Pretty useful when you get it working again.

It should be a really useful bit of kit I reckon once it's back up and running. I will probably enhance the usefulness a little further by taking advantage of the fact that the computer monitor is a standard, self contained composite unit (it's just tied into the computer by a single twisted pair) by sticking a raspberry Pi in the case too, so can then also use it to display manuals etc, play back instructional YouTube videos etc...as a 17" display is a bit more user friendly for that than a phone screen. Plus it will make an interesting talking point. I can do it without having to make any irreversible modifications to the unit save for drilling one small hole for a switch...though now I'm thinking about it, I think there's a rubber bung by the power switch for an optional connector I don't have, so would probably stick the switch in there actually...so no mods to the case at all.

I find it utterly fascinating - old 80s tech is so much less intuitive than the modern devices. equivalent. New tech does not need the "technicians" to know what the hell they are testing.

The modern GIGO is in the operators rather than the technology.

To be honest, this isn't bad...far more intuitive than quite a bit of consumer tech from the 80s! There's nothing this does that you wouldn't have the kit to already do in a decently equipped garage, but having something that does it all in one place surely would be quite the time and effort saver.

Because I'm me and find them far more interesting than I should, here are a couple of additional photos of the ridiculously overcomplicated status indicators built into the buttons.

It surprises me that they went to the lengths of building them into even just the momentary controls. You never actually *see* this one as the control is actually latched on software...the orange announciator in the button is normally hidden by your finger.

The actual indicator that this is active is a message that flashes at the lower right hand corner of the screen.

There is apparently a volts/ohms measurement capacity in there somewhere (which I've yet to figure out how to access), which is switched between the two modes using this control. Here it is in volts mode...

...and ohms mode.

Just surprises me this wasn't just done either on screen or using a status LED next to the control. I remember looking at this sort of control when I was building a power supply a few years back, and these things were *expensive* - even basic ones without legends like this. "We spared no expense" seems to be a running theme with this machine.

I've got a slightly more sane (though still offset) temperature reading now I've actually got the thermocouple plugged into it rather than a hall effect sensor!

I wanted to have a look at all the analogue cards to check for any additional socketed components, dirty contacts or dry joints.

Started out with the volts/ohms board as I know there are issues with that subsystem.

Had a brief "Ah ha!" moment when I spotted that toasty looking resistor...but checking it shows it to measure precisely the value that's stamped on the side of it. Nothing else obviously amiss.

The next board is the trigger control board.

This is quite important in that what it does is essentially listen for the ignition pulse firing on cylinder number 1, as that is the timing reference to which everything on the machine is slaved. Nothing amiss here that I can see.

Unsurprisingly, the next board along from that is the main timing board - this basically keeps everything in sync with the signal tracked by the trigger control board.

One of the more densely packed boards.

I initially thought that the next board (labelled "AMP" on the card cage) was going to handle a lot of signal amplification...but it actually appears to be the signal processing for the amps and temperature sensors.

This board does have a couple of dry joints that I'll give a tickle with the soldering iron tomorrow.

"CAL" is the next one, which I'm assuming given the precense of several relays, physically connects loads of known values across the inputs to undertake the calibration self test.

Again some of the soldering isn't great looking, but I couldn't actually see any dry joints...I may well reflow some of the heavier connections though as they could be better.

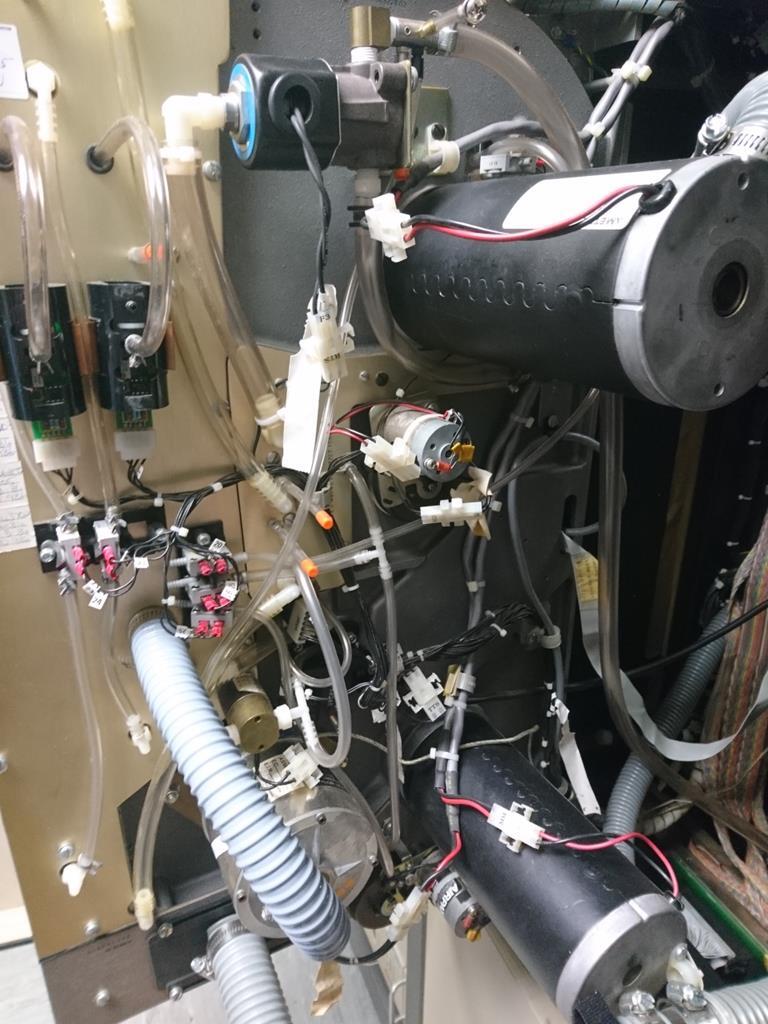

The fact that the only systems which are consistently failing the self calibration are the HC and CO meters is one of the reasons I want to have a really good look at the wiring from the I/O backplane to the sockets at the end of the boom.

Speaking of I/O, that's what the next board is tasked with dealing with.

Nothing wrong with this one that I could see.

Next up is the vertical pre-amplifier board, I believe this relates to the scope.

Quite obvious from the lovely old school hand routed traces that this one and the trigger control board are quite a bit older in design to the majority, though the date codes show they were actually made at the same time as the others.

"Logic Board No. 2" is next...though I don't recall seeing a number 1 anywhere!

I'm guessing a bit, but based on the hardware present that this is just handling some low level buffering or such like they didn't have room for in the main computer cage.

No signs of trouble anyway.

Finally we have an identical pair of cards containing quite beefy deflection amplifiers to drive the CRT (one card handles horizontal, the other vertical).

All of these boards could do with a good clean, as do the digital boards (which I'll grab proper photos of soon too) due to the close proximity of the cooling fan. Shame Sun didn't feel it worthwhile to fit a filter to it.

So nothing nothing obviously amiss there, aside from one resistor which has got a bit warm at some point and one capacitor on the amp/temp board that's got dry joints. I really did want to get them all out for a proper check over though. No socketed ICs or anything like that (which was responsible for the original display issue) in need of attention, but it was worth checking.

Looks like I might actually get a few hours free tomorrow afternoon, if so I'll hopefully get a bit more stuck into trying to work out what's going on with the faults.

The biggest irritation there really is that there don't seem to be many labelled test points, which would make checking to see if all the power supply rails are present and correct (there are a load of them!) a lot easier. Obviously given the card based construction it's a bit tricky to probe a lot of the machine when it's running as the cards are quite tightly packed together.

The other thing I wanted to check these cards for was whether they were hiding any more tantalum capacitors like I've seen on at least one or two of the digital boards, as once I've ascertained how many of them there are they will be getting replaced on mass. Wouldn't surprise me if that alone sorted a lot of the issues based on prior experience.