So what do you do if your ball’s the wrong shape?

Oh sorry. That’s the start of the post for bus thread.

So what do you do if your ball’s the wrong shape?

Play rugby I suppose…

The reason for the question will become clear in a while.

I also said…

Stand by your beds! Penultimate gear stick episode coming up.

…….

In the last part of this story I expect we’ll be bolting it to the side of the engine and trying to get it adjusted so it’ll select some gears.

James

I thought I’d bolt it on, connect it up, bit of adjustment and then off for tea and and medals in the Naafi. It didn’t turn out like that. It’s not going to be the last part of the story.

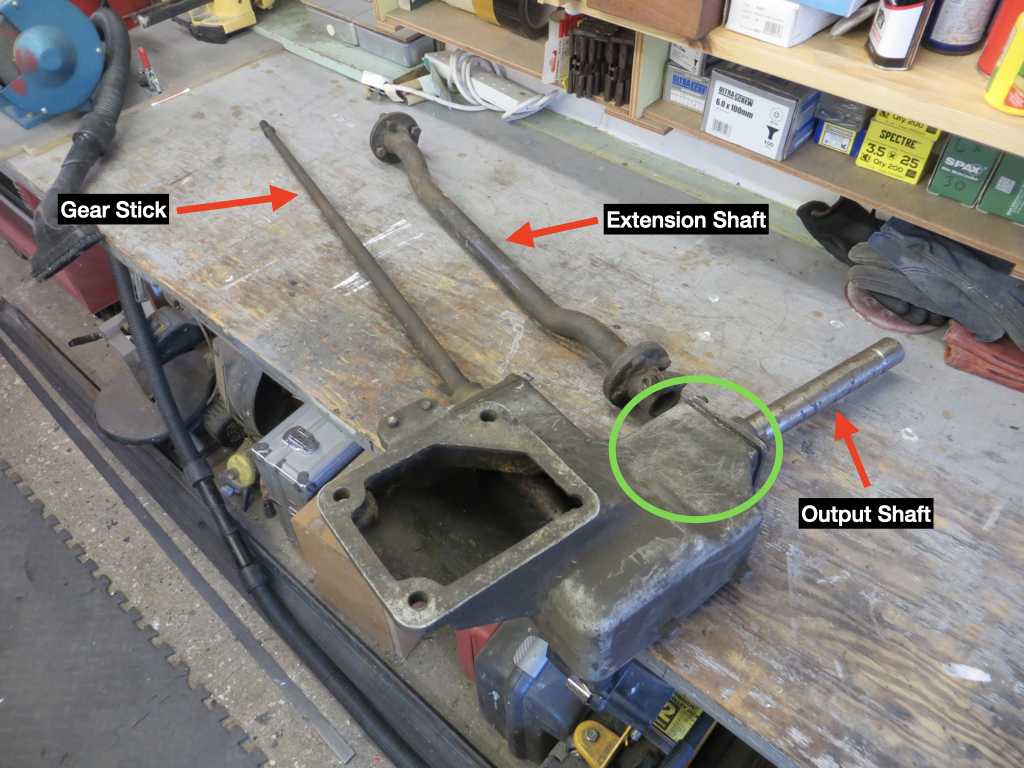

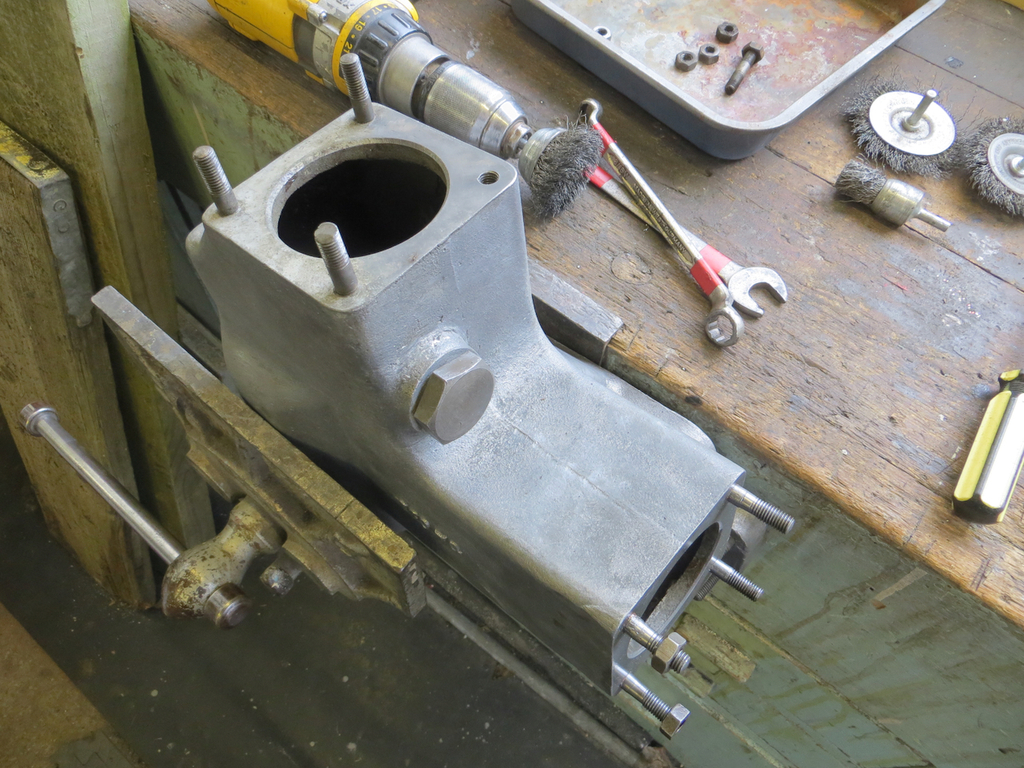

Bolting it to the side of the engine turned out to be harder than you’d think.It was way too unwieldy with the stick and output shaft installed so I removed them and just tried to bolt the housing to the engine block. But even that didn’t work because we’d already installed the clutch and brake pedals and you can’t get the housing over the studs with them fitted.

Here is me with the gear selector in bits for the umpteenth time.

I know what you’re thinking… “Oh so that’s what Sweetpea looks like! I didn’t expect him to look like that.”

Do you know what I’m thinking? “Oh my God, so that’s what I look like! Sh1t…”

Anyway, long story short, some time later it was in and connected to the gearbox.

The clevis you can see just next to it is the handbrake lever, the rod you can see just above the bellows is clutch linkage, and the black rod in the bottom right is the foot brake.

I should say that I forgot my camera on this visit. Muppet. What you see was snapped on my phone plus some taken by other members of the Friends of Chatham Traction that were there that day. Many thanks for letting be use them.

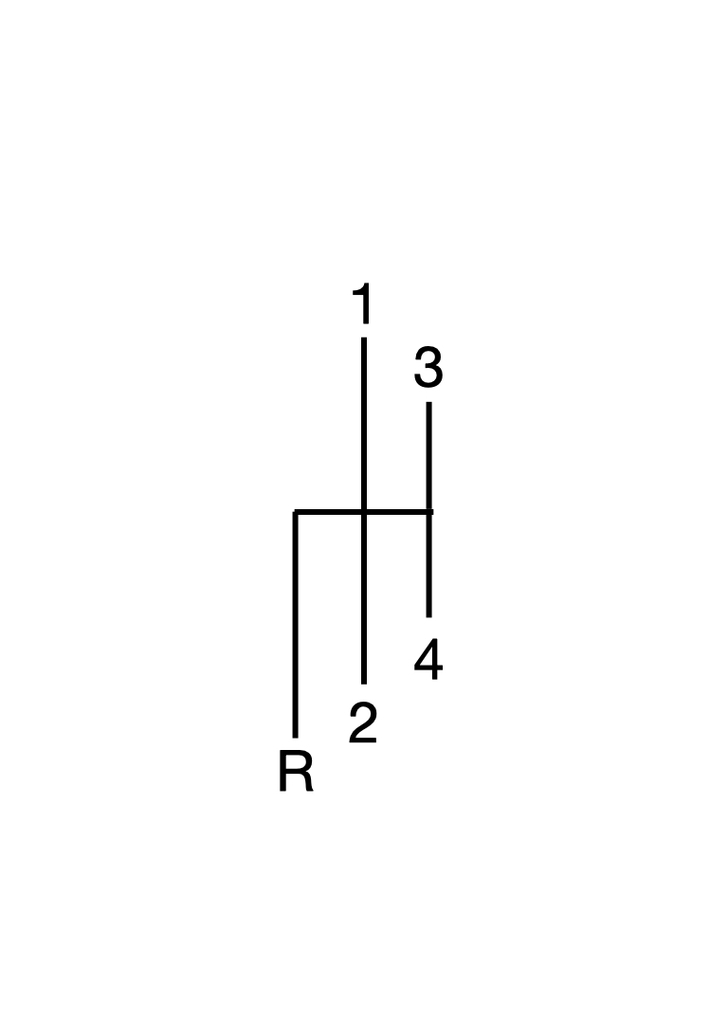

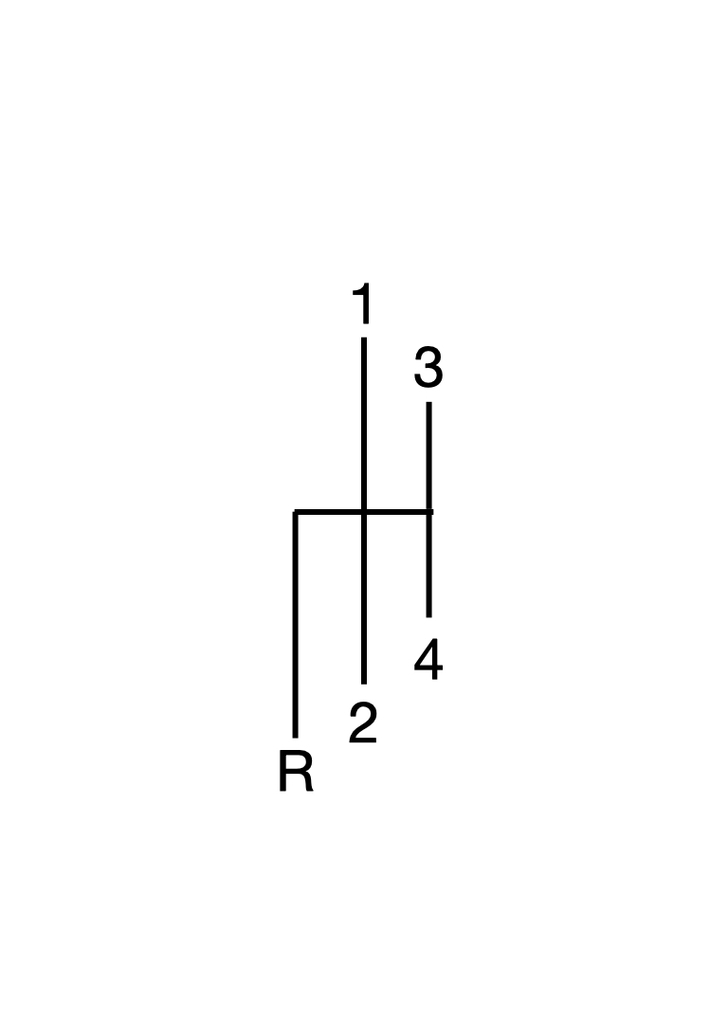

So can we get any gears? Well yes. All of them. But there is a catch and it’s a bit of a git. Firstly let’s look at the shift pattern.

All the gears are where you’d expect the to be but there are a couple of points to make.

Firstly the travel from 1st to 2nd seems to be somewhat longer than the travel from 3rd to 4th. And I suspect reverse is even longer but I’m not sure. It’s a bit odd and must be down to the selector forks in the box.

First is a crawler so normally you’d set off in second unless you were heavy and pointing up a hill. Well… It’s probably only got 70 or 80 HP so ‘heavy and pointing up a hill’ is relative.

The other thing is that, while it’s a long throw in and out of gears, it’s really short going across the box. And there is no bias spring that pushes the lever to one side or the other. If you wanted to set off in second you are unlikely to hit that gear unless you are pretty lucky.

That said, there is one thing that saves you. There is a gate that stops you getting the lever over to reverse and you have to lift the lever to clear it. So normally, to set off, you just go left, hit the gate, and then back into 2nd. And this is where we have a problem. We can get all the gears but you don’t have to lift the lever over the gate. That’s adjustable but remember it’s really short across the gate so it’s going to be really twitchy to get right.

And… this is the real problem… the lever binds up before it hits the gate. On my bench the output shaft is floppy, kicks around all over, and you don’t see the problem. But bolt it to the bus, constrain where the output shaft can go, and you can’t get over to the reverse gate.

Meh. So what’s going wrong then.

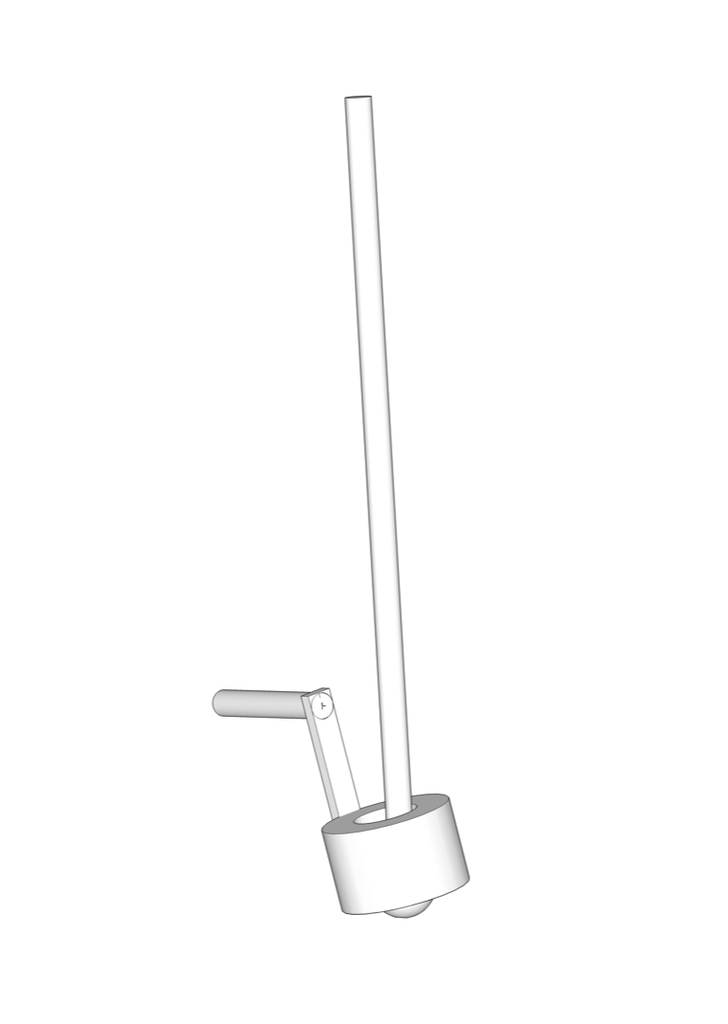

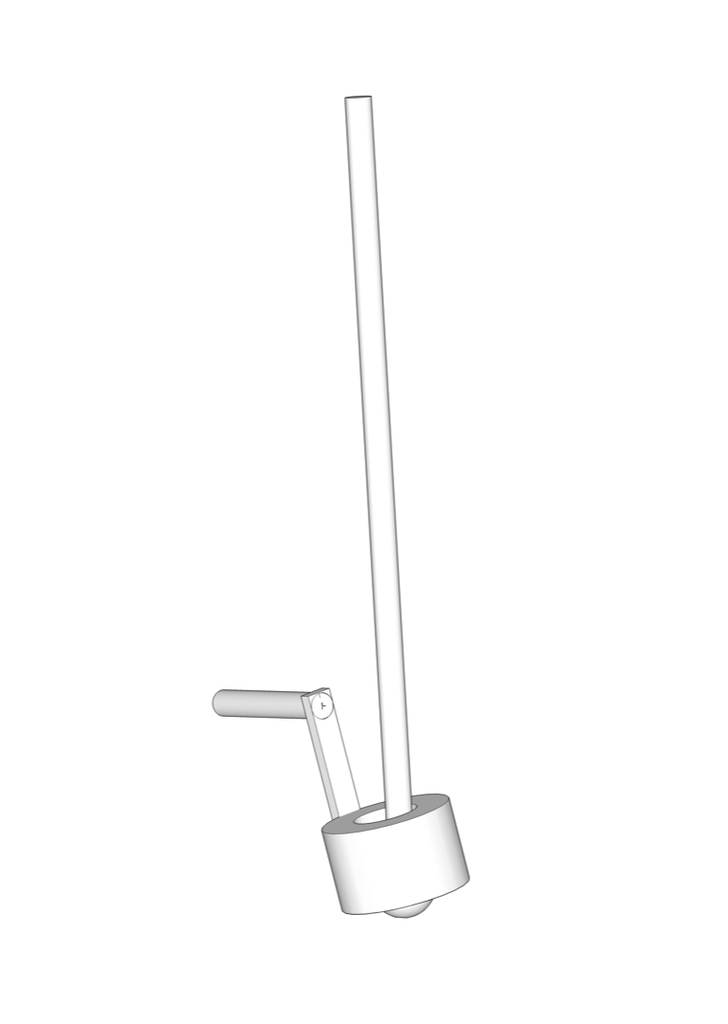

Here’s a 3D drawing of the gear lever what I ‘as done on’t confuser.

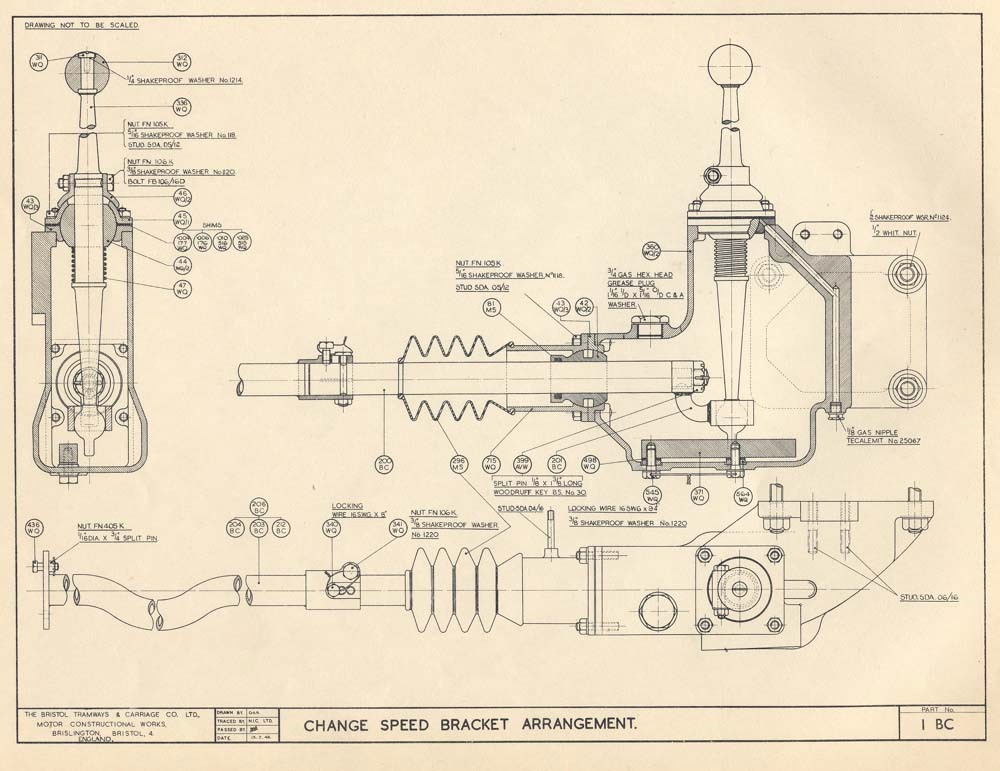

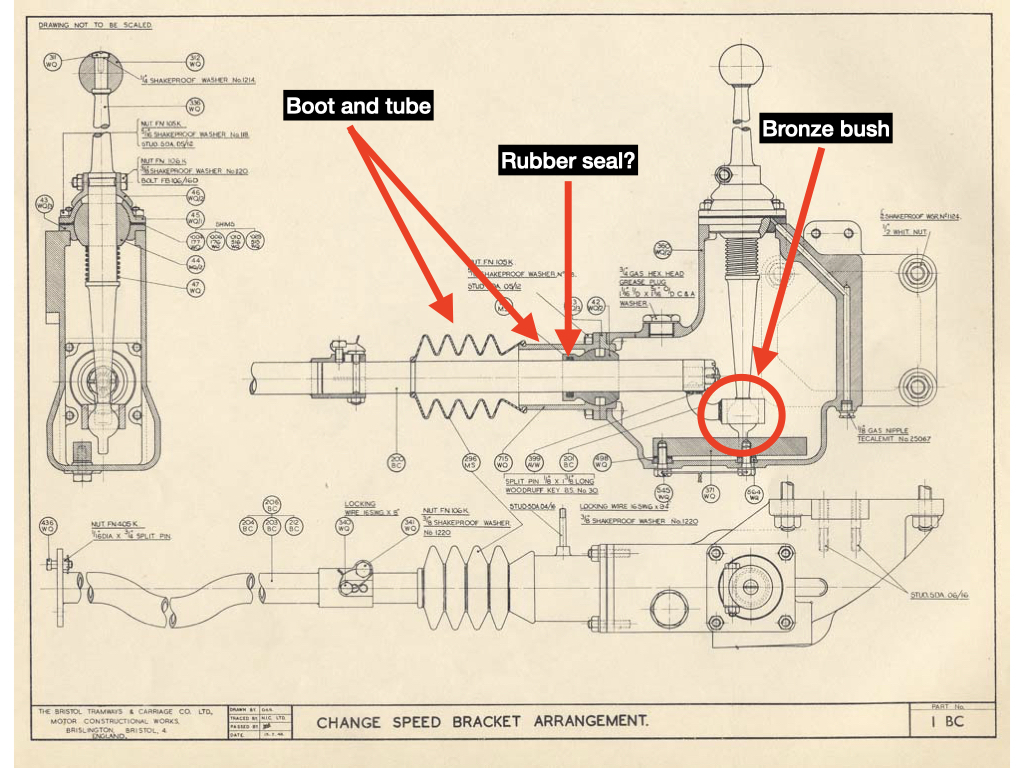

Gear stick coming down from the top with the ball on the end. That moves in a bush in that cup thing moving it from side to side. And the output shaft goes off to the left. Going across the box causes the output to twist, going in and out of gears slides the shaft back and forth.

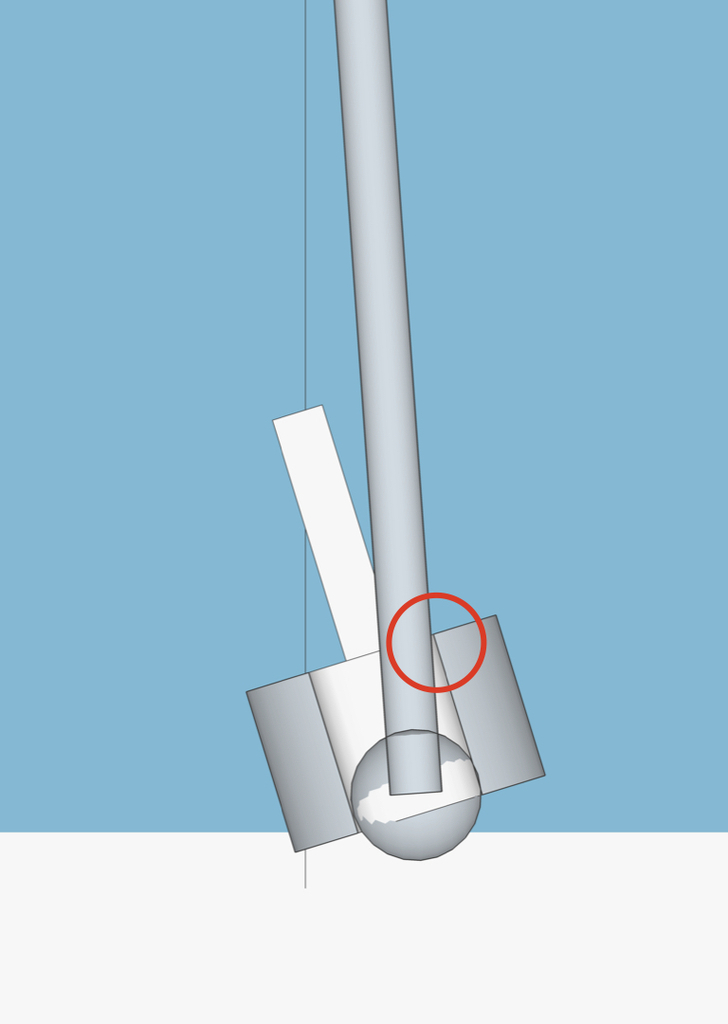

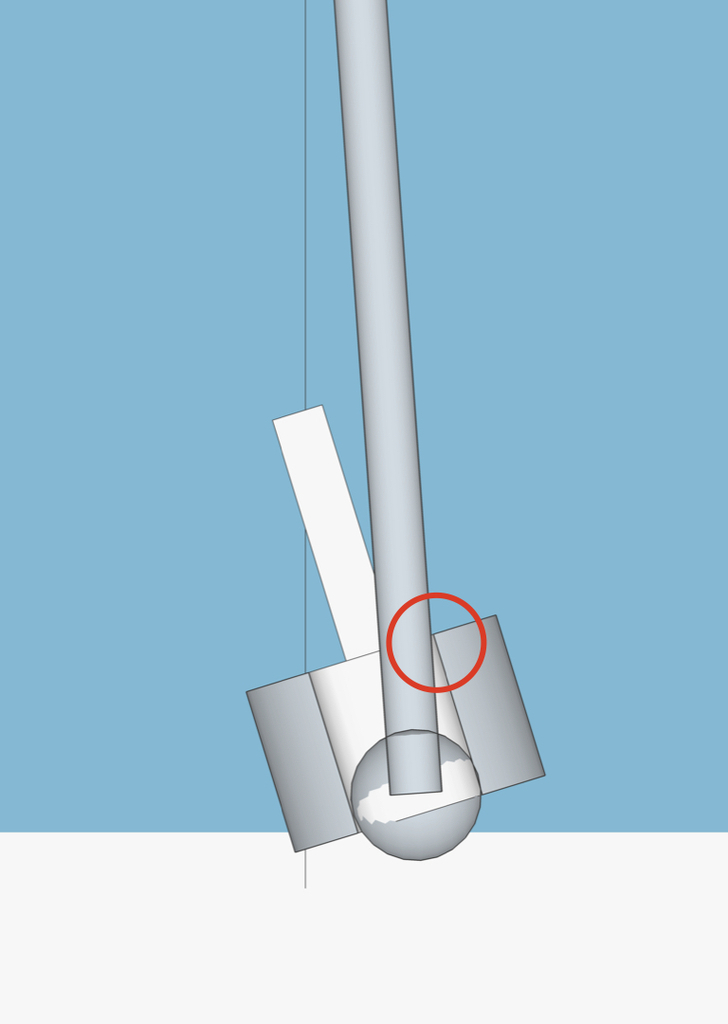

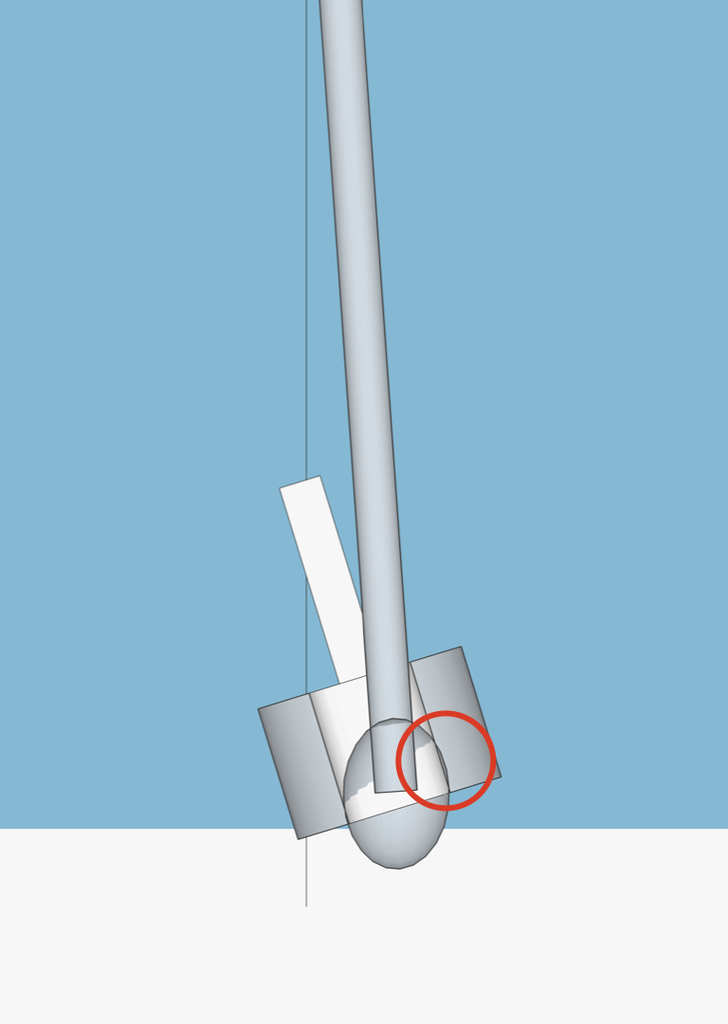

If we take a section through this…

…you can see that the maximum travel across the box happens when the side of the gear stick touches the top of the bush.

Cool. So that’s what should happen. The problem is that the ball on the end of the stick isn’t round. It’s worn away around the middle. It’s more like a rugby ball on its end.

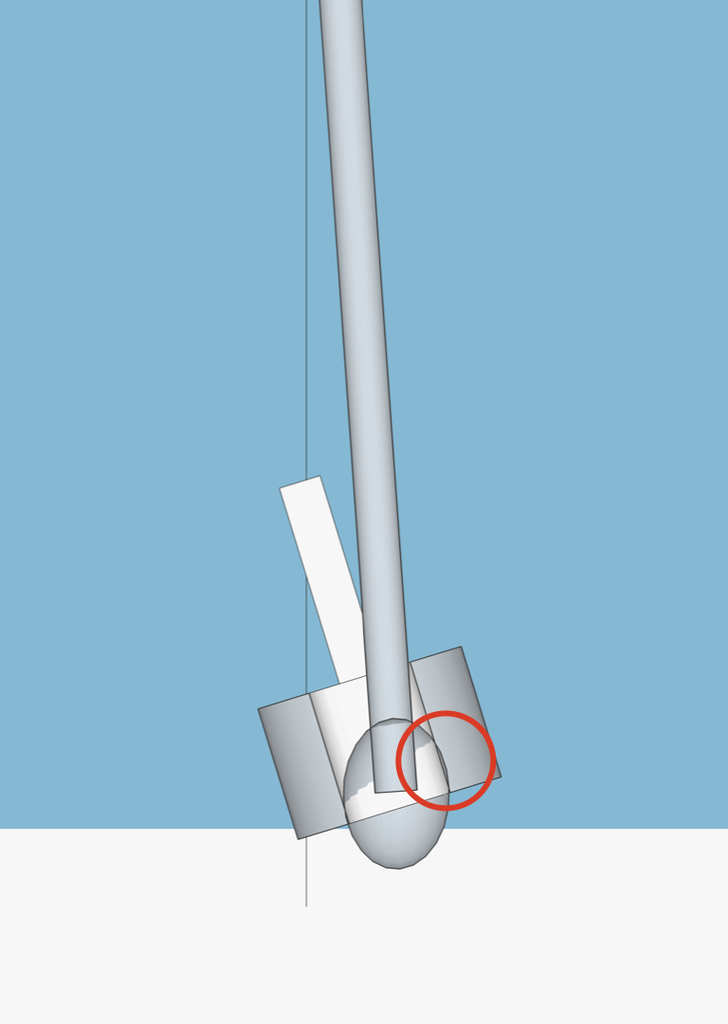

This next drawing is exactly the same, in the same position, but with an oval ball.

You can see that long before the stick touches the top of the bush the ball would bind up in the bush. Does that sound rude? Just me then.

So this is what we think is happening. The bush is new and was sized to be a reasonable fit across the ball, but it goes tight as you try to move it.

Before the bush was replaced the whole thing was so sloppy that there was no chance of anything binding up. In fact it was so sloppy that I think reverse was probably hard to get because the lever was hotting the side of the cab. You can see witness marks on the engine panel where it’s been thumped by the lever.

So that’s a problem…

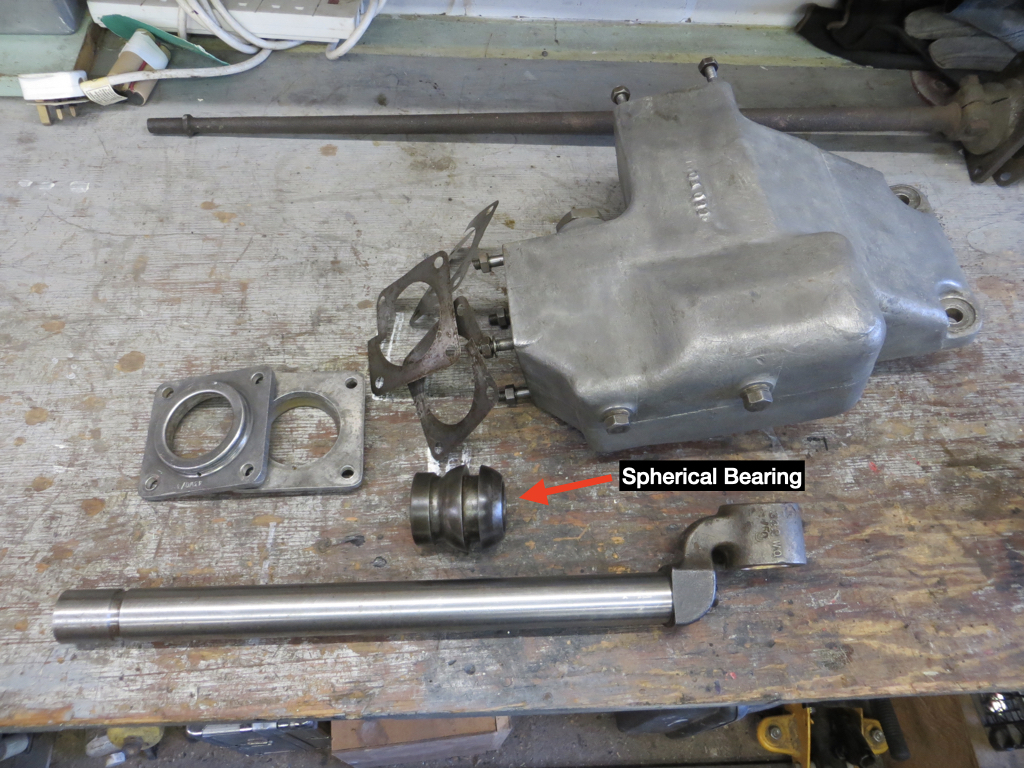

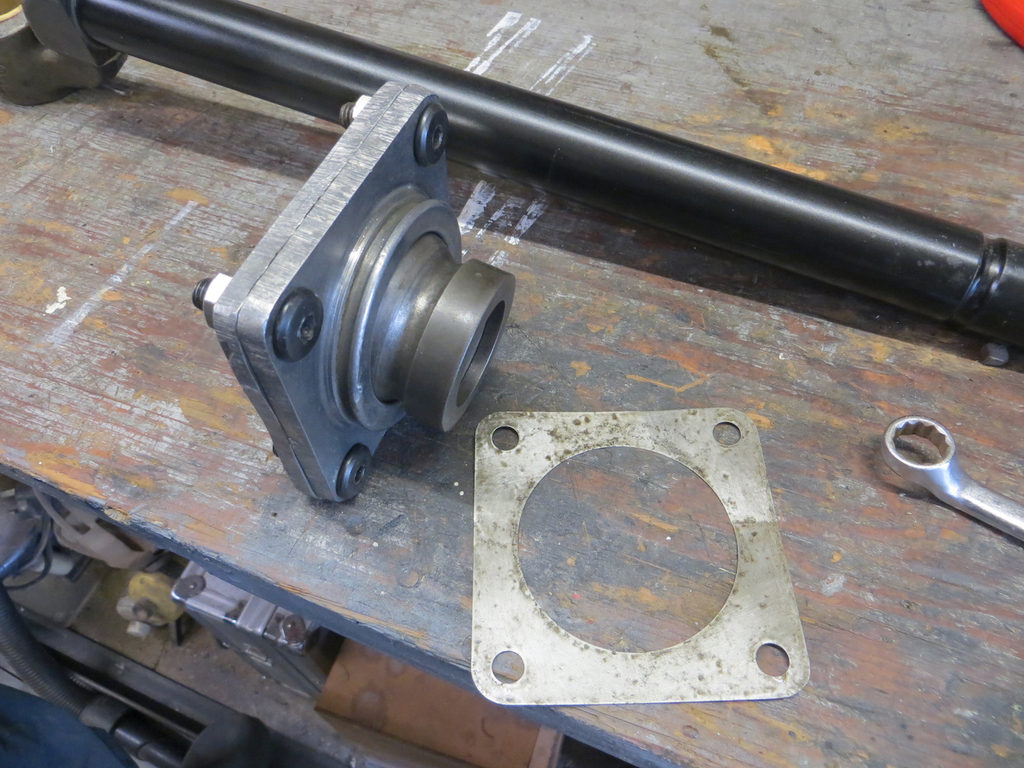

Next I should mention the felt seal in the output shaft bush.

I’d made a ‘seal’ from some closed cell foam. It was an experiment as much as anything. It didn’t really seal anything but it did support the shaft reducing contact with the bearing.

Colnrov and Jimi both had suggestions for proper felt washers - thank you both, much appreciated.

But in a completely unrelated problem,

Linky I had to buy a bearing for my oscillating saw so I bought a rubber O ring from the same place while I was at it.

If I’m about when we next bang our heads with the gear lever I might slip that in to see how it works.

What else happened?

Ian fitted the grill into the radiator.

Here he is trying to get the bottom bit refitted.

Have you noticed that in the last photo of Ian he was on his back with his head hidden under the bus? This photo…

You know… I’m not actually sure I know what he looks like.

Here are the results of his labours.

Very nice.

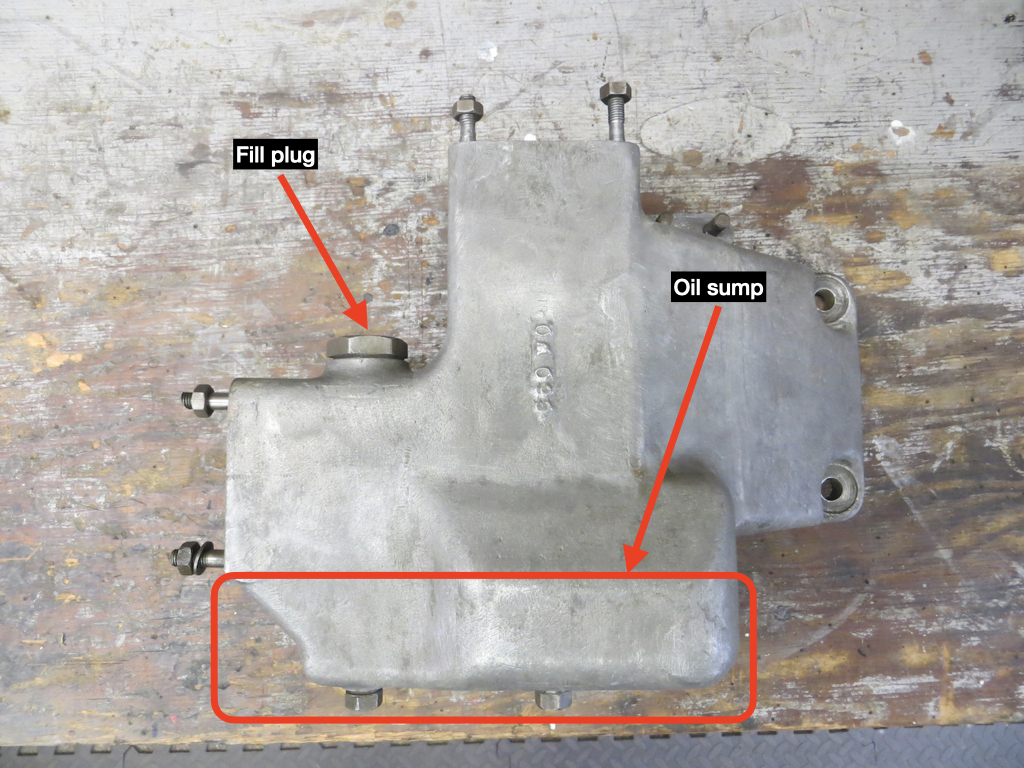

Once again I came home with some bits to play with.

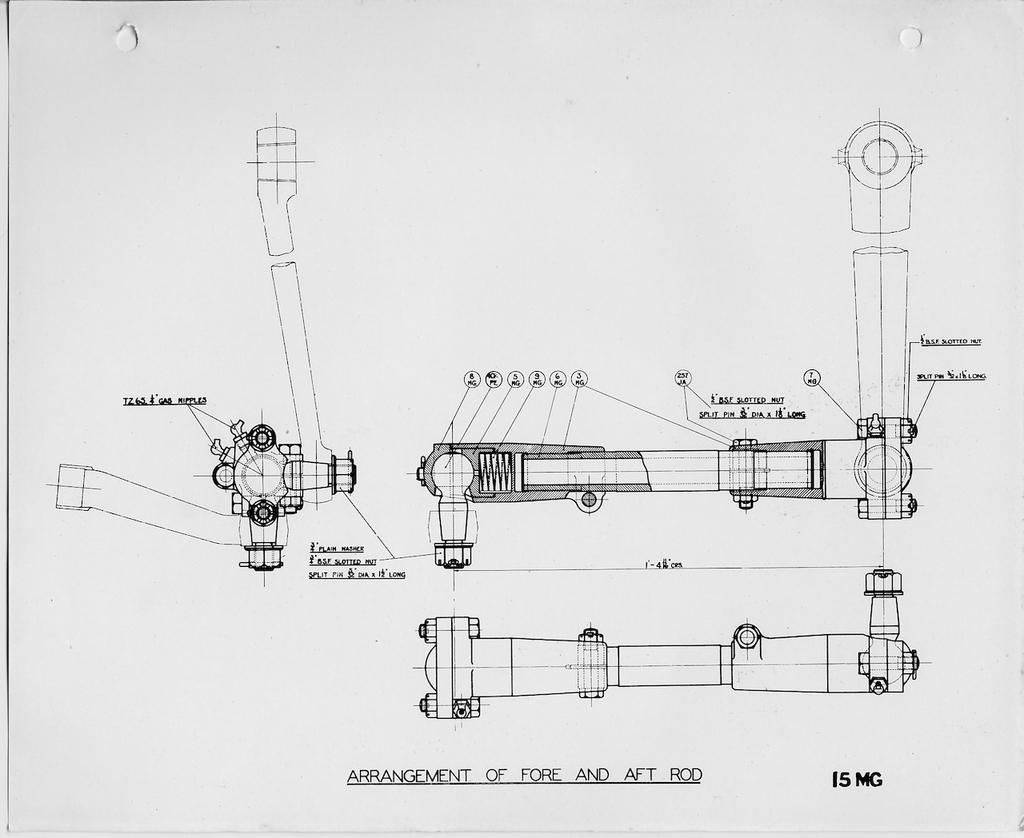

We had a couple of people correctly identify the gear stick in a previous episode. These are a bit harder… Any guesses?

James