|

|

|

Jun 11, 2020 21:06:44 GMT

|

I've a 2 pronged query and was hoping those more experienced than myself may be able to assist. 1. I'm in the process of restoring a Capri and am taking it back to bare steel, most of this is being done in a shed I use for sandblasting so it's no dramas however the doors etc I'm doing at home in the garage, the issue I've found is that each door has been painted approx 3 times and has a skim of filler so by the time I had 1/2 the driver's door to bare steel the garage looked like Pablo Escobar had sneezed in it. I've bought 2 20" fans and am going to build an enclosure for them for dust extraction but cannot for the life of me find anywhere outside of America that sells 20" filters. Does anyone know of a UK supplier for filters or even the material? 2. Due to the Narco's spec dust in the garage I don't want to clean it up with my crappy LIDL cordless wet'n'dry shop vac and was wondering has anyone diyed one of those cyclone style dust buckets that work as an in between? TLDR: Need a UK supplier for 20" square air filters or the material and info on cyclone dust collectors  |

| |

Rust is lighter than Carbon Fibre which is why old Fords are so fast.

|

|

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,879

Club RR Member Number: 39

|

|

Jun 11, 2020 21:20:31 GMT

|

|

|

| |

Last Edit: Jun 11, 2020 21:26:39 GMT by Darkspeed

|

|

|

|

|

Jun 11, 2020 23:34:28 GMT

|

That website is exactly what I was looking for and their stuff seems really well priced that's fantastic thanks 👍😊 |

| |

Rust is lighter than Carbon Fibre which is why old Fords are so fast.

|

|

|

|

|

|

|

Beats me why you going down this route in the first place when there is a far better solution - get yourself an old cylinder vacuum / Henry etc and a electric dual action sander used in conjunction with Mirka Abranet type discs & 98% of the dust goes into the vac - means you work in a pleasant atmosphere / workspace without the mess & faff   My vac collects kilos of sanding dust and saves the workshop & everything else from being covered in it The filters that you are planning will only collect some of the dust with the rest going through the fans to the atmosphere - but if you have anything close by / vegetation etc it will get covered in it - if you do go down the filter route a Binks type hit & miss filter is probably going to do the job better without clogging quickly - link below www.spraydirect.co.uk/acatalog/binks_standard_spray_booth_filter.html |

| |

Last Edit: Jun 12, 2020 6:34:25 GMT by Deleted

|

|

|

|

|

Jun 12, 2020 21:01:14 GMT

|

|

When there's a lot of layers of paint and filler I find it easier to use a hot air gun to take the bulk of it off then follow up with abrasives

|

| |

|

|

|

|

|

Jun 12, 2020 22:25:04 GMT

|

|

Why not use paint striper? I've just stripped a MK2 Jag bootlid, it took about an hour and took off at least three different paints and three lots of primer as well as some filler.

I used Starchem Synstryp which seems to work really well. Once most its gone I just ran over it with the DA to take any final bits off, it probably took around an hour to do the outside of the whole panel back to bare metal.

|

| |

|

|

|

|

|

Jun 13, 2020 16:51:10 GMT

|

Beats me why you going down this route in the first place when there is a far better solution - get yourself an old cylinder vacuum / Henry etc and a electric dual action sander used in conjunction with Mirka Abranet type discs & 98% of the dust goes into the vac - means you work in a pleasant atmosphere / workspace without the mess & faff   My vac collects kilos of sanding dust and saves the workshop & everything else from being covered in it The filters that you are planning will only collect some of the dust with the rest going through the fans to the atmosphere - but if you have anything close by / vegetation etc it will get covered in it - if you do go down the filter route a Binks type hit & miss filter is probably going to do the job better without clogging quickly - link below www.spraydirect.co.uk/acatalog/binks_standard_spray_booth_filter.htmlThanks for that @grumpynorthener, I have an airpowered DA sander but the sheer amound of filler was clogging up the pads so I used those poly paint & rust stripper pads for the angle grinder, My Vac is only a piddly LIDL cordless one, might have to invest in something more substantial...or buy a replacement for our Henry and retire him to the garage.  |

| |

Rust is lighter than Carbon Fibre which is why old Fords are so fast.

|

|

|

|

|

Jun 13, 2020 16:53:56 GMT

|

Why not use paint striper? I've just stripped a MK2 Jag bootlid, it took about an hour and took off at least three different paints and three lots of primer as well as some filler. I used Starchem Synstryp which seems to work really well. Once most its gone I just ran over it with the DA to take any final bits off, it probably took around an hour to do the outside of the whole panel back to bare metal. I was toying with paint stripper as a way of doing it, my only issue being I do a right bit of welding and grinding mild steel as well so wanted something that would cover all the bases for dust management as the garage usually has a fine layer of steel and abbrasive dust. How does paint stripper react with filler? I've no experiance with the stuff, angle grinders have always been my forte  |

| |

Rust is lighter than Carbon Fibre which is why old Fords are so fast.

|

|

|

|

|

Jun 13, 2020 18:42:16 GMT

|

Sweep and hoover up each day  ?? |

| |

|

|

|

|

|

Jun 13, 2020 22:38:33 GMT

|

Why not use paint striper? I've just stripped a MK2 Jag bootlid, it took about an hour and took off at least three different paints and three lots of primer as well as some filler. I used Starchem Synstryp which seems to work really well. Once most its gone I just ran over it with the DA to take any final bits off, it probably took around an hour to do the outside of the whole panel back to bare metal. I was toying with paint stripper as a way of doing it, my only issue being I do a right bit of welding and grinding mild steel as well so wanted something that would cover all the bases for dust management as the garage usually has a fine layer of steel and abbrasive dust. How does paint stripper react with filler? I've no experiance with the stuff, angle grinders have always been my forte  Paint stripper tends to make filler go soft and you can scrape it off, however, if its really thick you are probably better to powe sand it out. |

| |

|

|

|

|

|

|

|

|

|

Sweep and hoover up each day  ?? 2 walls are lined top to bottom with shelves and I am totally sick of having to clean the dust off them. It's that hateful metallic black dust that gets everywhere. The floor and benches get cleaned regularly and I wear my respirator but it would be nice to be able to reduce the cleaning. |

| |

Rust is lighter than Carbon Fibre which is why old Fords are so fast.

|

|

|

|

|

|

|

I was toying with paint stripper as a way of doing it, my only issue being I do a right bit of welding and grinding mild steel as well so wanted something that would cover all the bases for dust management as the garage usually has a fine layer of steel and abbrasive dust. How does paint stripper react with filler? I've no experiance with the stuff, angle grinders have always been my forte  Paint stripper tends to make filler go soft and you can scrape it off, however, if its really thick you are probably better to powe sand it out. Worth a shot, I'll get some of that screwfix paint stripper and try it. Thanks for the advice 👍👍 |

| |

Rust is lighter than Carbon Fibre which is why old Fords are so fast.

|

|

|

|

|

|

|

Paint stripper tends to make filler go soft and you can scrape it off, however, if its really thick you are probably better to powe sand it out. Worth a shot, I'll get some of that screwfix paint stripper and try it. Thanks for the advice 👍👍 The screwfix stuff I tried was rubbish, worse than modern nitromors. |

| |

|

|

|

|

|

Jun 14, 2020 10:56:20 GMT

|

|

|

| |

|

|

|

|

|

Jun 14, 2020 19:19:51 GMT

|

|

Surely if you put it in small sealable bags, the local scanks will remove it 😀

|

| |

|

|

|

|

|

Jun 19, 2020 21:14:41 GMT

|

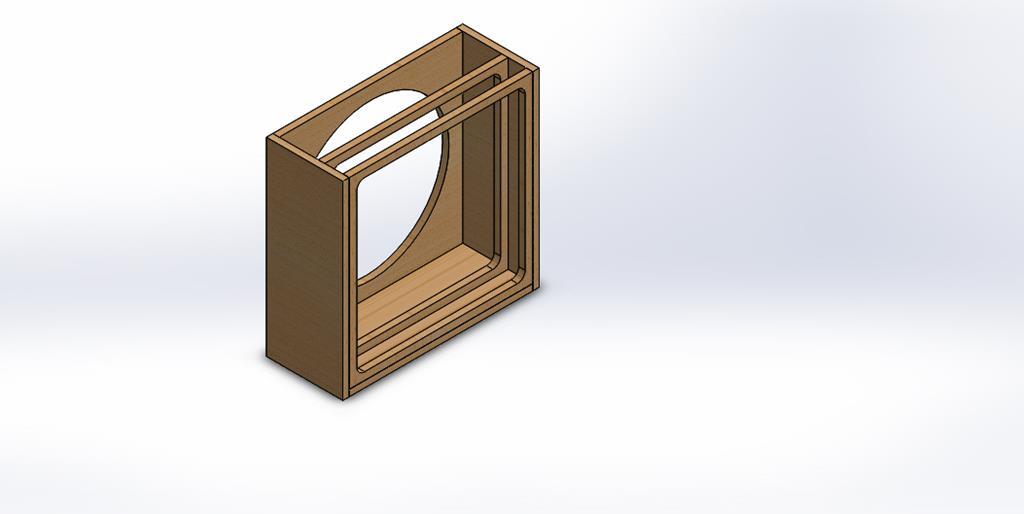

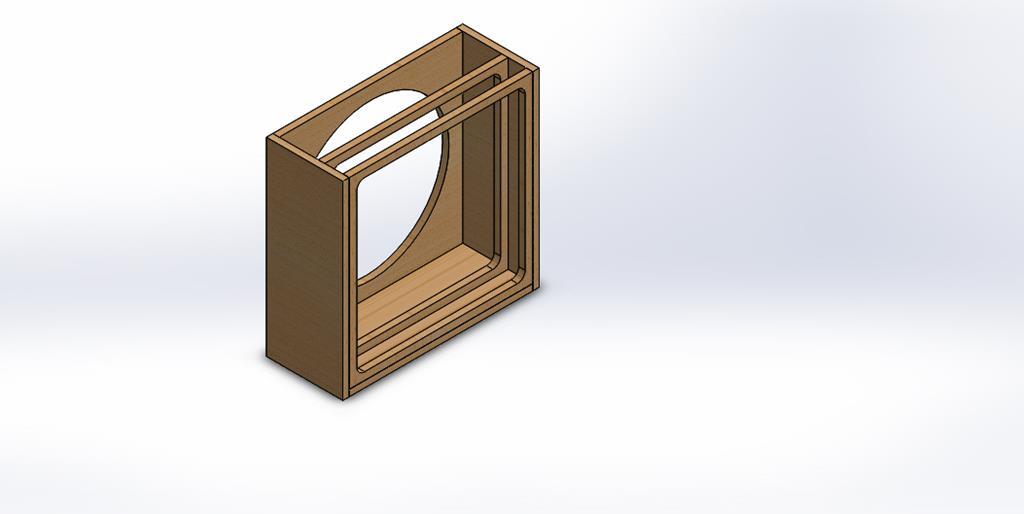

Paint stripper is bought and en route; continuing down the same route as originally planned however I've also set about building 2 fan extractors each using an 18" fan and 594mmx595mmx47mm filters. Have all bought and in the post (somehow both fans were shipped at the same time from the same seller using the same courier and the 1st has arrived and the 2nd is still in transit -.- ) in the meantime I threw together a plan so I could make a start on the frame. I hate working with wood, find steel a far more forgiving material oddly enough, so unlike my usual 'suck it and see' approach I actually sat down and used Solidworks for the first time in 6 or 7 years to make sure I knew the dimensions, how much wood i would need to buy etc. While the individual components were easy enough to draw up I have to say that the assembly mode is a nightmare, will have to spend a good bit more time sitting down with it to get to grips. After about 5 minutes on parts and over an hour  in assembly we have this monstrosity:  Filters are due early next week, so hopefully some Wednesday/Thursday I'll have the first one built and ready for a quick test. |

| |

Rust is lighter than Carbon Fibre which is why old Fords are so fast.

|

|

|

|

|

|

|

Finally managed to get some time back in the garage after work and life decided to get in the way, so this morning I threw together the dust extractor and am waiting on the sealant drying. Step 1 Take an 18" fan, Hvac filter and 18mm ply and throw them at the rip saw/hole saw/jigsaw Step 2 Marvel at my greatness     The frames for the filter turned out well but the fan shroud is a crime against woodwork so don't look too closely. Tested it before applying the sealant to all the joins and it works well, doesn't have enough draw to suck up sawdust but captures the fine dust that is causing me headaches with sanding paint. |

| |

Last Edit: Jul 8, 2020 15:17:55 GMT by maccamac

Rust is lighter than Carbon Fibre which is why old Fords are so fast.

|

|

|

|

|

Jul 14, 2020 13:35:44 GMT

|

|

Looks good! Thinking something like that with a beefier fan would be great for all the angle grinding I do. Gets bits of grit everywhere!

|

| |

|

|

|

|

|

Jul 14, 2020 20:34:36 GMT

|

Looks good! Thinking something like that with a beefier fan would be great for all the angle grinding I do. Gets bits of grit everywhere! I've the stuff to make 2 of them but I've it set up that the other fan blows towards the filter and i just work between them, seems to work well for the really fine particulate that gets everywhere with using angle grinders. You might be interested in 'The Fabrication Series', he built a grinding bench that basically sucks the dust down into it using fans and these types of filters, depends on the size of stuff you are grinding I suppose. |

| |

Rust is lighter than Carbon Fibre which is why old Fords are so fast.

|

|

|

|

|

Jul 14, 2020 20:45:17 GMT

|

Now that's an awesome idea  I do most of my grinding by my vice so could build something into the end of the bench just beneath it. It'd mean sacrificing some cupboard space but that's probably worth it for the sheer amount of dust that gets generated! |

| |

|

|

|

|

??

?? in assembly we have this monstrosity:

in assembly we have this monstrosity: