After Saturday's initial clean and inspection, it was time for Bodicea (she's been named that by the Burd as "she's aww boady") to head north to a friend's garage for a thorough examination.

The tank was brimmed (a rather surprising 24.78mpg) and she was parked up on Saturday evening.

Sunday arrived with a vengeance! -8 degrees and the need to defrost the door lock to get into the car.

Once inside it was no better – the inside of the windows were frozen. Luckily, a bit of choke and some throttle got the B series to fire, and she sat happily on the choke whilst I scraped.

The roads were a touch slippy, so it was slow and steady progress to the rendezvous point with my Brother for breakfast.

Suitably fed, we headed northwards. About 90 mins later, we arrived at our mate John’s workshop. It’s the ideal kind of place for working on such a car, as he has an eclectic mix of cars, and all the tools to suit..

It was -3 in the unit, so that aided and abetted some rapid working.

In no time she was up on axle stands and ready for perusal

At the rear end, the news was decent.

No cracked springs, axle looked ok (if a touch leaky) and the floor was in decent shape but had been patched.

There’s a fair bit of rot at the rear of the arches but the main parts of the arch are solid.

This was not unexpected as she’s 59 years old! The intention will be to clean it all up and repair where required before painting and coating in wax to protect it.

Next up was a look at the rear dampers, as the car became unsettled going over bumps

I suspect they are not in their first flush of use, so I’ll be seeking replacements.

We moved along the sills, not finding too much to worry about – plenty of sound, solid metal, and a modicum of surface rust.

Both front footwells are rough – especially along the sill sides and where they (used to) join to the wheelwell/bulkhead area.

On the passenger side, this is exacerbated by the original fitment asbestos heatshield. Over the years it has trapped plenty of mud and water, significantly rotting the floor.

We’re not too concerned re these areas as they are flat, square easy to access panels!

it’s a C for structural intergrity.

Next up was the brakes – having never driven and ‘all drum’ car before, I have to say I was less than enamored by Bodicea’s powers of stopping.

There was a squeal from the front right at low speed, and a fair amount of pedal travel before anything happened.

Off with the hubcaps and wheels then, discovering that the drivers front tyre was more like a 50p than a circle. That’ll be the wobble from the front end then.

We started at the rear. The handbrake mechanism was moving freely on both sides, so we decided to pull off the drums and check the shoe and cylinder condition.

This was good news all round.

We donned protective masks as we were unsure of the age of components – and don’t want to inhale any asbestos dust that may be present.

The drum retaining screws came out cleanly, and the drums pulled off (exhibiting no discernible lip).

The cylinders on both sides were clean, dry and functional.

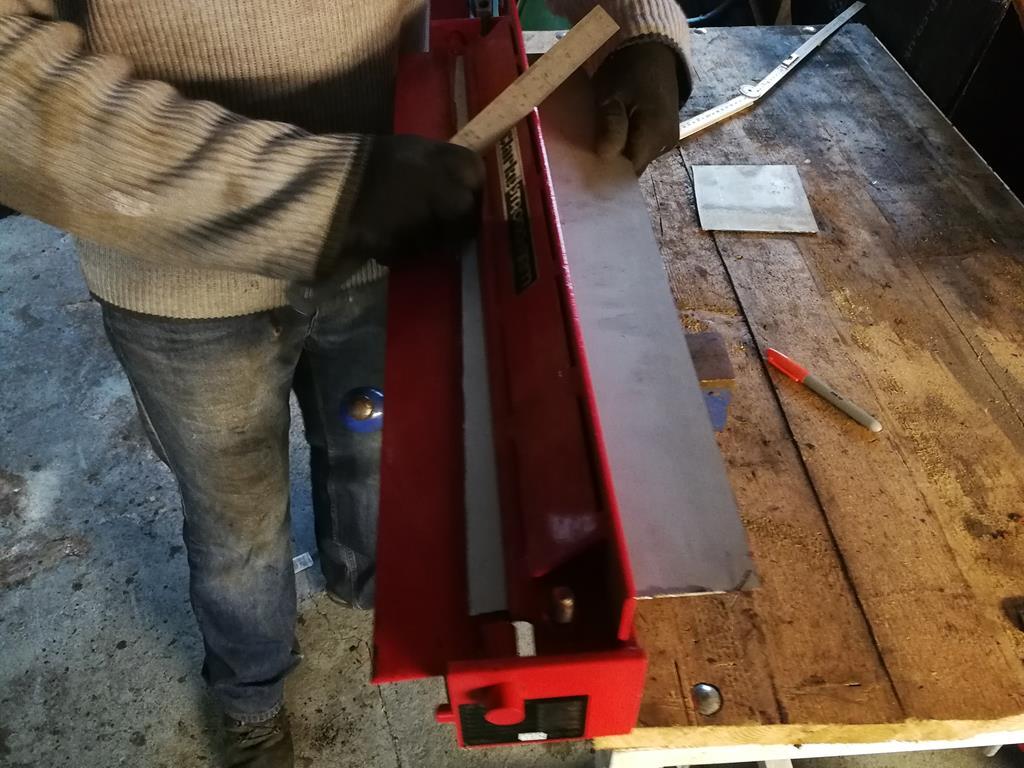

The adjustors rotated through their full range after some light cleaning, and the drums and shoes were lightly scuffed with sandpaper to clean them up.

The drums were refitted and the shoes adjusted to just drag slightly.

The fronts were much the same ( bar being twin leading shoe, with 2 cylinders per drum)

The only noticeable difference was a couple of missing ‘beehive’ shoe retaining springs – a likely cause of the squeal from the front as the shoes moved during use.

The cylinders, shoes and drums were all in good condition, so only some retaining springs required, and I’ll order them up.

With the shoes adjusted, the pedal feel of the car was improved too, so it’s a B for brakes (Geddit!?).

The next job was also brake related.

Prior to my purchase, the hydraulically operated brake light switch failed, meaning that the brake lights were always on.

The switch works by using the movement of fluid when the pedal is depressed to fill the switch and complete the circuit.

But in this instance, it was operated by a dash mounted switch.

Handily, the switch is located at the front of the engine bay, providing unfettered access for removal.

Not so handy are the myriad tales of brake line damage as the switch rotates the whole T piece due to years of detritus welding them together.

Such tales rang in my ears as I doused the switch in penetrating oil over a couple of days. Today was the acid test.

We braced against the inner wing with one pry bar, and used a hammer head beside the engine mount to brace the other side of the switch. Application of a socket and ratchet, plus a few muttered prayers lead to a successful removal of the old switch!

The new one was fitted, wired up and tested as working. Tremendous

The state of the old switch clearly shows that the cause was mingin brake fluid.

A decision was taken to bleed the brakes though with new fluid – easily done by pouring the fresh fluid onto the floor.

Well, not onto, more into!

At the same time, the gearbox oil level was checked using the handy dipstick.

I got a pic of it once wiped clean as it is a lovely looking thing!