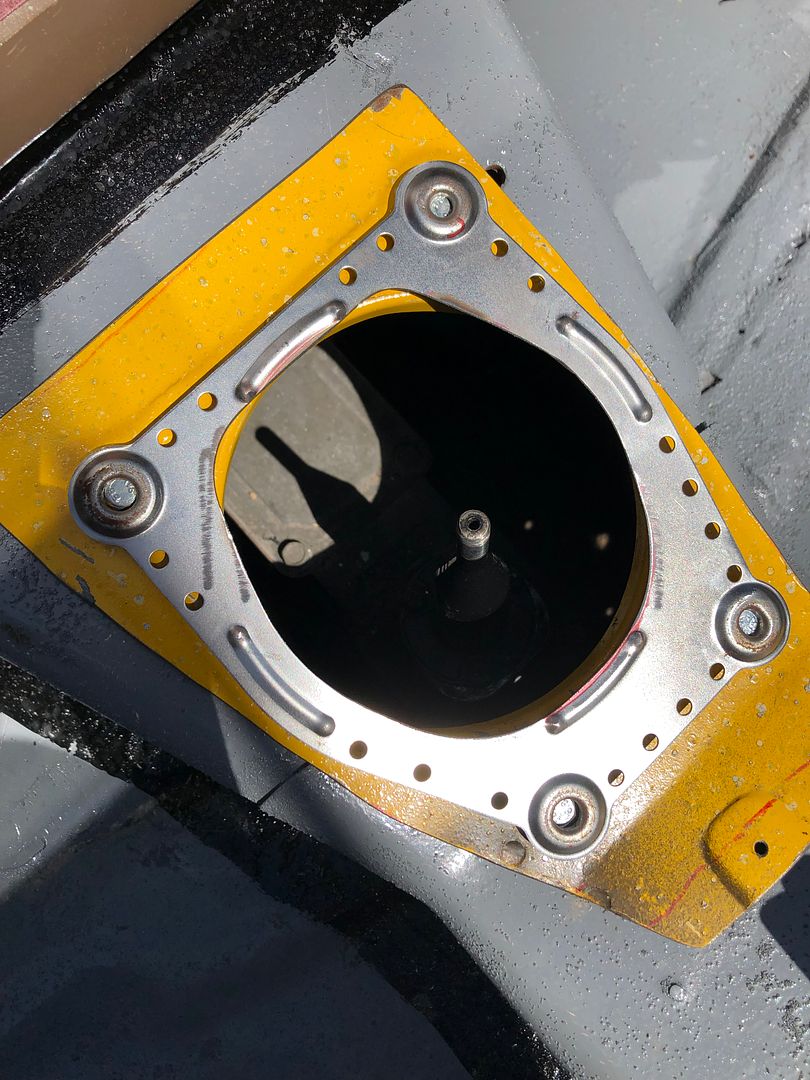

The various suggestions are that a 1/8 BSP fitting is suitable. That thread has a similar external diameter to M10, which is very common and the tapping size is 8.5mm. There is plenty of boss to get a water tight seal without a tapered thread. So if I can find a piece of at least 12mm brass, that's a few minutes lathe work. It will be straight, but soldering another piece at 90° is easy. That all depends on getting the stub out(which is true for all repair methods) and checking that the hole in the outlet will tap to the required size. I'd go for a brass parallel thread fitting with a flange on it, machine (or at a push file) the end of the alloy stub flat, use a rubber washer or O ring under the flange and loctite the thread, something like this Flattening the stub also makes drilling and tapping it easier, so it's definitely part of the procedure. As is some thread sealant; it's only a cooling system, so I doubt an O ring etc is necessary. If using an angled fitting the O ring helps in giving you a bit of leeway to get the right angle while still retaining a bit of clamp load in the joint. I think the important thing is that this will be a potential way of getting £100.00 back into this spiraling kitty. |

| |

|

|

|

|

|

|

|

Have to say there's a lot of doom and gloom about tapping that and then using a tapered BPS fitting . . . from the pictures, and the knowledge of my own MX5 engine transplant into a Dutton trials car, there's a lot of unnecessary worrying. Cut the bit of steel pipe off flush, countersink it, and then "go at it with an 8.5mm drill" but maybe with a bit of care and attention rather than "wing and a prayer". Tap it and wind in your PTFE taped fitting (although I would use Loctite pipe sealant) and stop when its close enough to what you want - add more tape if it stops past, less if you worry it might strip out. It's a decent bit of cast aluminium - it won't simply fall apart unless you are so kak-handed with tool and not knowing when to stop tightening you really ought to step away from any tool related task. Not everything needs to be tightened to full on F.T. settings, with a bit more for luck . . . Looks like there are a few options to consider. my own MX5 engine transplant into a Dutton trials car Please post a build thread link! Post in here if you do not have a thread, or do not want to start a thread, Alternately post a link if it is recoded elsewhere please. Personally, I'd whack the casting in the lathe (or the mill), machine the old fitting out and the end of the casting flat, tap it appropriately and then use a banjo fitting to get the 90 degree outlet in such a way as it cn go exactly where you need it. But the methods listed so far will all work fine. Agreed Glen. |

| |

|

|

|

|

|

|

|

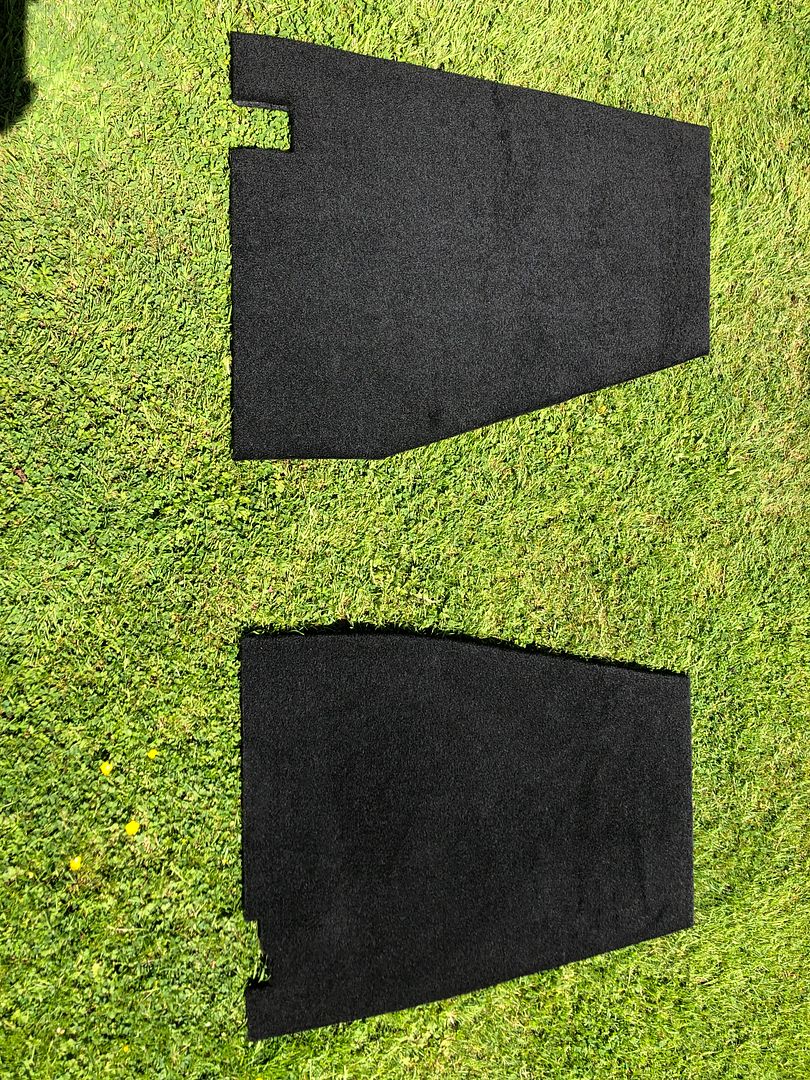

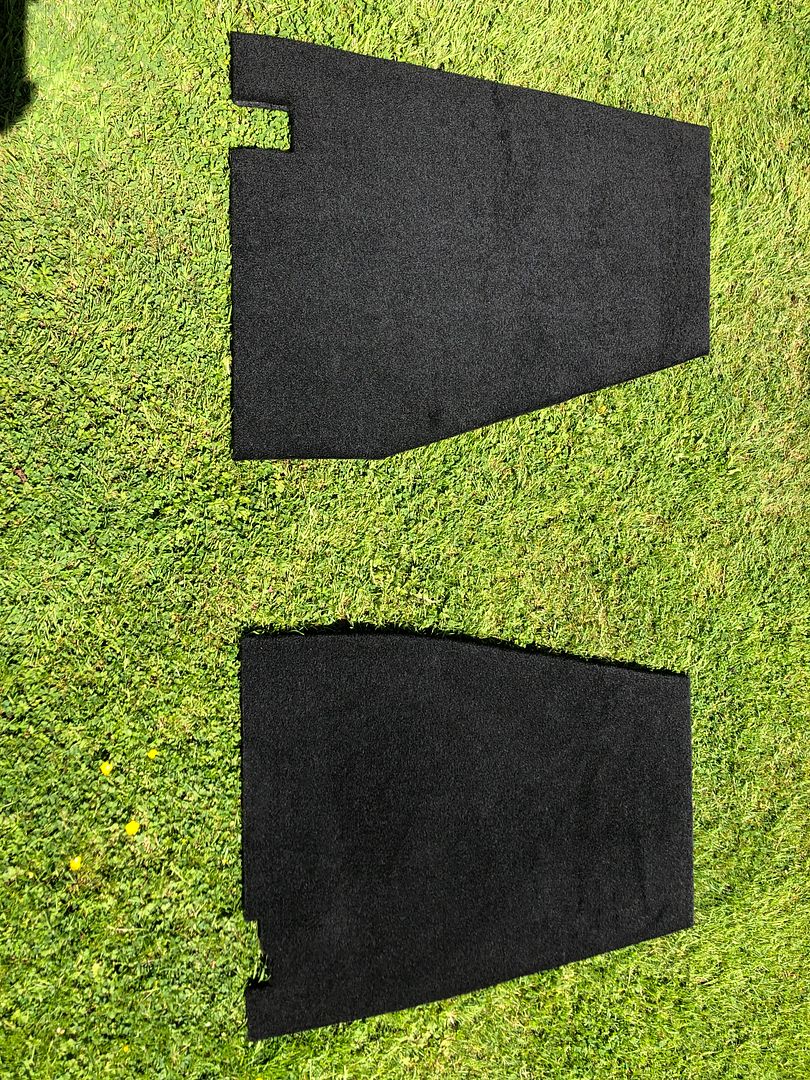

Friday. Message from craigrk in India. Seems the new RR LED lights have arrived, not,sure,what the final delivered price was. Also got some nice new number-plates ordered and delivered in 48 hrs. Time to start tidying up the interior some more. Carpets to be cut and glued some time today as I am working from home.    Happy Friday indeed. |

| |

|

|

mrbig

West Midlands

Semi-professional Procrastinator

Posts: 504

|

|

May 27, 2022 10:03:57 GMT

|

|

All looking good. My personal opinion is that your plan with the brass fitting will be more than fit for purpose, your average cooling system runs about 15psi or so, we're not looking at aerospace fittings here.

Can I ask where you sourced the plates from?

|

| |

Last Edit: May 27, 2022 10:40:06 GMT by mrbig

1969 German Look Beetle - in progress

|

|

|

|

|

May 27, 2022 10:13:01 GMT

|

Like this:   M10 thread, screw it in so the spigot can be clocked correctly, drill the hole and solder together. Gives you another small part to paint too  |

| |

|

|

|

|

|

May 27, 2022 10:21:49 GMT

|

All looking good. My personal opinion is that your plan with the brass fitting will be more than fit for purpose, your average cooling system runs about 15psi or so, we're not looking at aerospace fittings here. Can I ask where you sourced the plates from and did you have to send your documents off? I have little to no trust in the postal service not to lose my documents and all my local factors seem to have decided that the price of number plates should reflect the current cost of living crisis. They are show plates, not for legal or UK motorway use. I have the original front plate, which is legal, but scruffy. £15.00 a pair, delivered. Show plates You have PM. |

| |

Last Edit: May 27, 2022 10:29:53 GMT by grizz

|

|

|

|

|

May 27, 2022 10:28:53 GMT

|

Like this:   M10 thread, screw it in so the spigot can be clocked correctly, drill the hole and solder together. Gives you another small part to paint too  😂😂😂😂😂😂😂😂 Paint 🎨❤️ |

| |

|

|

|

|

|

May 27, 2022 22:32:01 GMT

|

I love the "get after it" mentality here but I would have already had something fitted in there. All the time spent typin' instead of doin'! Just messin with you but yeah- mail me that part and I'll fix it with something I have on hand  |

| |

|

|

|

|

|

May 27, 2022 22:34:00 GMT

|

Have to say there's a lot of doom and gloom about tapping that and then using a tapered BPS fitting . . . from the pictures, and the knowledge of my own MX5 engine transplant into a Dutton trials car, there's a lot of unnecessary worrying. Cut the bit of steel pipe off flush, countersink it, and then "go at it with an 8.5mm drill" but maybe with a bit of care and attention rather than "wing and a prayer". Tap it and wind in your PTFE taped fitting (although I would use Loctite pipe sealant) and stop when its close enough to what you want - add more tape if it stops past, less if you worry it might strip out. It's a decent bit of cast aluminium - it won't simply fall apart unless you are so kak-handed with tool and not knowing when to stop tightening you really ought to step away from any tool related task. Not everything needs to be tightened to full on F.T. settings, with a bit more for luck . . . THIS

|

| |

|

|

|

|

|

|

|

I love the "get after it" mentality here but I would have already had something fitted in there. All the time spent typin' instead of doin'! Just messin with you but yeah- mail me that part and I'll fix it with something I have on hand  Have to say there's a lot of doom and gloom about tapping that and then using a tapered BPS fitting . . . from the pictures, and the knowledge of my own MX5 engine transplant into a Dutton trials car, there's a lot of unnecessary worrying. Cut the bit of steel pipe off flush, countersink it, and then "go at it with an 8.5mm drill" but maybe with a bit of care and attention rather than "wing and a prayer". Tap it and wind in your PTFE taped fitting (although I would use Loctite pipe sealant) and stop when its close enough to what you want - add more tape if it stops past, less if you worry it might strip out. It's a decent bit of cast aluminium - it won't simply fall apart unless you are so kak-handed with tool and not knowing when to stop tightening you really ought to step away from any tool related task. Not everything needs to be tightened to full on F.T. settings, with a bit more for luck . . . THIS  Yes, progress is slow from the sidelines. But it is moving along. |

| |

|

|

|

|

|

|

|

|

codpiece

/ˈkɒdpiːs/

Learn to pronounce

noun

noun: codpiece; plural noun: codpieces; noun: cod-piece; plural noun: cod-pieces

a pouch attached to a man's breeches or close-fitting hose to cover the genitals, worn in the 15th and 16th centuries.

|

| |

|

|

|

|

|

|

|

Being out in the garden before 06.00 this time of year, does have it’s perks. Same can be said for insomnia and being done with early morning admin before 06.30 as was the case yesterday. First training meeting of the day was -9.15 on Teams. So I thought getting these to front floor sections wrapped up, made sense. Sections cut from the roll of carpet I bought. Contact adhesive both sides, laid down, trimmed, stretched, glued on the rear and two parallel sets of 10mm staples run in. Perfect. I hope.  Other side.  Done.  Happy with that. A small carpet will protect the heel area on drivers side. |

| |

|

|

|

|

|

|

|

So…… One of those awkward jobs done after work. Well, the prototype really. As I only have enough vinyl for one go at making the black gearstick gaiter. First job was to remove the rubber from the original MX5 rubber unit. It will be used to hold down the final gaiter…… far from a professional job, but anyone is welcome to pop over and make me one or mail me a complete replacement piece.  Measured and filed away the excess. For those who forgot….. the extension of the gear stick makes the sweep more exaggerated so the hole has to be bigger.   I fetched the roll of “Rusty patina” vinyl originally bought when I wanted to buy pedalcarjoe ‘s wagon, from the garage, Initial plan was to make 4 piece pyramid. Then lodger John arrived with 6 mini Pork pies, and a tub of Chicken Kiev Scotch eggs, a Sprite for me as I never use alcohol if power tools may be used and a Desperado beer for him. “Why not cut a huge circle, pierce the centre and drape it like a skirt, pin it top and bottom…. Job done” BUGGGERR…..Of course he is right, or is he. Both options.  Draped.  Captured.  So…….. Will it work??  Later today I will cut the black to size. Then the transmission tunnel carpet has to be measured, cut and glued down. Followed by refitting the floors, seats, maybe even the last time. But first, I need to get some new work shoes and apply for a new passport. |

| |

Last Edit: May 28, 2022 7:28:00 GMT by grizz

|

|

CaptainSlog

Part of things

Posts: 510

Club RR Member Number: 180

|

|

May 28, 2022 10:21:11 GMT

|

|

I like that - It looks like an old Alfa gaiter, 'tis rather brown though.

|

| |

|

|

|

|

|

May 28, 2022 20:18:18 GMT

|

I like that - It looks like an old Alfa gaiter, 'tis rather brown though. Function over form. That is a sample only to try and see if it could be made to work. I am kinda tired of the writing up at this point. Contemplating stopping wasting my time doing write ups, around an hour per posting, to load and then post on the 9 forums I serve. Gatvol vir kak. |

| |

Last Edit: May 28, 2022 20:19:06 GMT by grizz

|

|

|

|

|

May 28, 2022 20:27:15 GMT

|

|

Don't stop posting 😮

I know I don't comment much, but I'm thoroughly enjoying following along....

It's the first thread I turn to...

Can't wait to see it on the road😁

|

| |

|

|

|

|

|

May 28, 2022 20:38:49 GMT

|

Don't stop posting 😮 I know I don't comment much, but I'm thoroughly enjoying following along.... It's the first thread I turn to... Can't wait to see it on the road😁 I think some days I just feel that I am not sure if I am wasting my time as it takes more than a few minutes to create this content. And I do see this as a record for my own reference. This is not a pity party or anything like that, but it amazes me at times when clearly (I wrote and post on another 8 forums) people only read the photos, and then ask some pretty stoopid questions. And if you point it out, they either leave or make some limp wristed comment . So, to answer your request. Today I did two jobs, along with buying a new pair of work shoes and a £39.00 pair of very neat flip flops, not garage level either…. Some gardening, taking aound 50 photos of myself to try get a passport application in. And it kept failing me, as it saw my eyes being shot (not) and then my face and the magnolia wall being indistinguishable…… Eventually made it to the garage around 3.00pm. But I also made up a plate for the removable show plate to fit on the front      There was more done. Pics uploading as I type this up. |

| |

|

|