|

|

|

|

|

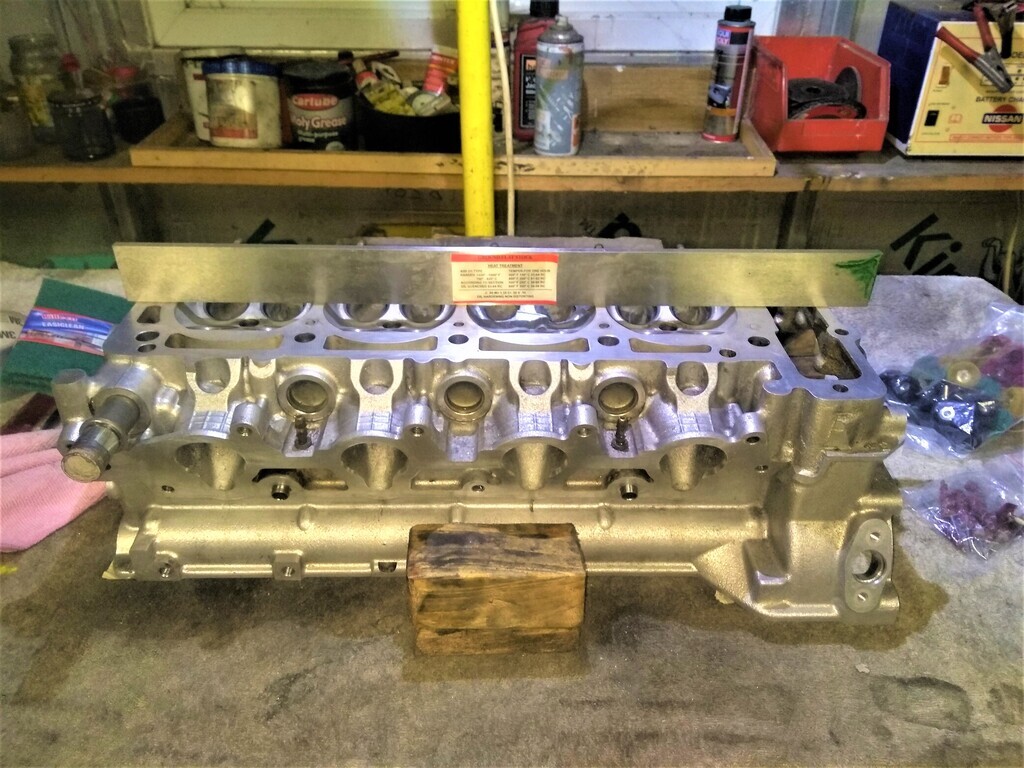

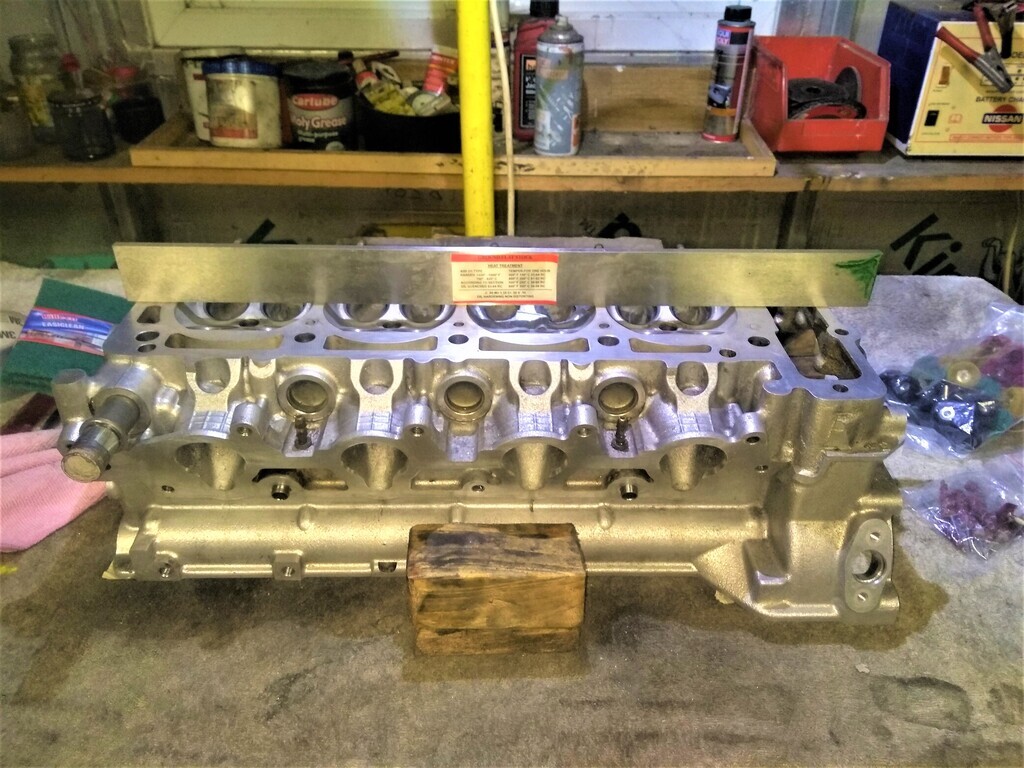

Decided to see if I could do something with the exhaust ports. Just a bit of very mild porting, as I've no real experience. As can be seen from the photo this is a typical port, all four are very similar. The black outline is were the exhaust manifold gasket actually mates to the head, so anywhere from the outside edge of the line can be removed. I think that's a reasonable amount of material overall. And more can be removed further inside heading towards the valve seats. I'll go easy there as I've no idea how much can be removed.  Started doing some porting. I've opened up the exhaust ports to the manifold by approx 12% in diameter and back into the ports just before the port divider which is approx 10mm. As for the rest of the ports to the valve guides I'm only sanding rather than grinding leaving the ports polished with all the casing marks removed. I've decided not to port the inlet side, to my untrained eye it looks good with a nice machined surface to promote atomization of air & fuel and there's not much meat to remove were the ports meets the inlet manifold. Also, I reckon if there's any real gains to be had it's on the exhaust side as the S/C does the work to get air in but on the exhaust side any possible back pressure should be reduced as much as possible. Now, I may not make any significant gains from porting the exhaust side but my view is it won't do any harm and can only aid expelling the exhaust gases, plus it costs nothing to do really except time which is fine, and the bonus is, I'm out of sight of Mrs Woofwoof! Initial porting.  Decided while I was at it to lightly port all of the exhausts rather than just sanding polishing. I took it easy as I just don't know how much can be removed without doing damage. But I go rid of the casting lines and improved the valve bowls and got rid of a few sharp edges plus overall the ports are larger with diameter increase of 1-1.5mm Ideally, to do maximize the porting an old head chopped up showing the cross section would've been ideal. Just sanding & polishing left to do which will again help flow. I know the photos are curse word, it's difficult to get real clarity with a camera phone and average lighting.  At long last my straight edge arrived on a second attempt. I originally ordered an ''engineers straight edge'' as it was called but it never arrived which turned out a bit of blessing. After another online search I came across steel Gauge Plate or Ground Flat Stock as it's also known. This has a tolerance as good as the ''engineers'' steel straight edge (thickness: +0.05mm/-0.00mm per meter) and better still it arrived within a few days and as a bonus was 1/3rd the price of the first straight edge I ordered from a non premium brand. Checked the head just incase at several points, all good 6 x 40 x 500mm  |

| |

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

|

|

A little progress.  |

| |

Still learning...still spending...still breaking things!

|

|

|

|

|

Nov 10, 2023 22:23:42 GMT

|

Had the day off today, so I went sanding & polishing. All the exhaust ports are finished, well finished as far as I'm concerned. They're far from perfect but for a first time effort I think there're passible. No doubt somebody with actual experience would disagree and probably rightly so too. Next up, is to clean the head 100% and fit valve seals and refit the valves.   |

| |

Last Edit: Nov 10, 2023 22:24:13 GMT by Woofwoof

Still learning...still spending...still breaking things!

|

|

|

|

|

Nov 22, 2023 18:38:26 GMT

|

The block coolant drain valve was semi seized so I didn't tackle it until the exhaust manifold and head were removed to allow far better access. After a good hour's work with a blow torch, penetrating oil, socket and pullbar, vice grips with tube extension I got it out in one piece. Removed and cleaned the port of the left behind alloy valve threads with a homebrew thread chaser and used plenty of brake cleaner to remove any swarf. Used a generic M18 x1.5 gearbox/diff drain plug as a replacement for the original valve. Delighted to get this issue sorted now rather than trying to do it with engine back together. Original drain valve.  Once removed.  New plug and Dowty washer/seal (hope it works o.k.)  And in it's new home.  My 2p's advice on avoiding a situation like this which could have meant taking engine out if the valve broke which is very possible, don't attempt to open drain valve to carry out a coolant change. Especially if the car is old, the valve is aluminium and also located on the exhaust manifold side (hot side). I was lucky and really took my time just moving the valve 5mm either way at a time.

|

| |

Last Edit: Nov 23, 2023 12:00:23 GMT by Woofwoof

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

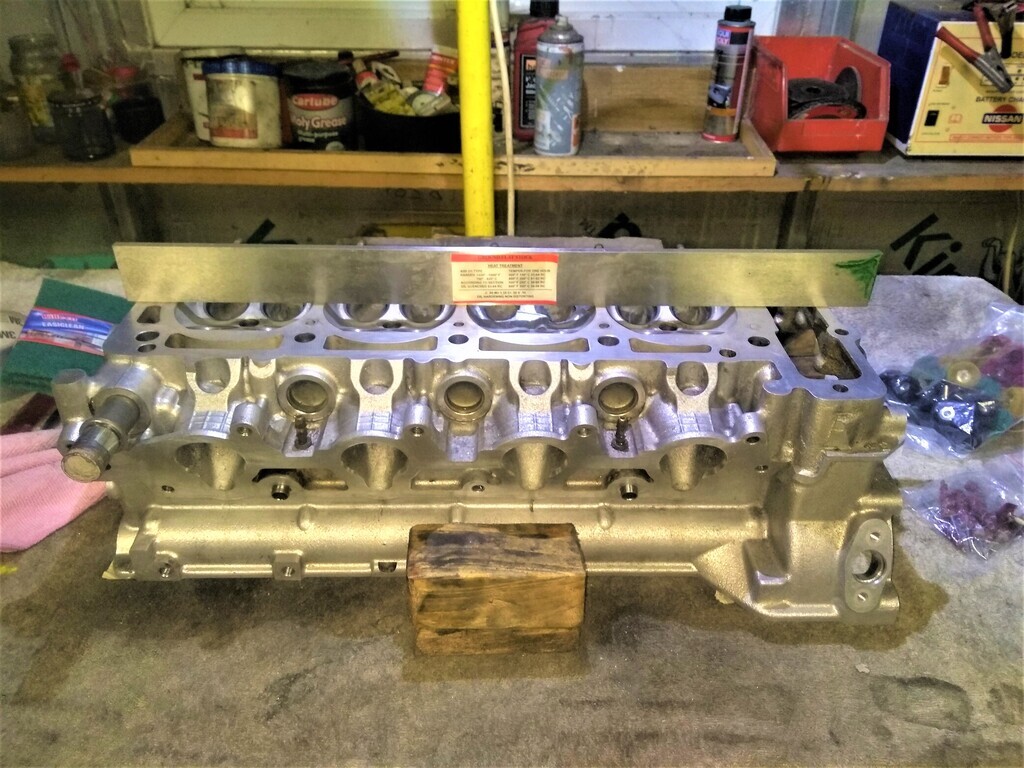

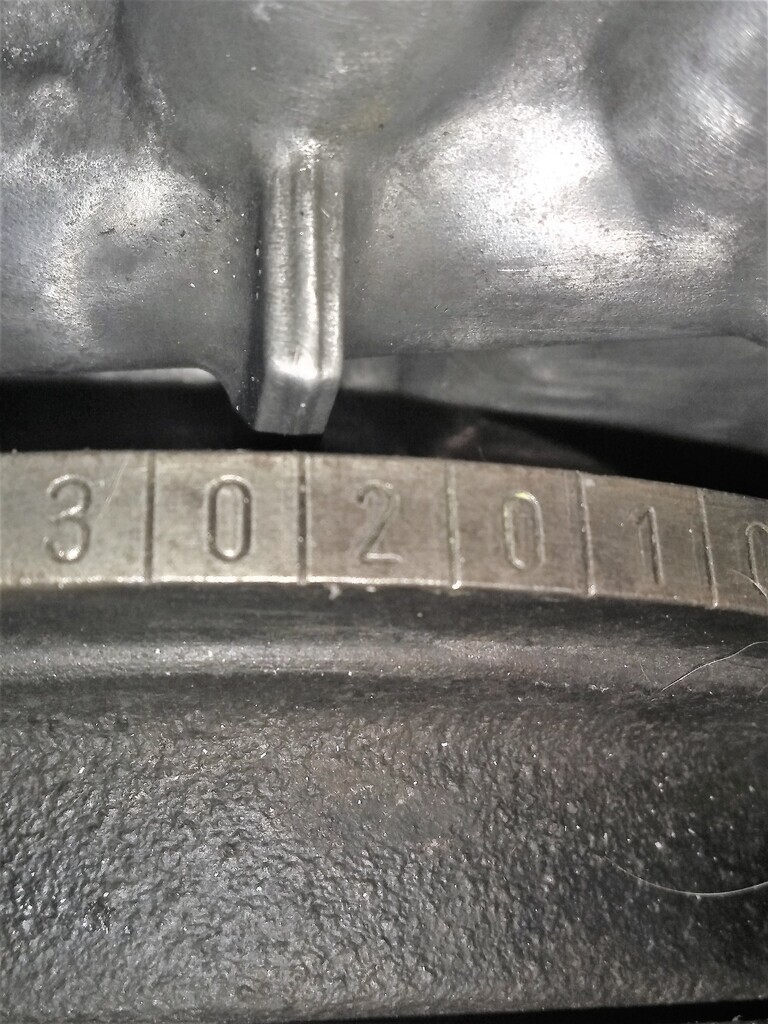

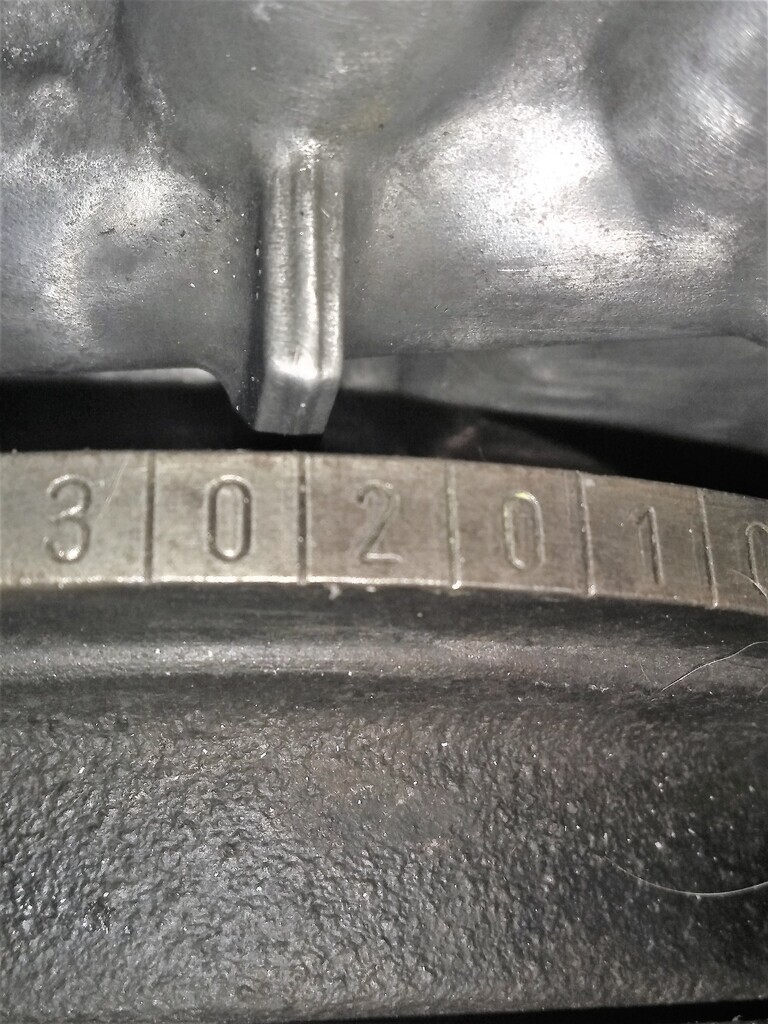

Slow going, mojo lacking a bit but getting there. The head is back on and the cams all timed up with new chain, tensioner and 3 x guides. The chain was worn, more worn than stretched I reckon. Inlet Cam was @ 27-28 degrees ATDC (factory spec 20-30), now 20-21 degrees. Exhaust Cam was @ 33 degrees ATDC (factory spec 25-35), now 25 degrees. If that improvement doesn't give me back 10-15BHP I'll eat my hat! Inlet  Exhaust  |

| |

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

The 'plan' was to have the engine running on 1st day of this new year, fresh start and all that. Well, that didn't happen but I'm only six days behind. That's almost a miracle for me! I'm delighted to say I got the engine finished today and started. All good, let the fuel pump prime the system and it fired first turn of the key. Was initially rather noisy until the valve lifters filled with oil and the assembly lube got diluted which took a good five minutes an some rev'ing. After that it sounded good, no noise from the timing chain or lifters, the only things I can hear now are the injectors (normal), the fan when the clutch is engaged and the badly worn alternator bearings. Two things I've already noticed even without having driven it yet, the AFR is slightly leaner on idle and there's a deeper growl from the exhaust on start up and idle. Engine idle is slightly steadier, there as always an intermittent fluctuation of 50 RPM (really annoying when I notice it) it's still there but occurs far, far less and it's probably down to only 30 RPM now. Test drive within the next couple of days. Expecting good things with the timing back to factory new specification along with cleaned up valves and seats and the mild porting of the exhaust ports and header. It will be interesting if nothing else. Fingers crossed all goes well.  |

| |

Last Edit: Jan 7, 2024 23:40:17 GMT by Woofwoof

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

Well, all didn't go to plan. I had an oil leak from the sump gasket. Changed that and took the 'opportunity' to clean up the sump as it was oxidized and looking sorry for itself. Gave it a going over with a brass wire brush attached to the wheel death and also used the Dremel with fiber sanding wheels. Then a good clean and some VHT matt grey paint, nothing fancy, no bling just dull old grey. There was little cleaning to do on the inside and the oil pickup was spotless. I removed the oil level sender and gave that a good clean and tested it, and it works.  Took it out for a blast, first time since September. Happy to report it driving better than ever. It will be interesting to watch the live data as the miles get put on, I'm expecting positives in all key parameters. |

| |

Last Edit: Jan 15, 2024 1:25:37 GMT by Woofwoof

Still learning...still spending...still breaking things!

|

|

dikkehemaworst

Club Retro Rides Member

Posts: 1,640

Club RR Member Number: 16

|

|

|

|

|

Nothing constructive to say , but i'm really enjoying your tinkering!

Please continue doing so!!

|

| |

|

|

|

|

|

Jan 16, 2024 22:06:30 GMT

|

Nothing constructive to say , but i'm really enjoying your tinkering! Please continue doing so!! Thanks dikkehemaworst. Well, I've nothing constructive to say either, which is probable a good thing as I've nothing to report, thankfully! I do have a belt tensioner pulley bearing gone but in the big scheme of things that's nothing. I will have some tinkering (that's a great word, it covers everything not to mention my screw up's) to do before I put the car on the road, hoping to improve the induction side of the supercharger, there's 'plan' in progress and I want to manipulate the IAT signal to the ECU, timing pull vs IAT is set very, very conservatively by Mercedes and consequently there's the potential loss of power when it's not justified. Will update in due course. |

| |

Still learning...still spending...still breaking things!

|

|

|

|

|

Jan 23, 2024 22:20:15 GMT

|

An update as such. I've only clocked up 60miles/100 kms partly in thanks to recent cold weather and a major storm over the last couple of days and there's another due. So far but all seems well. Live data parameters are spot on and I'm very happy, really happy with performance. Boost pressures are: 8+psi @ 2500 going wide open throttle and 13 psi max @ 6000 rpm. A major difference from the stock maximum of 7 psi. As usual there's a few smaller things I want to attend to and I want to experiment with a resistor for the MAF IAT signal. One other item on the list is to look into the induction side of the S/C, I'm still not happy with the set up including the air filter housing itself even having gone from the original to two modified versions. I think I'm on hiding to nothing as I want freer flowing cool induction air while keeping S/C noise to a minimum. I have ideas but that's it!  |

| |

Last Edit: Jan 23, 2024 22:22:20 GMT by Woofwoof

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

Jan 26, 2024 22:26:21 GMT

|

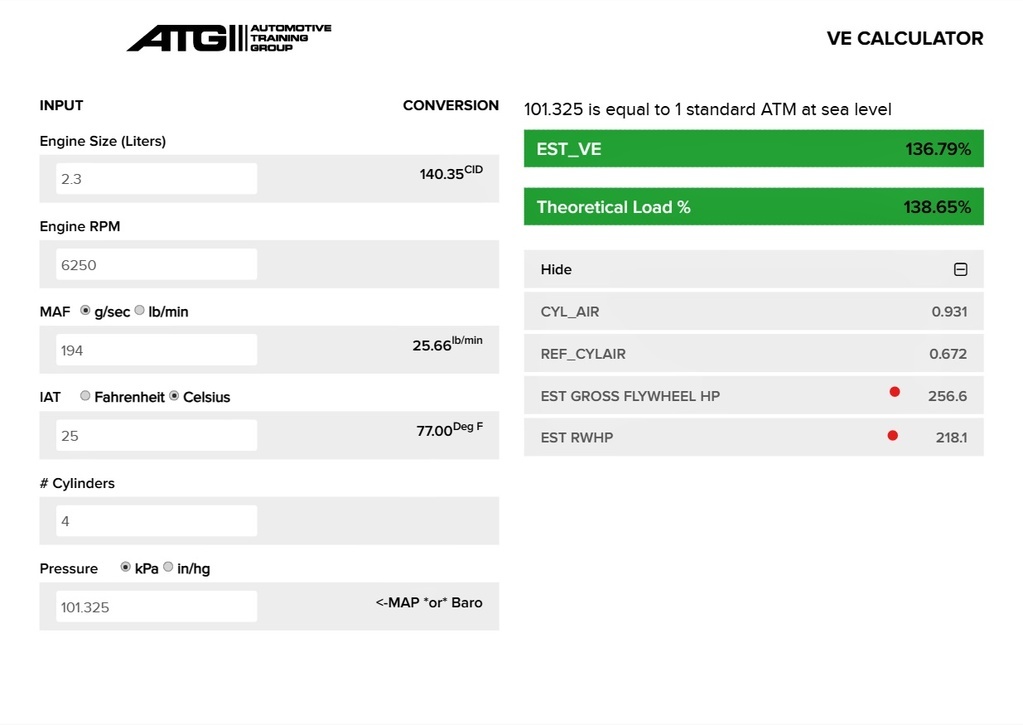

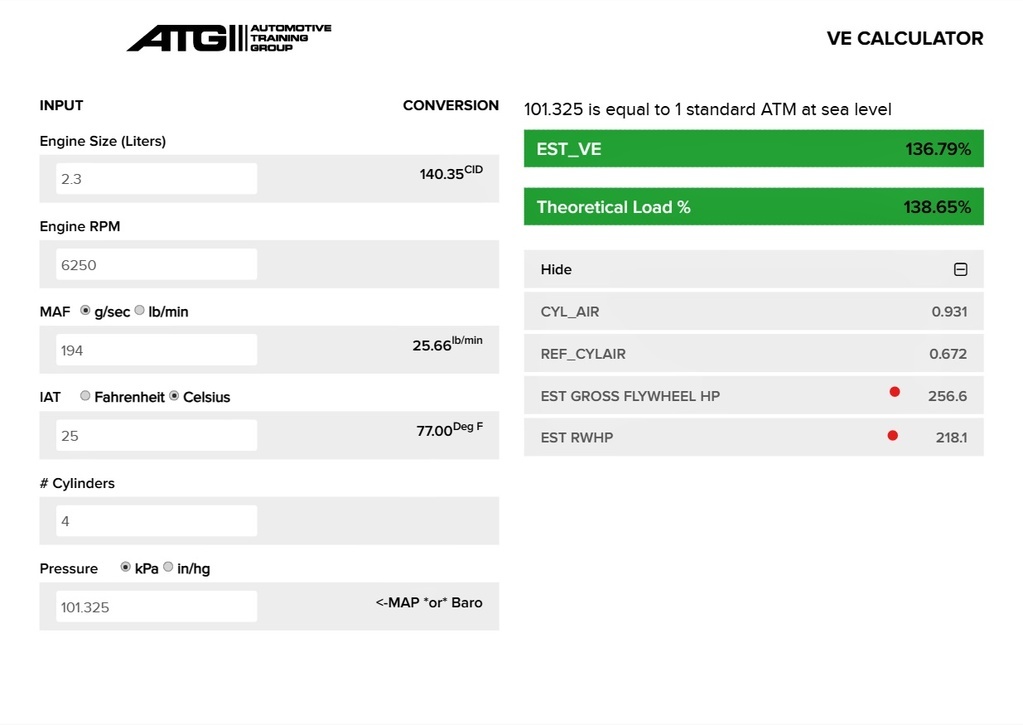

Getting a few miles on the car now and recorded the final piece of live data, MAF flow. 3rd gear MAF g/s 184. 4th gear MAF g/s 193. The expectations for max engine power was between 250-260bhp by those with experience in tuning these engines particularly by the guys who have extensive experience with highly modded SLK's and CLK's on the Continent, Australia and U.S.. Well, I'd say they're spot on judging by the way the car performs and the live data figures. It certainly performing even better than expected. It just proves what an improvement it can make to replace a worn timing chain (still within manufacturers operating parameters) and cleaning up the head, at a guess there was a gain of 25 BHP. Also, using this VE calculator confirms the expected BHP figures to be very realistic. Regardless, my target was always 200+BHP @ the wheels and 180 BHP/tonne which I believe I've achieved. Happy days!  |

| |

Last Edit: Jan 27, 2024 18:14:35 GMT by Woofwoof

Still learning...still spending...still breaking things!

|

|

|

|

|

Jan 29, 2024 18:27:23 GMT

|

|

Good to see someone fiddling with something different over here rather than the usual stuff. Have you got it on a "vintage" policy (My TT is 01 and is), or do you daily this?

|

| |

|

|

|

|

|

Jan 29, 2024 21:19:26 GMT

|

|

Yep, it's a different from the norm. A nice change from the usual BMW's etc. Mind, it was a learning curve (supercharged & canbus),in the big scheme of things they're not popular to modify compared to usual stuff.

I have it on a classic car policy, limited to 5000 miles a year which suits me fine and it's not costly.

|

| |

Still learning...still spending...still breaking things!

|

|

|

|

|

Jan 29, 2024 22:00:01 GMT

|

|

No certainly not costly, Campion at €290 for the year. Not modification friendly country but you can get around things.

Good to see something leftfield. Keep up the good work.

|

| |

|

|

|

|

|

Feb 18, 2024 19:45:28 GMT

|

Following this thread, some great information to be got from it. Both myself and a friend have 2.3 kompressor swapped c180s in Ireland too and are looking for more power. I plan on keeping mine supercharged for a while, my friend is going turbo with his. Not many 202s left on the road in Ireland, my original c230k got rear ended and written off so I had to convert my c180 instead. Theres a good few of us young lads with 202s trying to keep them alive.  |

| |

|

|

|

|

|

Feb 18, 2024 22:08:56 GMT

|

Good to hear you find the thread interesting. I often wondered was there any other C230 Kompressors on the road, surprised there is as they were not popular, people buying new tended to go for the C280 or the C250TD if they wanted a bit more power than the base models. It will be interesting to see how your friends conversation goes as there's been many blown engines over the years when dumping the S/C and going turbo. Can you remap the Bosch ME2.1 ECU? |

| |

Last Edit: Feb 18, 2024 22:11:46 GMT by Woofwoof

Still learning...still spending...still breaking things!

|

|

|

|

|

Feb 18, 2024 22:43:22 GMT

|

|

Yes it’s a shame, most were c180s here and a couple of diesels. Another friend converted his c180 to 2.0k from a clk, and there is a couple more lads interested in doing the same. Finding a donor Kompressor car isn’t easy anymore, even clk and slks have gone thin on the ground.

Turbo wise he is doing all the fabrication himself, custom manifold etc.Not sure what size turbo he is going to use, he is only looking for relatively low power, about 300hp as all the car is used for is driving during the summer and donuts on a slab. From what I’ve seen in posts online 1.2 bar is safe with the standard ecu, he knows very little on the electrics side so we are going to try figure it out together. I’ll follow what you did with the maf clamp and iat resistor, then just try to get it to fuel alrightish with bigger injectors and adjustable Reg.

Hopefully it should be fine on the standard ecu for around 300. Big power would need a standalone alright. As for mapping I bought a kess clone to read the ecu but I haven’t had luck with finding someone who knows how to remap one, bar the Swedish lad who didn’t have much success with the torque map. I’ll do a bit more digging, the Eastern Europeans love electrics and old mercs so I’m sure someone somewhere knows how. Ecumaster DET3 piggybacks could be an option too, a lad called Andrew Kenna sells and sets them up

|

| |

|

|

|

|

|

Mar 10, 2024 22:39:51 GMT

|

So, this new found extra power after doing the T-chain, overhauling head and some extra Supercharger porting is great, car was flying. But, what does more power do? Answer, find parts that are on their way out and it does it quickly too!  I had a drive train vibration develop very quickly in just over a hundred miles. After crawling under car and checking all the obvious I couldn't find anything amiss with the propshaft, suspension or the rear subframe. I suspected it was propshaft related and removed it, everything looked perfect and there was only 40,000 miles on the rear rubber coupling and centre bearing assembly. The front vibration damper and rubber coupling were original but in perfect condition. After removing the prop on closer inspection reveled the UJ/Hardy Spicer was notchy in both direction planes. Relief that I found something wrong. It's sealed unit which I get a specialist to replace and also check the shaft for balance. Fingers crossed I found the issue.  |

| |

Last Edit: Mar 10, 2024 22:46:01 GMT by Woofwoof

Still learning...still spending...still breaking things!

|

|

|

|

|

Mar 10, 2024 22:43:35 GMT

|

I’ll follow what you did with the maf clamp and iat resistor, then just try to get it to fuel alrightish with bigger injectors and adjustable Reg. I forget to mention, I have a spare, almost new Split Second MAF adjustable voltage clamp unit. Let me know if you or your buddy are interested. |

| |

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

|

I could be interested in the maf clamp. I fitted my spare ported supercharger with smaller pulley, went to fit the crank pulley extension and found out its the wrong size, its for a facelift EVO engine I think. Id imagine ill need a maf clamp when I get a crank pulley.

Though I am thinking of getting an Ecumaster DET3, as I can use it to do a MAF to MAP conversion and it will tidy up my boost pipes. I should be able to set a voltage limit on it too to not trigger the fuel cut. Might be able to limit the iat voltage through it too. All comes down to price really, DET3 is 250 and then the hassle of wiring it and trying to figure out how to set it up.

I just finished polybushing my rear end and fitting solid steel diff mount bushings, made a massive difference. Bought h&r anti roll bars but have yet to fit them.

Trying to get my car driving good, got it tracked and my front passenger caster is still off unfortunately. I hit a kerb drifting a roundabout in it like 3 years ago and it still doesn't drive straight, I thought replacing my control arms would fix it but the wheel is still too far back, really hope I didn't bend the chassis. Cant see a bend in it but I cant see how else my wheel could be pushed back. I cant imagine getting the chassis jigged will be cheap.

|

| |

|

|

|

|