|

|

|

|

|

Started to gap the top of the door on the nearside where it was very tight (for some reason they all are)  This requires some fettling on both the A post & the edge of the door skin  I still have shims to go into the hinges to space the door back slightly only 1mm / 1.5mm but that will make all the difference that I need it make  New quarter panel for the rear shroud in the making  The original has been previously repaired somewhat poorly  I wanted to attain the basic profile prior to cutting out / removing the original  Trimmed the bottom out the original to allow the profiling of the new panel to fit  Old panel removed and a flanged rebate let in  New panel progressed & trial fitted - still requires further work & trimming prior to making up the lower section of the B post - door gap is currently over wide but the door has yet to be shimmed back on the hinges - More tomorrow |

| |

|

|

|

|

eternaloptimist

Posted a lot

Too many projects, not enough time or space...

Too many projects, not enough time or space...

Posts: 2,578

|

|

|

|

|

I love to see a car on period tyres. If I ever get the early P6 I’ve promised myself (City Grey 2000TC with a red interior) I’d be on the phone to get a set of Pirelli Cinturatos pdq.

|

| |

XC70, VW split screen crew cab, Standard Ten

|

|

|

|

|

|

|

Repair section back off  Lower flange drilled & a couple of nut inserts added  This now allows for the panel to fastened through the lower sill flange  Next is to rebuild the lower section of the B post  Its a fiddly panel and for that reason I built it in a few separate sections and tacked them together  One I had refitted the quarter panel and checked the alignment with the door etc the repairs to B post were fully welded & dressed back  Repair panel refitted and checked again  Now well on our way  I need to fabricate a bridging section between the sill & the quarter panel next - this also ties in with the rear wing which bolts through the rearward edge of the quarter panel - I have made a start on the pattern for it and shall complete it in the morning |

| |

Last Edit: Jun 2, 2020 19:46:54 GMT by Deleted

|

|

|

|

|

|

|

Recent progress includes  Rear quarter / rear wing reinforcement bracket being trial fitted  And with the quarter repair removed it could now be fully welded & dressed back  Then the repair panel could be refitted & the rear wing trial fitted  To allow the centres to be marked for the wing fixings which were duly drilled  Then the rear wing could be refitted / aligned / checked for fit etc  Which I am quite happy with  There is piping bead that goes between the wing joints once the car is painted and the wings refitted  Alignment with the repair section of the quarter panel is good  And the reinforcement panel does the job has intended  Away from the side of the vehicle - the bonnet hinge boxes are quite thin & weak and I would probably spend more time repairing them than making new ones - I have already patterned up & cut the steel - the hinge arms are also getting replaced - these break easily in fact one them has already been previously repaired - the Clubs spares department has supplied new ones  More tomorrow |

| |

Last Edit: Jun 8, 2020 20:37:44 GMT by Deleted

|

|

|

|

|

|

|

|

Great progress as usual! hope the customer is well happy so far, what a difference from the starting point!!

|

| |

|

|

|

|

|

|

|

|

The number of areas that need to line up and fit well are very numerous with this lower panel...all in relation and with equal importance of all the other panels you are having to deal with. The car is better than factory, but still in keeping with what Jowett probably intended for fit and finish/quality, ect.

I love the work you are doing and it continues to inspire!

great stuff Grumpy!

JP

|

| |

I know its spelled Norman Luxury Yacht, but its pronounced Throat Wobbler Mangrove!

|

|

|

|

|

|

|

Great progress as usual! hope the customer is well happy so far, what a difference from the starting point!! Just had a e mail from the client (he reads the thread) 'Very impressed / over awed with the new parts going in - and yes the client is very happy with what he see's - obviously impressing a few others too' |

| |

|

|

|

|

|

|

|

Once I had flanged the sides & profiled the sections - I assembled & welded up the bonnet hinge boxes  Dressed back and the new hinge arms fitted  The area that the hinge boxes fasten to on the bulkhead is quite thin - on the early cars this leads to fractures in the bulkhead steel around the hinge box apertures - I have already welded the fractures up and dressed them back on the bulkhead  These are reinforcement plates in the making for the hinge boxes copied from factory originals which I shall complete & fit in the morning  Meanwhile I made a start on working the dents & scrapes out on the nearside rear wing & door   They still require more work but both panels are somewhat straighter  They have also had buzz over with the DA and P80's to clean them up  More tomorrow |

| |

|

|

|

|

|

|

|

|

GN, I'm looking forward to seeing how you let in that repair section. Thanks as always for our daily bread.

John

|

| |

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

|

|

Just a Q GN... The rear shroud side panel you're making... It looked like this originally:  And your repair like this:  Despite that the wing to panel joint looks pretty nice. Are you going to introduce the original step still? |

| |

|

|

|

|

|

|

|

Jun 10, 2020 21:19:42 GMT

|

Just a Q GN... The rear shroud side panel you're making... It looked like this originally:  And your repair like this:  Despite that the wing to panel joint looks pretty nice. Are you going to introduce the original step still? Now here comes a shock Alex - No is the answer - not that its not possible but take a look at this image  The wing carries a piping bead - reinstate the swage and it holds the piping bead ever so slightly off the quarter panel - net result is that traps dust & dirt in between the piping bead & the quarter panel Now the next image  Notice the swage in the quarter panel at all ? - Nope because its not there - this Jupiter has also had the quarter panels replaced but with the same flush - non swaged panel - thing is you cant practically see it when it remains - why Jowett bothered I'm not quite sure  Likewise on this car too   Not even the concours judges have noticed on the cars that I've undertaken this quarter panel conversion - don't get me wrong if a client wants it reinstated then that's what I will do - but it's of no detriment to the car either way |

| |

Last Edit: Jun 10, 2020 21:21:41 GMT by Deleted

|

|

|

|

|

Jun 10, 2020 21:32:21 GMT

|

So lots done and next to nothing to show for it (some days are like that)  Bonnet hinge reinforcement panels were completed and fastened insitu complete with the hinge boxes - the factory relied upon pop riveting the bottom of the reinforcement and the bolts for the hinge boxes secured the upper section - this was down to the fact that they were retrofitted after the cars left the factory when they discovered that they had a problem with the bulkheads fracturing around the hinge boxes  Quite a few repair sections / reinforcing sections made up & trial fitted to the alloy outer panels - and that was my day gone  Final shot - just a progress pic - I do a bi-monthly roundup of any restoration work happening on all Jowett models for the club magazine and my deadline is this Friday - I normally just forward a handful of various images that I have and let the editor use has he wishes  Long road trip tomorrow - so back to the work on this one on Friday |

| |

Last Edit: Jun 10, 2020 21:35:28 GMT by Deleted

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

|

|

|

Hm, the quote got messed up, so removed it to reflect my response better.

So in this case practicality overcomes OCD. I just knew there would be a reason behind this, but as you usually go to almost extremes to match originality I had to ask... ;-)

|

| |

|

|

|

|

|

Jun 11, 2020 15:15:30 GMT

|

|

You mentioned "no detriment to the car either way"... I think it goes one step further to help protect the longevity of the car/repair area. I understand purity of restoration, but this type of improvement is, in my humble opinion, necessary.

If Jowett had to fix their hinge box area with reinforcements to stop fractures on a recall basis, then it makes sense to do this mod on the lower panel/piping/fender mating surfaces too!

the work on the body panels is extraordinary!

JP

|

| |

I know its spelled Norman Luxury Yacht, but its pronounced Throat Wobbler Mangrove!

|

|

|

|

|

|

|

|

Cat's out of the bag now....those judges are going to be working up a sweat!!!

|

| |

'80 s1 924 turbo..hibernating

'80 golf gli cabriolet...doing impression of a skip

'97 pug 106 commuter...continuing cheapness making me smile!

firm believer in the k.i.s.s and f.i.s.h principles.

|

|

|

|

|

|

|

Cat's out of the bag now....those judges are going to be working up a sweat!!! Yep just like they attempt to score a Jupiter down if it has a Javelin engine fitted - they are identical / built of the same parts on the same production line in the same factory - 1 digit on the engine number identifies the engines has either Jupiter or Javelin - They built 800 Jupiter's & 25'000 Javelins - Surviving Jupiter's number low 400's - surviving Javelin's circa 1,000 - the engines can be fragile if mistreated - they suffer from corrosion in the water galleries & head studs to the point that renders them useless - Surviving Jupiter engines are quite rare - there are far more surviving Javelin engines and therefore quite a few Jupiter's have non original Javelin engines in them - (non original by ONE digit on the engine number) - when I discovered that the judges were scoring the cars down for this I took a different angle to it - the owner has retained a 70 year old rare car on the road by having no choice but fit an original Jowett engine type to the car therefore any scoring down on a engine number difference gets discounted - this is Jowett Jupiter - it survives and has important as a club concours event is - it's no 'Pebble Beach' either |

| |

Last Edit: Jun 12, 2020 12:20:23 GMT by Deleted

|

|

|

|

|

|

|

|

Is there anything to stop you machining the number off and re-stamping the original?

There are a few engines where you have to do this if you skim the block anyway.

|

| |

|

|

|

|

|

Jun 12, 2020 19:45:38 GMT

|

Is there anything to stop you machining the number off and re-stamping the original? There are a few engines where you have to do this if you skim the block anyway. Kevin - You could - but you would have to do both crankcase half's - its a lot trouble for the sake of a number - I suppose if the cars were worth mega bucks and all matching numbers made a significant difference to the value of the car then yes you would do it but 99.8% of owners accept the cars for what they are |

| |

|

|

|

|

|

Jun 12, 2020 19:50:29 GMT

|

Door & rear wing removed yet again  I wanted to ensure the bare metal on the reinforcing plate was primed and there are still a few areas that require seam sealing prior to the panel being fitted permanently - I also need to make up a few repair sections for the door skin which is why the door has been removed  Sid called in for a progress report too |

| |

Last Edit: Jun 13, 2020 19:36:40 GMT by Deleted

|

|

|

|

|

Jun 13, 2020 19:44:03 GMT

|

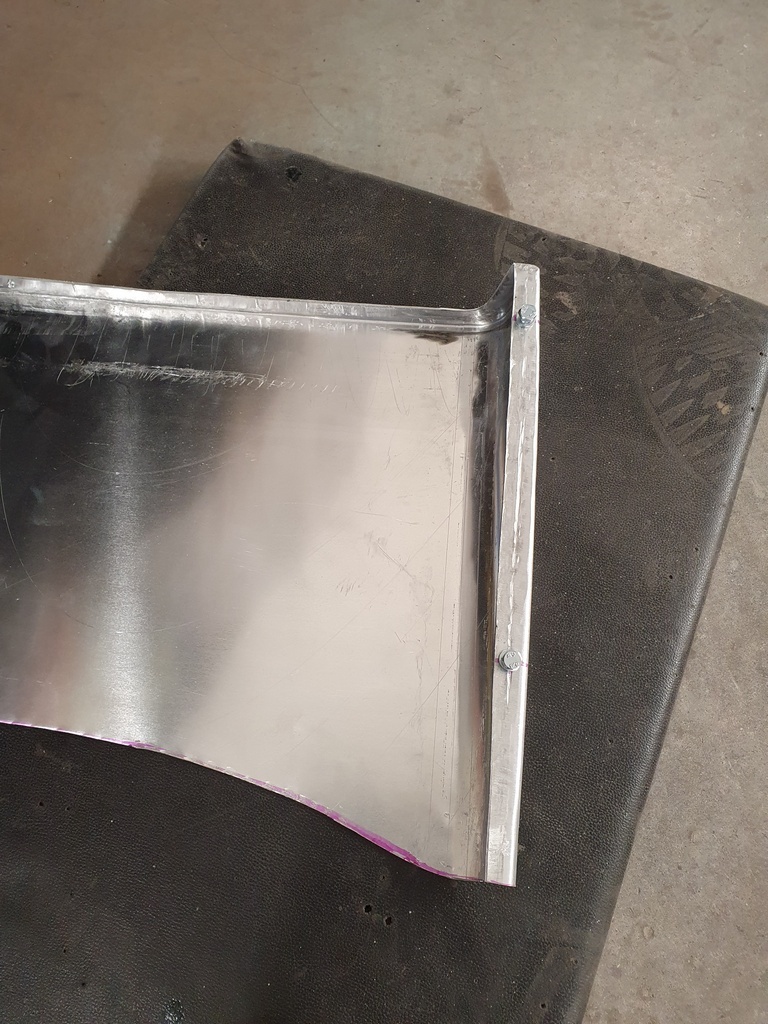

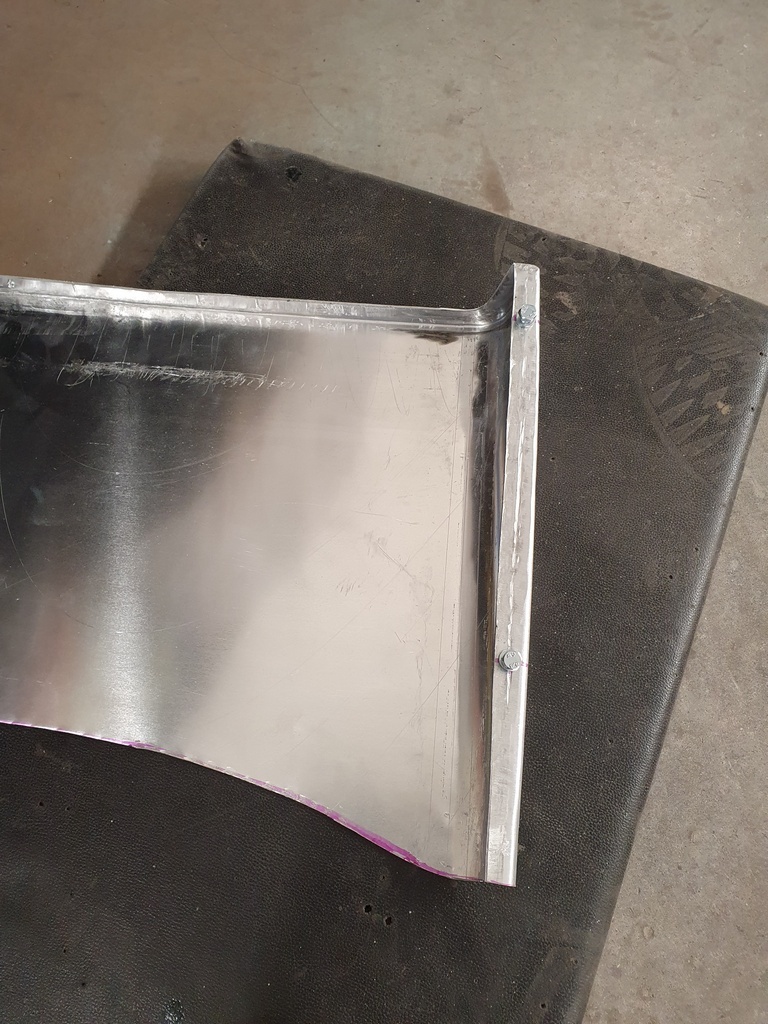

With door off I can now access the repairs to the alloy door skin which numbers several areas  The largest repair is under the bottom door hinge  Fresh repair panel trial fitted  I have another few small repair areas to make & prepare on Monday then all the current repairs on the nearside outer panels can be made permanent  And whilst the repair panel for the shroud quarter is removed the remaining seams were sealed |

| |

Last Edit: Jun 13, 2020 19:44:40 GMT by Deleted

|

|

|

|