Tamber

Part of things

Shattered. Held together by spite and tape.

Shattered. Held together by spite and tape.

Posts: 340

|

|

|

|

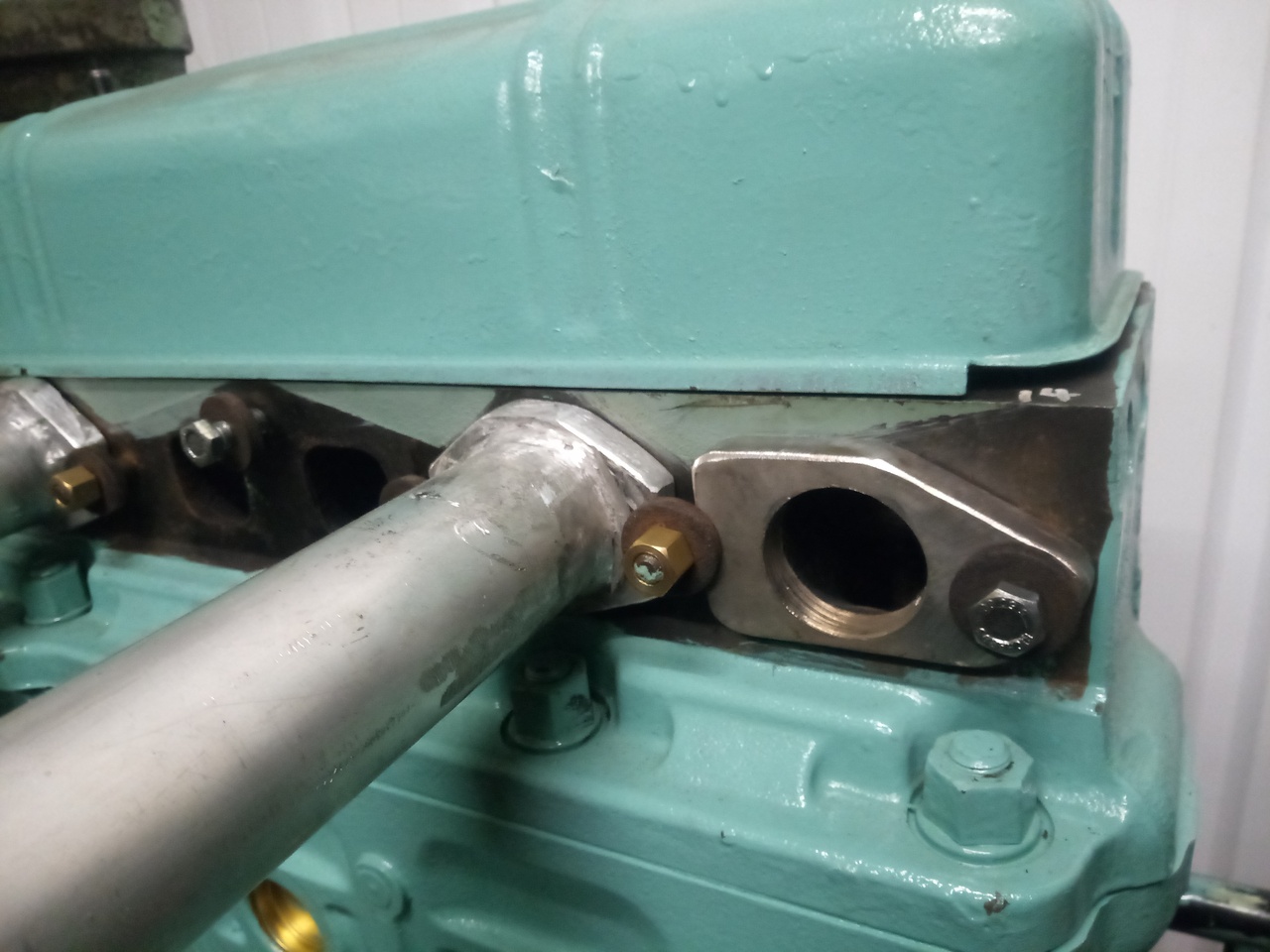

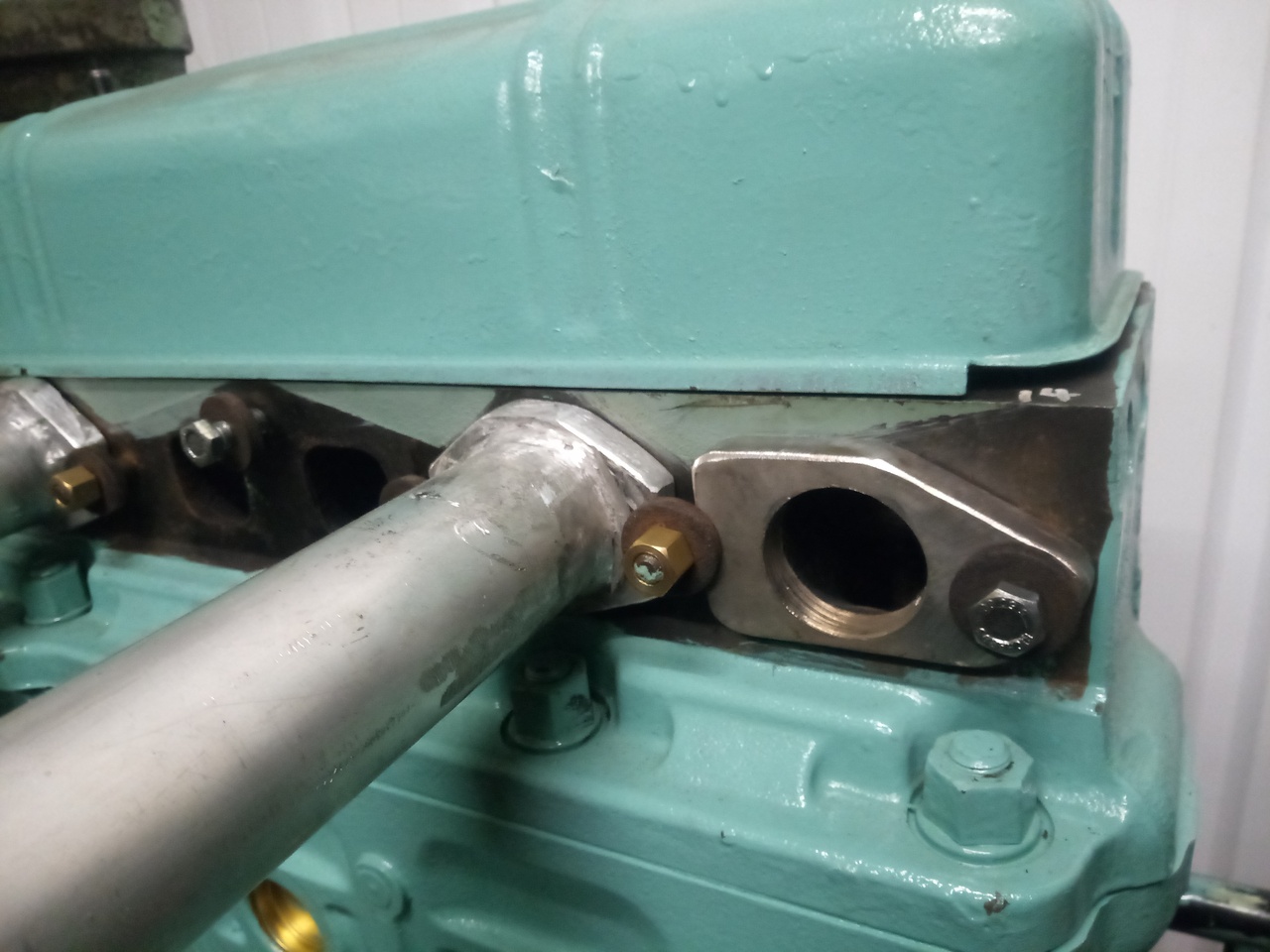

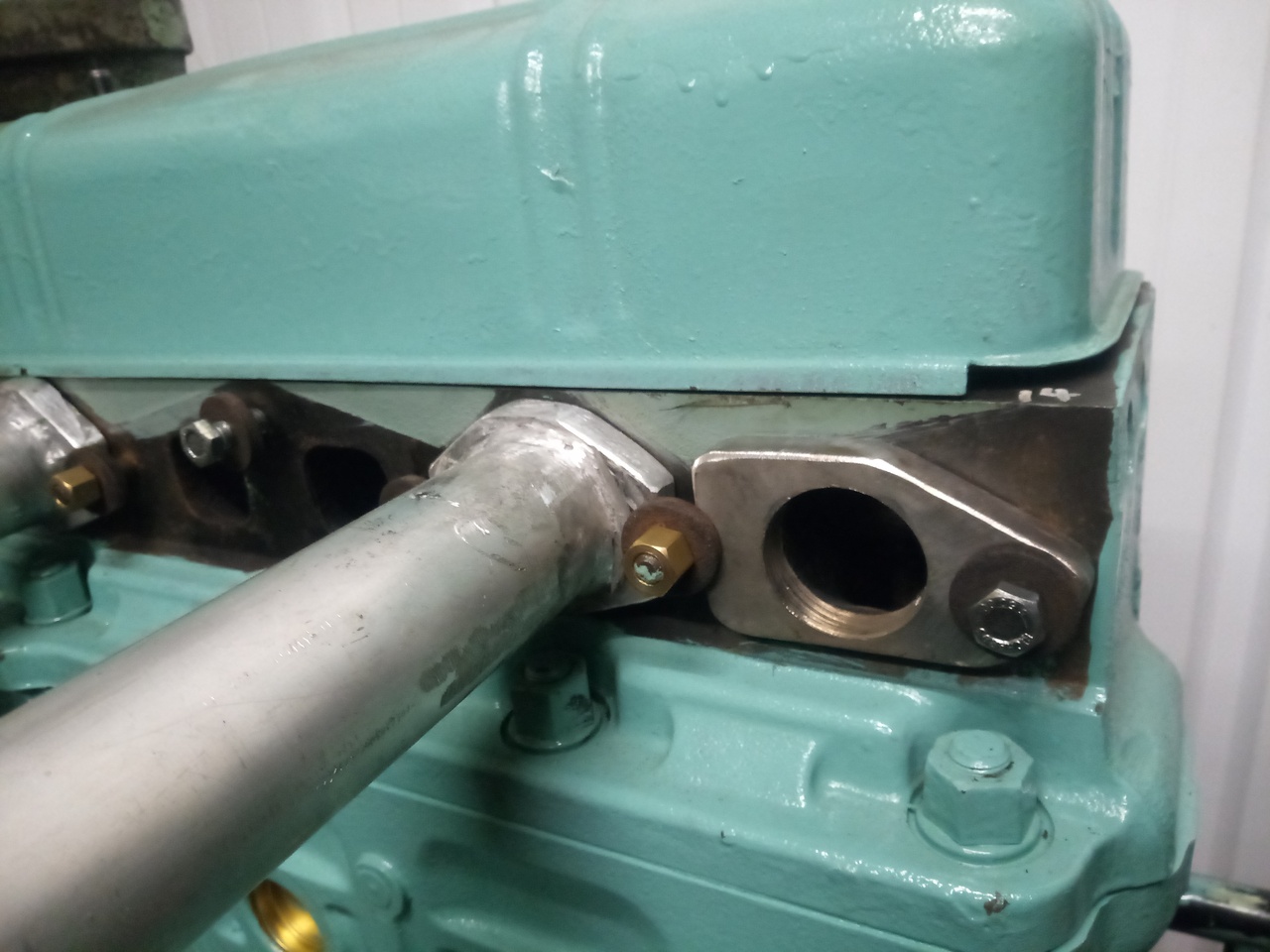

Yeah, at current prices I'd be expecting somewhere in the region of £150 just to fill the tank; and how far I can get on that still remains to be seen. At the moment, it's really good on fuel... doesn't use any!  Hoping to fix that by the end of the year, though. Anyway, what have I done since last time I posted? Sori, Bangor!  (Ond ddim mewn gwirionedd.)  --     Painty painty... -- Flush with Sky Blue success, I decided to put a hole in some stainless steel.   Which, with some angry-grinder action, comes out...  ...er... Wonky. Oh well, the second one came out much better, so I'll put the wonky one up on cylinder 1, then I don't have to look at it every time the engine cover's up. I also got some stainless steel elbows with which to start the exhaust manifold.  I got the wrong ones. That's a bit, er... racier than I would like! I only got two of them, though, and it's not like I'll never need a pair of 2" dia. stainless 90s. Right ones -- 1-1/2" dia -- ordered now. To be trimmed to length/angle as needed. But, of course, I'll need to get the engine buttoned back up, and the bellhousing & rear engine plate bolted up in order to know what I need to miss. I've got the stuff for sealing up the sides of the main-caps and whatnot; then I can get the sump back on, rebuild my little engine cradle and get the engine off the stand so I can put the bellhousing/etc on... oh, and ideally head out on my upcoming week off work so I can get a bottle of gas for the TIG welder... Don't think I'll be able to get the fuel injection stuff done by the end of the year; I don't work fast enough for that.  But if I can have a decent chunk of the exhaust manifold done, and have enough of the wiring done that I can run the ecu in ignition-only mode, then I'll fire it up on the carb. I am absolutely missing hearing that big six pot burble. Anywho! Onward, slowly~ |

| |

-< Welder. Allegedly a mechanic. Bodger of Things >-

* 1958? Bedford RL - Progress: Glacial.

* 1994 Skoda Favorit - It's baaaaaaaack!

* 2018 Herald Classic - Gone!

|

|

|

|

Tamber

Part of things

Shattered. Held together by spite and tape.

Shattered. Held together by spite and tape.

Posts: 340

|

|

|

|

Fancy screws!  For holding that lumpy bit on the bottom of there.  Another fine piece of work by the phosphoric acid! Bit of etch primer'll see that right.  Not sure how this ever worked...  Maybe I don't have the alternator bolted on correctly? ...but I think all the brackets are in the right place. I'll deal with it later. It needs a different pulley anyway; the one that's on there is for -- as best I can tell -- a Z section belt (10mm), and the truck takes an A section (13mm) belt. But I don't remember it being that far off before, and it never tossed/flipped the belt. Hm. Hopefully I've just got something assembled wrong.  Ah, so it was sky blue underneath the army standard gloss! Scrub, sand, etch-prime, grey primer, realise I painted the whole lot of it and the mating faces need to be bare metal, sand off the mating faces (durability testing of the etch primer, y'see.), and oops it just fell on.  And now, a brief time-travel interlude... And now, a brief time-travel interlude...If you'd just step into this police-box for a moment... no, it's okay, it's bigger on th... yes, quite. Anyway, if you'll just step into the police-box, you'll see the state of the flywheel back in 2019...  Quite grim, wouldn't you say? Anyway, if... 'scuse me... if you step back outside again...  Freshly resurfaced -- please pay no attention to the DA sander lurking just out of shot... I said, pay no attention to the sander behind the curtain -- and looking pretty good!  *ahem* *ahem*A very light clean-up with a 60-grit disc on the DA shows it to be in much better condition than it first appeared. The dark ring is noticeable under the fingers, but certainly not bad enough to warrant machine-work to the flywheel. I think a new clutch will bed in just fine on that. I've got a line on a new friction disc, and a NOS release bearing, so I'm pretty sure I can make this work.  And I also managed to confirm that -- somehow -- when I added additional timing marks (10, 15, 20, 25 BTDC) to the flywheel, I got them in about the right place. So that's nice! Next is: - Waiting on my next paycheck to land.

Lots of things to buy... engine oil, spark-plugs, plug terminals, thermostat, and other assorted bits. Lots of things to buy... engine oil, spark-plugs, plug terminals, thermostat, and other assorted bits. - Bolt the starter up. It still needs rebuilding, but that can wait. Right now, I'd rather it be in place so I know where I can't put the exhaust.

- Finish cutting out those exhaust flanges. Yaaaaaaay, more holesaw action...

- Odds and sods of gaskets, hoses, etc.

Oh, and I think I've come up with a solution to having a reverse-light switch that isn't just banged into the dash! It involves a little magnetic proximity switch, and drilling a hole in the gearbox casing. Should be entertaining. |

| |

-< Welder. Allegedly a mechanic. Bodger of Things >-

* 1958? Bedford RL - Progress: Glacial.

* 1994 Skoda Favorit - It's baaaaaaaack!

* 2018 Herald Classic - Gone!

|

|

|

|

|

Nov 26, 2021 12:09:28 GMT

|

|

Hi mate,

Good work on this.

One question,

What is the point of fuel injection? Is it for fuel consumption and performance? And wouldnt the gearbox/ diff's ratio's counter this anyway? (Sorry if I have missed any explanation)

Watching for more updates.

Steve.

|

| |

|

|

Tamber

Part of things

Shattered. Held together by spite and tape.

Shattered. Held together by spite and tape.

Posts: 340

|

|

|

|

38mm stainless tube, 38 mm stainless 90 degree pipe elbow.  Well, it's a start. Also, the bolts I ordered for the starter are wrong. Well, they're what I ordered, but not what I need. Starter bolts are 3/8UNC. I scrounged up some old ones temporarily just to hold the starter in place while I build the exhaust (and you see how well that's going.), and ordered some of the right bolts too. Also, not totally overjoyed with the box section I got for the inlet manifold stuff, now that I've sat there and stared at it for a bit. Seems a bit thin. Mm, we'll see. |

| |

-< Welder. Allegedly a mechanic. Bodger of Things >-

* 1958? Bedford RL - Progress: Glacial.

* 1994 Skoda Favorit - It's baaaaaaaack!

* 2018 Herald Classic - Gone!

|

|

Tamber

Part of things

Shattered. Held together by spite and tape.

Shattered. Held together by spite and tape.

Posts: 340

|

|

|

|

Hi mate, Good work on this. One question, What is the point of fuel injection? Is it for fuel consumption and performance? And wouldnt the gearbox/ diff's ratio's counter this anyway? (Sorry if I have missed any explanation) Watching for more updates. Steve. A bit of fuel efficiency, possibly a bit of performance out of having a bit better control over the fuelling but I'm not expecting miracles. And also I hate foxing about with carburettors.  I don't think the gearbox/diff ratios would make much nevermind, really. They are what they are. |

| |

-< Welder. Allegedly a mechanic. Bodger of Things >-

* 1958? Bedford RL - Progress: Glacial.

* 1994 Skoda Favorit - It's baaaaaaaack!

* 2018 Herald Classic - Gone!

|

|

Tamber

Part of things

Shattered. Held together by spite and tape.

Shattered. Held together by spite and tape.

Posts: 340

|

|

|

|

Drilled a hole in the gearbox, today, for a reverse light switch. Then I drilled another one, in the right place.  Measure three times, still cock it up, and all that.

Anyway, now I just have to make up a little retainer plate to hold the switch in, and cover the hole I drilled in the wrong place. I might even tap some threads into that hole, just so it looks like it's actually for something, in case anyone ever looks in the future.  |

| |

-< Welder. Allegedly a mechanic. Bodger of Things >-

* 1958? Bedford RL - Progress: Glacial.

* 1994 Skoda Favorit - It's baaaaaaaack!

* 2018 Herald Classic - Gone!

|

|

glenanderson

Club Retro Rides Member

Posts: 4,353

Club RR Member Number: 64

Member is Online

|

|

|

|

|

Tap a thread in it, then wind a suitable grub screw in with a bit of loctite. No one will ever know. It’s not like it’s on the internet or anything. 👍😀

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

Frankenhealey

Club Retro Rides Member

And I looked, and behold, a pale horse! And its rider's name was Death

Posts: 3,882

Club RR Member Number: 15

|

|

Dec 11, 2021 13:49:58 GMT

|

Tap a thread in it, then wind a suitable grub screw in with a bit of loctite. No one will ever know. It’s not like it’s on the internet or anything. 👍😀 Don't listen to that glenanderson with his techno-solutions. You need a REME quick fix, whittle a stick to nearly the right size and wallop it in with a lump hammer. Proper job  |

| |

Tales of the Volcano Lair hereFrankenBug - Vulcan Power hereThe Frankenhealey here |

|

Tamber

Part of things

Shattered. Held together by spite and tape.

Shattered. Held together by spite and tape.

Posts: 340

|

|

|

|

Picked up a couple of my BSP taps from work, so I could tap that additional hole and put a fitting in to make it a breather. Completely forgot to actually do that, though. In the meantime: The technical details on the crank/cam trigger sensors I'm using: It's a Ford 6C11-124073-AA cam sensor, as used in Transits, Peugeots, and whatnot. Figured I'd be best off using an easily available, affordable, designed-for-the-job sensor. We'll see whether or not it's actually stable enough to handle reading a 36-1 trigger wheel at the sorts of engine speeds I'm expecting. (3400RPM absolute max "Captain! She cannae tak it!" levels) (To be honest, the only reason I'm using this sensor is because I had a used one from work; pulled it out of an engine that had a loss of cam phase signal, replaced it with a new one, and then discovered the actual reason that there was no cam phase signal is because the cam wasn't spinning. Then I bought two new ones once I'd tested that the concept was sound. They're in the region of £20 apiece.) And I'm using the 1W7T-140464-MA connector, except it's from Simtek where it's a CON-366C. From the back, pin 1 on the left, this looks like:  Pin 1: +12V Pin 2: GND Pin 3: Signal. GROUNDED WHEN ACTIVE, floating otherwise. (I put a 1kOhm pull-up resistor to +12V on this line.) I write this all down, because it took me an hour of fiddling about testing every combination of wires because apparently I never wrote it down anywhere useful, the last time I did all this trial and error for my shoddy test-setup months back.  Maybe this is useful info for other people who need a cheap, plentiful option for an automotive hall-effect sensor; might as well take advantage of all the money someone like Ford spent on R&D and mass-production, right?  Also, yes, the engine turns over that slow. Part of it is that it's still very, very tight; with fresh rings, fresh rope seal, etc. Part of it is that the starter's rather tired. I am definitely thinking a gear-reduction replacement, if/when I can ever get the money for it. Could have the original starter rebuilt, buuuuuut I could also save that money and put it towards one that should turn the engine over faster without working as hard.

Also also, since that video was filmed, I have discovered how to rescale the tachometer on the tunerstudio display, so that it's got an appropriate range.

|

| |

Last Edit: Dec 20, 2021 0:57:50 GMT by Tamber: tach comment

-< Welder. Allegedly a mechanic. Bodger of Things >-

* 1958? Bedford RL - Progress: Glacial.

* 1994 Skoda Favorit - It's baaaaaaaack!

* 2018 Herald Classic - Gone!

|

|

Tamber

Part of things

Shattered. Held together by spite and tape.

Shattered. Held together by spite and tape.

Posts: 340

|

|

|

|

So much for "engine running by the end of 2021", eh? I was hoping I could get some tinkering time over the christmas break, but instead spent it completely wiped out by flu. Got a new clutch friction disc, to be stashed aside for later:  Got a new throwout-bearing, only to find out it's not the one I need.  Started welding up exhaust headers but was struggling with exhausted shaky hands and tired eyes, so I seemed to spend more time sharpening the tungsten than welding.   The plan is to bring cylinder 6 in to drop down with 4 and 5, in a sort of triangular stack of pipes -- draw a straight line from that elbow off cylinder 6, until the point it crosses 4 & 5, then follows them down -- that merge together right into a 2" elbow; 1, 2, and 3 will be the same sort of layout but flipped accordingly; and then the two 2" elbows will merge into a 2.5" section.

Will it be any sort of performance boost? Probably not! Will it sound good? I hope so! Will it look good? ...ehhh, jury's out on that.

Motivation meter is sitting on the lower stop, for multiple reasons: 1: It's dark and cold by the time I leave work. Time will continue to improve this; also, I managed to clean out my oil-burning heater so it works again. Turns out, it will utterly refuse to run on anything but clean kero/diesel.) b: I'm exhausted by day's end. (Combination of multiple things but I'm mostly going to blame two years of 6-day/55+ hr weeks during a freaking pandemic, so I'm run into the ground and constantly stressed. Also doesn't help that I'm a night-shifter at heart, and mornings are a horrific experience for me.) iii: I'm freaking cycling to/from work for the foreseeable future, at least until I get the Skud welded & MOT'd (in part held up by items 1 and b.) |

| |

-< Welder. Allegedly a mechanic. Bodger of Things >-

* 1958? Bedford RL - Progress: Glacial.

* 1994 Skoda Favorit - It's baaaaaaaack!

* 2018 Herald Classic - Gone!

|

|

|

|

glenanderson

Club Retro Rides Member

Posts: 4,353

Club RR Member Number: 64

Member is Online

|

|

|

|

|

Progress is progress.

I hate getting up in the morning, and my winter time mojo is always low too, so I feel your pain.

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

Jan 17, 2022 10:18:20 GMT

|

|

If your stuck for a release bearing stick some pictures and dimensions up and I will have a rumage, ive got a few new old stock truck bearings

I'm not a brilliant morning person, 8 is my ideal rise and shine time!

|

| |

|

|

|

|

|

Jan 17, 2022 12:40:13 GMT

|

Started welding up exhaust headers but was struggling with exhausted shaky hands and tired eyes, so I seemed to spend more time sharpening the tungsten than welding.  Not wishing to be critical but you do know that for the full bosozoku look the pipes need to go upwards? Preferably through the cab roof and then off at odd angles. That said, if they 'blue' like the ones on Medusa did it's still going to look really quite cool. I suspect a lot of people are knackered at the moment. I'm blaming tiredness for the silly things I've done recently and I don't really have an excuse as I've been working from home for as long as I can remember. Some of the folks at work are really bushed now and things aren't easing up for them. James |

| |

|

|

Tamber

Part of things

Shattered. Held together by spite and tape.

Shattered. Held together by spite and tape.

Posts: 340

|

|

Jan 17, 2022 23:51:08 GMT

|

Not wishing to be critical but you do know that for the full bosozoku look the pipes need to go upwards? Preferably through the cab roof and then off at odd angles. Ahhh! So that's where I've gone wrong! I need to turn 'em into six foot tall zoomies! That said, if they 'blue' like the ones on Medusa did it's still going to look really quite cool. I'm hoping that they'll turn all sorts of colours once they get some heat into them; should look pretty snazzy! Just so long as they don't turn black and sooty from exhaust leaks, anyway... I suspect a lot of people are knackered at the moment. I'm blaming tiredness for the silly things I've done recently and I don't really have an excuse as I've been working from home for as long as I can remember. Some of the folks at work are really bushed now and things aren't easing up for them. I wouldn't say you don't have an excuse! Working from home is its own set of stress & hassle, and it all builds up on top of everything else. But, yeah, once the exhaustion starts creeping in, it brings mistakes & clumsiness with it. There's only so long we can run without proper rest & relaxation... |

| |

Last Edit: Jan 17, 2022 23:51:29 GMT by Tamber

-< Welder. Allegedly a mechanic. Bodger of Things >-

* 1958? Bedford RL - Progress: Glacial.

* 1994 Skoda Favorit - It's baaaaaaaack!

* 2018 Herald Classic - Gone!

|

|

Tamber

Part of things

Shattered. Held together by spite and tape.

Shattered. Held together by spite and tape.

Posts: 340

|

|

Jan 17, 2022 23:58:06 GMT

|

If your stuck for a release bearing stick some pictures and dimensions up and I will have a rumage, ive got a few new old stock truck bearings I'm not a brilliant morning person, 8 is my ideal rise and shine time! It's a 100mm O/D, 59mm I/D, and I did a little cleaning to find out it's an SKF 414292B; seems like the inner extends out quite a way and the groove for the clutch fork is also part of it. I'll have to get a decent picture next time I'm down there. Left to my own devices, I tend to head off to bed at 0700 and roll myself back into the land of the living at 1500H...  I'm probably offset into a US timezone somewhere, honestly... |

| |

-< Welder. Allegedly a mechanic. Bodger of Things >-

* 1958? Bedford RL - Progress: Glacial.

* 1994 Skoda Favorit - It's baaaaaaaack!

* 2018 Herald Classic - Gone!

|

|

|

|

|

Jan 18, 2022 10:14:20 GMT

|

What a read! Just done the whole 15 pages last night and this morning and love what you're doing! The motor seems like some proper progress is being made and looks the dogs  will be keeping up with this! |

| |

|

|

Frankenhealey

Club Retro Rides Member

And I looked, and behold, a pale horse! And its rider's name was Death

Posts: 3,882

Club RR Member Number: 15

|

|

Jan 18, 2022 11:51:29 GMT

|

Hi mate, Good work on this. One question, What is the point of fuel injection? Is it for fuel consumption and performance? And wouldnt the gearbox/ diff's ratio's counter this anyway? (Sorry if I have missed any explanation) Watching for more updates. Steve. A bit of fuel efficiency, possibly a bit of performance out of having a bit better control over the fuelling but I'm not expecting miracles. And also I hate foxing about with carburettors.  I don't think the gearbox/diff ratios would make much nevermind, really. They are what they are. I had a Bedford RLHZ aka Green Goddess, same engine/carb, and the carburation drove me mad. Originally designed for post war fuels, with modern fuel I got lots of vaporisation on hot days. Not pleasant cutting out when your brakes depend on manifold vacuum and you're 6.5 tons coming up to a roundabout. I looked at fuel injection, running on Autogas even a downdraught Weber. In the end solved my fuel problems with a Cummins 6BT conversion. Kudos to Tamber for this project which I follow obsessively. |

| |

Tales of the Volcano Lair hereFrankenBug - Vulcan Power hereThe Frankenhealey here |

|

|

|

|

Jan 18, 2022 14:13:22 GMT

|

The only one I have near is this but its marked up as SKF 414293D, its 102mm OD, 59mm ID and the overall height is 47mm, the groove is 11.3mm wide   |

| |

|

|

Tamber

Part of things

Shattered. Held together by spite and tape.

Shattered. Held together by spite and tape.

Posts: 340

|

|

|

|

The only one I have near is this but its marked up as SKF 414293D, its 102mm OD, 59mm ID and the overall height is 47mm, the groove is 11.3mm wide Certainly looks like the right shape! It'll probably be Saturday before I get down to the unit to give it a proper beating with the measuring stick, but I'll let you know! I had a Bedford RLHZ aka Green Goddess, same engine/carb, and the carburation drove me mad. Originally designed for post war fuels, with modern fuel I got lots of vaporisation on hot days. Not pleasant cutting out when your brakes depend on manifold vacuum and you're 6.5 tons coming up to a roundabout. I looked at fuel injection, running on Autogas even a downdraught Weber. In the end solved my fuel problems with a Cummins 6BT conversion. I remember the thread! I did consider a Cummins, but it did seem rather a squeeze to get into the "Big Bedford"; perhaps the 4-pot would work better, it's probably about the same weight as the Bedford 6-pot gas-guzzler, and in the same vague region power-wise. Still always a possibility for later, though! Kind of a shame that large petrol inline sixes have gone out of favour; a V6 or V8 is a lot harder to fit in there!  EDIT: ...that said, having looked up some dimensional drawings for various configurations of LS engines, it looks like it'd be possible! Looks like a standard truck motor, with the standard accessory setup, is 23 inches wide at its widest point; and the Bedford's engine mounts -- according to the chassis dimensional drawing -- have 24-1/4 inches between 'em. Hmm! ...no, best not. I'd only break something. Thankfully, the brakes on mine are backed up with air-pressure rather than vacuum, so I should have a few more good pedal presses before resorting to screaming and pulling hard on the steering wheel! (Especially since I'm going to have much more air reserve than the truck did from factory!) ...I'll be honest, though, back when I first saw the pictures of the truck I couldn't help but think about stuffing a screaming 2-stroke Detroit in there. (How to make it even heavier, noisier, drink more fuel, and leak more oil...  ) What a read! Just done the whole 15 pages last night and this morning and love what you're doing! The motor seems like some proper progress is being made and looks the dogs  will be keeping up with this! Thanks! Progress comes in short bursts! Current revised goal is engine running with the ECU doing ignition-only at first; mostly just for that mojo-boost of hearing it run, while I put together all the inlet manifold (and pump, injectors, fuel rail, etc). I'm making life a whole lot harder for myself by refusing to modify the original manifold, but I don't want to ruin it... It absolutely does need to run to free up, though, it's so tight that the already-weak starter is really struggling! Very gentle initial ignition timing to get it to pop off in the right direction, methinks... |

| |

Last Edit: Jan 19, 2022 0:36:42 GMT by Tamber

-< Welder. Allegedly a mechanic. Bodger of Things >-

* 1958? Bedford RL - Progress: Glacial.

* 1994 Skoda Favorit - It's baaaaaaaack!

* 2018 Herald Classic - Gone!

|

|

tofufi

South West

Posts: 1,462

|

|

|

|

I've just read the whole thread from start to finish. Great stuff, and something a bit different which is always refreshing. Looking forward to seeing further progress on it!  |

| |

|

|

|

|

But if I can have a decent chunk of the exhaust manifold done, and have enough of the wiring done that I can run the ecu in ignition-only mode, then I'll fire it up on the carb. I am absolutely missing hearing that big six pot burble.

But if I can have a decent chunk of the exhaust manifold done, and have enough of the wiring done that I can run the ecu in ignition-only mode, then I'll fire it up on the carb. I am absolutely missing hearing that big six pot burble.

But if I can have a decent chunk of the exhaust manifold done, and have enough of the wiring done that I can run the ecu in ignition-only mode, then I'll fire it up on the carb. I am absolutely missing hearing that big six pot burble.

But if I can have a decent chunk of the exhaust manifold done, and have enough of the wiring done that I can run the ecu in ignition-only mode, then I'll fire it up on the carb. I am absolutely missing hearing that big six pot burble.

Maybe I don't have the alternator bolted on correctly? ...but I think all the brackets are in the right place. I'll deal with it later. It needs a different pulley anyway; the one that's on there is for -- as best I can tell -- a Z section belt (10mm), and the truck takes an A section (13mm) belt.

Maybe I don't have the alternator bolted on correctly? ...but I think all the brackets are in the right place. I'll deal with it later. It needs a different pulley anyway; the one that's on there is for -- as best I can tell -- a Z section belt (10mm), and the truck takes an A section (13mm) belt.

Lots of things to buy... engine oil, spark-plugs, plug terminals, thermostat, and other assorted bits.

Lots of things to buy... engine oil, spark-plugs, plug terminals, thermostat, and other assorted bits.

I'm probably offset into a US timezone somewhere, honestly...

I'm probably offset into a US timezone somewhere, honestly...

)

) will be keeping up with this!

will be keeping up with this!