|

|

|

|

|

![]()  I'm starting this thread to chronicle the goings-on with my turd of a 1985 760 Turbo that my wife has affectionately christened the "Jurbo" (that's pronounced YUR-bo, get it right). The plans are to get the car back to a real stage zero, then add a few go-less-slow parts. My long term goal is about 250hp. I purchased the car in November 2017 after running across the world's most detailed Craigslist ad- complete with exactly zero pictures and no mention of condition or maintenance at all. What it did mention, however, was the mileage at a hair under 78k original. Called the phone number in the ad, set up an appointment, and travel to the address the seller gave me- a podunk repair shop in the south suburbs of Minneapolis. My expectations were extraordinarily low. The car fired right up, but had idling problems. It died immediately on the test drive the first time I tried to get it to boost, and lots of the interior trim was in the trunk. It died occasionally while moving, apropos of nothing. It was going to need everything rubber replaced from being driven less than 500 miles in the last decade. Bummer. The good news is that the stack of work orders that came with it was thicker than my forearm, it had spent most of it's life garaged in Colorado, and the mileage was verified to really be 78k. Party on. This is what it looked like when my we picked it up-  Neat. At this point, the plan was to park the car in my garage stall at our apartment until I could find a work space for it, then pick away at the things I knew it needed until was reliable enough to be my DD. This did not happen. Shortly after this purchase, my wife's '98 Honda Accord (RIP to the only rust free Honda in MN) was stolen from our parking lot and totaled. She couldn't drive my MINI, and needed to get to work. "What about the Volvo?" she asked. We had the requisite discussions about the car being old and pissy, and that almost none of the maintenance or repairs that needed doing had yet been done. The Jurbo was then pressed into service as a way to get her to work and back. Turns out, she loves the damn thing warts and all. Since she was now driving it, I figured I should fire up the parts cannon and get to work. The lack of idle was traced to a flaky IAC- popped it open and was greeted with this-  Mmmm... toasty. Right then- off to ebay for a replacement. Now it idled! Woo.  Where did all the brake fluid go?  Oh yeah. That's not good.  Throw a bunch of money at IPD, aaaaaaaaaaaaaaaand...  Installed the new MC and bled the brakes-  Cool. Now it's significantly less of a deathtrap. Despite itself, it did start and run for her every day, even when we had a high temp of -2F in February. Once it was warmed up, it ran and drove pretty well. It looks damn good too, which helps.   During these few months, it would still have intermittent running issues and returned an average of 11mpg. Even for a 7er, that's kinda garbage. It was also even slower than a 760 Turbo is normally. After consulting the oracle (read- TB's Maintenance forum), it was suggested that I check the engine timing. I had a timing belt invoice from three months prior in the aforementioned giant stack of records, so I figured it was worth checking. Turns out Podunk McGee's Auto Emporium had timed the motor two teeth off, and the car had been running that way this whole time. In a Minnesota winter. I was blown away. So then, new timing and accessory belts in hand, we did the needful (as well as a bunch of deferred maintenance):  At the same time, we undid all of the bodges the previous shop had made to get it to run with the timing so far out. The car was back on the road- holy hell I had forgotten how much fun boost is. My mojo was restored as the sun set over this beautiful slab of Swedishness.  The Jurbo behaved itself quite well during our house purchase and my wife continued to use it as a daily driver until May of 2018 when she went out to the car to go to work and was greeted by a car that refused to run. If you grabbed the harness that runs under the intake manifold and jiggle it, it would start and run just fine. Boo. At this point, I decided that it was going to get parked and gone through completely- the wiring elsewhere in the engine bay was looking very crispy and the vacuum lines were all old enough to remember the Reagan administration, so into the garage it went. Here it is, looking quite sorry for itself.  Started taking things apart:  The offending bit of wiring harness. There is an invoice for the "repair" of a coolant temp sensor and a new wire run to the ECU. What they really did was perhaps a bit less than that. Lazy bastards. At least I have a whole new harness from Mr. Barton now.  While I was waiting for a few parts (read: when I should have been working on cleaning up the engine bay), I decided to give it it's first polish and coat of wax since god knows when. This is how it sat in June of 2018-  I love this stupid thing. TL:DR- guy buys old 760, car is pissy from sitting and shoddy work, guy does a few things to make it run a bit better, wiring harness stops play. |

| |

Last Edit: Oct 3, 2019 13:34:41 GMT by redblock

1985 Volvo 760 "Jurbo"

|

|

|

|

|

|

|

|

|

I then got the engine bay cleaned up, new spark plugs and wires in, and finished replacing the top end seals that needed it after the scrubdown (valve cover/front cam seal/distributor seal). Before:  After 3 rounds of ZEP purple degreaser concentrate:  Not perfect, but at least we can see red again. Also finished pulling the old wiring harness out of the engine bay- found this gem of a "repair" on the oil pressure sender.  I'm no scientist, but I'm pretty sure that copper is supposed to stay inside the insulation. I initially thought it was the stock wiring failing (which we already knew about), so for ****s and giggles I followed the wire path from the sender around the front of the motor and found that someone had spliced in a new section at some point. I don't particularly care for this routing considering how close it comes to the drive pulleys and how susceptible that area is to leaks,and it bore out here- the whole length of the repair was oil soaked, crumbling, pinched in the edges of the hangers etc. I'll figure out soon if I want to keep the stock routing, but at this point I doubt it. Also, I cleaned and fed the leather-  The driver's seat might need a more intensive conditioning, but the hides are now softer and look pretty nice after the cleaning.  At that point I fell down the rabbit hole of small engine repair when our 25 year old B&S mower decided it would mow no more, so garage time was temporarily devoted to that. |

| |

1985 Volvo 760 "Jurbo"

|

|

|

|

|

|

|

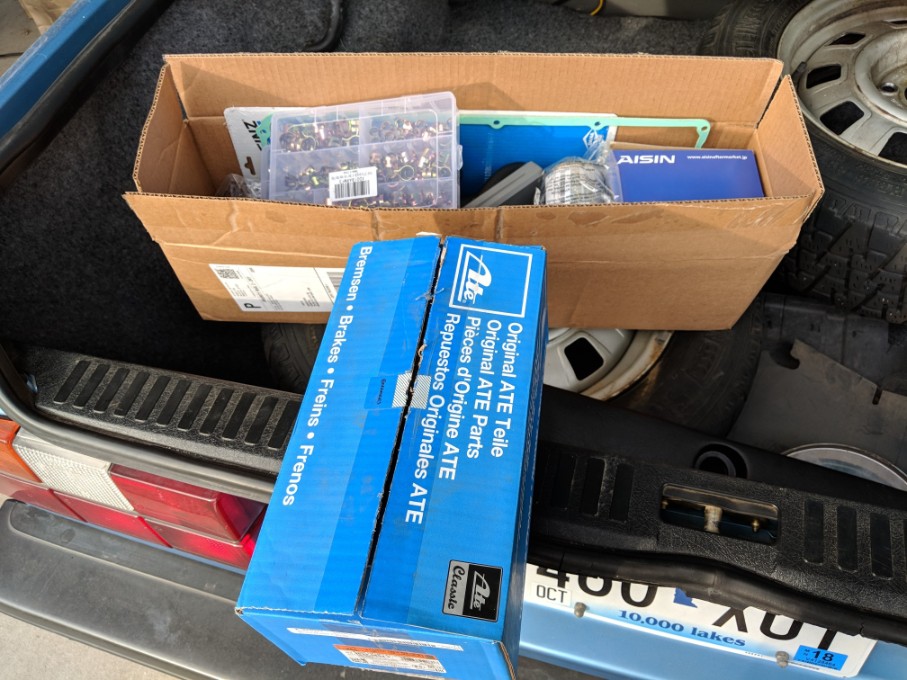

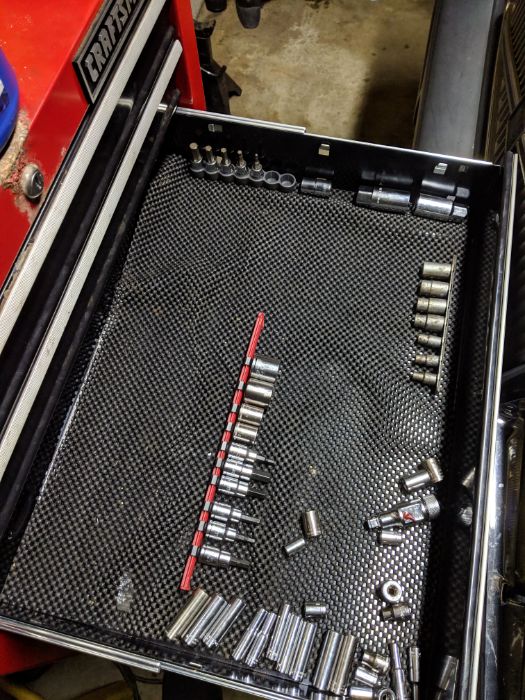

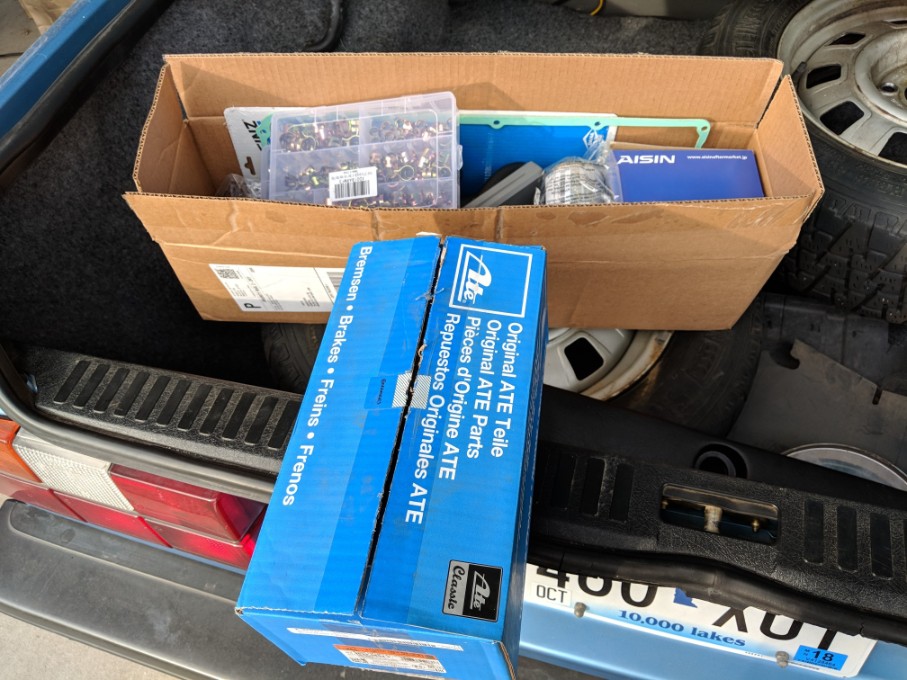

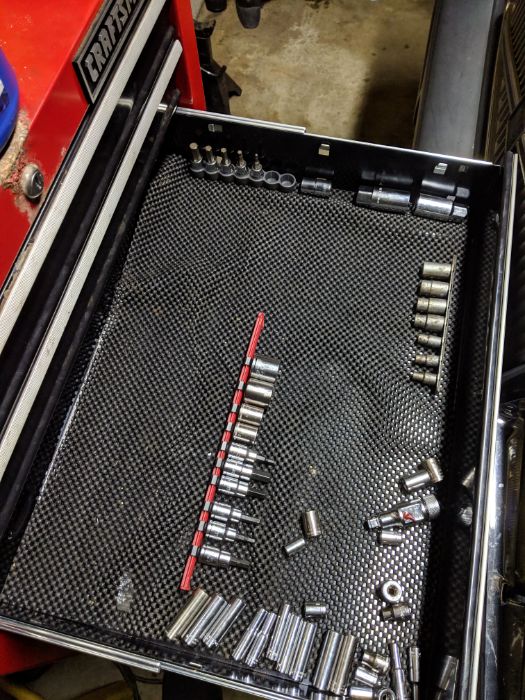

Proof that I finally got the old wiring harness out and the new one in. This was a good day-  However the car still refused to drive until it was up to temp. More sacrifices to the Old Gods of Volvo diagnosis would be needed. Later that week, I came home to my garage door looking like this:  And my toolbox looking like this:  Hrmm. This stopped play for a while, since I couldn't really do much without even a basic metric socket set. I was mostly disappointed that they took my old Craftsman impact- it was a gift from my dad when I first started working on cars, and I'm a sentimental curse word. My toolbox now has a cage around it made of 2x1/8" steel bar. Not enough to be theft proof, but delaying enough to allow my alarm to go off before they abscond with my tools again. Onwards then. Once I got over the theft, I made a vacuum testing tool out of a plumbing cap, an HVAC smoke generator, and an old bike tube-  This immediately showed what the cold running problem had been the whole time- curse word exhaust manifold gaskets. It took about 5 seconds to find the leaks when smoke started pouring out of the manifold to head sealing surface. I popped off the turbo and manifold, and was greeted by this:  Not doing much sealing then. I cleaned up the flanges, and installed a YoshiFab fitting for the turbo's drain. I also purchased a Kinugawa feed line for the stock T3. I don't want to battle with the stock hard lines again, because I am lazy.  Cleaned up the turbo and hit it with some cast-iron stove polish. We'll see how it holds up. I'm not expecting much, but it's pretty.  I also fabbed up a crappy bracket for my shiny new cupholder armrest.  Spent a few months screwing around with turbo drain routing, and then was finally able to put a few miles on the car. Result! |

| |

1985 Volvo 760 "Jurbo"

|

|

|

|

|

|

|

TL;DR- It lives, and it's awesome. A week or two after the post above, I found time to finish tweaking the oil drain and feed routing for the T3, got the Remflex manifold gaskets in to compensate for the slightly warped manifold, and buttoned it all up with some nice shiny hardware. Ran it up to temp and adjusted the MAF, seems to run nicely now even if it still pulls low vacuum when it's cold. Need to pursue that yet. Unfortunately my stove polish idea for the manifold lasted exactly one heat cycle. Requisite engine bay shot-  There are two things that still need doing beyond vacuum leak tracing- you can see in that photo my idiotic vac line routing to the CBV. The unit itself will be getting a bracket that puts it in a less stupid place shortly. You can also see that the Kingsbourne plug wires are exposed to the manifold- some plug boots are on order now to fix that as well. Now that it was running well, I decided it needed a stress test. Rush hour in downtown Minneapolis on a 95F day with 75% humidity seemed suitable.  Success- A/C blew ice cold the whole drive there and back, and the temp gauge climbed to a max just a couple ticks above the 12 o'clock position and stayed there. I'll consider that a win. Safely in the office parking garage-  Since I was so pleased with it, I decided to treat it to a weekend clay/polish/wax session. It was nice to finally clean off a years worth of garage dirt and see it as it's supposed to be. It also got some wiper blades that aren't 20 years old, and a few other small things done that actually make it a usable car again. Looks pretty sharp if I do say so myself.  Now that the motor was healthy, it immediately uncovered a problem with the AW71 gearbox. It was hanging on to gears much too long with almost no throttle input, and it shifted harder than the built drag transmission that lives in my friend's G-body Cutlass. It wouldn't go into 4th/OD until about 85mph. I was hoping it's a mis-adjusted kickdown cable, but it was not. |

| |

Last Edit: Oct 3, 2019 13:44:44 GMT by redblock

1985 Volvo 760 "Jurbo"

|

|

|

|

|

|

|

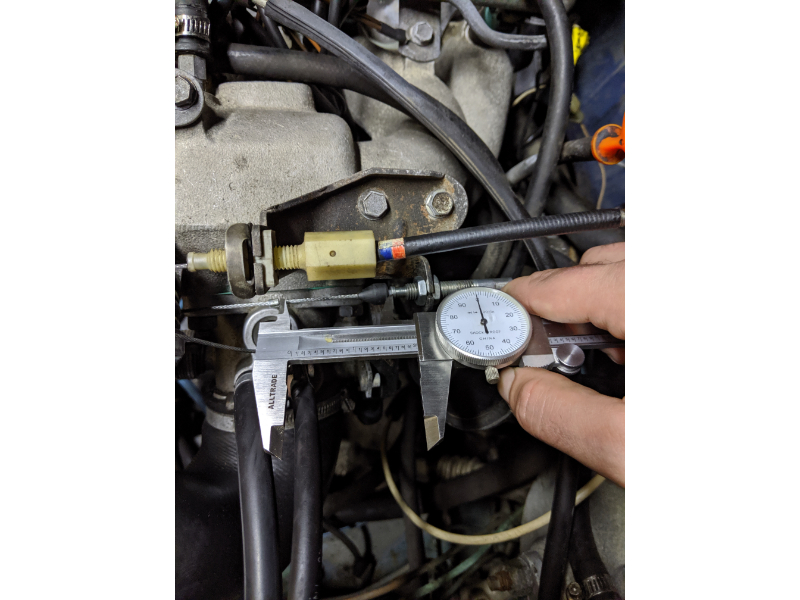

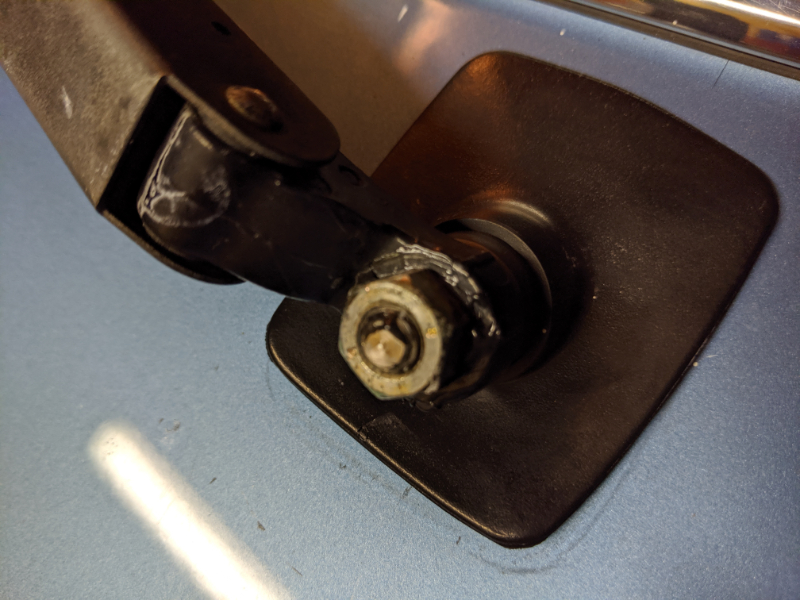

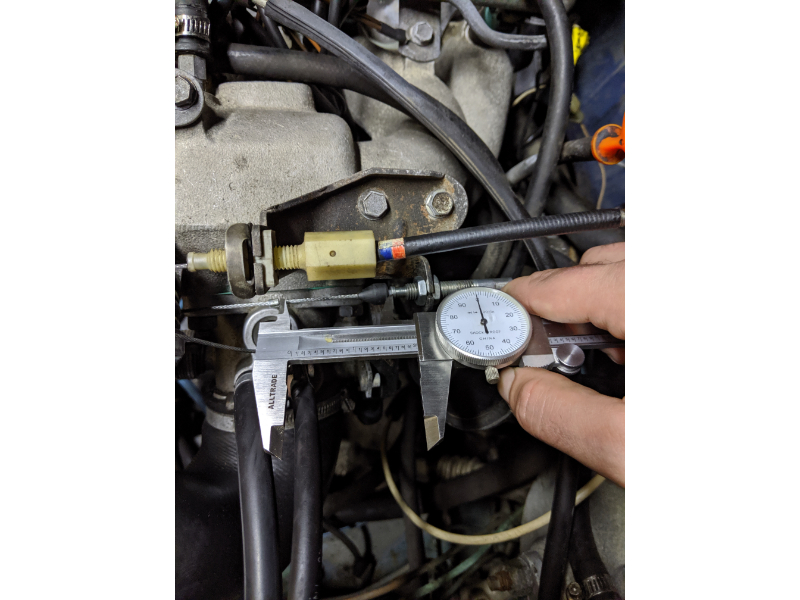

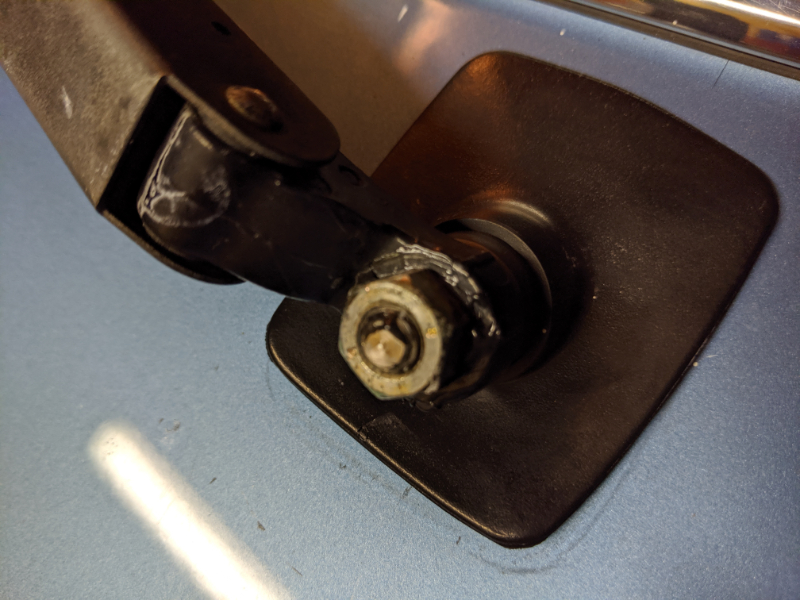

In our previous episode of "Man Has No Idea What He's Doing", I noted that the kickdown cable was broken on this car. Well, after fighting the old cable tooth and nail, I fixed that with a new Febi item-  Checked gasket fit (I wasn't convinced of the quality of the Meistersatz stuff from FCP, but it fits just fine) and treated the pan to an Allison magnet (as found in a Chevrolet HD2500 Diesel truck) and new drain plug-  Then cleaned the pan as well as I could, refitted it, and adjusted the new cable. This was my first attempt at crimping the little ferrule, and I got it almost dead nuts on the 2 in. (+/- a few fractions) spec listed in the Volvo Transmission manual. Excellent.  Refilled the transmission with a few quarts of Valvoline Dex/Merc, and took it for a very VERY cautious test drive. Well, it started out cautious anyway, but the car was behaving itself so well with the cable fixed I couldn't help but give it a run out on the highway. 4th now engages at ~62 mph, and overall it drives much more like a big luxury car should. However, during my drive, it started to rain. As I pulled off at my exit, this happened-  Well balls. That'd be a stripped wiper arm or standoff then. Let's investigate.  Is that JB weld holding the wiper to the motor? Of course it is. Do I have an invoice for new wiper arms in the big pile from the previous owner? Of course I do. I admit I feel a bit dumb for not noticing when I replaced the blades last month. Total garbage. So then, after removing the previous shop's "handywork", I drilled and tapped each wiper arm to accept a 10-32 set screw. I used a 1/4 inch, in case anyone needs to replicate this on their own car.  The wiper boots were also very crispy upon removal, so they got fed over a couple days with some rubber restorer I had on hand-  Then the wiper arms got a fresh coat of black and clear before going back on the car like so:  Much better. I started using the car daily with the goal to put at least another 1000 miles on it before the end of the year. The next day, one of our local constabulary alerted me to a brake light problem I was having. I had noticed the warning light on and off periodically, and I had assumed it was a bulb failure relay problem. It was not.  What the actual hell is this? Why do? What is? How even? Once I got over my initial *mild* irritation, I noted that the brake light bulb in the same location on the other side had been removed, but at least that holder wasn't still stuffed full of old bulb. New bulbs, clean contacts, and one new holder later, the warning light is out and everything is fully functional. I'd like to say I'm going to start ramping up the projects on this to the big stuff like cam/turbo/etc that I will do eventually, but I'm honestly just enjoying it like it is right now. Feels good to actually use it like a car instead of treating it with kid gloves like I had been. In the meantime, I'll keep making small improvements, and the next project is definitely rustproofing. Minnesota winter does loom, after all. |

| |

1985 Volvo 760 "Jurbo"

|

|

|

|

|

|

|

|

Congratulations on your purchase and diligence in getting the vehicle back in order. Sorry to see that you also have your fair share of scumbags who think they are entitled to take other people's property.

|

| |

|

|

|

|

|

Nov 10, 2019 15:26:28 GMT

|

Not much to report on this, just finished preparing the 760 for winter duty, with the exception of having the winter tires mounted on the steelies I have for it. Still chasing the poor cold running issue, and it's worse now that it's around -6C for an average outside temp. If you get even a little bit of heat in the motor it runs and drives just fine, but if you try to drive it ice cold it'll fall on its face and stall whenever you release the throttle pedal. I'm thinking there's a vac leak somewhere that's worse when cold, so more testing is needed. To make myself feel less irritated about it, I polished it up and applied some Fusso99 as this years choice for winter paint protection. I found it recommended on a Finnish car forum as being the best for nasty winter weather, and since Minnesota gets similar conditions to much of Finland, I figured it'd be worth a try. It doesn't look half bad either, so I couldn't help myself from taking the car a few blocks over and taking a few shots while the leaves are still looking their best-  It always makes me laugh that I live in the "rough" part of Minneapolis, and it still looks like this. Not a bad trade off for the brutal winters, honestly. |

| |

1985 Volvo 760 "Jurbo"

|

|

|

|

|

Nov 10, 2019 16:25:06 GMT

|

|

Lots of great work and progress on the car.

I see the license tags have changed.

Do you get a new tag and numbers issued every two years as well?

|

| |

|

|

|

|

|

Nov 10, 2019 16:54:33 GMT

|

Lots of great work and progress on the car. I see the license tags have changed. Do you get a new tag and numbers issued every two years as well? Thank you for the kind words- I've been really enjoying the work you've done on your C10 as well. The license plates were a bit of a silly thing I wanted. In my state, you can keep the same plates more or less indefinitely (unless the vehicle use type or tax scheme changes at which time they give you new ones). However, the modern style Minnesota plates (in blue and white) don't really suit the era of this car, so when I saw that they still made the beige and brown 80's style "Critical Habitat" plates unchanged from my youth I had to get a pair. You just make a donation to our state Department of Natural Resources and viola- malaise era plates for me and a slightly increased budget for the folks charged with maintaining our abundance of lakes, trees, and critters. I will say though that I felt much sillier about wanting period plates on my car before I started perusing this forum. It seems like in many threads someone is nitpicking their numberplate font at some point. It's excellent! |

| |

1985 Volvo 760 "Jurbo"

|

|

|

|

|

Nov 10, 2019 19:05:47 GMT

|

|

Nice car you have and some good work done. Its not always about massive changes or mod's.

I can't remember the film but Dudley Moore was in it, I think they had people doing adverts and they did a Volvo ad that stated

"Volvo, they're boxy , but good"

An apt tribute to the 7series sedan (saloon over here).

As for plates, yeah we're a bit odd sometimes , but in a good way......

|

| |

Needs a bigger hammer mate.......

|

|

|

|

|

|

|

Jan 15, 2020 23:13:26 GMT

|

|

Perfect model (the luxury one with leather seats and all the trims), perfect engine, perfect colour, perfect body shape. And the US front lights. Mmmmm.

I would LOVE this car here in the UK.

Please keep us updated!

|

| |

The Millenium Volcon"Get yourself a Volvo if that's what you really want, you might be dead next year. In the meantime, you could be going sideways in a gigantic land barge."

|

|

|

|

|

Feb 16, 2020 21:14:11 GMT

|

|

Nice build mate

|

| |

smoke tyres not drugs

|

|

thomfr

Part of things

Trying to assemble the Duett again..

Trying to assemble the Duett again..

Posts: 694

|

|

Mar 15, 2020 17:51:18 GMT

|

|

Lovely car! Nice color also. They where advertised when new in that color here.

Bite the bullit and get that starting issue solved by someone with the right (old) test equipment. You will love this car even more if it has no starting issues.

Thom

ps: nice job done up to now.

|

| |

73' Alfa Giulia Super

64' Volvo Duett

65' Volvo Duett

67' Volvo Amazon 123GT

09' Ford Focus 1.8

20' VW ID4

71' Benelli Motorella

65' Cyrus Speciaal

The difference between men and boys is the price of their toys

|

|

|

|

|

|

|

Lovely car! Nice color also. They where advertised when new in that color here. Bite the bullit and get that starting issue solved by someone with the right (old) test equipment. You will love this car even more if it has no starting issues. Thom ps: nice job done up to now. Thanks everyone for the kind words! Thomfr, the issue is that when cold, the car will start perfectly, but it will sometimes idle somewhat poorly and run very rich. It's been a combination of problems so far, but it's gotten better with each thing I've fixed. To fix it once and for all, I've actually spent the winter making the LH2.2 test tools I need based on the Volvo Greenbooks, so I'm aiming to do some more testing now that the winter is leaving us. In the meantime I went to go start it yesterday and spotted a small leak from the water pump to head seal, so parts are on order to completely refresh the cooling system, water pump to heater valve and radiator- as you do. This past fall I also adopted another low-mileage 80's machine that's in need of tinkering-  It's a 1981 Yamaha XJ550 Seca with a hair under 7k miles. A good friend gave it to me after hearing I was learning to ride. He knew about my work with the Volvo and my penchant for preserving rather than hacking apart, and he wanted his first brand-new bike to go to a good home. It's really in superb original shape, just needs the same things doing as the Volvo really: everything rubber is perished, and it needs some tweaks to make it run properly. Now that project funds are split somewhat, I'm trying to decide which gets my attention first! Admittedly, this is a good problem to have. |

| |

Last Edit: Mar 17, 2020 0:41:41 GMT by redblock

1985 Volvo 760 "Jurbo"

|

|

|

|

|

|

|

That, "like," was for the whole thread by the way.  |

| |

|

|

|

|

|

|

|

That, "like," was for the whole thread by the way.  Thank you! Glad to see some folks are interested in the goings-on of an old boosted brick. To that end, I've been doing small things here and there to get the car ready for it's spring duties. One of the things that had always bothered me was that the temperature gauge never seemed to go above the quarter mark unless the A/C was on and it was 90F+ outside. I figured this can't have been helping anything, but never knew if it was the gauge being untrustworthy or if the car really was running cool. I borrowed an IR thermometer and got my answer-  It really is running cool- by about 50F. That would explain it then. I also had time to put my O2 sensor test tool to use- I say tool, but it's really just two lengths of wire, a resistor, and an LED soldered together. You put one leg on the negative terminal on the battery, and the other in a test point terminal on the offside firewall. My O2 sensor failed pretty miserably by all accounts, so a new one was procured. At the same time, I also purchased a new correct 87C thermostat, a new MAF to Turbo intake hose, and coolant temperature sensor to go along with the new O2 and the water pump I mentioned above.  I then set out to do the simplest things first, mostly because I wanted to see their effect on the car's running. The MAF to Turbo hose has always looked like this:  Which I'm guessing is the result of the profoundly clogged PCV system that the car had when I got it. The system pukes oil vapors directly into this hose, and it can get messy. I had a much smarter person than I evaluate the turbo itself last summer as the other possible culprit, but the old T3 still seals well surprisingly. Let's try the new hose on for size-  Or not. Very disappointed in this part from IPD USA- they're usually great about stocking quality items. Standoffs and ports in the wrong place entirely, to say nothing of the fact its four inches too short. Oh well, the old one will go back in place for now while I save my pennies for the swanky Do88 silicone version or get sick of it all and decide to roll my own. Since I had limited time left in the garage, I decided to replace the next thing on the list- the O2 sensor. No pics of this unfortunately, as access is an absolute nightmare with the early turbo Volvo's and I was too busy swearing and cobbling together the right combination of extensions and u-joints that I thought would free the old sensor. However, it did finally yield, and it is certainly past it's best-  Looks like most of the other O2 sensors I've pulled in the past, just a hair crispier if anything. Tossed the new one in. The million dollar question then- did it fix the cold idle issues? No, but it did improve them substantially! With this replaced, I have also now noticed a small leak from the turbo to downpipe flange. Looks like new studs and nuts for the downpipe connection will be next on the list. The good news is that instead of the car now taking 5-6 minutes to be driveable, it took less than 2. In addition, the all around driveability of the thing is dramatically improved- boost comes on faster and hits much harder, the tip-in response is very much improved, and generally it feels like the mixture is much closer to what it should be, if not dead on for LH 2.2. While I hated driving on a coolant weep that I knew about, I was so pleased with the change that I couldn't resist topping up the reservoir and taking it to procure some essential isolation supplies.  My beverage of choice seemed an appropriate errand for such a fine Scandinavian machine (yes, Linie is Norwegian but it's my favorite. Just don't tell that to my grandfather from Sweden). Hoping to get the cooling system sorted in the next few days. Hope too that you all are staying healthy and practicing the same kind of social distancing via garage time! |

| |

1985 Volvo 760 "Jurbo"

|

|

melle

South West

It'll come out in the wash.

Posts: 2,010

|

|

|

|

|

Linie is good stuff, although I personally prefer Aalborg Jubilæums Akvavit (from Denmark). Cool car by the way!

|

| |

www.saabv4.com'70 Saab 96 V4 "The Devil's Own V4" '77 Saab 95 V4 van conversion project '88 Saab 900i 8V

|

|

|

|

|

|

|

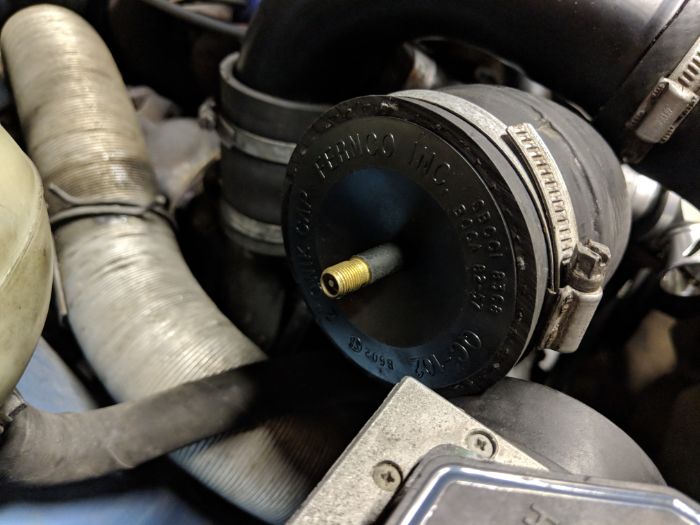

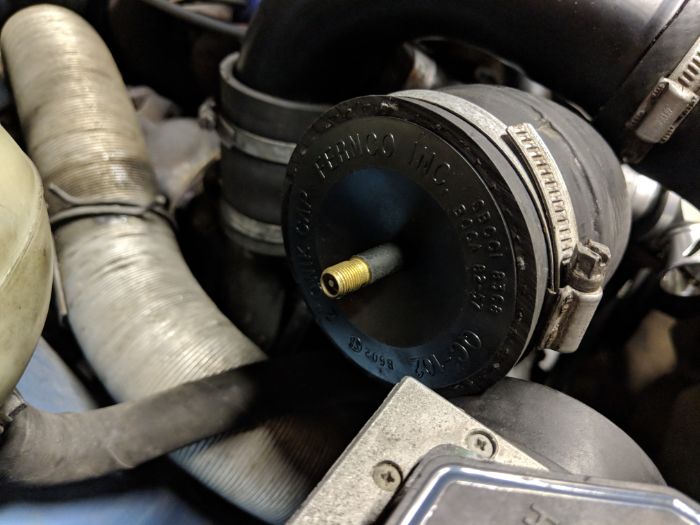

So since I've had plenty of time to work on the Volvo, I decided to address a major annoyance of mine with this era of Lh2.2 740's and 760's- the cam-driven distributor. Often the shaft oil seal will start leaking, allowing the distributor to get oil inside, which will in turn destroy the hall sensor eventually. I've rebuilt this one twice now, which is always a pain. It will seal for maybe a month or two, then start leaking again. It involves a homebrew jig to drive out the pin that holds the drive gear to the shaft:  It's obnoxious and I hate it. So, what to do? Well, under a freeze plug (under the intake manifold) runs the intermediate shaft. If I'm luckily, there will be a gear there to drive a 240 block mounted distributor. I can then plug the back of the head with the appropriate oil seal and retainer and never deal with this again. So then, what's the verdict?  I have the geared shaft! Result. I ordered up the requisite 240 Turbo ignition components:  Then cleaned up the used distributor:  Not perfect but with a new cap and rotor it'll be fine for testing. I then set about relocating the ignition coil from the left side of the engine bay to the right side. Stock location is here:  The coil will live where the non-operational vacuum pump lives now:  So removed the line and plugged it. I'll remove this line completely if this is successful and the car doesn't flip out with no pump.  Then mounted the coil and ran some 16 gauge wire and loom to the new position:  I'm going to try to test fire the thing, then tidy up the wiring with the appropriate clamps and such. I then soldered in the new wires, covered them in silicone grease, then heat-shrink, then wrapped in electrical tape and loom for some abrasion protection.   Then I proceeded to clean up and repaint the used 240 ignition coil (the ends are different to the 740/760, so it had to be swapped as well). The seller I bought the coil from included a replica Bosch decal for maximum nerdy- it's little but stuff like this makes me happy.  Then I had the thought that I should check the injector seals, as they're a common source of subtle vac leaks on this engine:  Yup, that will be done for then. All the pintle caps were cracked as well, so I have new seals, nylon spacers, and caps for them on order. While I'm waiting, I kept thinking how nasty the intake manifold has always looked.  A couple hours with some very weak aluminium brightener, and it looked a lot better. I also took this opportunity to dress the injector sealing surfaces with emory cloth- they were looking rough.  Again, not perfect, but I'm much happier with that, especially the injector sealing surfaces. Now I'm just waiting for the injector parts, and we can try a test fire with the converted distributor. |

| |

Last Edit: May 11, 2020 1:47:52 GMT by redblock

1985 Volvo 760 "Jurbo"

|

|

|

|

|

May 11, 2020 21:07:24 GMT

|

|

Nice mod

|

| |

|

|

|

|

|

|

|

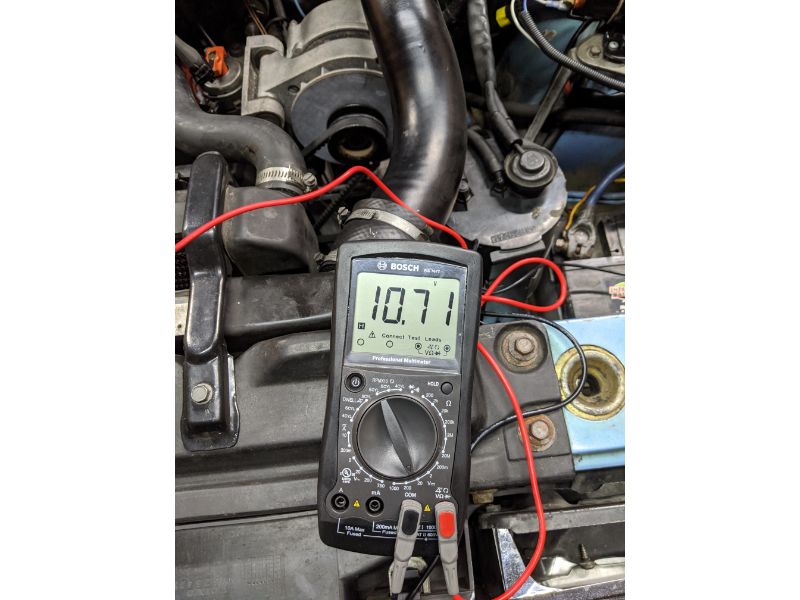

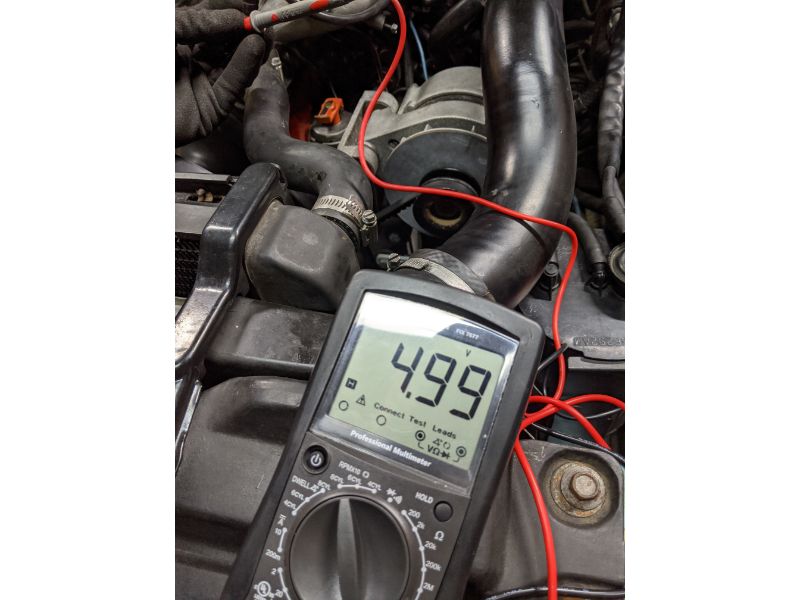

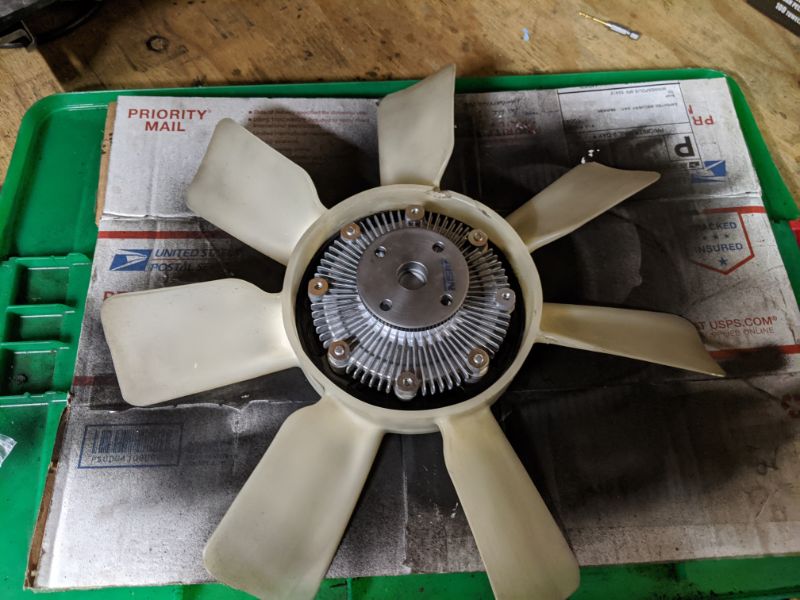

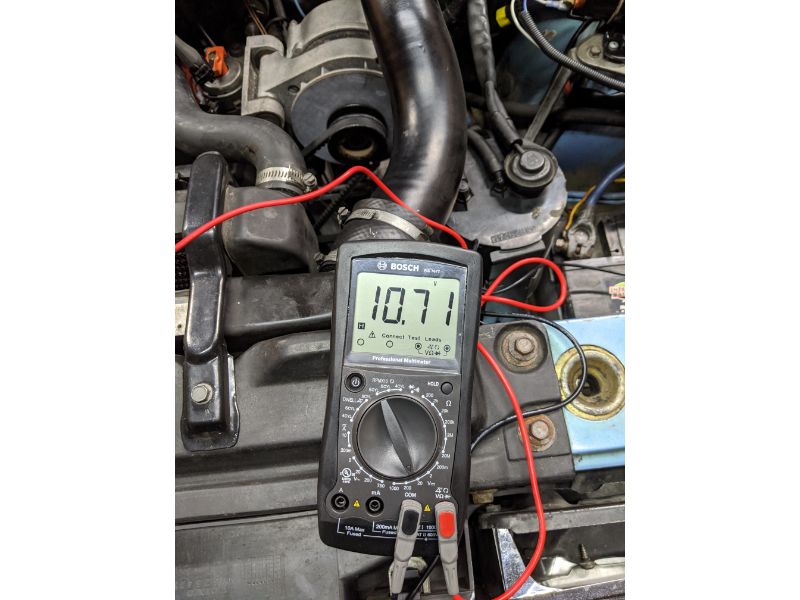

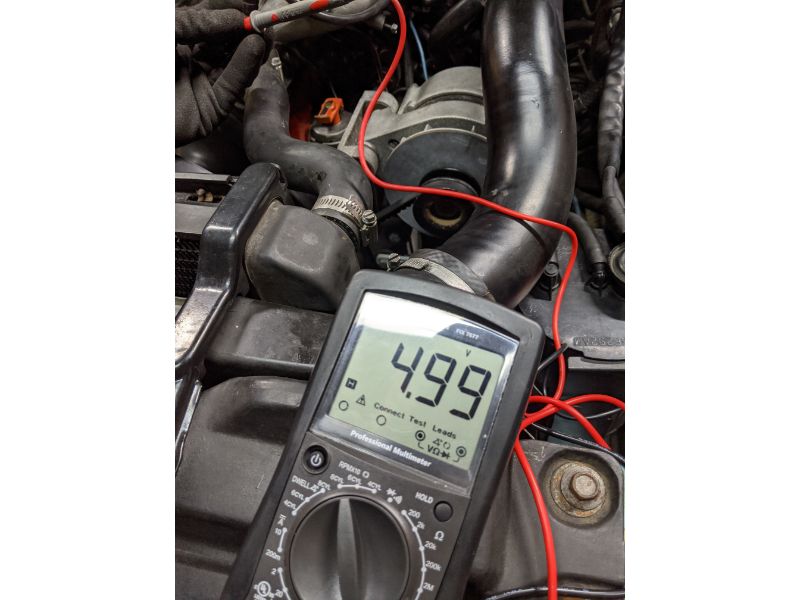

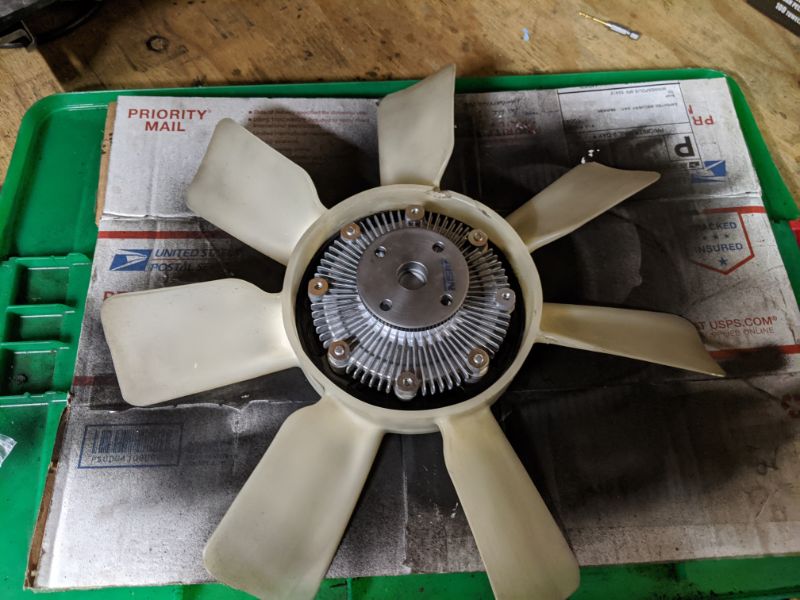

So then, proceeding with the block-mounted distributor conversion, I had to check that the hall sensor wiring (for ignition pulse signal) would reach the new location. Luckily it did:  However, you'll notice I had to clearance the rear timing cover in order to get it to fit. Still not sure why, as most Volvo 240's from '86-'88 had LH2.2 and the distributor in this location. Part numbers for the timing covers are the same for those cars and mine. Strange. Since the test fit was looking good, it was time to re-assemble the intake and put it back on, so I installed the new o-rings and pintle caps on the injectors. I regret not painting them when looking at this picture, but at the end of the day the chance of me masking something wrong and toasting an injector just seemed like an unnecessary risk.  Then finished cleaning all the hardware up and put the intake manifold assembly back together-  Definitely an improvement. The intake mating surfaces on the head were looking nasty, so they were cleaned up:   And then it could all go back together for a test fire:  The test start, however, was a bust. It would crank freely but the fuel pumps weren't turning on. If anything in the ignition system pre-distributor isn't working correctly, LH 2.2 automatically will not turn the fuel pumps on. It's a nifty safety system. I had two main concerns here- that I had somehow cause a short in the coil wiring I extended, or that the Hall Sensor wiring had broken internally when I relocated it to the drivers side of the block instead of its normal home on the back of the head. So then- let's break out the multimeter and test the hall sensor wiring first. According to what I could find, the three pins on this connector are (from left to right) power, signal, and ground. With 12V applied, we should get 11V between the power and ground terminals and 5V between the signal and ground terminals.  That's good!  Also good. I also checked the coil wires for continuity, and those are looking good as well thankfully. That leaves two possibilities- the distributor is timed incorrectly to the engine, or the hall sensor is outputting no signal. To test, I just plugged the hall connector into the old distributor on the back of the head. Turning the key, I could immediately hear the fuel pumps come on- so it looks like the "good used" distributor I bought isn't outputting signal correctly. Lame. I set about finding another distributor, but that's been a bit of a task. I think I have one on its way to me now, so I'll have to wait before I can test firing again. I also re-timed the motor and distributor just for good measure, and in the process threw some paint on the timing cover and installed a new fan clutch that I've had laying around forever.     So at this point I'm biding my time until the new distributor gets here. I'd be more anxious about getting it done, but my hobbies seem like much more of a luxury than normal at the moment- that point was driven home when I went to go fill up the daily at the local petrol station:  Pretty surreal stuff to see in your own neighborhood. At any rate, I'm looking forward to getting this back on the road, but staying safe is kind of the priority at the moment. The Volvo is providing a welcome distraction at least! |

| |

1985 Volvo 760 "Jurbo"

|

|

|

|