|

|

|

Jul 22, 2022 22:08:27 GMT

|

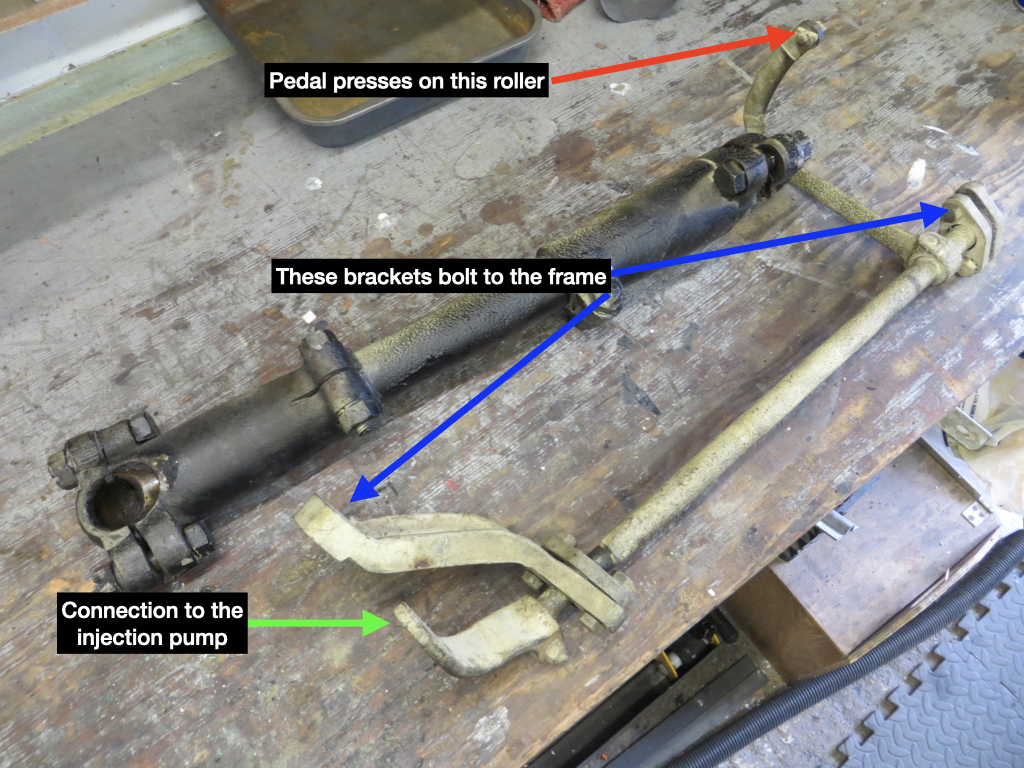

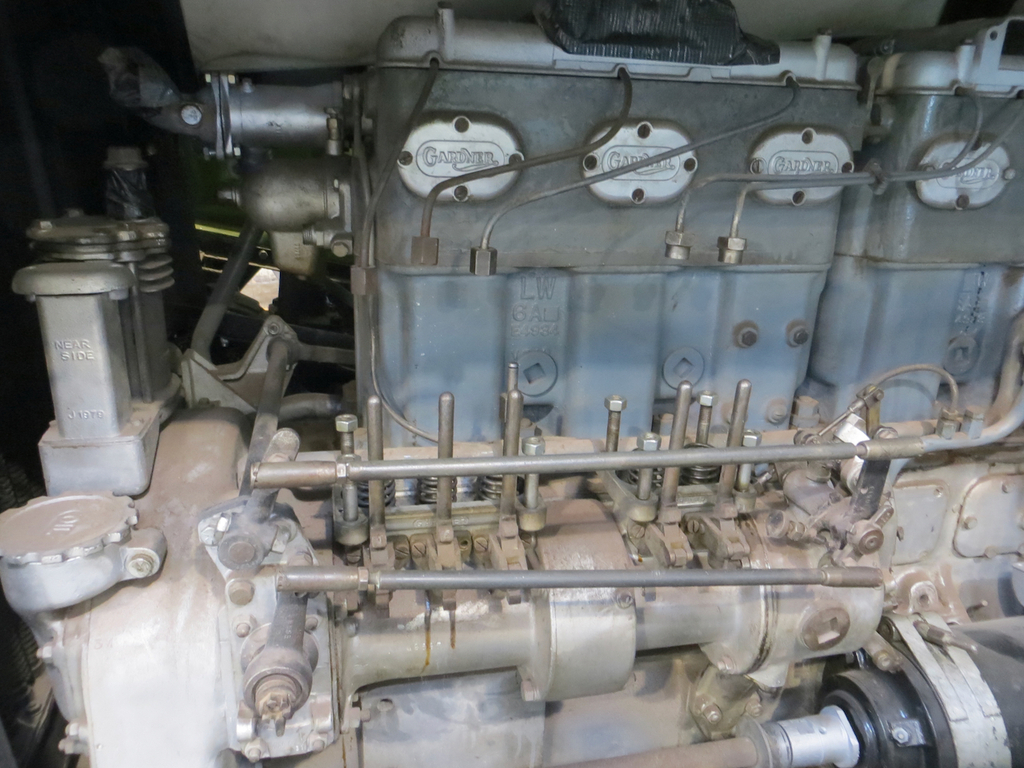

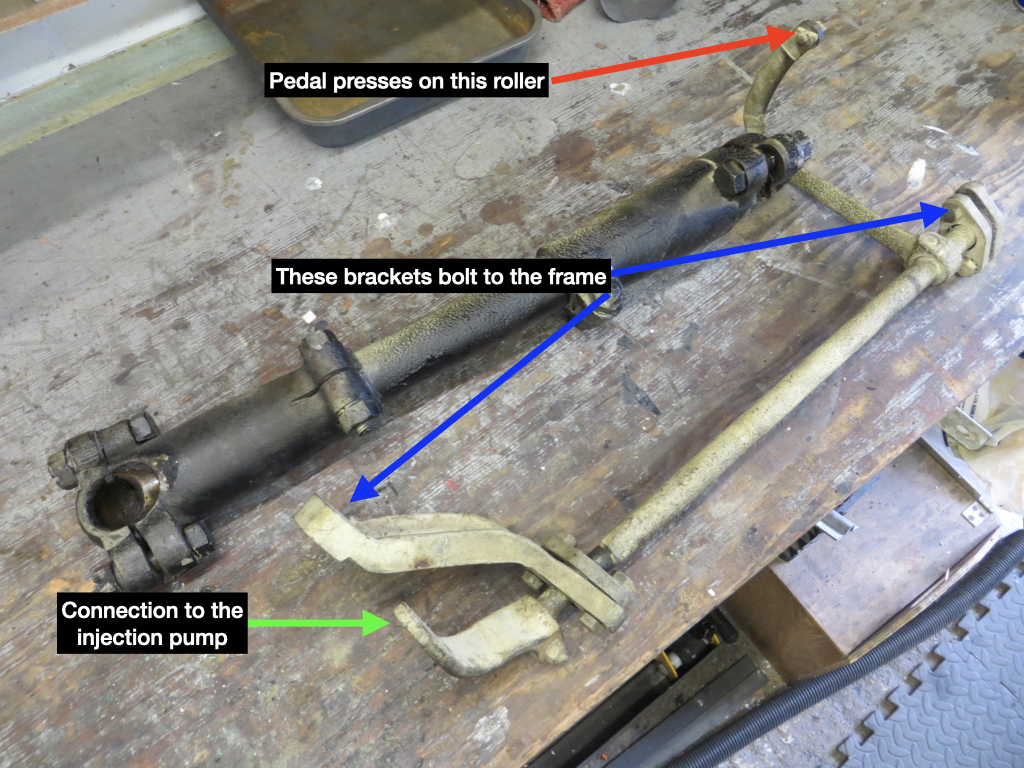

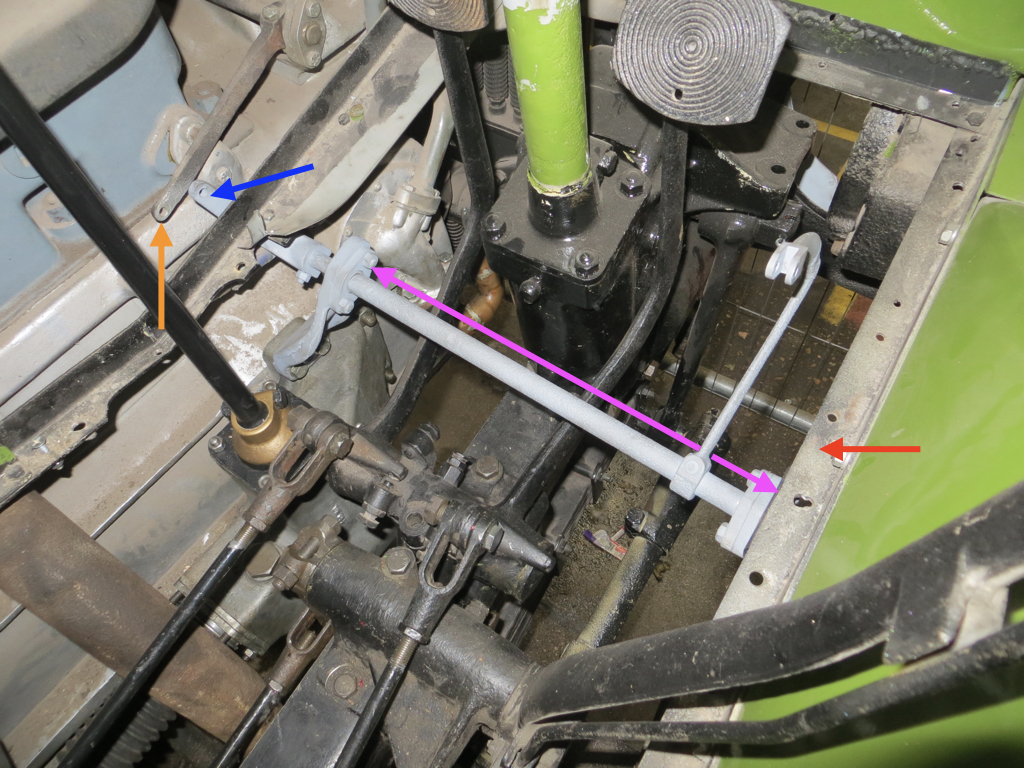

Bonjour mon petit bonbons. That throttle linkage…   It runs across the cab just under the floor. The throttle pedal is hinged off the cab floor and presses on a roller on the arm at the right hand side. And there is an arm on the left side that connects to the rack on the injection pump (eventually). In reality the engine is in the way and there is a set of linkages running round the front of it. The brackets on ends bolt to the chassis. Well, the one on the right does. The one on the left actually bolts to the gear selector housing. Remember the mysterious studs with no obvious purpose? These ones just ahead of the gear stick…   Well they are a mystery no longer. They are for throttle linkage. So the linkage is bolted between the chassis and the engine… Are you wondering what happens as the engine rocks around on its rubber mounts? It doesn’t rock around. There are no rubber mounts. The engine is bolted solidly in the chassis. I guess in the late ’30s the definition of the word ‘comfort’ was having a roof on the upper saloon. So what condition is it in? Well the shaft that the roller runs on has a slight notch in it.   It’s 1/4 inch diameter so we’ll need to make a new one. I’ve put the roller on a 1/4 inch drill (thats the only thing I have of the right diameter) and it’s not too sloppy to be honest. A new shaft and a blob of grease and I reckon it’ll be fine. The next problem is that somebody cut the top off the forks that hold the roller.   Yet another problem is that the arm has been broken in two places and brazed back together.   And just to cement the problems it was brazed back together with a twist in it.   Yeah… That might be a problem. First off a good trip through the sand blaster to clean it up and see what it looks like.   Let’s have a closer look at the fork that carries the roller.   I guess somebody cut it off to stop it dragging on the back of the pedal as the shaft wore down. Shame they’ve been a bit excessive and actually cut it through the shaft hole. Can I blob some MIG on the top and reprofile it? I reckon this is a cast steel maybe? And it’s likely to be a dirty steel that’s going to contaminate the weld pool. I’m expecting this to weld like i’ve forgotten to turn the gas on. Suck it and see as the bishop said to….. Moving along.   I jammed a bit of copper in the fork so I didn’t have to worry about that side and… I was wrong. It’s lovely stuff and welds really well. After a bit of profiling it’s looking ok.   I mean it’s not the neatest bit of reconstruction I’ve ever done but it’s functional and it’s under the throttle pedal so you can’t see it. I’m happy with that. So, if need be we could reweled where it was broken and take the twist out. Except it’s been brazed and the braze will contaminate the weld. Hmmm. What we will do is fit it to the bus and offer the pedal up. Then we can make a judgement as to whether the twist is a problem. If it is then we can consider redoing the braze or trying to clean it up and welding it. I’ve not got the gear to braze it so it’d have to go off with Ian. There is another possibility that there may be a serviceable part on what’s left of GKE 65, the sister bus that was converted into a truck. But that’s miles away so not too convenient to go and look. One last thing… The Friends of Chatham Traction want to have a push to screw this old girl back together and take it for a ride. It’s near Maidstone in Kent. Are you handy with spanners and want to get involved? You’ll almost certainly get to meet the superstar and social media mega influencer that is me. What more could you wish for? Well there is more! You’ll also get to lie in a puddle of engine oil ‘cos the sump plug is leaking. If you are interested in helping then let me know. It’d be lovely to meet some of you. James |

| |

|

|

|

|

|

|

|

Jul 31, 2022 19:38:10 GMT

|

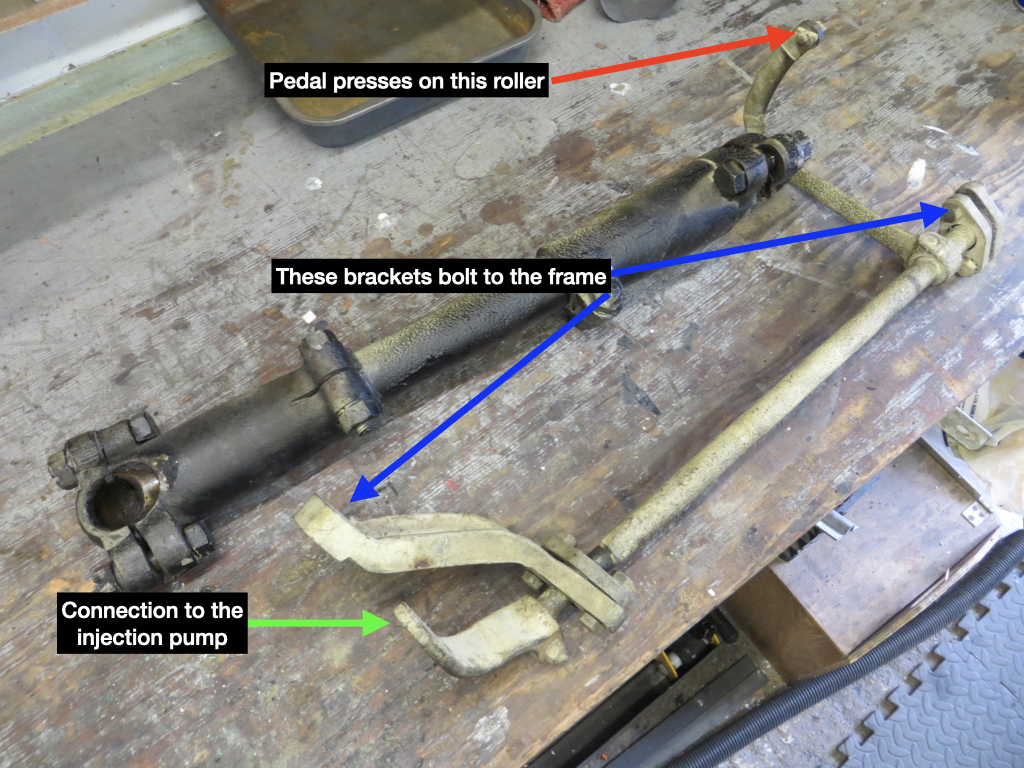

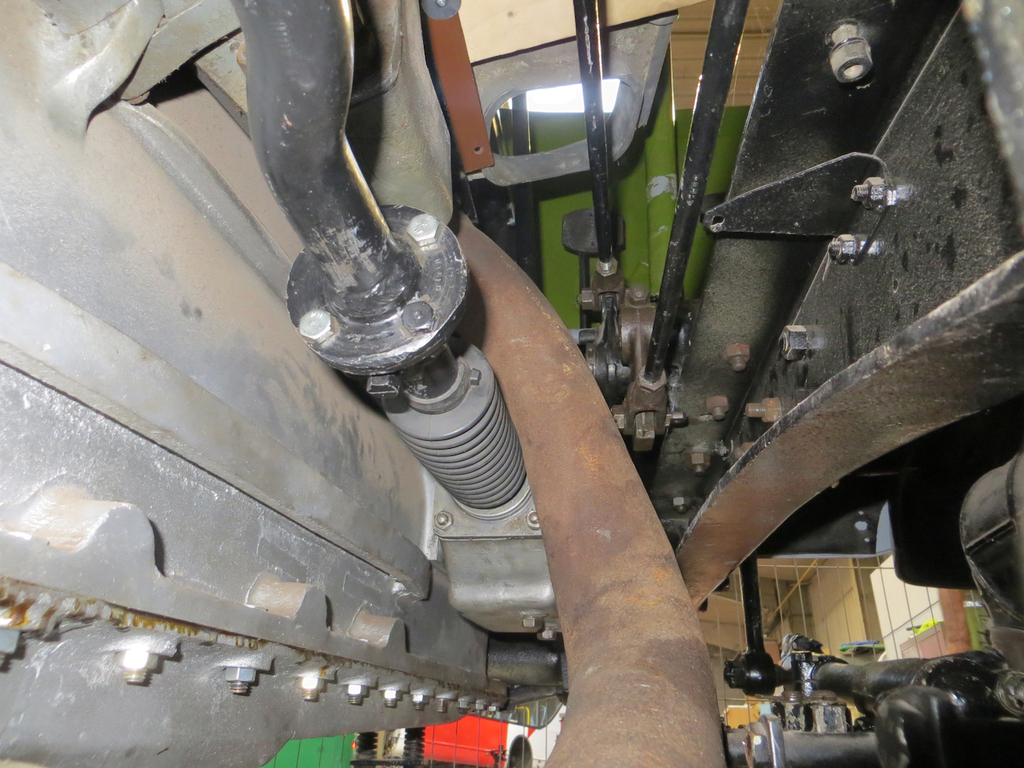

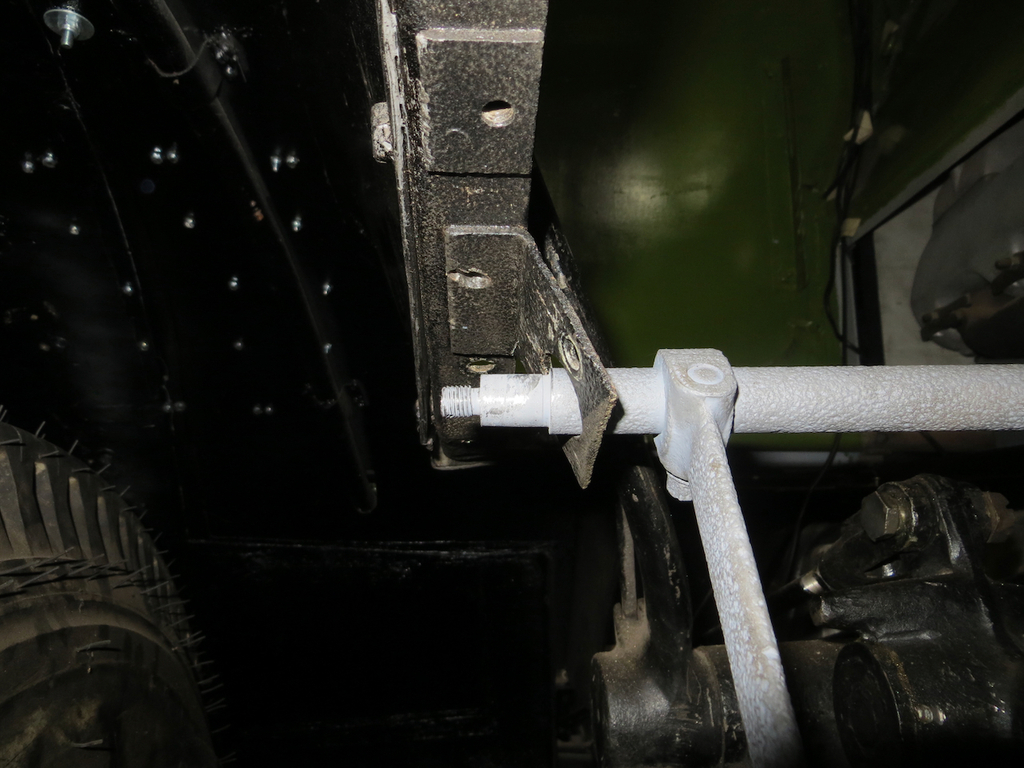

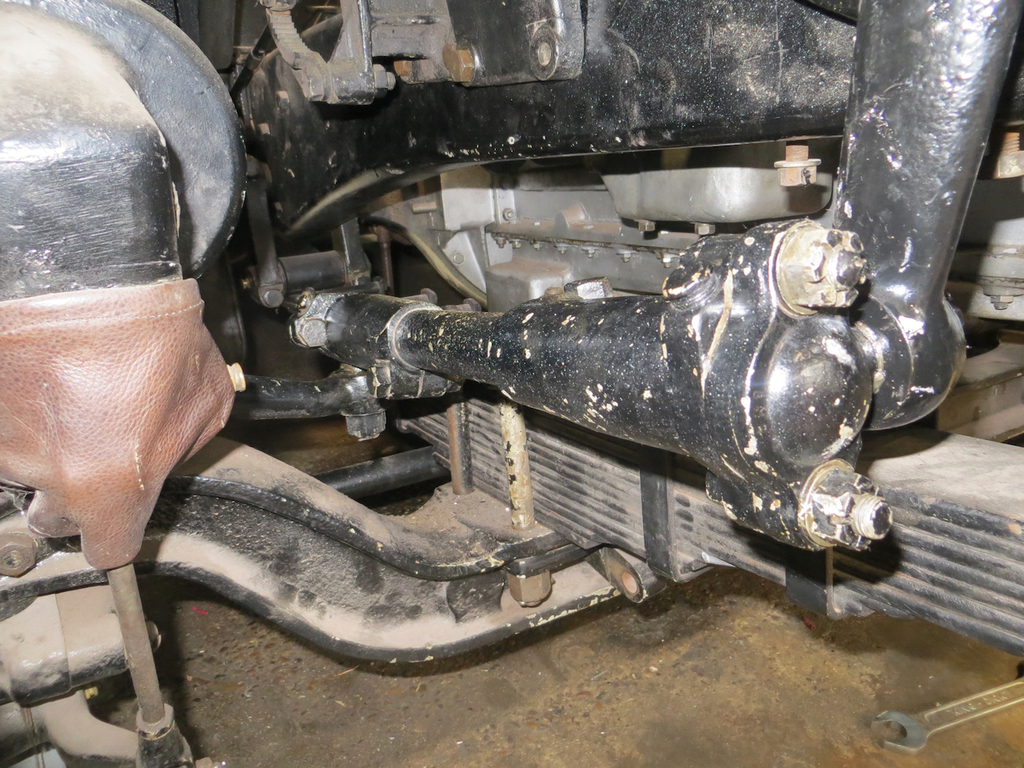

Well I have to say I’m a little disappointed. I give you a once in a lifetime opportunity to lie on a concrete floor in a puddle of bus dribble and the response is, er, well, less than I’d hoped for. Are you men or mice? I say ‘men’ and I’m making a slight assumption that there aren’t that many women reading this. However I did invite a female friend of mine to come and spend some time working on GKE. Haven’t heard from her for a while… Anyway, I’ve been back. First job was to refit the steering drag link that I’d had at home.   You are quite right I’ve not fitted the split pins. There are quite a few bolts missing around the pedal assembly so we are going to have to go through the whole lot and check it. This is more about making sure we have all the bits and that they all fit. Of course I needed to tweak the link positions to get it to fit so I had to pop the steering wheel on… Honest, I really did.   Whilst I was doing that Ian was working on the exhaust. Look, I have a photo of him!   I still don’t know what he looks like. Next on my list was to fit the throttle linkage. It’s only four bolts. That won’t be difficult. Yeah right. Essentially it has to go over studs at one side and through a fixed bracket at the other. You could do one or the other but not both. I have no idea how they got it out. I think they bent the bracket. Anyway, Ian came up with the answer - remove the studs (which weren’t perfect anyway) and use bolts instead.   This got it in but it’s really tight between the engine block and the bracket on the chassis. It barely turns, and when it does it’s spinning the spherical bearings in the holders. Here’s the bracket.   The bracket and the structure it’s fastened to is original but the structure further back is new. I’m guessing when it was rebuilt it’s not quite in the right place. Sadly it’d be a piece of cake if it was marginally slack, but marginally tight is going to be tricky to fix. The bracket was a little bent, I’m assuming it was ‘pushed out of the way’ to get the linkage out. So I took it all to bits and then spent half an hour thumping it with hammers. It’s flat now and I’ve pushed it back a little but it’s still way too tight. Let’s come back to that. The point of doing this is to offer the pedal against the twisted linkage to see if it’s a problem. The pedal is connected to a piece of floor.   The gear stick goes through the hole on the left and the handbrake through the hole on the right. So let’s drop that over the levers and see what it looks like. Er, no. Let’s not. You see that would only be possible if the handbrake and gear stick were parallel. They aren’t.   If you hook the floor over the handbrake the gear stick hole misses by about a foot. So the only way to fit the floor is to remove the gear stick from the top of the shift box. Remember we had a problem with gear selection? While I was stuck in Oslo Ian had another go at it and got it working. But we needed to double check that it really was working and bolt everything up before doing anything else. It did work really nicely and I spent the next little while bolting it all together properly. We’ll do the floor next time. Ian pretty much got the exhaust on.   Look, it’s a sports bus with side pipes…   There is a small problem… Remember I put a rubber bellows on the gear selector output shaft? It’s not going to survive.   I think we might be cutting that off. As a last treat, while I was working in the cab the fully adjustable drivers seat was getting in my way so I wanted rid of it.   Judging by the electrical cables at the side of it I assume it’s power adjusted. I’ve also heard that it’s heated. But only by the drivers bottom when he sits on it. Again, not wishing to make assumptions about the sex of the drivers but I guess in 1939 the bottom would have belonged to a bloke. That said, when all the men went off to fight for the glory of King and Country (a rather strange phrase that I mentally translate as “went off to get shot”) did they bring in women bus drivers? I’ve never heard of it happening but I can’t see why it wouldn’t. Does anybody know? Back in the ’80s I knew a very slightly built lass called Yvette who did many hours in the cab of Lodekka. That had the advantage of a semi-automatic gearbox but it did not have power steering. She managed just fine with it despite looking like she’d blow away in a stiff Yorkshire breeze. Anyway, the point was that in order to get the bolts out of the seat I had to drop the electrical box.   Which gives us a chance to look inside it.   I think the big black thingy is the regulator for the dynamo. I’m guessing we’ll have to work through all this lot and make sure it’s ok before we wire it up. Just at the moment the switches hardly move. But that might just mean I need to be a little bit firmer with them. A bit more ‘Yvette’ and a bit less ‘James’. James |

| |

|

|

|

|

|

Jul 31, 2022 21:39:33 GMT

|

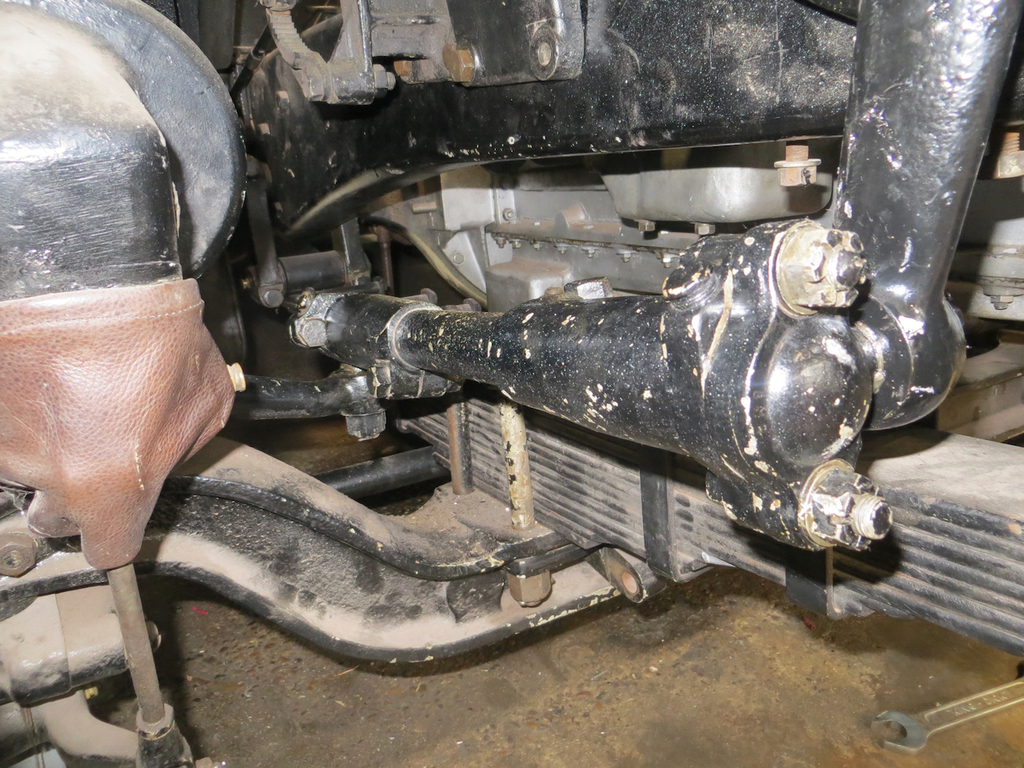

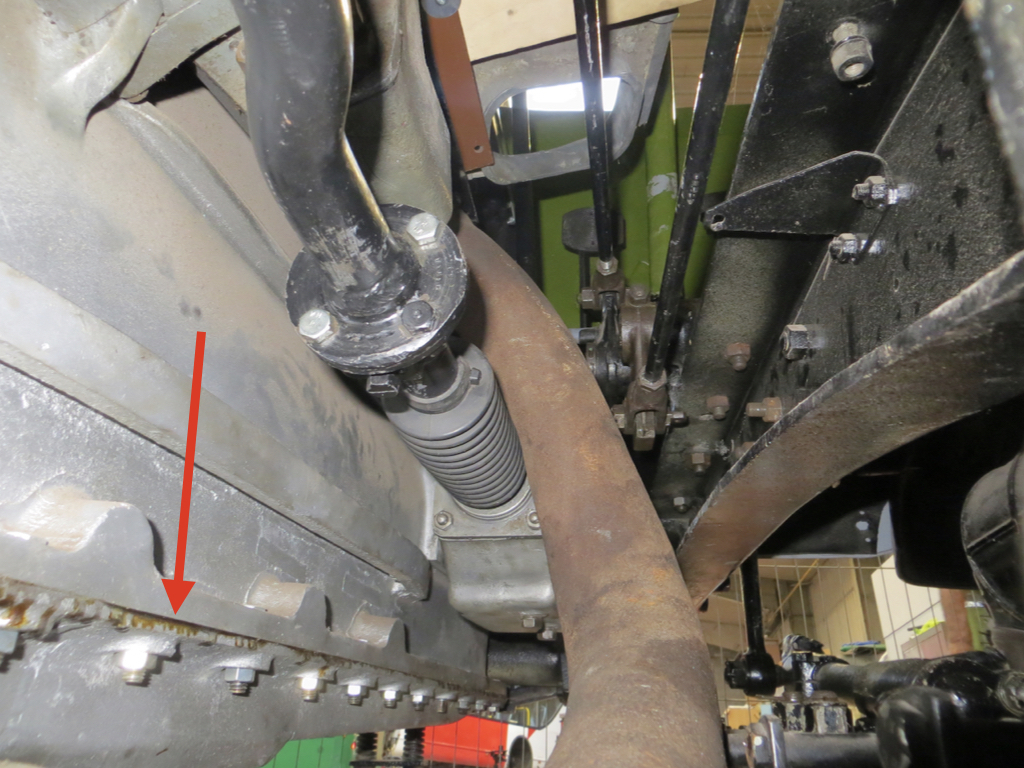

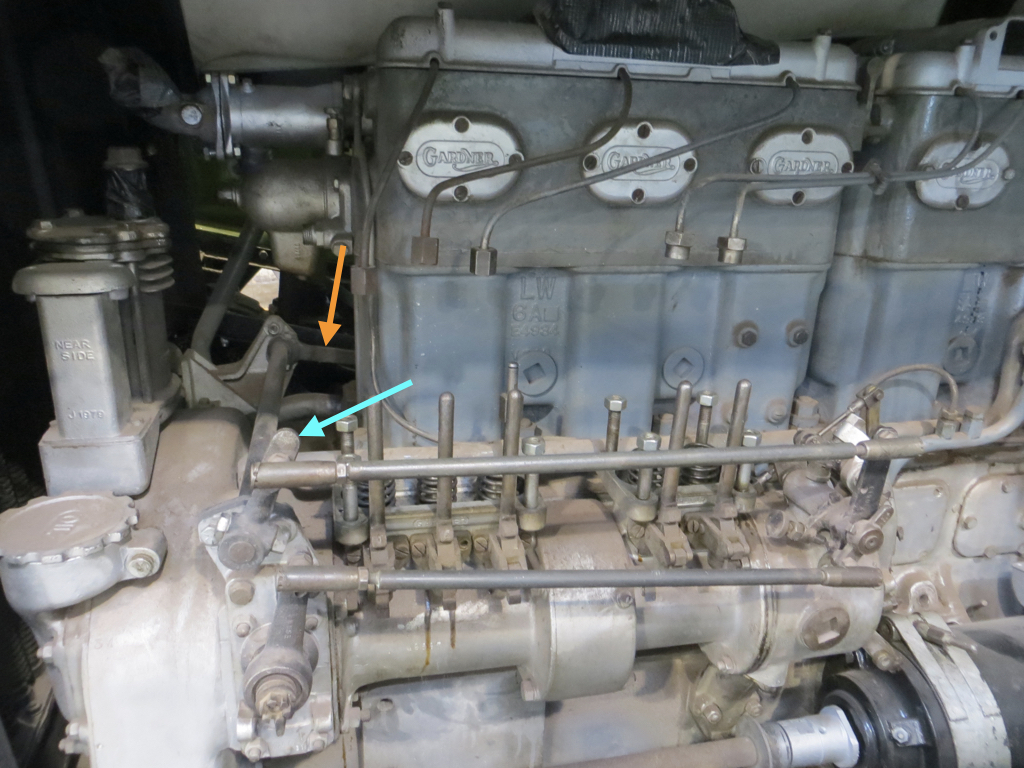

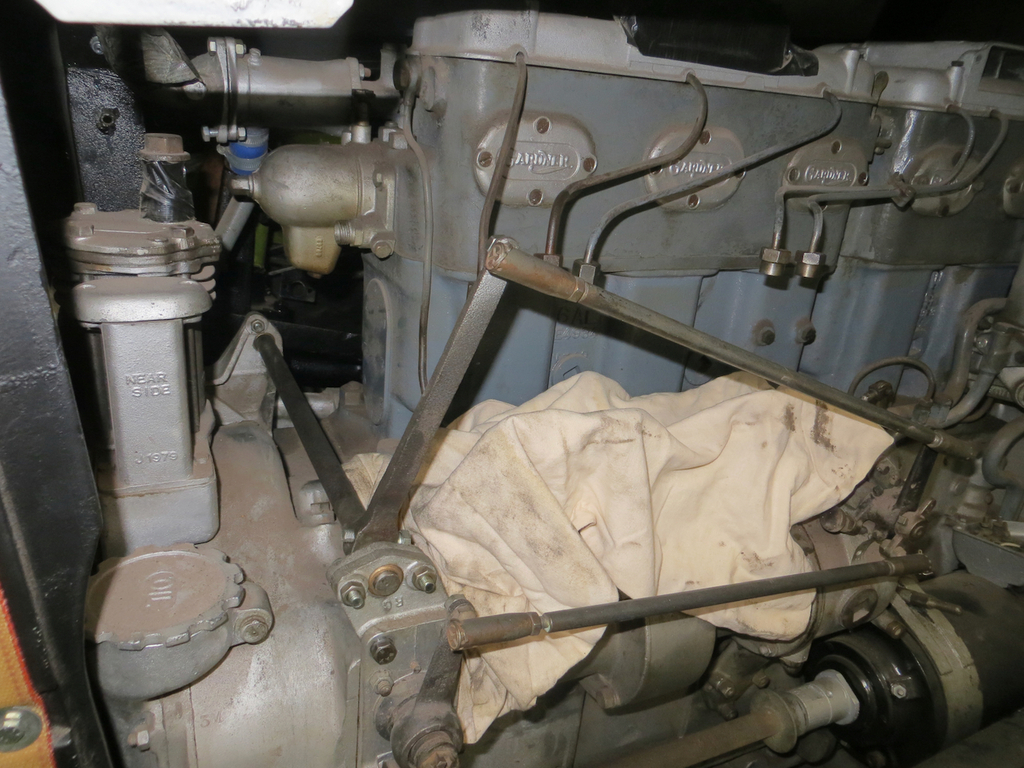

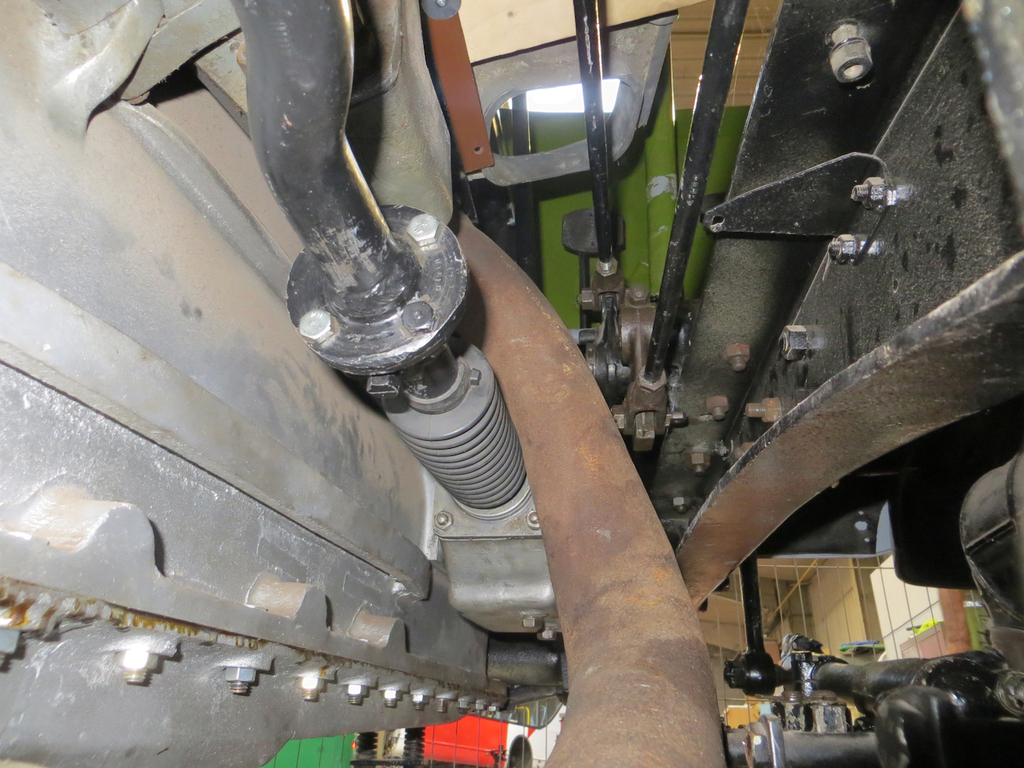

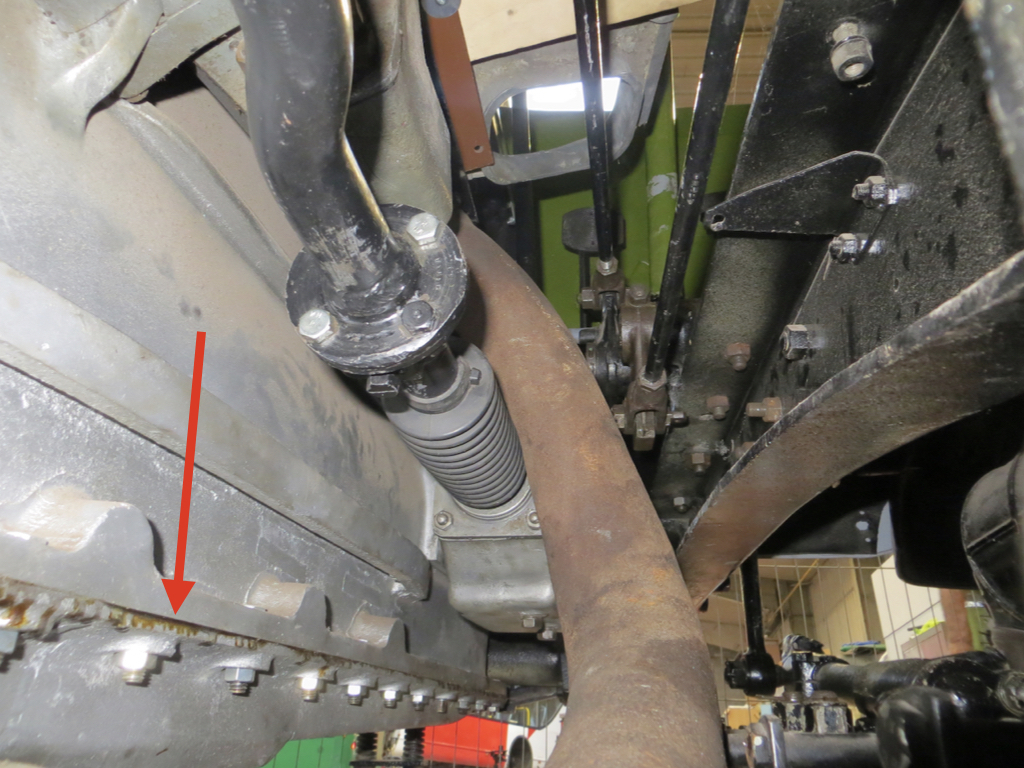

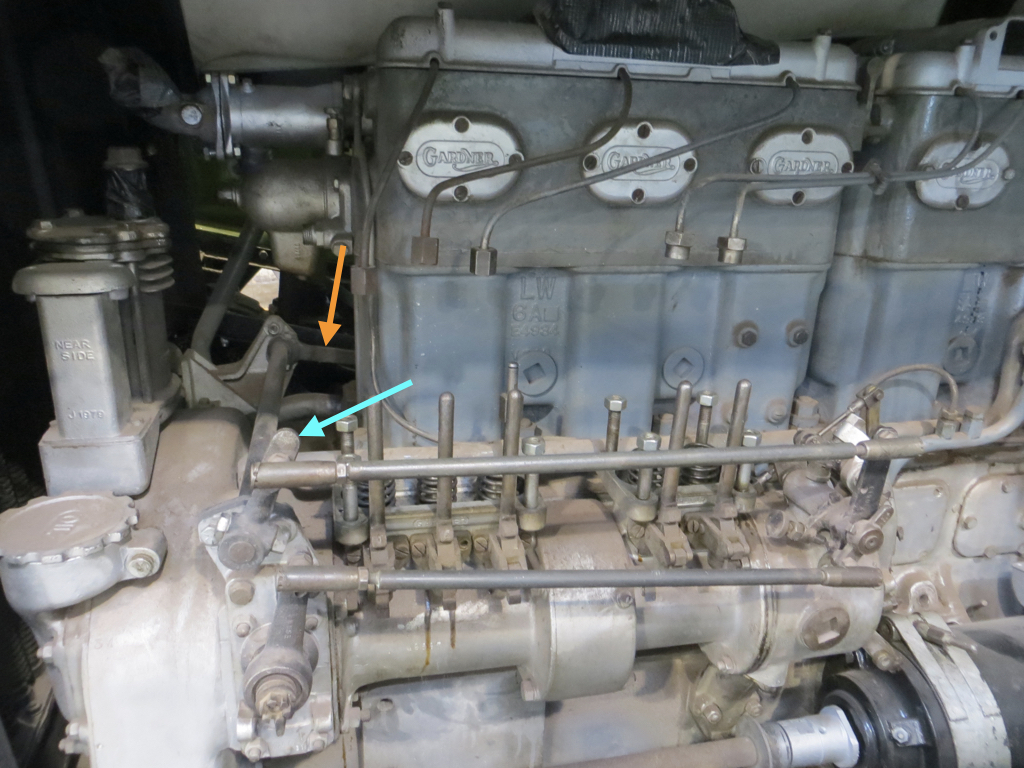

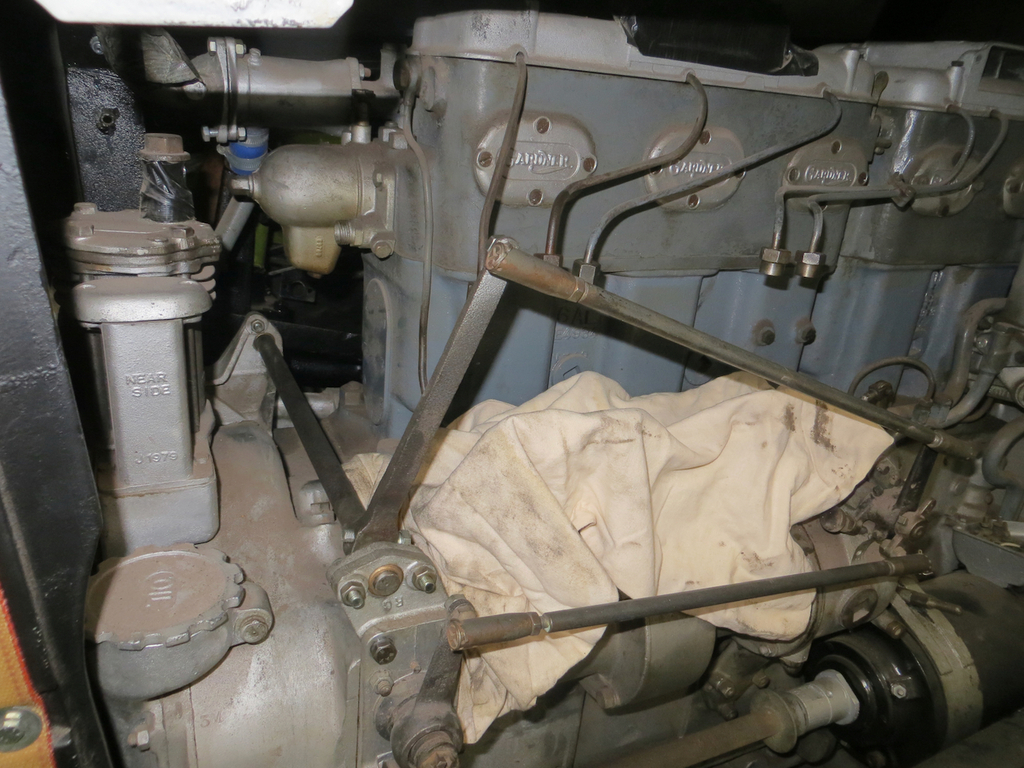

Captains Log - Supplemental. Star Date - Last Friday I reckon. I realise that I’ve not told you where the old lass is. Well she’s in the corner of a working bus garage belonging to Nu-Venture. Apart from the few years she was at South Eastern Coachwork this is where GKE normally lives. Interestingly NuVenture have painted a couple of their vehicles in Chatham Traction colours over the years. Click the linky and Google will furnish you with some photos of them. Nuventure bus in chatham traction coloursI didn’t pinch one and reproduce it here ‘cos these aren’t my photos. Nu-Venture is, I believe, part owned by and run by a chap called Norman. I’ve met him a couple of times although I doubt he knows me from Adam yet. Anyway, I was watching the local news a while back and Norman was being interviewed. He was commenting on how the local council has pulled another load of bus routes because they can’t afford to run them. Before you get the wrong impression of me I need to say that I wouldn’t normally be caught watching the local news because, well, because I know how to turn the TV off. But this day, due to a tragic miscalculation, I saw a bit of it. “Oh look” I said, “that’s Norman on the news!” “Who’s Norman?” asked Mrs Sweetpea. Anyway I bumped into Norman on Friday and asked about his interview. “Yes”, he said “The cuts won’t affect us too much but it badly affects the people that depend on those services. We are working on plans to try and get some of those services back.” So there you go, Nu-Venture, not only supporters of GKE 68 but also running buses for the right reasons. While we’ve been pondering the throttle linkage Ian realised that the rack on the fuel pump is seized. The rack slides in and out (or it should do) to alter the amount of fuel injected. The pump is split into the top and bottom. In the bottom is the cam and lifters and the top meters the fuel and pushes it into the injectors. So Ian took the pump top off ready to go away for fixing.   When Ian removed the pump top he found the bolts weren’t tight. Hmmm. Apart from this another problem has shown up… The throttle linkage that I’ve been working on connects to another linkage that runs across the front of the engine.   In other words, the red arrowed bit connects to the yellow arrowed bit. How exactly? And, as it stands, the long ‘yellow’ arm is hitting the water manifold. An old photo of GKE has been found showing the engine side.   This shows the long ‘yellow’ arm on the nearside of the engine. We have it on the offside so that bit has been assembled incorrectly. Yeah… When we were bolting the exhaust down pipe to the manifold it turned out that the intake and exhaust manifolds are rattling around too. Hmmmm… Ok, another thing. This puddle of oil on the floor that I keep rolling around in. I think I said it was coming from the sump plug, but look at this photo again.   It’s actually leaking from the oil pan. The bolts that hold it to the block aren’t tight either. It seems we have some work to do before we try and start it and it throws nuts and bolts all over the workshop. Until then I stole a couple of plant pot saucers from Mrs Sweetpea to catch the drips. Hopefully we’ll then be able to mop up the floor and I won’t have to wash my hair five times to get the oil out of it. I told Ian. “Ian, I stole a couple of plant pot saucers from Mrs Sweetpea to catch the drips. Hopefully we’ll then be able to mop up the floor and I won’t have to wash my hair five times to get the oil out of it.” Ian gave me a silent look but his face was clearly saying, “If you are going to play with vintage buses getting oil in your hair is rather unavoidable.” I gave Ian a silent look back saying, “One drives a Lexus don’t ‘cha know. Pip pip old chap! What ho!” James |

| |

|

|

|

|

|

Sept 7, 2022 21:55:00 GMT

|

Another day in Maidstone another day spent doubled up in the cab of GKE68. You know, it doesn’t look like anything has changed. In fact I think we’ve taken even more bits off rather than putting them on. We do, however, have a plan. Where shall we start our story? Let’s start in the middle. It’s less complex than the beginning. I’m not sure how I’m going to write the beginning so starting in the middle seems like a good beginning. Are you keeping up? As we have the gear selector working I needed to tighten all the nuts. One of them was inaccessible because the exhaust down pipe was in the way. We only put it on last time and it’s already in the way. So I loosened the downpipe and the manifolds enough to wiggle them out of the way of my nuts. You know what I mean. Except… The manifolds were already pretty loose.  Here’s the question… If the manifolds were never properly fitted do they have gaskets on them? Even if gaskets had been fitted GKE has been dragged around Kent a few times and they could well have just dropped out. Well, with the manifolds slightly loose I could almost get my finger up the back and couldn’t feel any gaskets. Hmmmm. Ok, let’s just take them off and find out for sure. It’s only 5 nuts and spreader bars to remove them.  Oh, and half the cab interior also has to come out. I couldn’t be bothered with that and they did slide back far enough to do a proper inspection. Indeed two of the exhaust gaskets fell out.  The other three were still in position. And there are no inlet gaskets. So how, I hear you ask, do you prevent gaps between the inlet and the head from sucking unfiltered air in? Well, remember it’s a diesel so there is no throttle and no inlet vacuum to worry about. No turbo either so no pressure deal with. But also, in 1938, Gardner had a novel way dealing with the potential issue of unfiltered air getting sucked in through gaps in the manifolds. They just didn’t fit air filters so it didn’t matter. The inlet comes over the rocker covers. Well, while trying to bolt it back together I noticed that the rocker covers aren’t tight either. The bolts are bottomed in their holes and haven’t touched the covers. Great, another job for another day. We'll do the first part of the story in the next post. Or maybe the last part... What do you reckon? |

| |

|

|

|

|

|

Sept 8, 2022 16:30:35 GMT

|

|

I reckon the export models sent off to the antipodes would have air filters.

Just because of the word antipodes.

Then there's a need for gaskets. But, in the podes of Coventry the peons and proles don't need that.

You're making good progress, even if you have to disassemble the entire Meccano set each time a bolt needs tightening.

Phil

|

| |

|

|

|

|

|

Sept 9, 2022 19:33:22 GMT

|

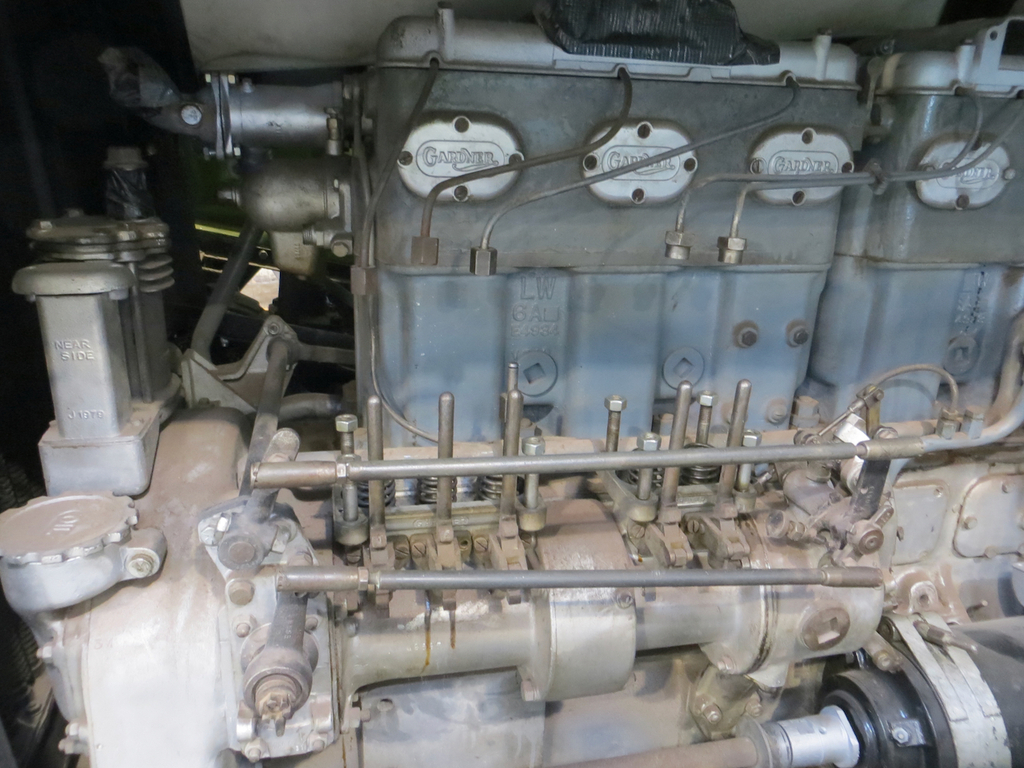

You're making good progress, even if you have to disassemble the entire Meccano set each time a bolt needs tightening. Phil Given how big the thing is it's surprising how tight space is. There is a long twisting vacuum pipe to fit soon and I do wonder how much we'll need to take off to get it in. Probably nothing, it'll just drop in. There is obviously provision for air filters. It breathes through these openings cast into the rocker covers...  I've seen photos where an elbow is bolted to those intakes with a pancake air filter on the top. And there is space under the bonnet to fit them. They just weren't fitted. Clearly they were not thought to be important in the UK. Interesting thought about export models. I'm not sure if Bristol had much of an export market. Bristol got merged into Leyland Buses eventually and I know Leyland put a lot of effort into exports. I'm not sure if Gardner sold abroad either. I do remember reading that Gardner engines were in short supply at times but that could have been because they were flogging them all abroad. I might have to read up about Gardner. They were ubiquitous, the engine of choice for many commercial vehicle, industrial, and marine applications. And then in a fairly short space of time completely failed to exist. |

| |

|

|

|

|

|

Sept 9, 2022 19:41:52 GMT

|

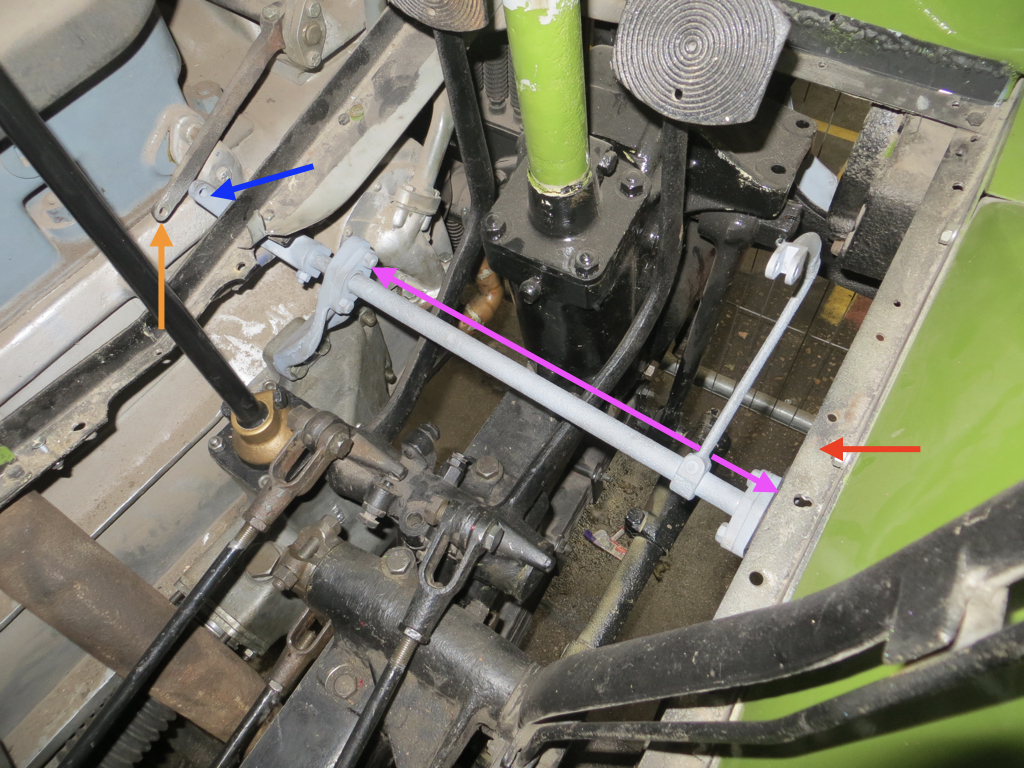

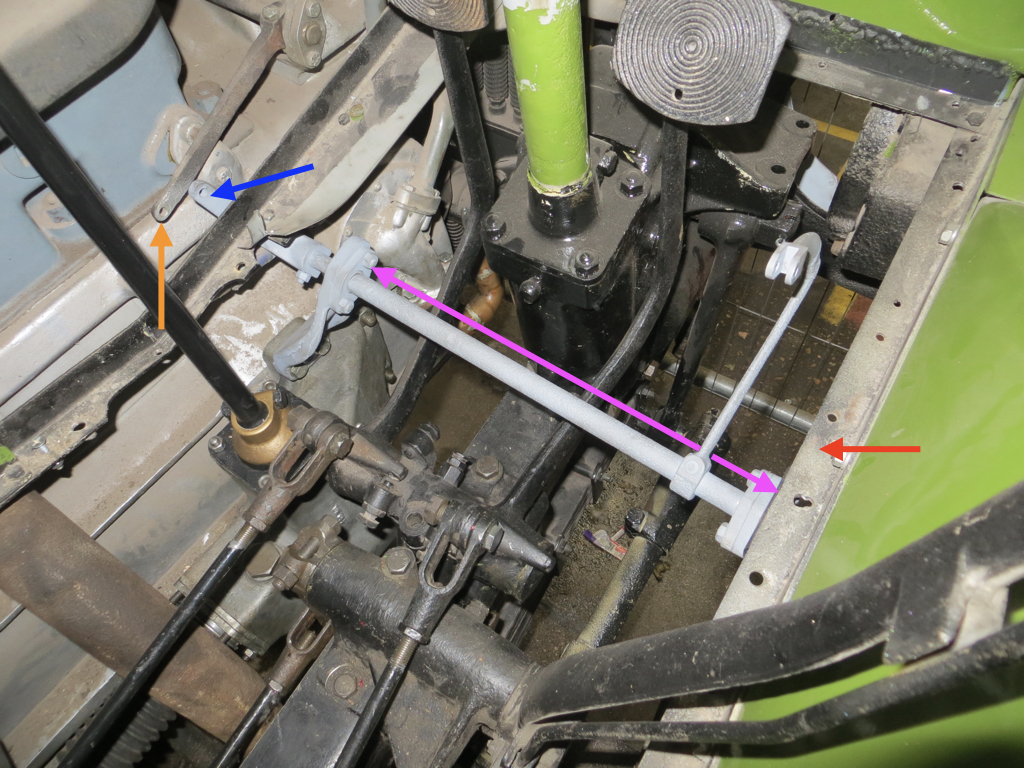

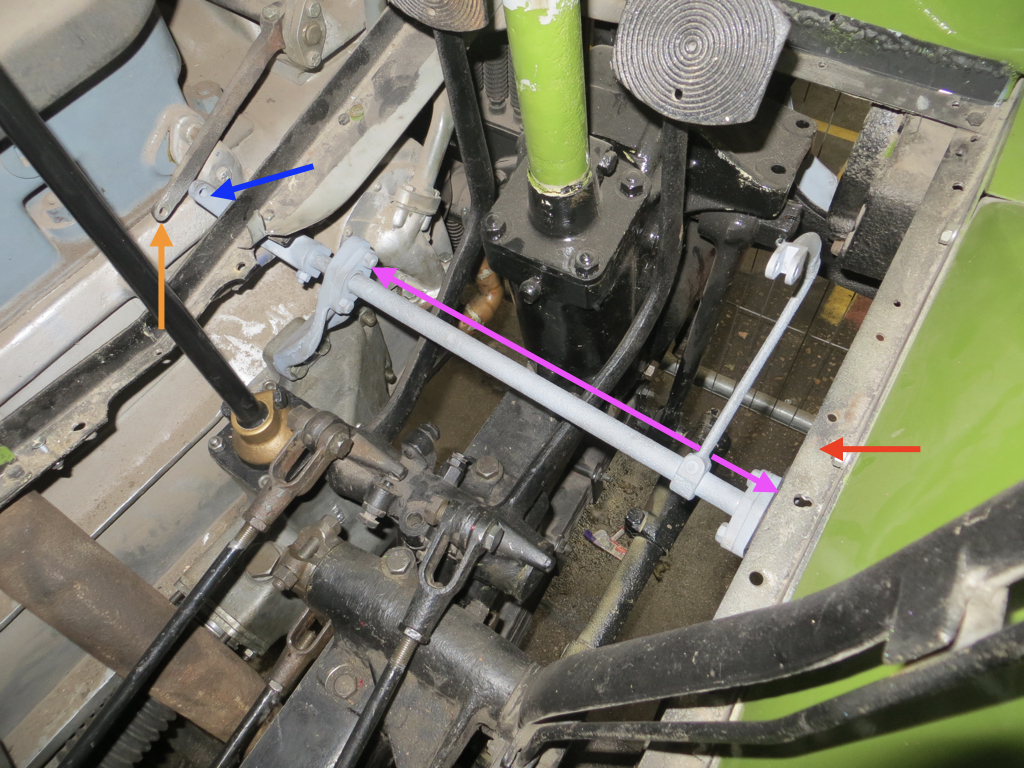

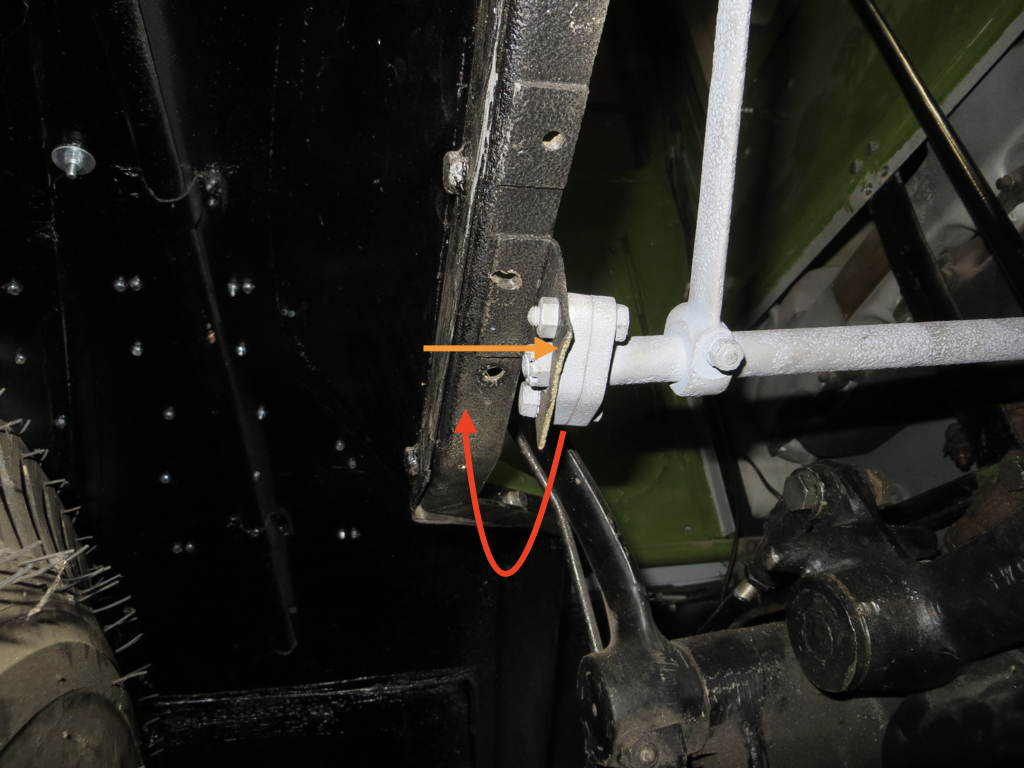

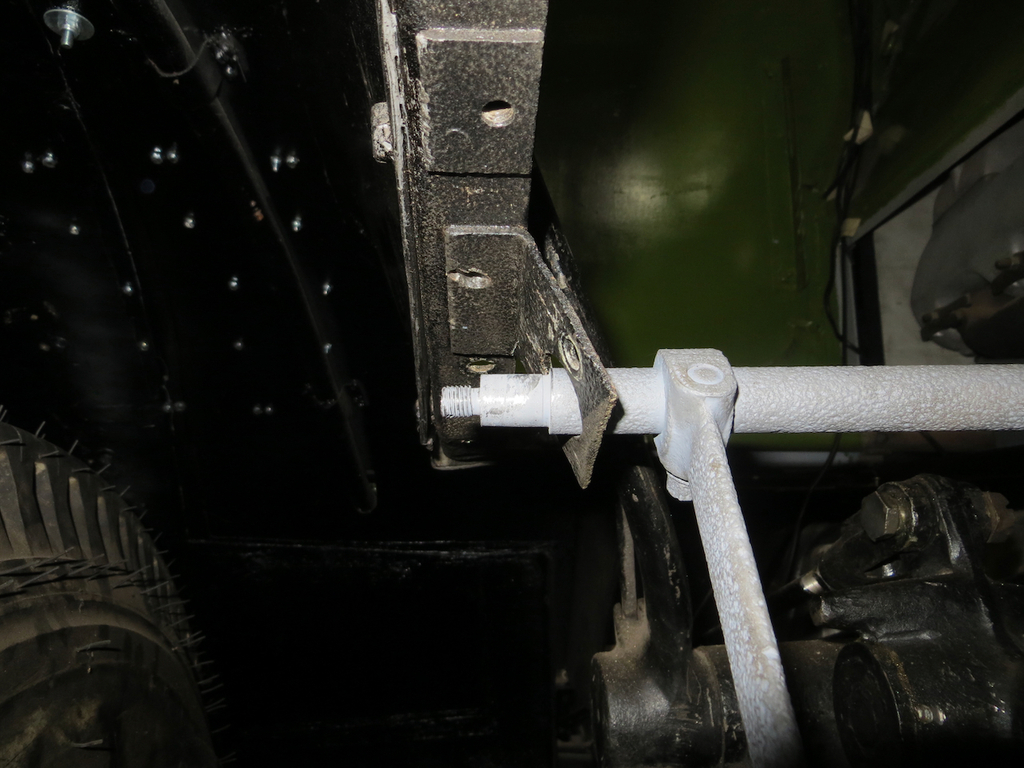

Now we’ve done the middle of the story lets go back to the start. Tell you what, let’s go beyond the start and remind ourselves of last time out. Here’s a photo of the cab and the problems.  When I put the throttle cross shaft in it was too tight across the cab. That’s the purple arrow. A lot of the wheel tub and supporting structure on the right of that photo is new and I suspect it’s slightly too far to the left where the red arrow is pointing. Only by 8mm or so but it’s enough to trap the cross shaft. I was sitting on the loo last week when I had a moment of genius. An epiphany. I do my best thinking while sitting on the loo. I’ve often thought that if I replaced my sofa with a toilet I could change the world. It’d quickly become uncomfortable so the world can stay as it is. Anyway the thought was this… The bearing block near that red arrow bolts to a bracket on the cab floor. If we move the block to the other side of the bracket and thump it over to the left a bit maybe it’d all fit together. Like this…  Bloody brilliant idea eh? Some days I surprise even myself. Sadly reality didn’t line up with my brilliance.  That’s not going to work. Let’s park that problem for a moment because there is something else to ponder. The cab floor in that region is a cast aluminium plate. If the opening is too narrow across that area the plate won’t fit in the hole.  Well it does, but it is very tight and the bolt holes don’t quite line up. So that confirms that the opening is a few mill too narrow there and explains why the throttle cross shaft is tight. Let’s also park that thought in our mental car park (or ‘thought park’?) and ask yet another question. The cab floor that fits round the pedals and steering column is actually a rubber mat. There is a hole in it for the throttle linkage to come through. Does this actually fit and does the throttle linkage actually hit the hole?  The answer is… Not really. As in it doesn’t fit and the throttle linkage doesn’t quite hit the hole. You can’t see the linkage as it’s behind the pedal but trust me, it’s less than perfect. And where the red arrow is pointing you’ll see a gap between the cab structure and the rubber mat. It actually doesn’t quite reach the front wall either. There is a good reason for this. Although the mat is out of this type of bus (I guess a K or L series) it’s not out of this particular bus. There is another odd thing about this mat. It doesn’t appear to have anything underneath it. It just bolts onto the frame. Now 80 years ago that was probably fine but it’s way too fragile these days so it needs something under it for support. So, to recap… The throttle cross shaft is too tight across the cab It doesn’t pop through the hole in the mat. The mat doesn’t fit in the hole in the floor. The mat needs supporting from below. So here’s the plan. Ian has cut the bracket that carries the end of the throttle cross shaft off the bus. He’ll either make a new one or modify this one. Then we’ll bolt it back onto the cab frame in just the right spot so it’s not too tight and so the throttle lever comes through the hole in the floor mat. Next time out I’ll take a load of cardboard and make a pattern for the hole where the floor mat doesn’t fit. I’ll cut that pattern into a piece of ply and then fasten the mat to it. That’ll fill the gaps and provide the necessary support. Good eh? It almost sounds like we thought about it. James |

| |

|

|

|

|

|

Sept 9, 2022 22:26:00 GMT

|

. I'm not sure if Gardner sold abroad either. I do remember reading that Gardner engines were in short supply at times but that could have been because they were flogging them all abroad. I might have to read up about Gardner. They were ubiquitous, the engine of choice for many commercial vehicle, industrial, and marine applications. And then in a fairly short space of time completely failed to exist. Gardner engines sold well all over (particularly in the commonwealth), they were/are well regarded for reliability. Unfortunately, like a lot of British industrial sectors, they didn't keep up with the competition. High powered, high revving turbocharged diesels from the likes of Cummins and Rolls Royce were out competing them for the domestic truck market. Trying to compete with the Swedes and European offerings, their engines didn't take well to turbos, quickly looking antiquated. (Look at a late 70s LX and it won't differ too much from your 30s one). They are in demand for marine applications still, and for years were used by showmen to power generators long after the lorries they were fitted in reached the end of their working lives. And they sound bloody lovely. |

| |

Last Edit: Sept 9, 2022 22:27:58 GMT by generallee

|

|

|

|

|

Sept 10, 2022 8:48:21 GMT

|

I was reading this last night... Gardner linkyIt basically says the same, that they were reluctant to move into turbo engines, lack of development, wouldn't meet the Euro emissions regulations, and so on. Sad really. I still struggle to tell the difference between our LW engine and the later LX. The most obvious thing being the injection pump. But you do get the feeling the LX was just an evolution of the LW. When the fair came to town and everybody was playing on the rides with the bright flashing lights, I was the sad git paying more attention to the Gardner gen set strapped across the back of the cab of the truck. Apparently I haven't changed much in the last 40 years! |

| |

|

|

|

|

|

Sept 13, 2022 11:51:16 GMT

|

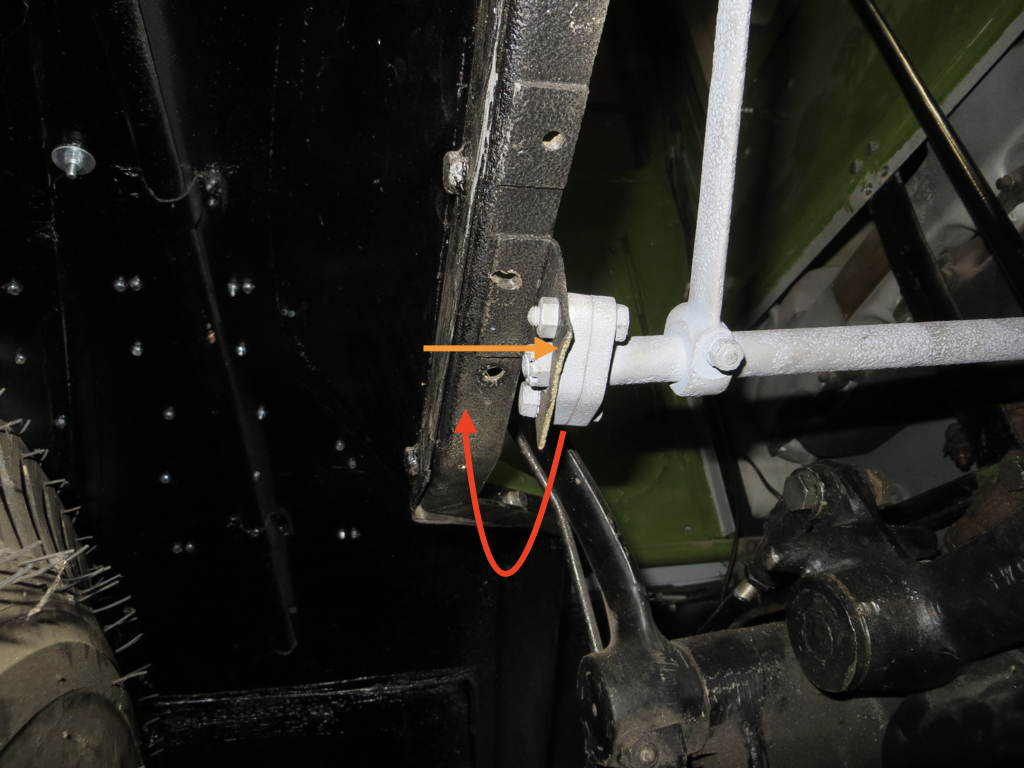

Now that we’ve done the middle part of the story first and the first part in the middle, and then had a diversion into other questions, I guess we should do the last part, er, what’s left? I do believe we should do it last. Back to that photo of the throttle linkage.  See the blue arrow on the left of the linkage? That’s supposed to connect to the bit with the orange arrow. Well that’s not going to happen. It turns out that the shaft that runs across the front of the engine is on backwards too.  So the long, orange indicated link should be where the short, light blue indicated link is and visa versa. But also it can’t possibly work with the arms at 90 degrees to each other. They actual need to be at 180 degrees. There’s only one thing to do at a time like this. We turned it round and put the arms on at 180 degrees to each other. You can’t quite see it but the one on the far end points roughly downwards now.  So here’s a question, how did somebody manage to get one of the arms on in the wrong orientation? I strongly suspect this is a question we’ll be revisiting shortly. Mostly because the linkage is in my garage where it’ll require some fettling. James |

| |

|

|

|

|

v8ian

Posted a lot

Posts: 3,828

|

|

Sept 29, 2022 17:56:21 GMT

|

Only, "Just Because" I have found it and its local me a M&D double decker in Hastings probably in the 60s before the town centre was pedestrianised.  |

| |

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

|

|

|

Sept 29, 2022 20:36:40 GMT

|

It looks like that roof panel has come into contact with a few branches, lampposts, and bridges  |

| |

|

|

|

|

|

|

|

So here’s a question, how did somebody manage to get one of the arms on in the wrong orientation? I strongly suspect this is a question we’ll be revisiting shortly. Mostly because the linkage is in my garage where it’ll require some fettling. Yeah, I did take the linkage home and I haven’t had the time to even think about it. It’s still on the bench exactly where I left it. Now this is only a problem in that Ian is back in Maidstone tomorrow so I’m going to have to take it back to get it all to fit and then bring it home again. Of more concern to us at the moment is that I also brought this back to tart up. I’d quite like to leave it with the bus tomorrow and that means I need to get all tarty with it.   Can ya tell wad id is yit? Oh, sorry, probably not supposed to quote Rolf anymore are we… I’ll tell you. It’s the thermostat housing. You can tell this because it’s still got the thermostat inside it.   In fact I think we can safely say that it’s in there forever. It’s not coming out. I hope it actually works. Best chuck it in some hot water and find out.   Phew! There is a good chance Ian already tested it. So I taped the openings up and chucked it in the home made media blaster.   Looks ok don’t you think? James |

| |

|

|

jimi

Club Retro Rides Member

Posts: 2,152

|

|

|

|

glass beads ? Looks great  |

| |

Last Edit: Oct 6, 2022 21:51:25 GMT by jimi

Black is not a colour ! .... Its the absence of colour

|

|

|

|

|

|

|

glass beads ? Looks great  Yep, glass beads. I have been known to put dried builders sand in it very occasionally but that way lies terrible lung disease so I generally stick with the glass. Edit... What I should do is get some proper more aggressive media but, like I say, glass bead does pretty much everything I need to do. |

| |

Last Edit: Oct 6, 2022 22:23:46 GMT by Sweetpea

|

|

jimi

Club Retro Rides Member

Posts: 2,152

|

|

|

|

I tend stick with glass beads as well, hard work with heavy corrosion but leaves a really nice finish on all the metals I've tried, also good for etching glass   |

| |

Black is not a colour ! .... Its the absence of colour

|

|

|

|

|

|

|

jimi , I've always wondered about etching glass but never had an application to do it. Well, accidentally I suppose, it makes a right mess it makes of the glass pane in the top of the blaster. I do have a question though. I guess you used a mask to protect the bits you want to keep clear. Where'd you get the mask? Or how did you create it? James

|

| |

|

|

v8ian

Posted a lot

Posts: 3,828

|

|

|

|

|

media blasting is the more modern way, can be problematic with tempered glass, the old fashioned was Hydroflouric Acid, some seriously dodgy sh-t, we used to use it for dissolving pyrex glass casting cores in magnesium, it would dissolve the complex cores but not attack the magnesium,

|

| |

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

jimi

Club Retro Rides Member

Posts: 2,152

|

|

|

|

the old fashioned was Hydroflouric Acid, some seriously dodgy sh-t Your not kidding, I steer well clear of that kind of stuff  I do have a question though. I guess you used a mask to protect the bits you want to keep clear. Where'd you get the mask? Or how did you create it? James James I use self adhesive sandblast vinyl to create a stencil. I cut it on an old Craft Robo cutter (basically a plotter with a cutting blade) you use a vector image to create a outline image using free software, once cut you have two options, mask the outline and blast the image (the glasses in my previous post) or mask the image and blast the background (pretty much the same technique I developed for my Jimi brackets) like this  It's possible to do the same without the cutter, originally I used to print the stencil, put 2" wide vinyl insulating tape on the job, stick the stencil to the tape then use a scalpel to cut out the stencil, takes time and much care, the Craft Robo is much easier once you get to grips with it and the software + you can use it to cut any type of vinyl for signs, logos etc If you are going to try it keep your air pressure low, 60/70 psi otherwise you may lift the vinyl, I found this out the hard way, and mask off everything you don't want blasted, those glass beads sneak in everywhere  I've used this technique successfully so far on metal (s/steel, brass, copper, aluminium) glass and various plastics. |

| |

Last Edit: Oct 9, 2022 15:58:06 GMT by jimi

Black is not a colour ! .... Its the absence of colour

|

|

|

|

|

Oct 16, 2022 19:41:13 GMT

|

Thanks jimi. For some reason I always imagined those cutters to be prohibitively expensive so never even looked into it. Actually they aren't too bad if you have a good excuse to play with one. I was talking to a friend at work last week and he pointed out that resin 3D printers are reasonably affordable now. The world is full of toys that need me to play with them. Just wish I had time. I damn well need to retire. |

| |

|

|

|

|