|

|

|

Apr 23, 2019 21:10:43 GMT

|

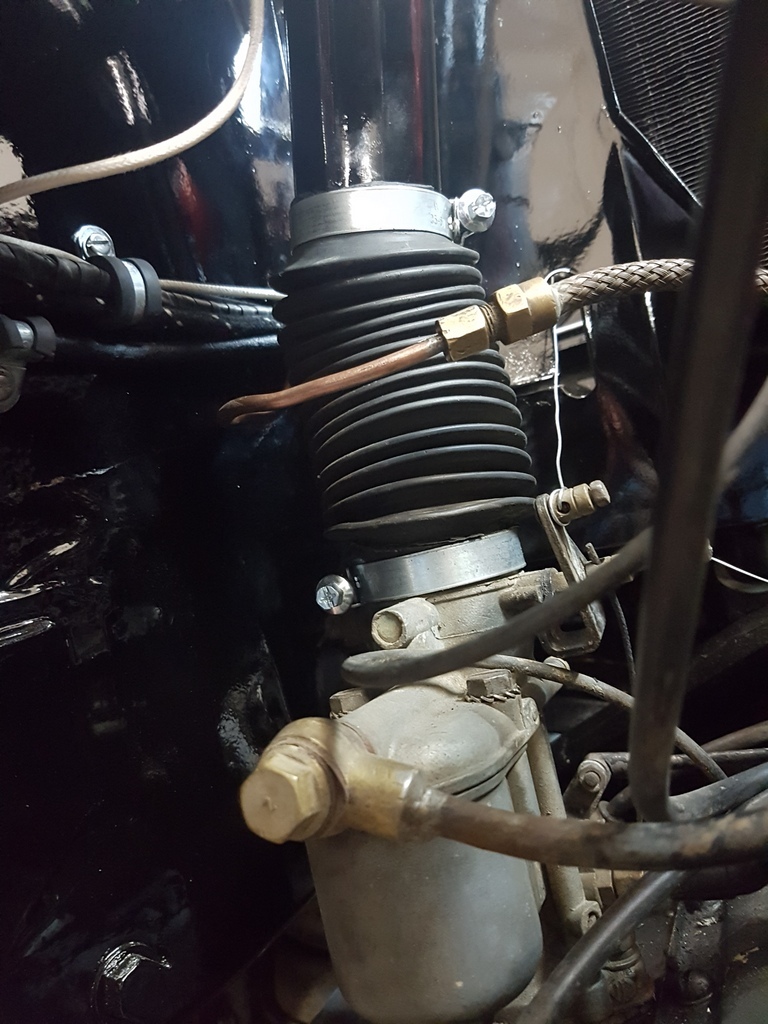

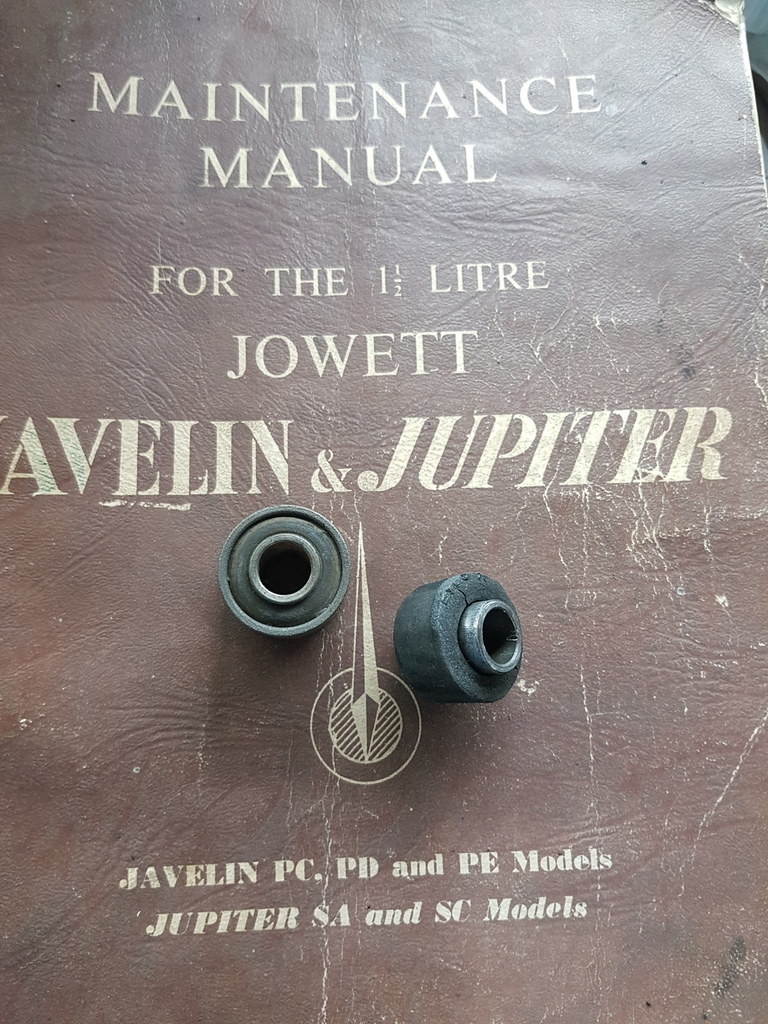

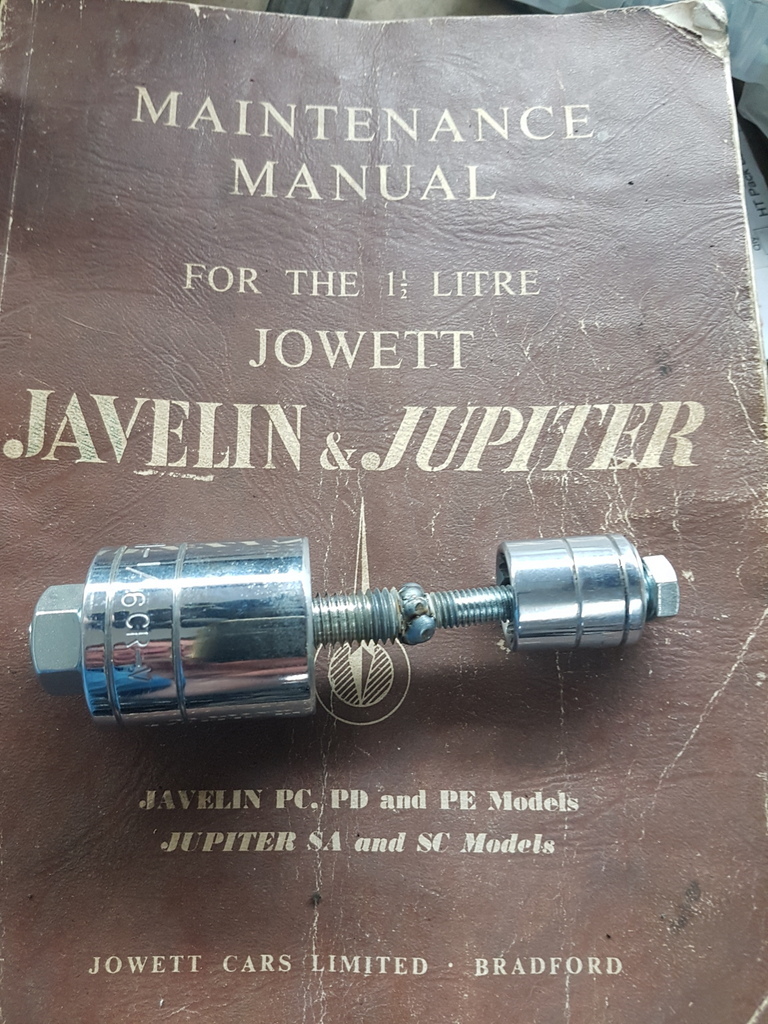

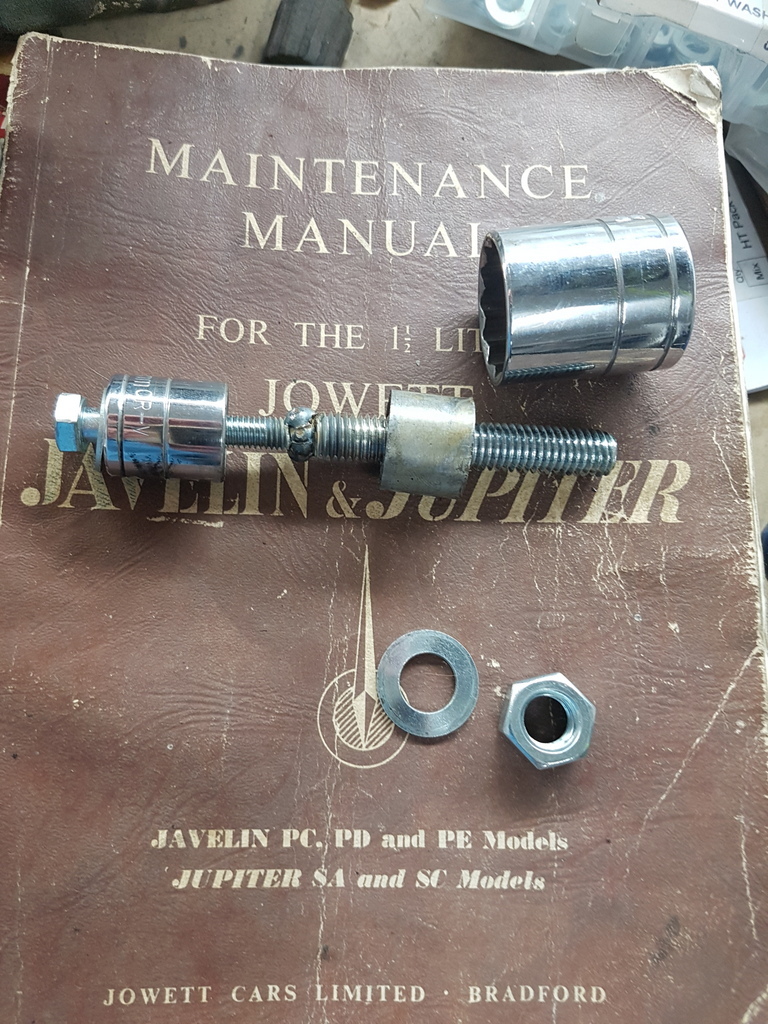

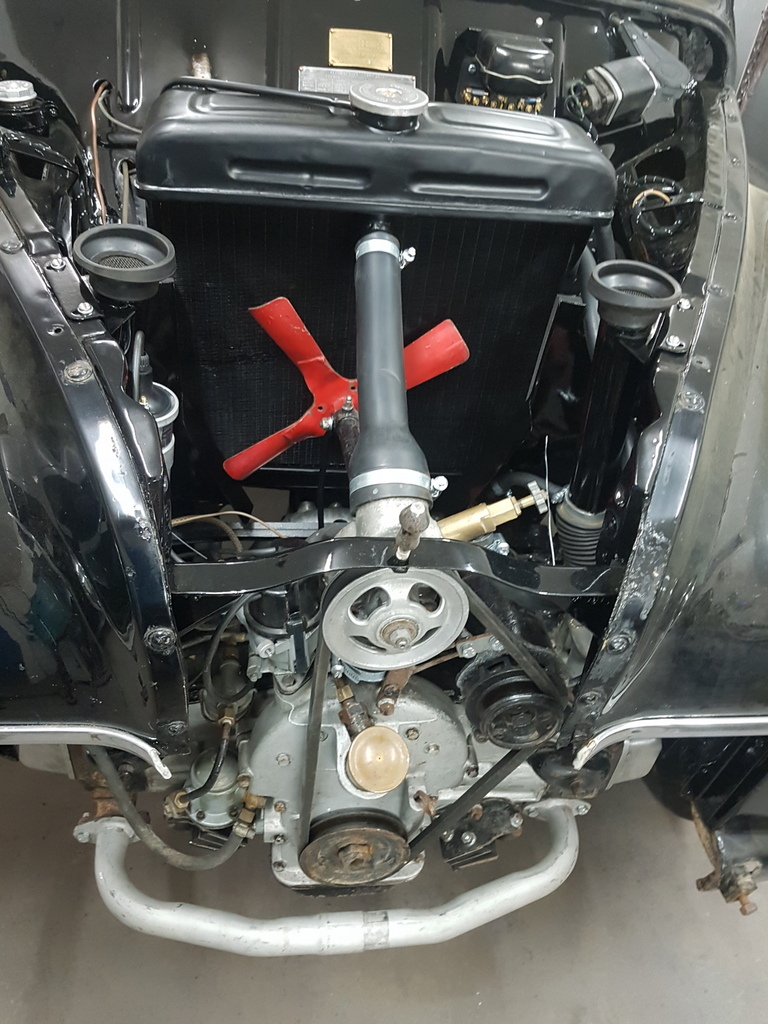

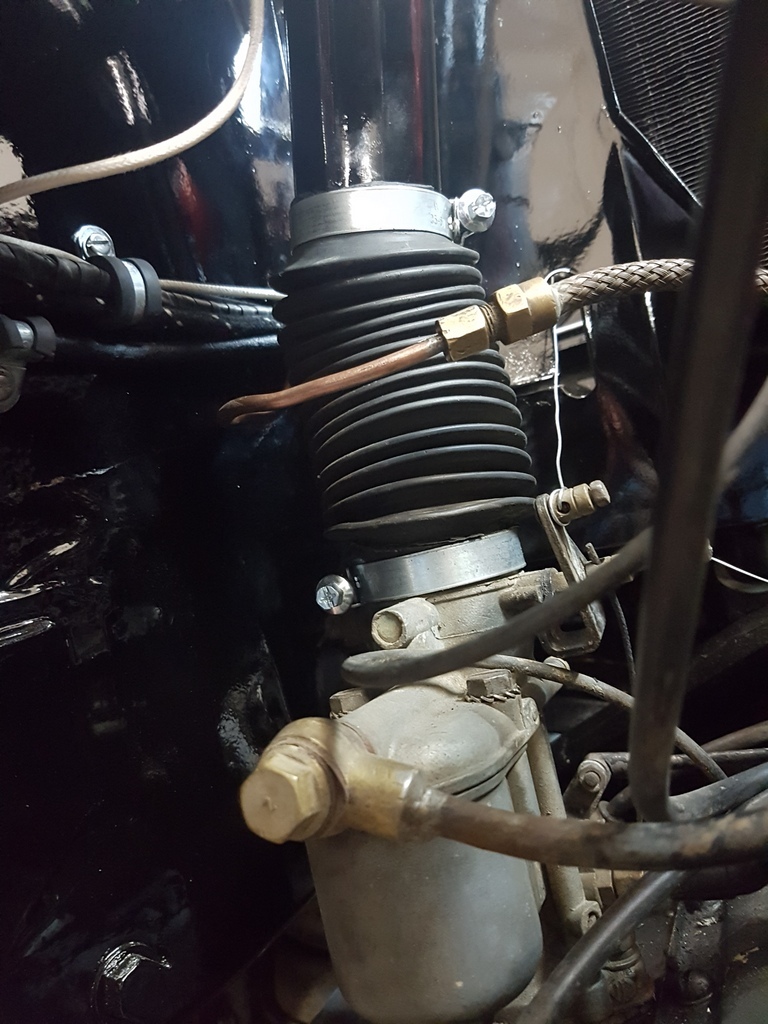

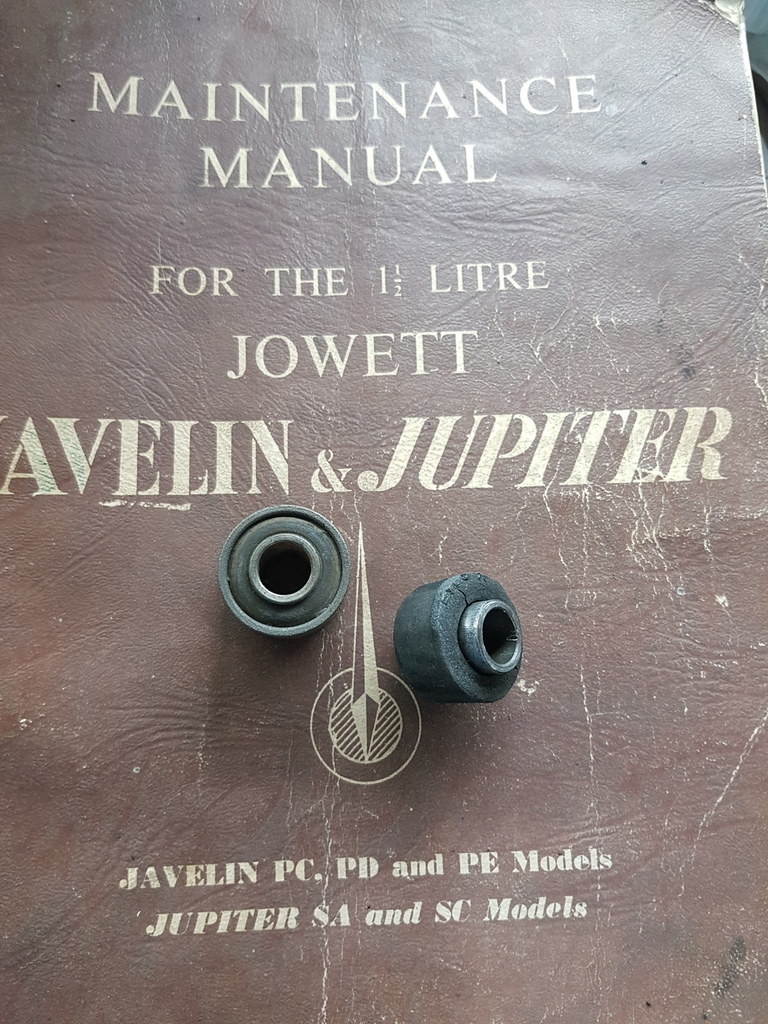

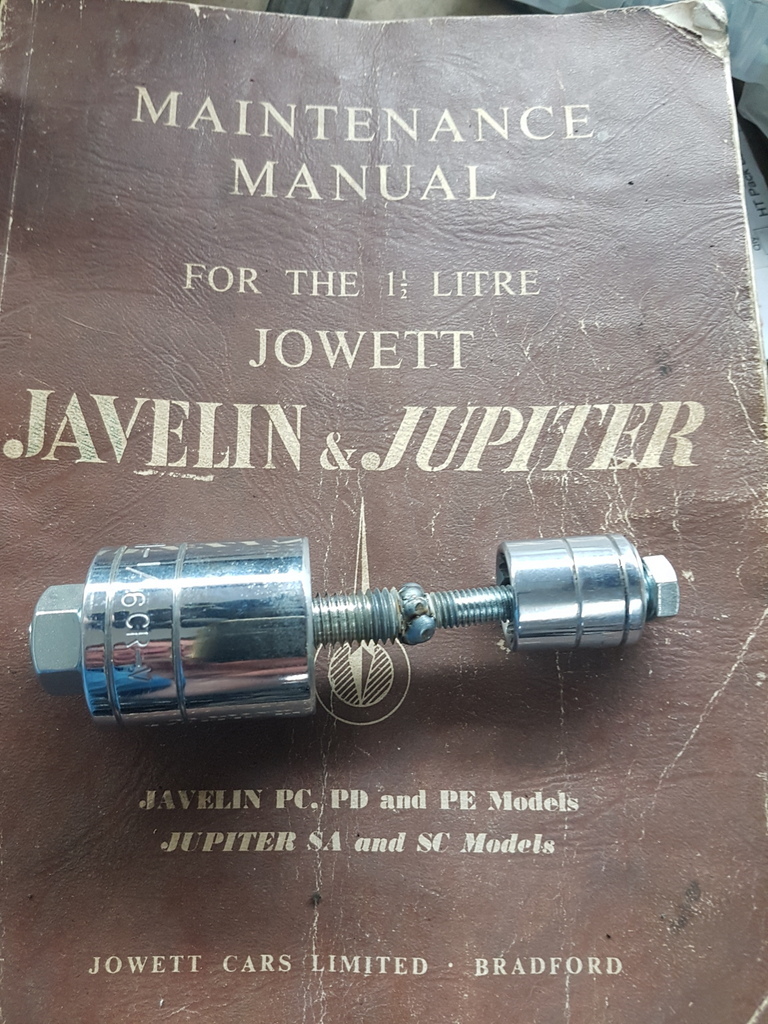

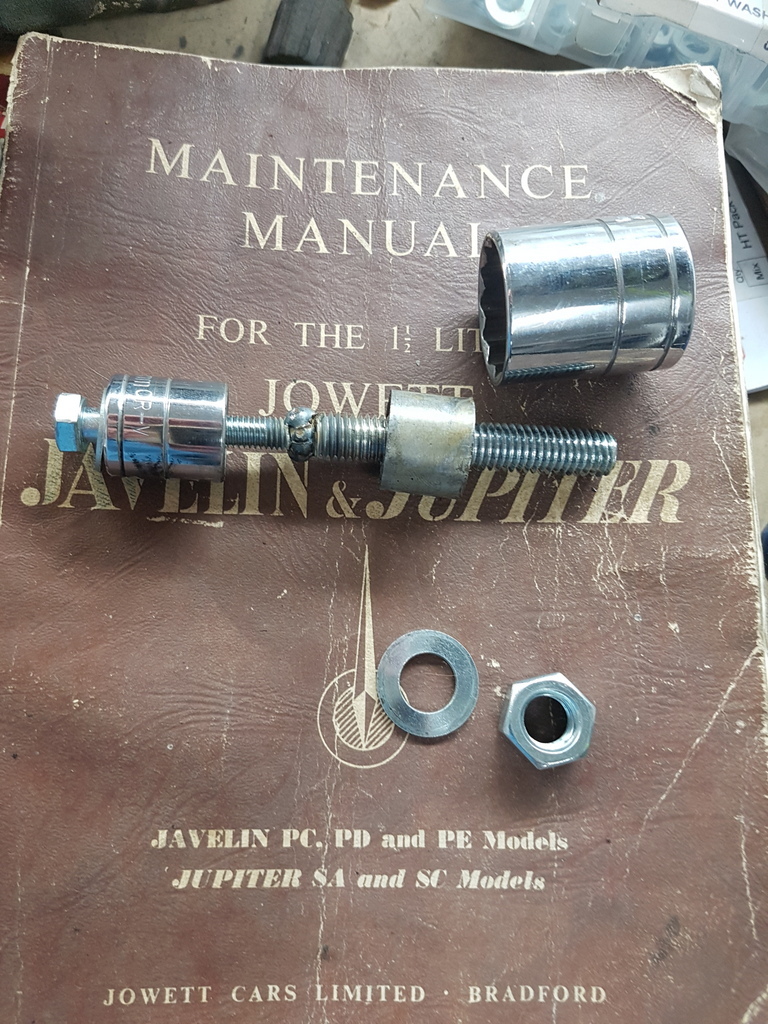

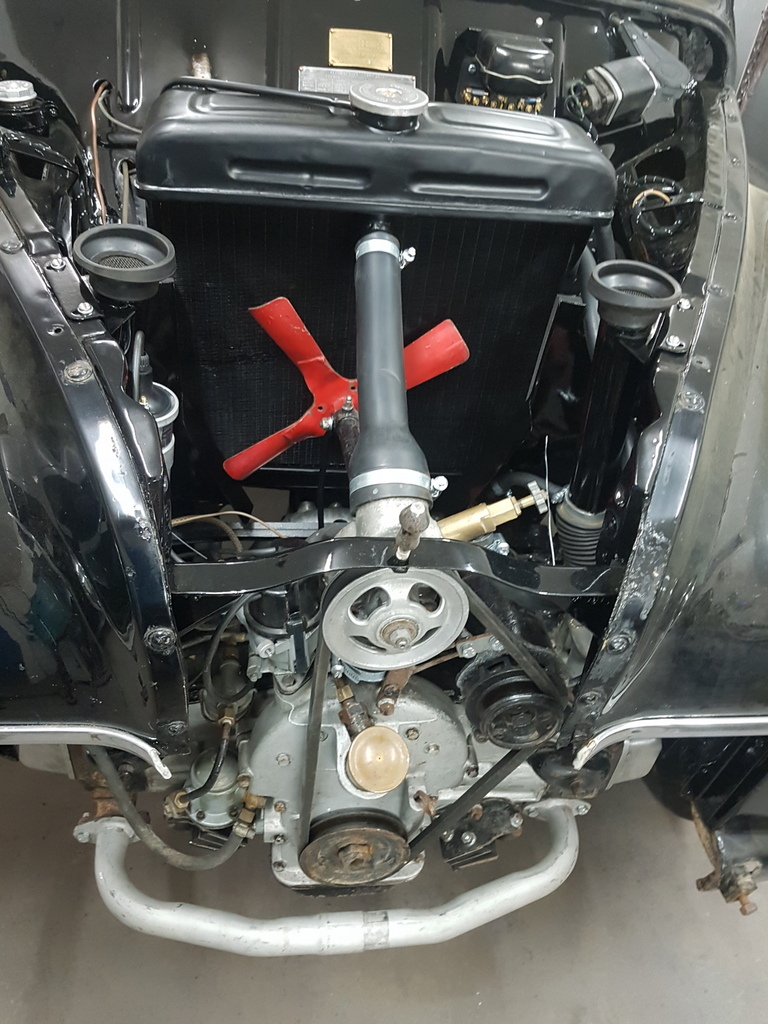

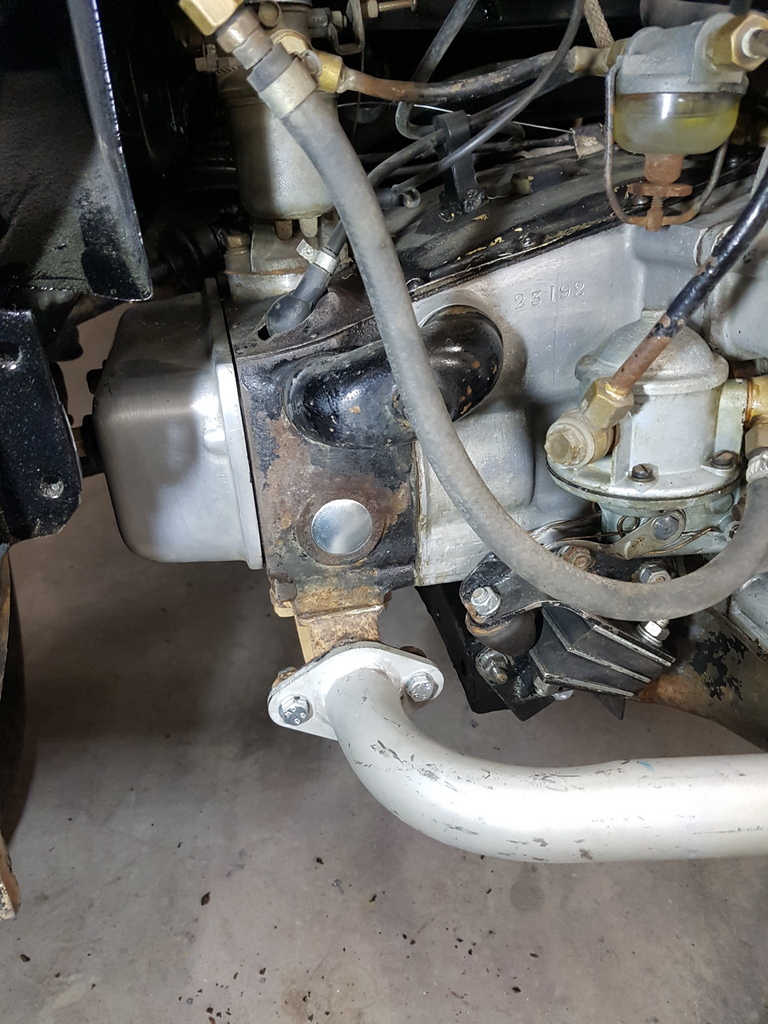

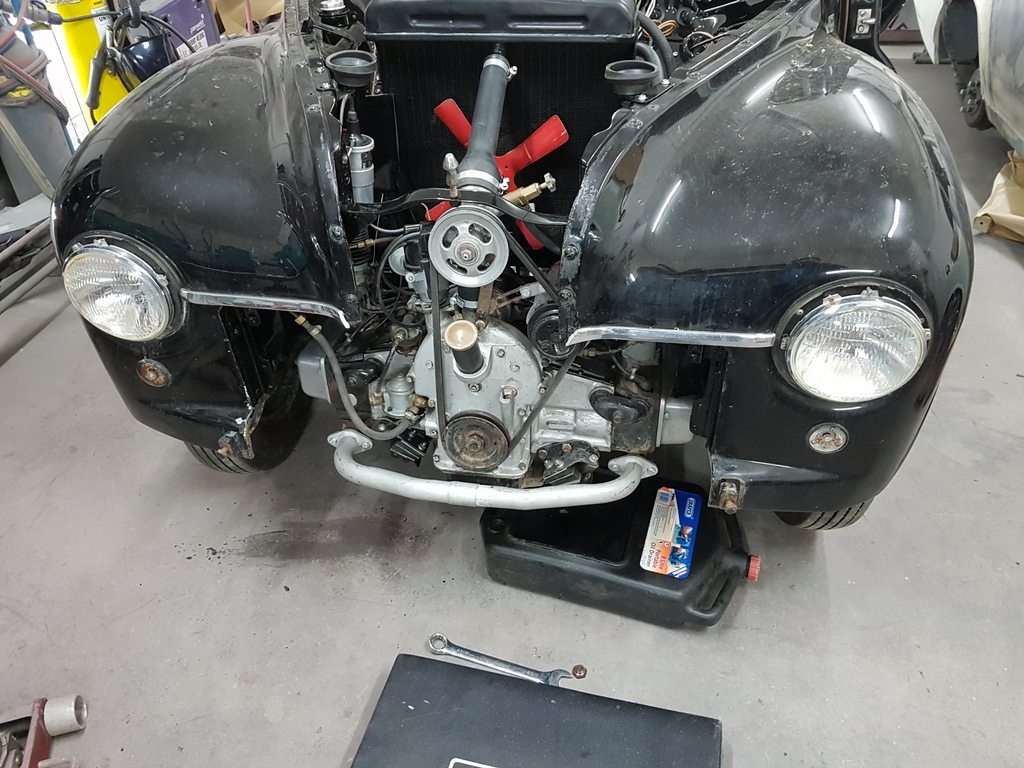

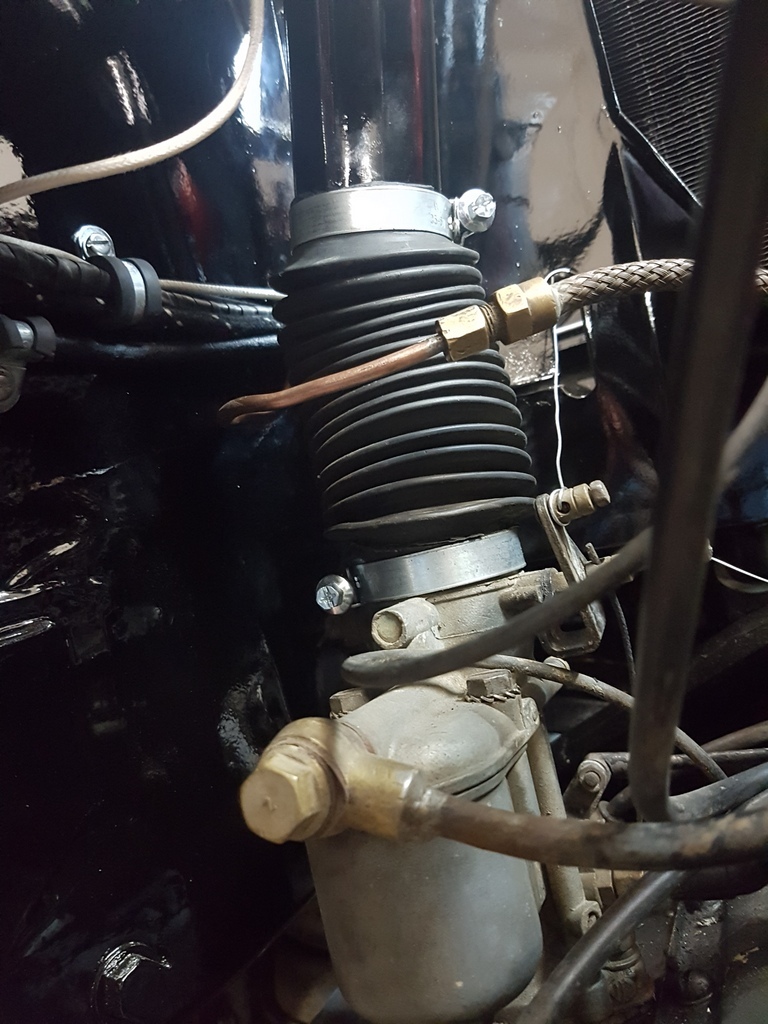

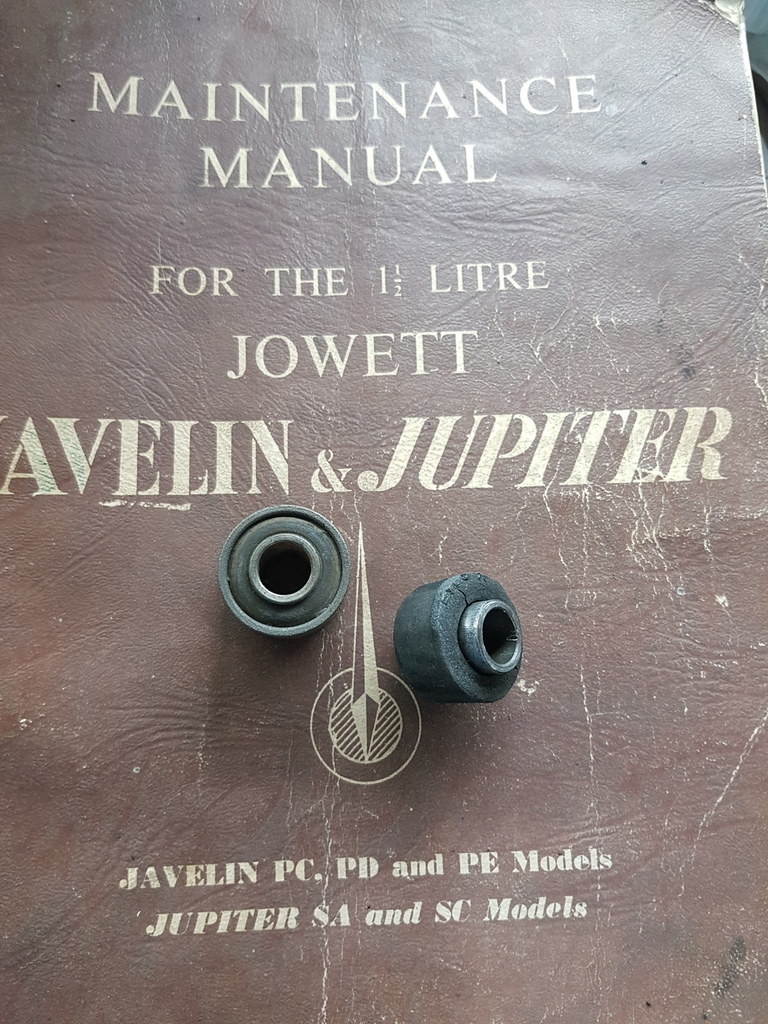

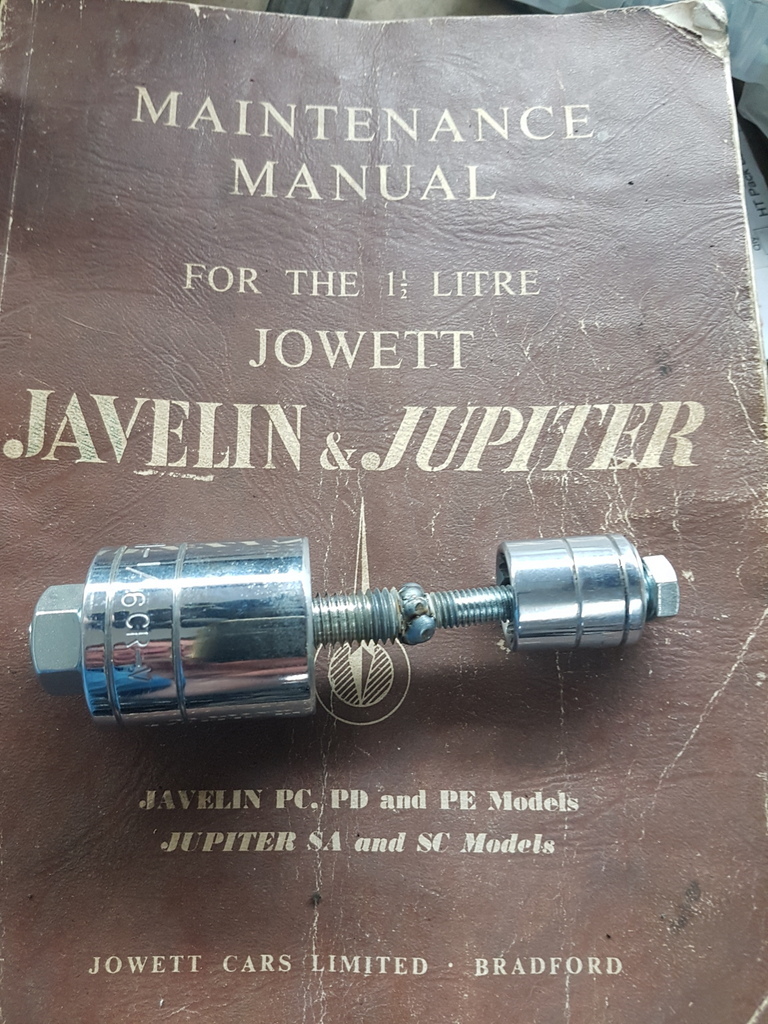

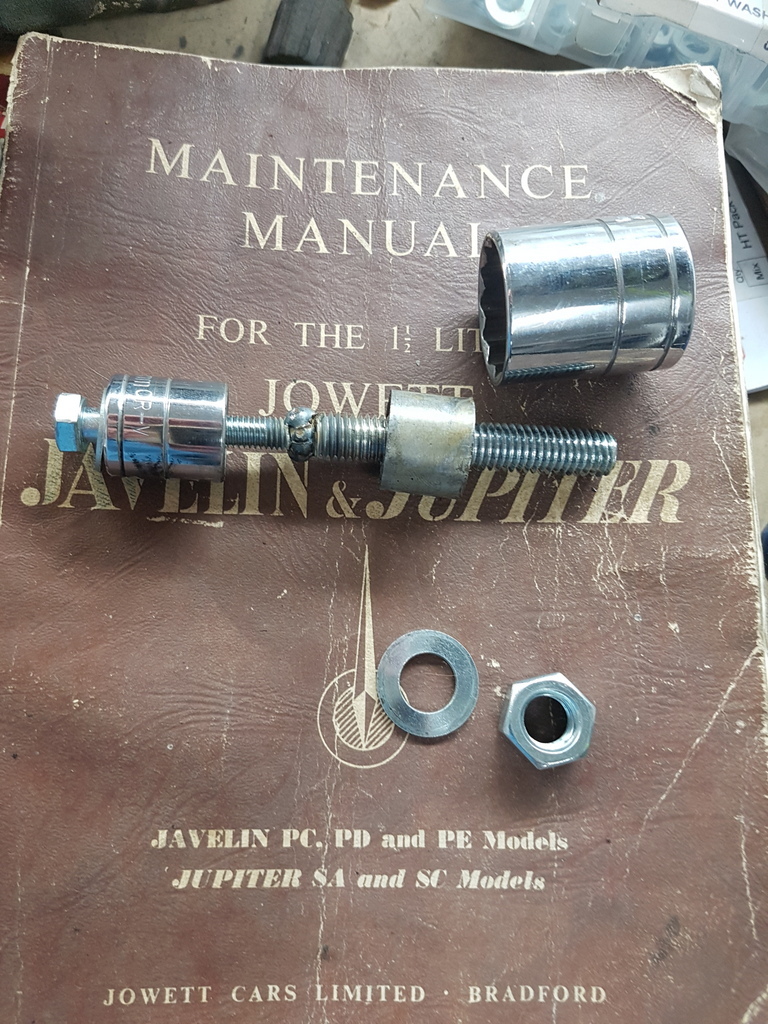

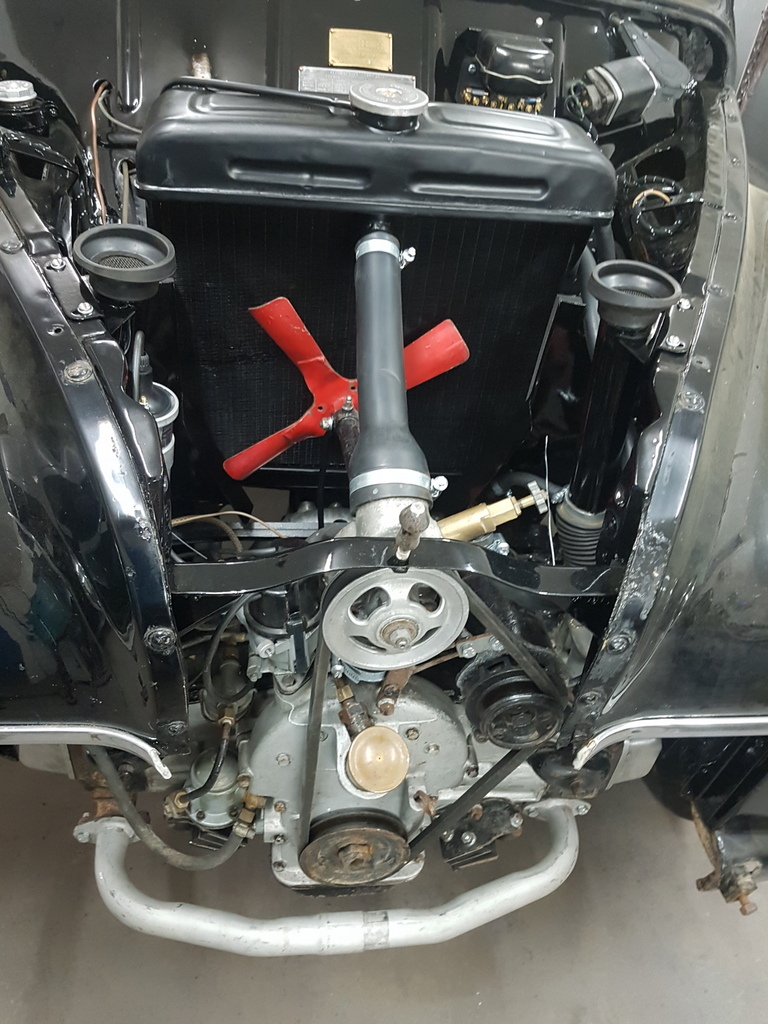

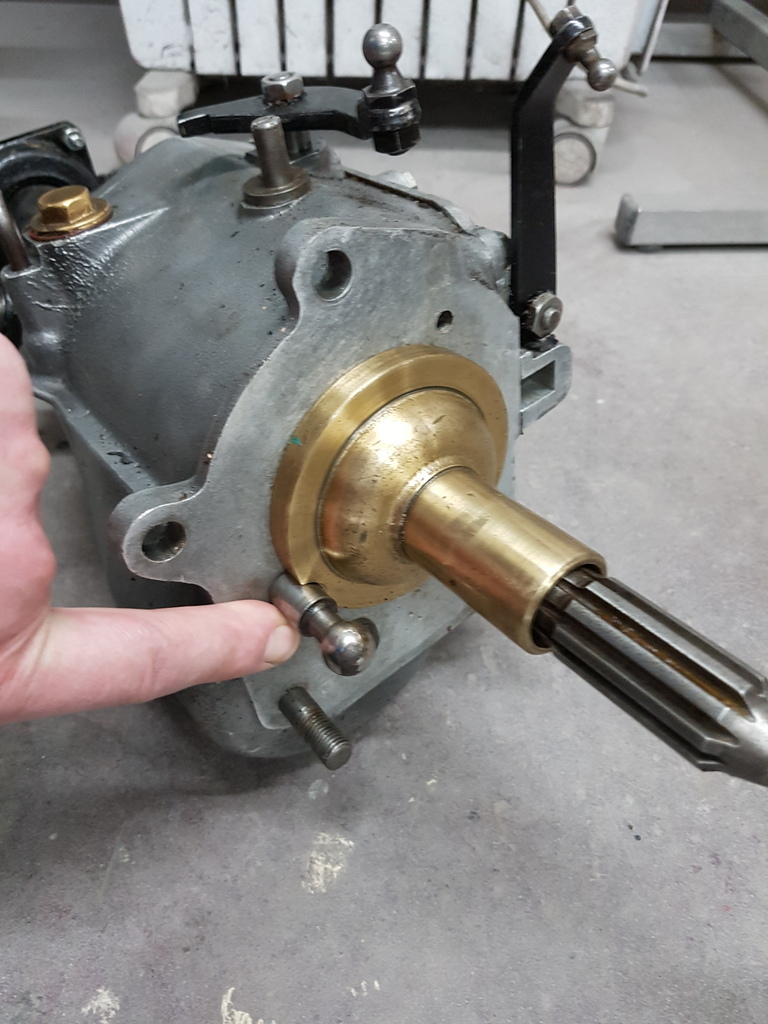

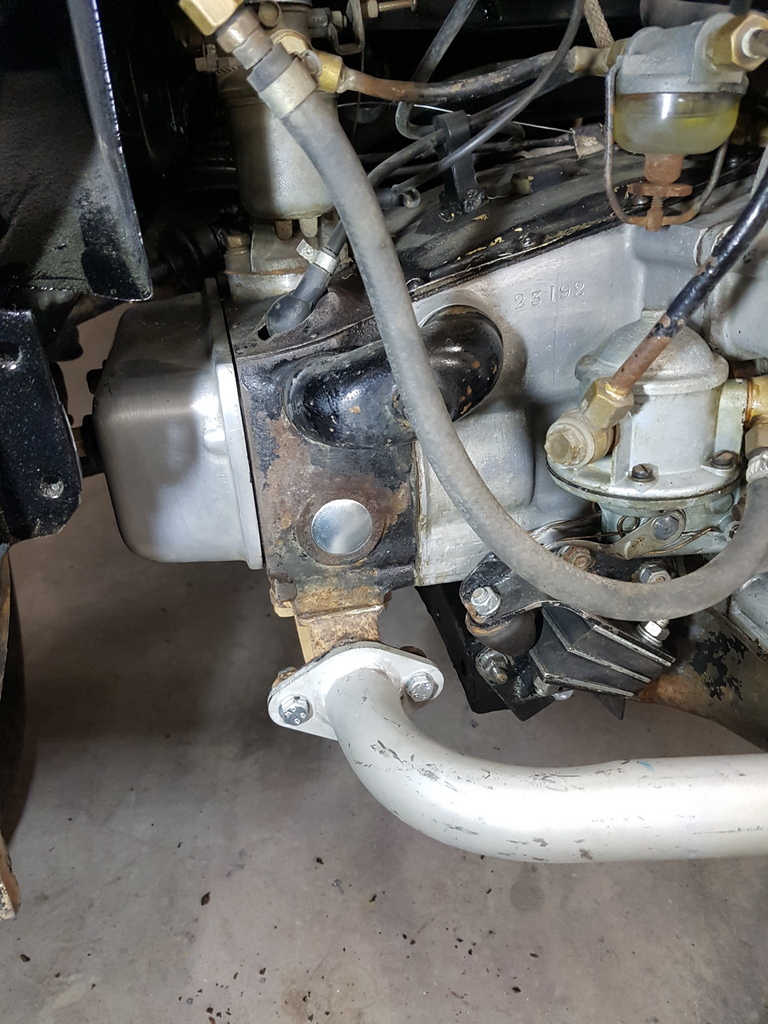

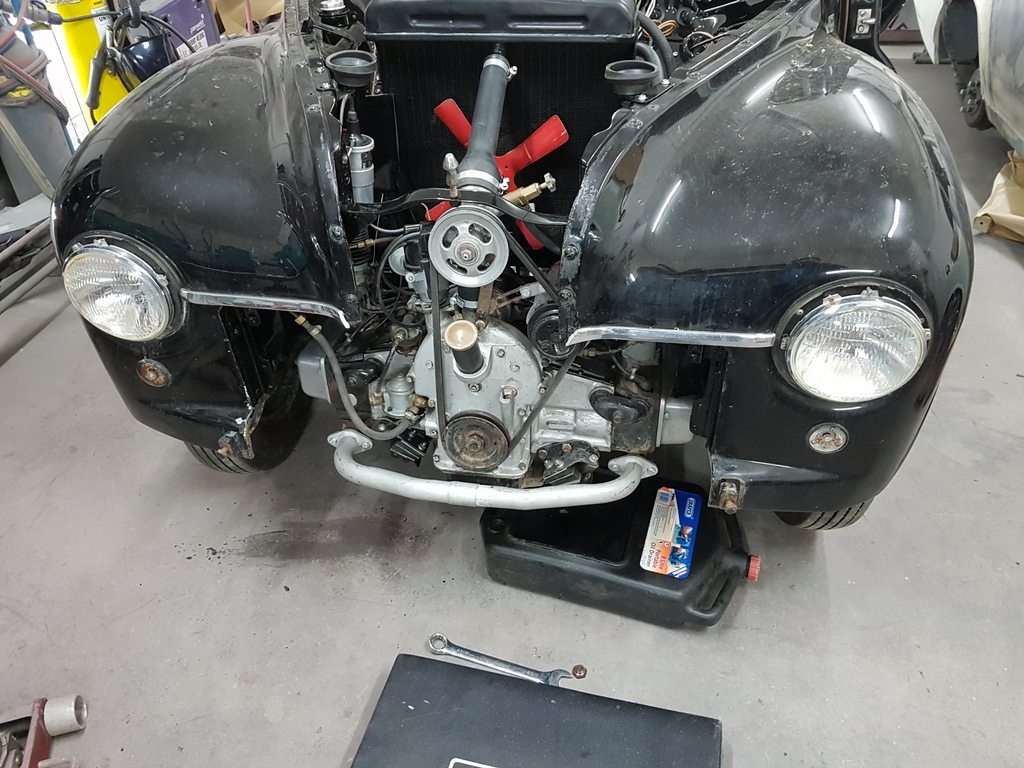

One of those days when every thing you planned to undertake and complete within a few hours - actually takes all day   Mounting bracket for the fan shaft welded up - I then removed the other one and painted them both up before refitting them - fan also refitted  Then fitted the air tubes - these direct air down to the carbs  Connected to the carbs by bellows  New grommets were fitted to the air tubes too - the old were badly perished - the air cleaner (oil bath type) is actually on the underside of the bonnet nose  Final engine bay connections made - chokes coupled up etc  Next was to replace the bush at the bottom of the column gearshift shaft - this had given problems along with the gearbox whilst out in Switzerland last year  New bush on the left - old one on the right - only that the old one had left the outer sleeve of the bush in the location aperture on the base of the shaft - I tried tapping it out but it was having none of it and I did not want to damage the shaft  So I made up a sleeve puller from a couple of sockets - a bolt and a small length of studding  Said sleeve puller in action  Sleeve removed  New bush is a tight friction fit hence that had to be drawn down into the aperture on virtually the same principle but now I could utilise thick washers instead of the sockets  Bush fitted & column reattached  I could now fit the gear selector rods from the shaft to the gearbox - I'm missing a locknut so I will have to run over to the barn at some stage to collect a spare - but its easily fitted through the access hole in the floor - The column change selects all gears too (in a static mode so that's a good sign)  Prop shaft connected back up and a new supply lead from the solenoid to the starter made up and fitted  Previous owner had an obvious habit of missing his 'Spec Saver' appointments - these were the washers off the prop bolts - all different sizes & weights - needless to say it now has matched washers of equal weights  Underside of gearbox insitu - new earth lead made up & fitted  Sid called in to do the quality inspections  And was nothing but very through with them too  Bodged copper shim on the end of the clutch rod - I have now redrilled the pedal leaver to round from the oval state that it was in and will cut the end of the rod and add a new right angle section to it (but ran out of time for use of noisy equipment like the angle grinder so will sort this in the morning)  Hence I left the offside front of the car up on a stand until the clutch linkage is sorted  But certainly getting there with the front end of the car - it needs to go back outside tomorrow and I need to press on with the paying jobs  But before then I needed to clear the decks with all the kit that I have had out (I hate not being able to find anything)  20 mins later it was sorted  More tomorrow |

| |

Last Edit: Apr 23, 2019 21:17:46 GMT by Deleted

|

|

|

|

|

|

|

Apr 23, 2019 22:06:14 GMT

|

|

really nice work. I like the ingenuity with the sleeve puller....

JP

|

| |

I know its spelled Norman Luxury Yacht, but its pronounced Throat Wobbler Mangrove!

|

|

|

|

|

|

|

|

I had a similar problem when I was replacing my suspension swing spring eye bolt bushes last year. I made up a similar device with threaded bar and sockets but ended up making 4 of them as the threads kept stripping. Eventully had to cut the old bushes out carefully with a hacksaw. The quality of some steel these days is appalling.

|

| |

Last Edit: Apr 24, 2019 8:47:45 GMT by Badwolf

|

|

|

|

|

Apr 24, 2019 11:04:56 GMT

|

are those fan shaft supports as per factory? given the rest of the engine , they look the most under engineered of components. Pete - Yep factory original - problem is that if you make something up that is well engineered and sturdy - it will not allow for the flex that the shaft needs from the water pump - next thing you know is that you are replacing the water pump bearings & the fan shaft every 2,000 miles - so the idea of the factory originals is to allow sufficient flex on the fan & shaft to avoid damage to the water pump still cant help thinking that despite being obviously very well versed in lateral thinking that they could have come up with a more "engineered" solution. on the flip side i assume that the support has given 60 years of service despite its simple and underwhelming form. |

| |

'80 s1 924 turbo..hibernating

'80 golf gli cabriolet...doing impression of a skip

'97 pug 106 commuter...continuing cheapness making me smile!

firm believer in the k.i.s.s and f.i.s.h principles.

|

|

|

|

|

Apr 24, 2019 12:15:59 GMT

|

Pete - Yep factory original - problem is that if you make something up that is well engineered and sturdy - it will not allow for the flex that the shaft needs from the water pump - next thing you know is that you are replacing the water pump bearings & the fan shaft every 2,000 miles - so the idea of the factory originals is to allow sufficient flex on the fan & shaft to avoid damage to the water pump still cant help thinking that despite being obviously very well versed in lateral thinking that they could have come up with a more "engineered" solution. on the flip side i assume that the support has given 60 years of service despite its simple and underwhelming form. If that was being engineered nowadays it would be a rigid pillar with a rubber bush or mount to take up the movement, the rubber could be tuned to damp vibrations and give different characteristics in each direction if required. |

| |

|

|

|

|

|

Apr 24, 2019 19:20:37 GMT

|

still cant help thinking that despite being obviously very well versed in lateral thinking that they could have come up with a more "engineered" solution. on the flip side i assume that the support has given 60 years of service despite its simple and underwhelming form. If that was being engineered nowadays it would be a rigid pillar with a rubber bush or mount to take up the movement, the rubber could be tuned to damp vibrations and give different characteristics in each direction if required. Its all ready been done for the Jupiter (same engine & drive train) - no one really ever bothers about doing one for the Javelin - has they very, very rarely give any problems |

| |

|

|

|

|

|

Apr 24, 2019 19:40:19 GMT

|

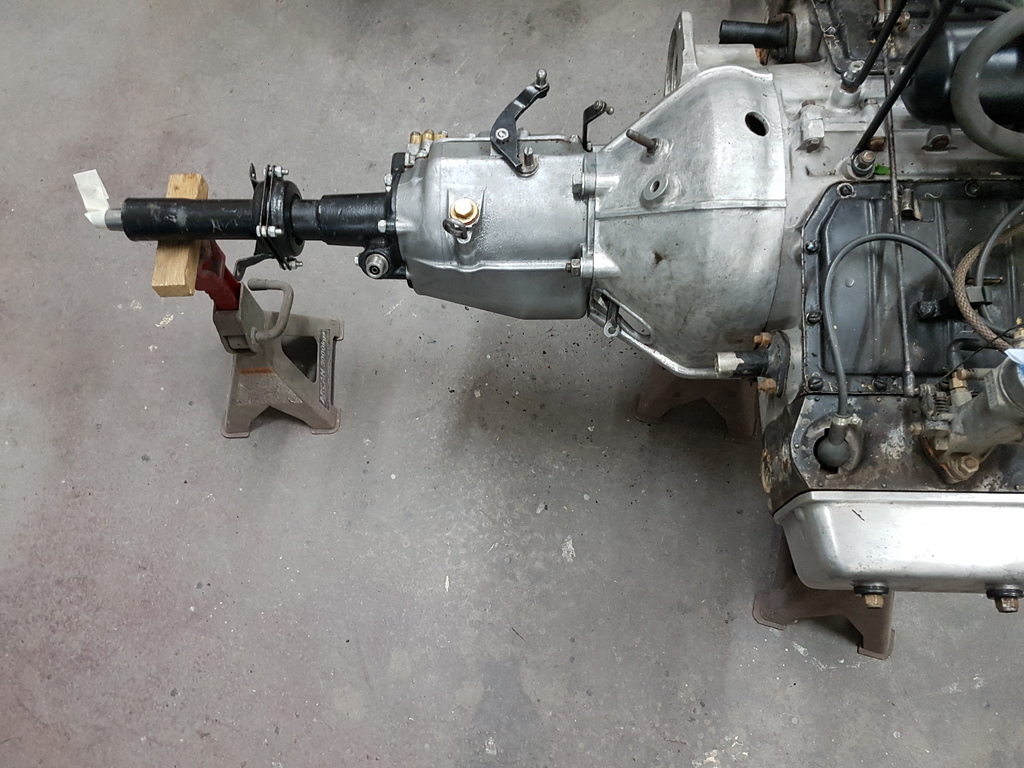

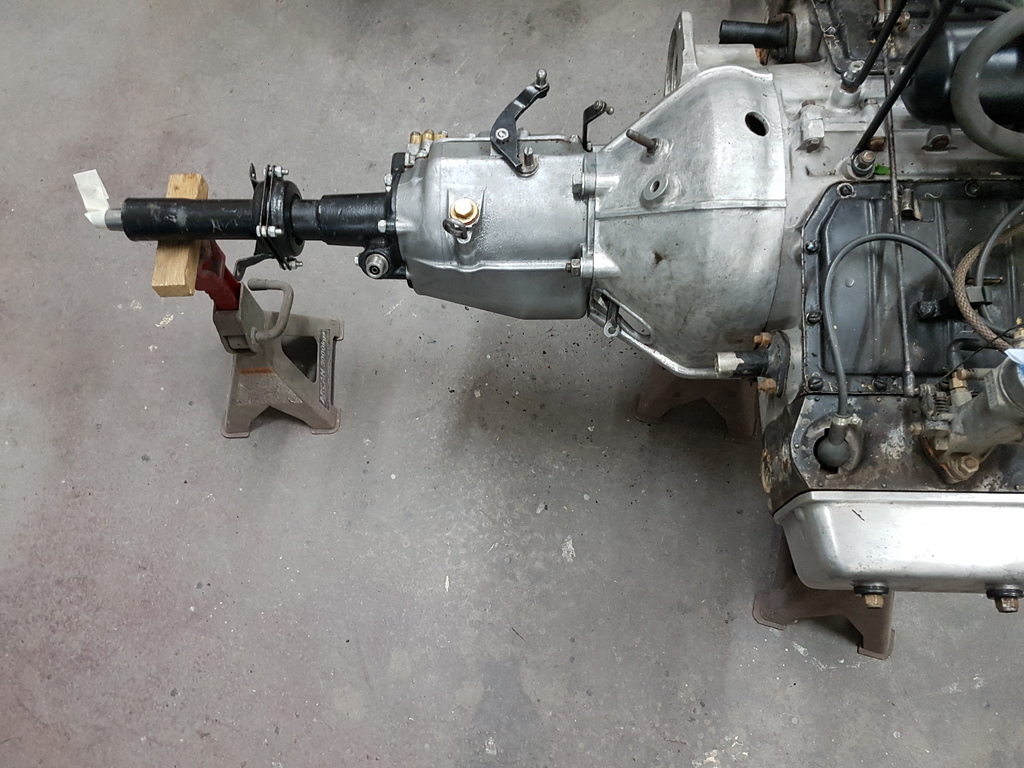

Sorted the repair on the clutch rod  Then connected it all back up  Made use of my single handed clutch & brake assistant  Annnd - Bu88er the clutch will not disengage  Spoke to Keith one of my fellow Jowett owners / club member that did the clutch on this car just prior to my ownership several years ago - transpires he had a bucket of problems with it to the point that engine & box was in & out of the car 3 times before the issue was resolved - talked it through with him and I have read up on the various issues - there is a chance that it can be resolved with the engine & box in the car but I have run out of working time for my own motors until the weekend - the paying jobs are sat waiting for my attention  Back outside for now ! |

| |

|

|

|

|

|

Apr 24, 2019 19:58:25 GMT

|

|

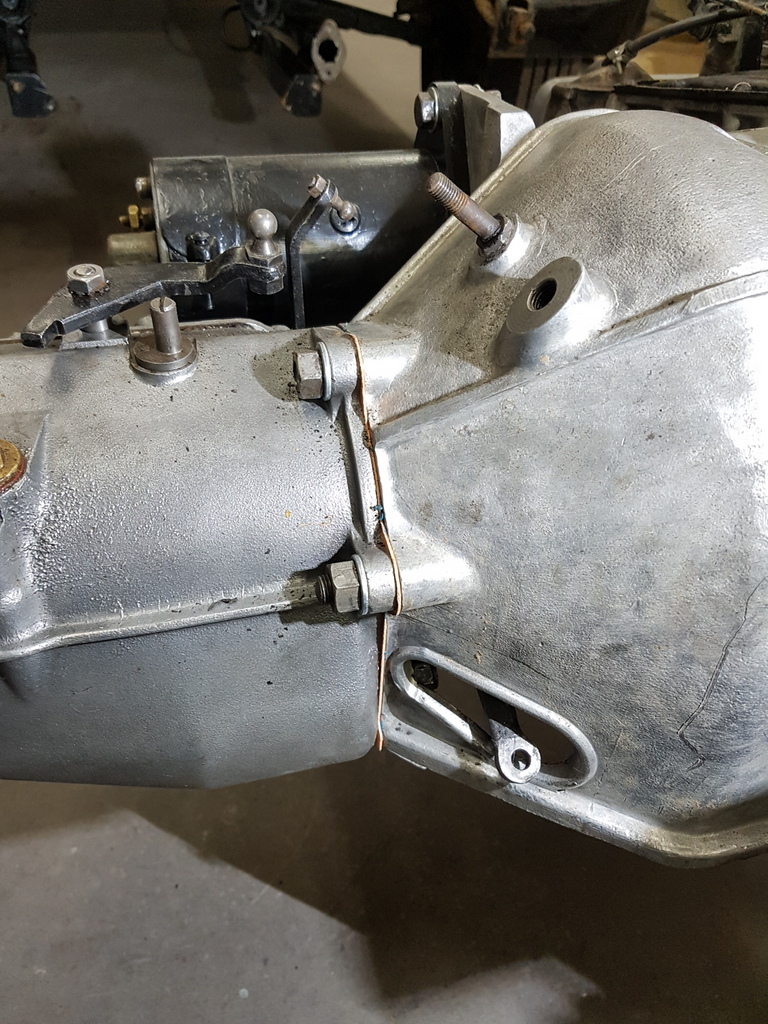

shame about the lack of clutch but that split bell housing is another joyous idea!

|

| |

'80 s1 924 turbo..hibernating

'80 golf gli cabriolet...doing impression of a skip

'97 pug 106 commuter...continuing cheapness making me smile!

firm believer in the k.i.s.s and f.i.s.h principles.

|

|

|

|

|

Apr 24, 2019 20:26:31 GMT

|

shame about the lack of clutch but that split bell housing is another joyous idea! Absolutely and it looks like I can access what I need to in order resolve the issue (hopefully)  |

| |

|

|

|

|

|

Apr 24, 2019 20:42:11 GMT

|

|

Hopefully, yes, something you can get back into without too much hassle. Just did a clutch on a new mini....the Jowett is much more straightforward!....(and the mini is easy by todays standards!)

Let us know how it goes!

JP

|

| |

I know its spelled Norman Luxury Yacht, but its pronounced Throat Wobbler Mangrove!

|

|

|

|

|

|

|

Apr 24, 2019 21:19:00 GMT

|

And was nothing but very through with them too  we call that "dobbing". you know like those sponge tip bingo pens or paper glue applicators. marty the ginger swear police frequently has a black nose, well, because land rover. |

| |

|

|

|

|

|

Apr 26, 2019 16:42:20 GMT

|

dobbing update from marty, scent correction completed.  |

| |

|

|

|

|

|

Apr 27, 2019 20:03:40 GMT

|

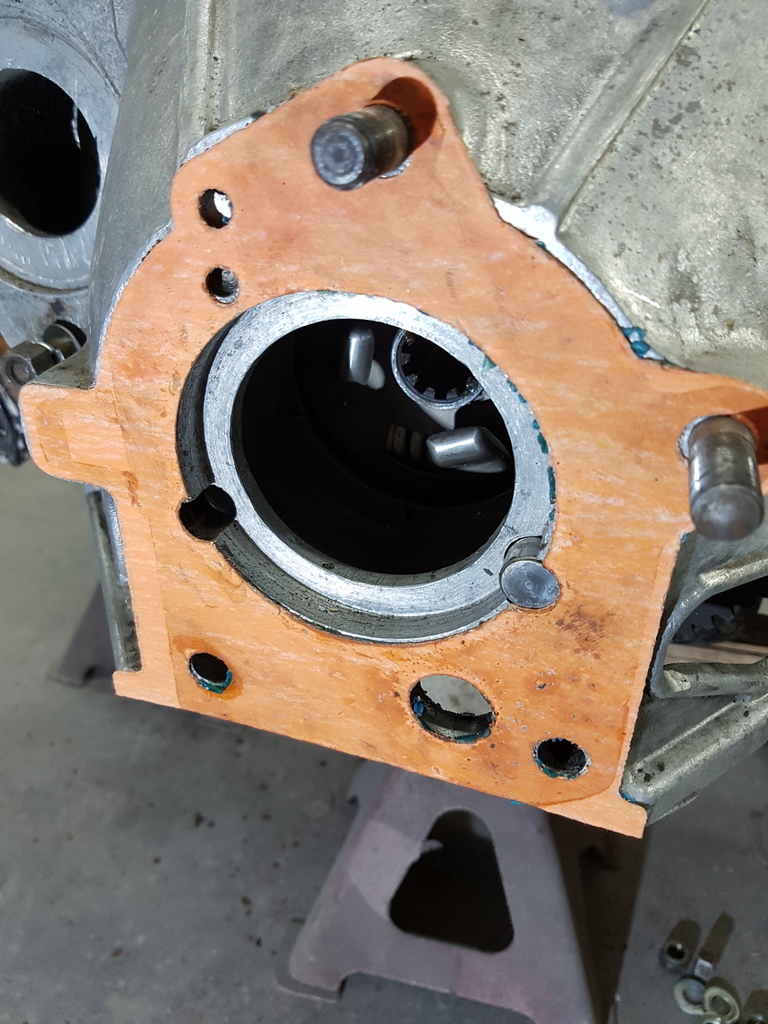

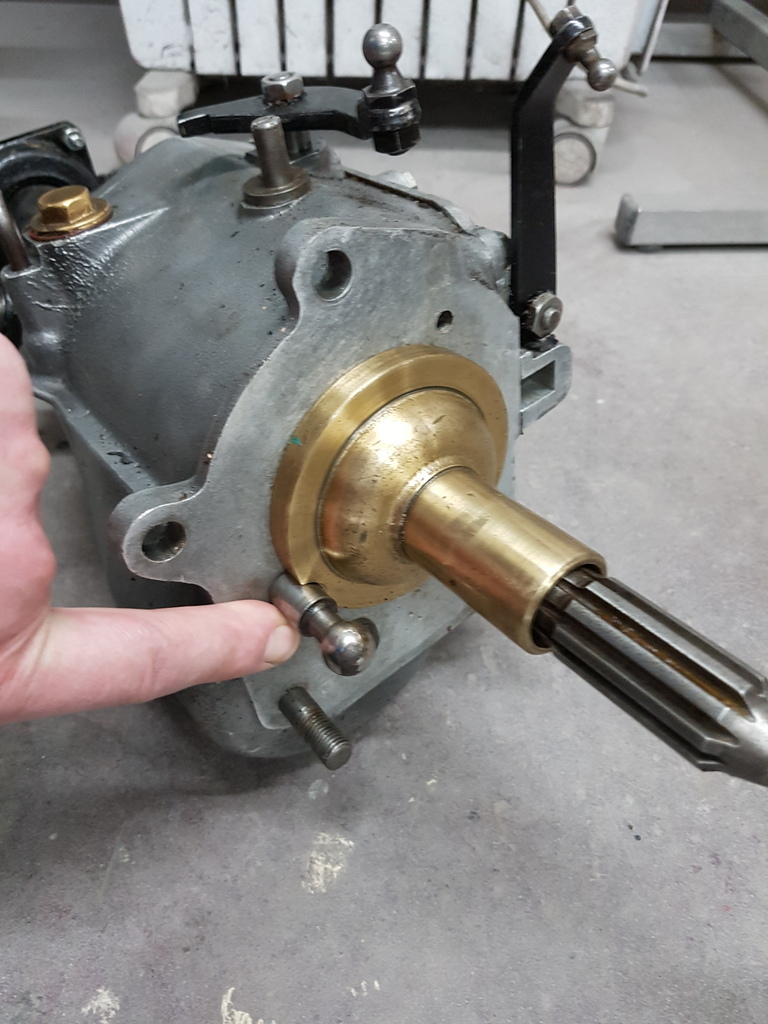

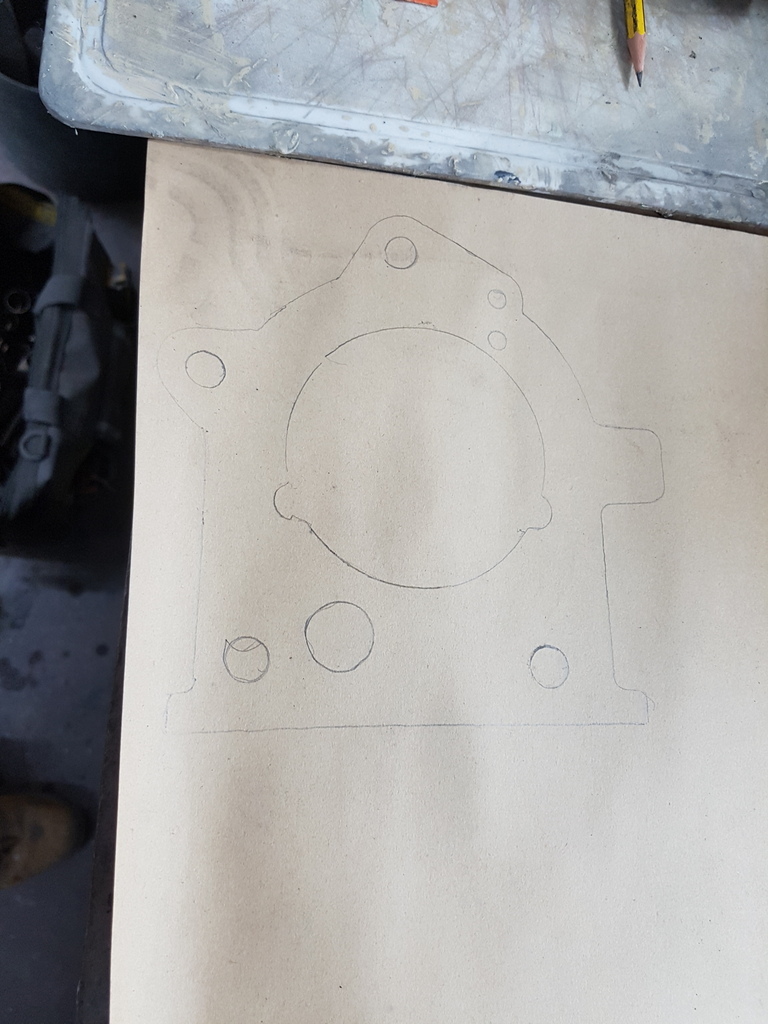

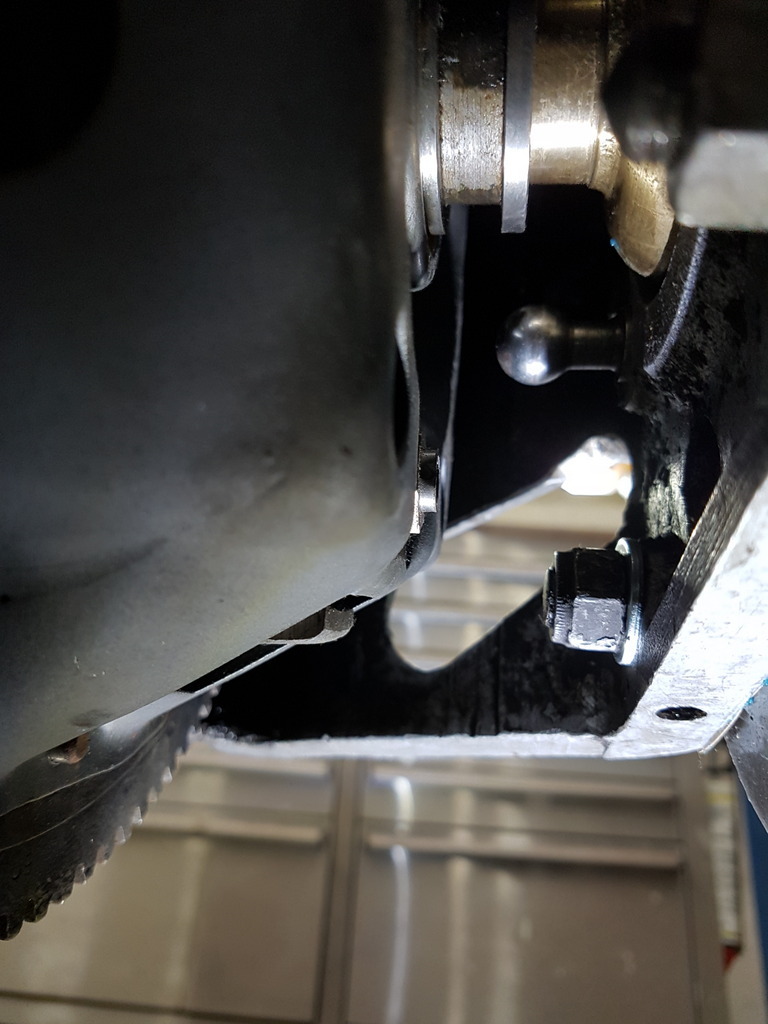

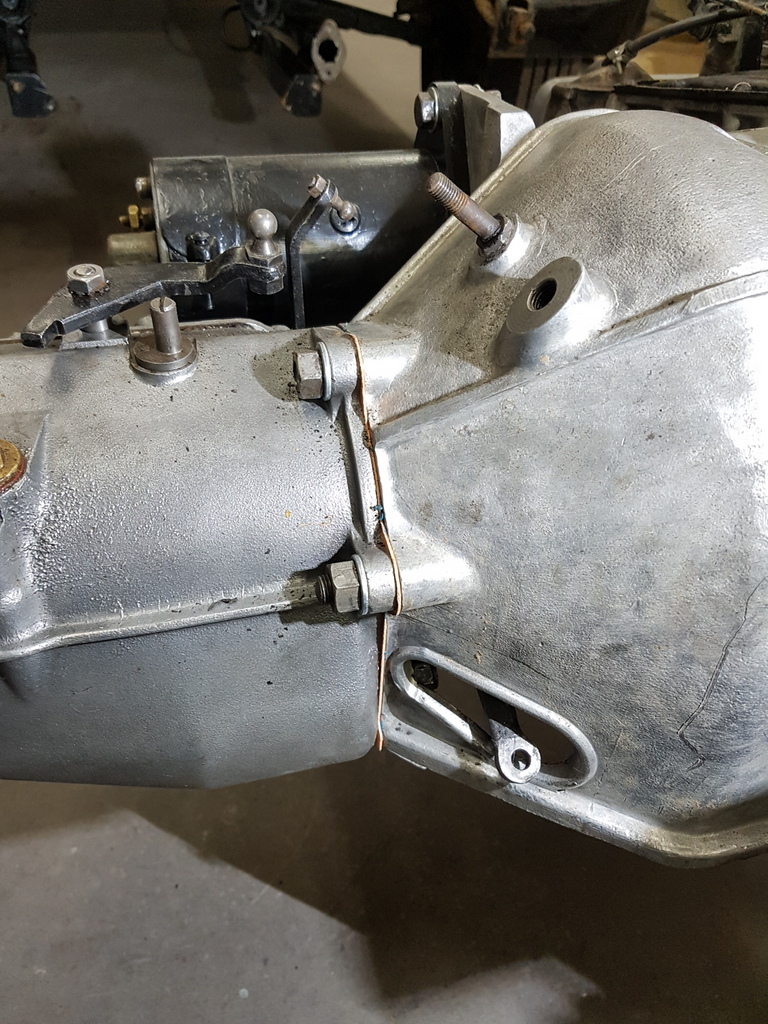

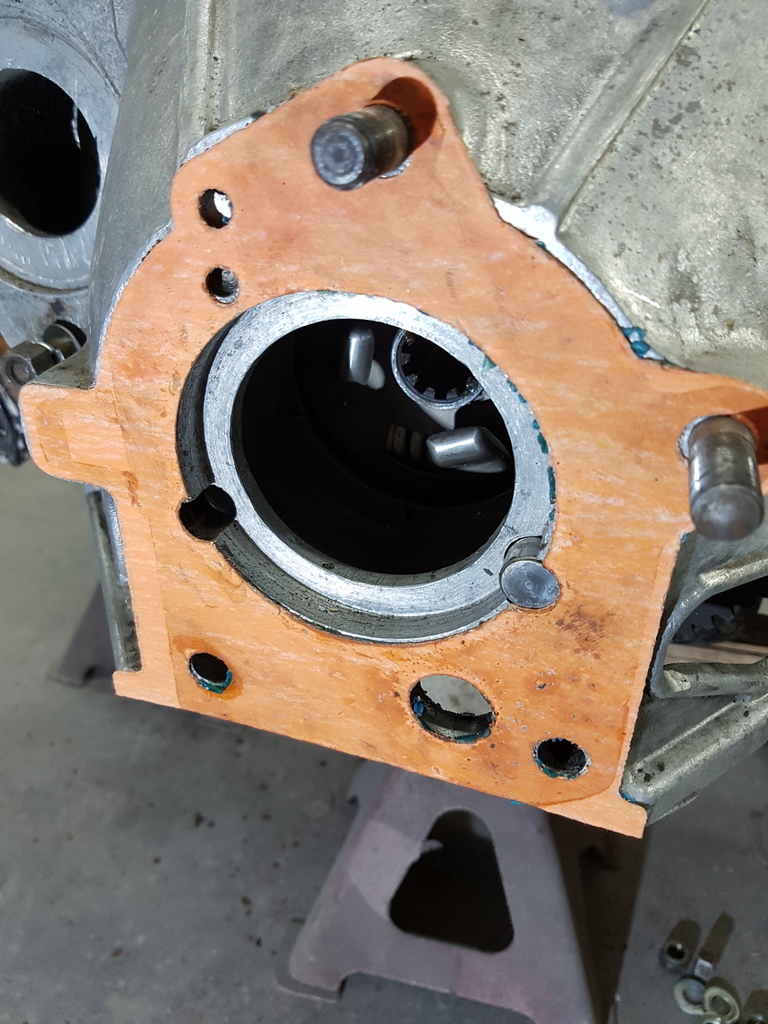

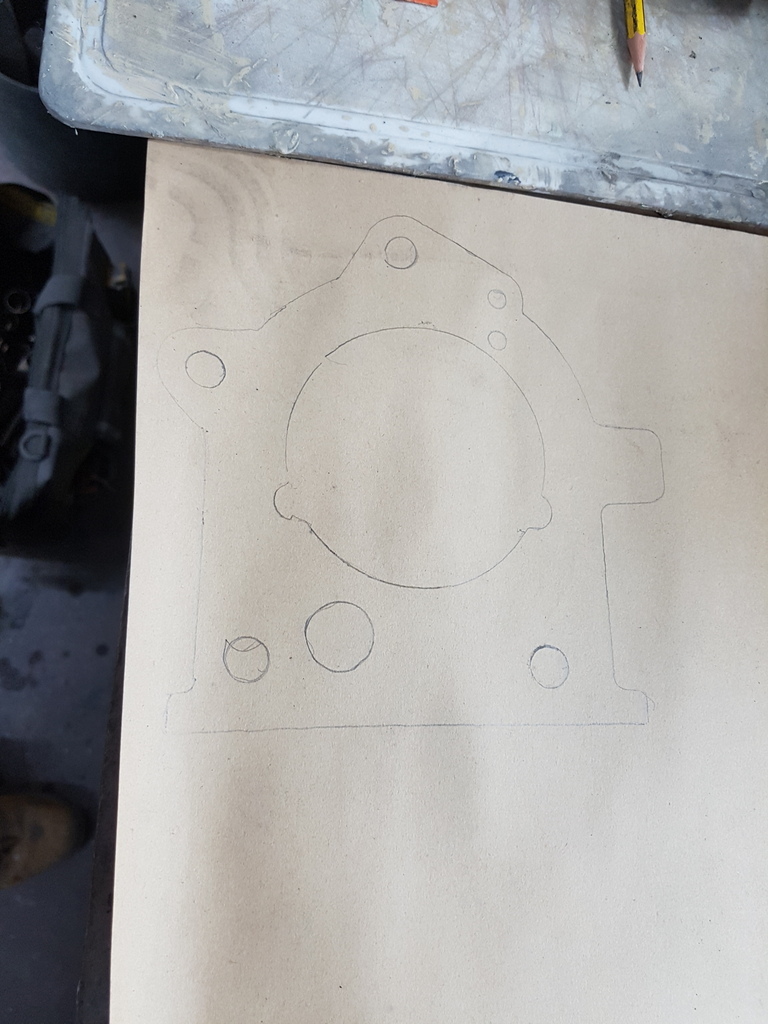

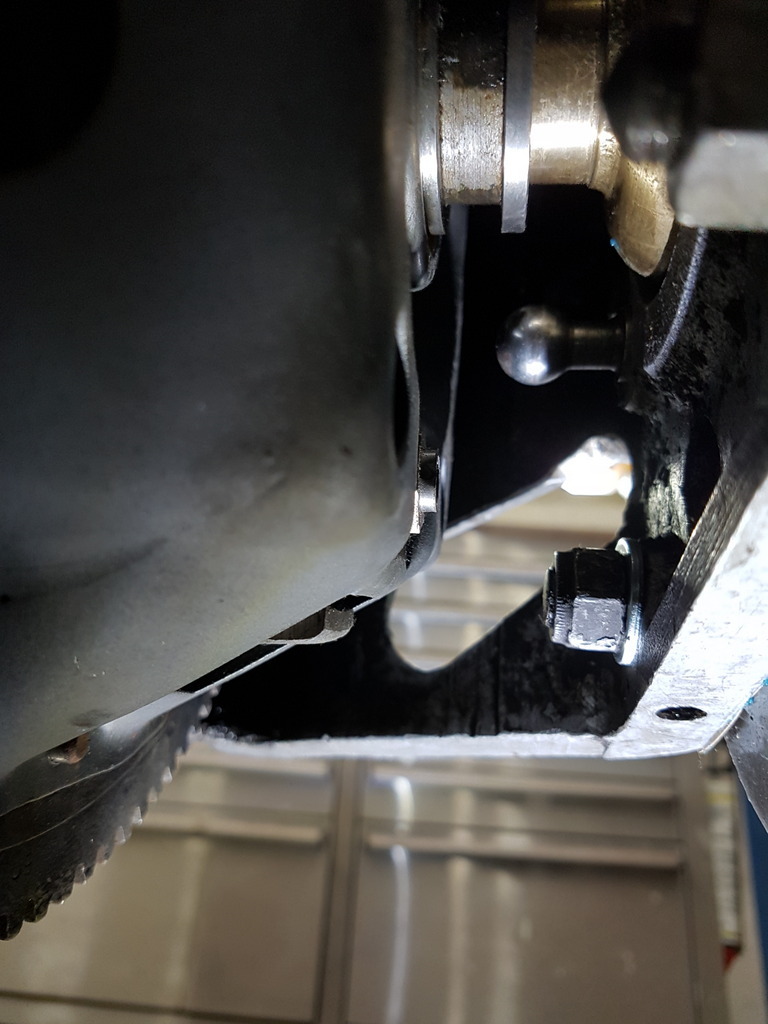

Javelin dragged back into the workshop this afternoon  Up in the air I poked - prodded & inspected the offending clutch & mechanism - then made an executive decision  Engine & box back out - I hadn't refilled the fluids - and it didn't take that long before it was out  Up on stands for stability & safety - plus that fact it made easier for me to crane my head under the bellhousing to see what was happening  Box is going to have to come back off - but its only 4 nuts  Having talked it through with one of my fellow club members / Jowett owner we think that this gasket is over specified in thickness - so it moves the gearbox back - we are only talking 1.05mm of thickness here - but has we all know size matters  What this does is reduce the length of the pivot that the clutch fork sits on - once you take the leverage difference into account on the end of the fork - I am loosing between 3 - 5 mm and that is the difference between the clutch clearing and it not - at first we thought that we maybe able to pack the pivot out - but it was far quicker & easier to just remove the engine & box - pivot shown in the pic below  Solution - make a thinner gasket - this is 0.35mm - so 0.70mm less  Gearbox refitted and a check underneath reveals a far better fit of the pivot  Then something that I ought to have done in the first place - checked that the clutch cleared before fitting the engine & box  We have a winner  All ready for the refitting in the morning   Time to go and crack open a beer or two or maybe a gin - I like being spoilt for choice  |

| |

Last Edit: Apr 27, 2019 20:10:57 GMT by Deleted

|

|

|

|

|

Apr 27, 2019 20:09:54 GMT

|

At least it was an easy-ish fix... even if it involved a bit of head scratching  |

| |

|

|

|

|

|

Apr 27, 2019 21:48:42 GMT

|

|

Well done.

Would a small bead of sealant not of done the same job or is there a specific reason why it had be a paper gasket?

|

| |

|

|

|

|

|

Apr 27, 2019 22:35:55 GMT

|

|

Is there a reason for gasket, period? Can't be a liquid seal, and it's not dissimilar metal barrier

|

| |

Last Edit: Apr 27, 2019 22:36:51 GMT by darrenh

|

|

|

|

|

|

|

Is there a reason for gasket, period? Can't be a liquid seal, and it's not dissimilar metal barrier Gearbox oil is fed to the clutch shaft on the gearbox and the bronze dome that you see in the pic - so oil can make its way towards the clutch housing if you don't use some form of gasket - the original one was supplied by the club spares department - its a recent batch and I don't think they are currently aware of the difference it makes to the pivot - I could have used a liquid seal but didn't want problems if I had to part it again - that and you know me I'm pretty old school it only took 5 mins to knock up the gasket that I used to refit the box with |

| |

Last Edit: Apr 28, 2019 7:06:25 GMT by Deleted

|

|

|

|

|

|

|

|

plus with the gasket you have absolute control of the thickness which you don't with sealant. in this instance as that was the issue its a no brainer.

|

| |

'80 s1 924 turbo..hibernating

'80 golf gli cabriolet...doing impression of a skip

'97 pug 106 commuter...continuing cheapness making me smile!

firm believer in the k.i.s.s and f.i.s.h principles.

|

|

|

|

|

|

|

|

If this works, and I see no reason why it shouldn't, its amazing that a simple gasket thickness has caused such a problem. Well done for thinking it through. I would have had the car down to the local garage, got a bill with several '000's' on it and more than likely a rubbish job. All for the sake of .7mm. Hope that the congratulations are not premature. By the way, in your pic of dragging the car into the workshop do I detect a spy hole in the hedge (LH side, half way up) with two eyes looking through or is it just my imagination!!??

|

| |

|

|

|

|

|

Apr 28, 2019 21:38:24 GMT

|

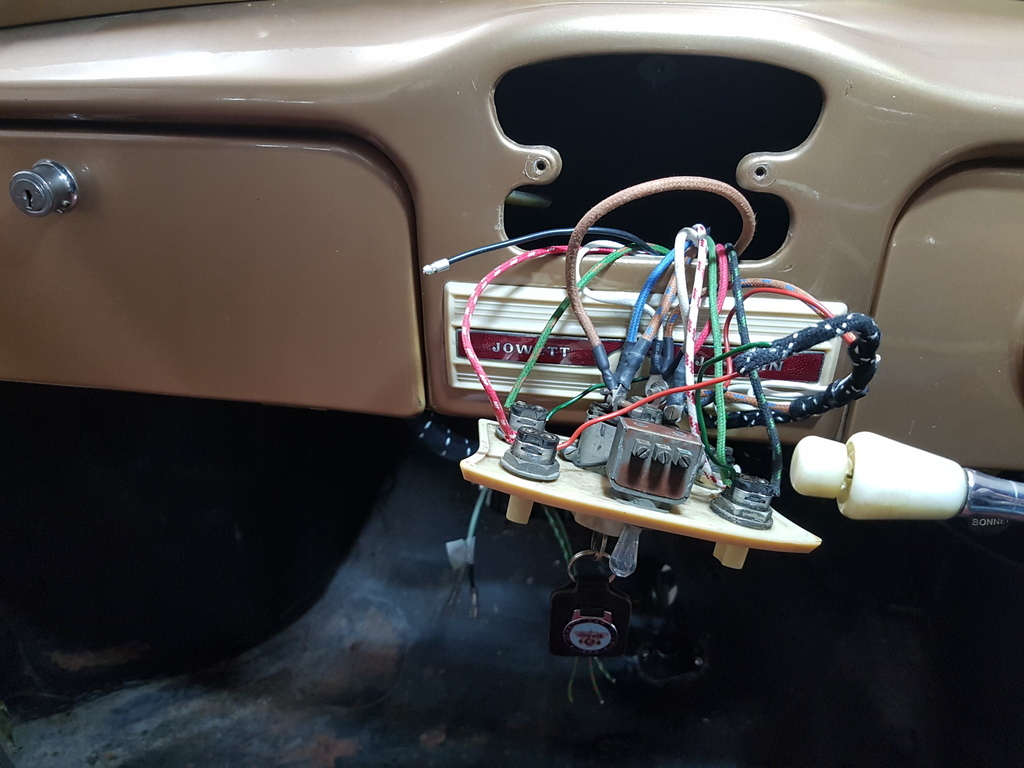

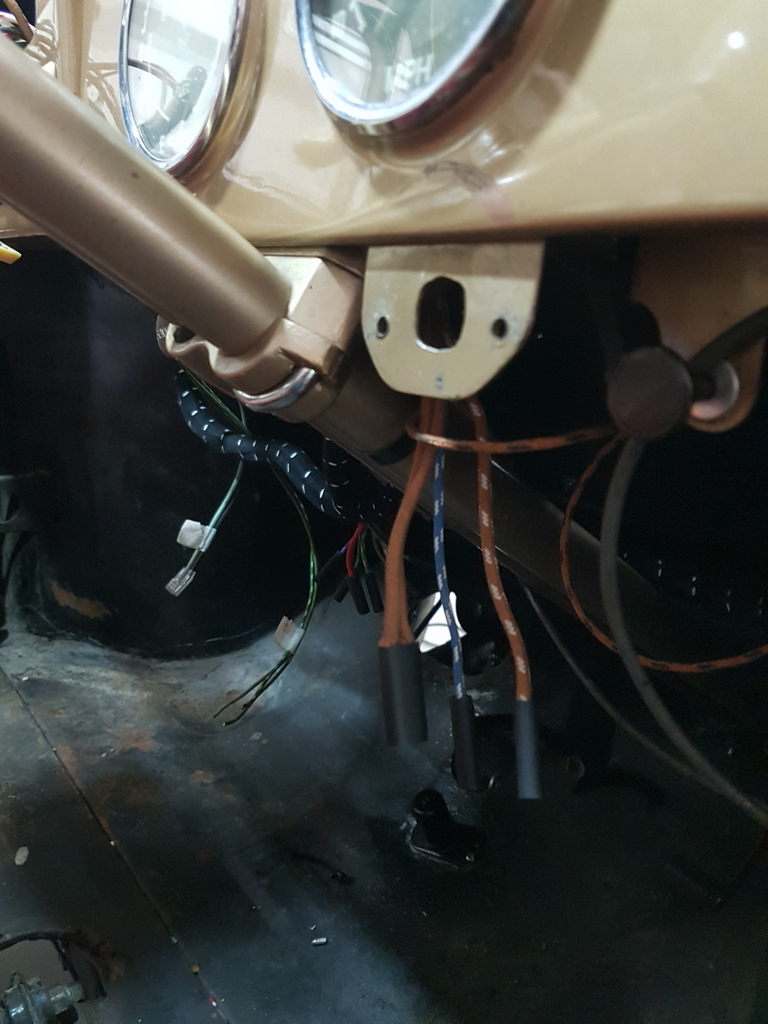

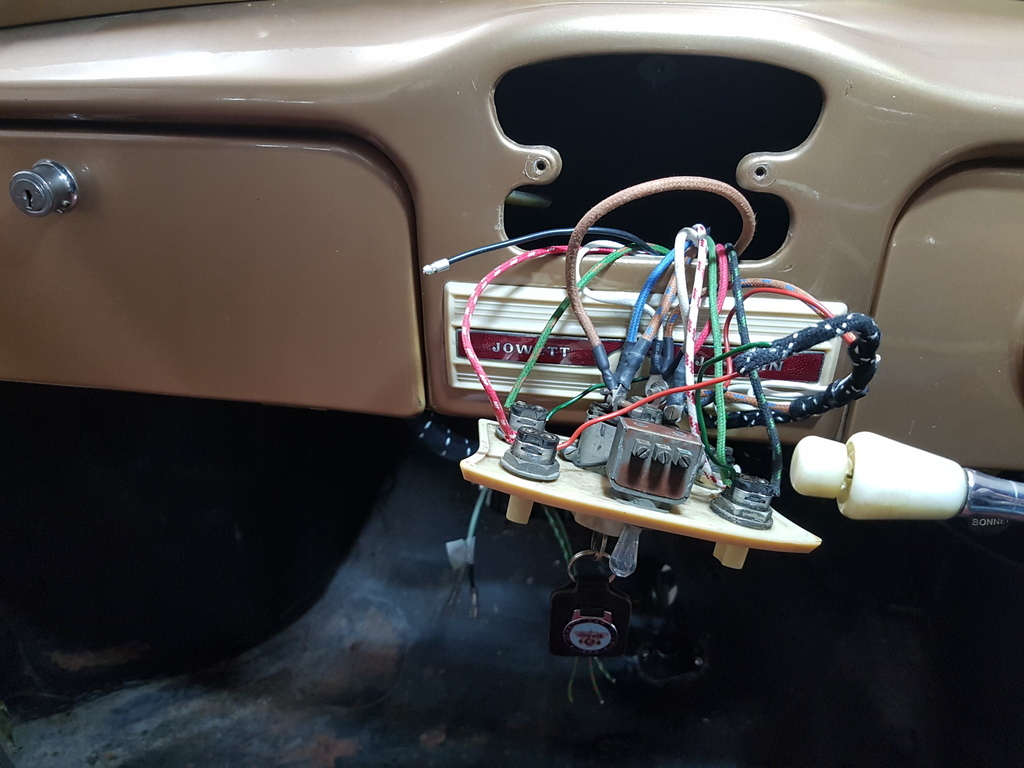

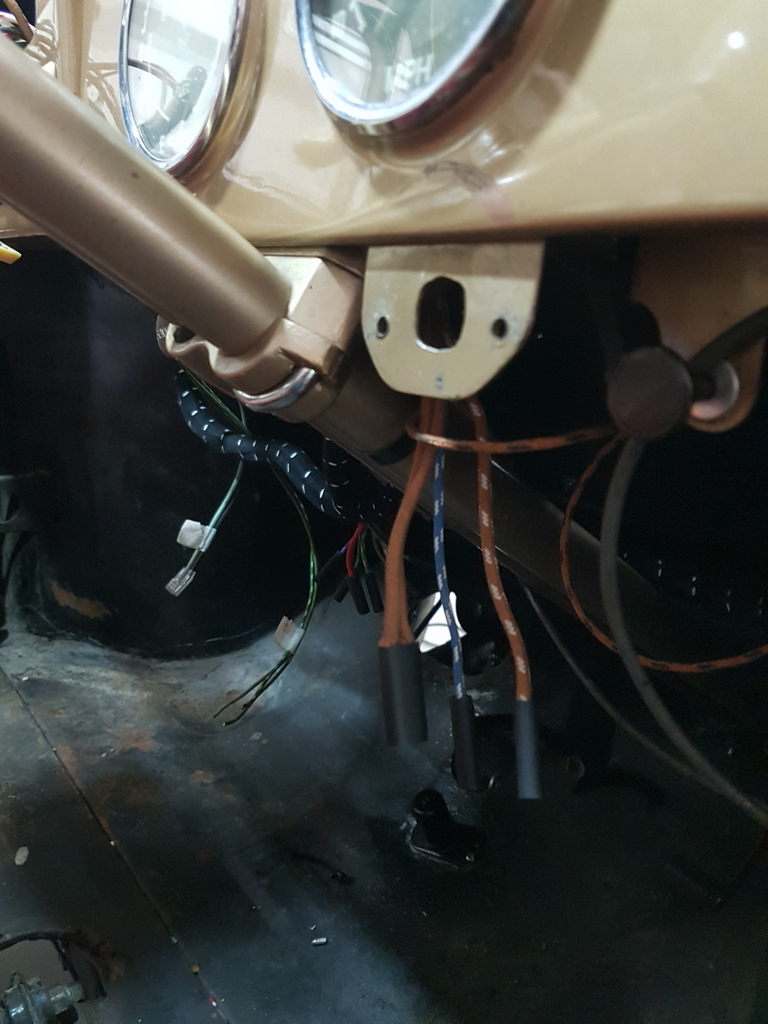

So - engine & box back in  Bolted up on the mountings - then the first thing I did was to connect the clutch - then try it - and guess what - the clutch clearance that I had yesterday with the engine & box out of the car had disappeared - gone - vanished - not there back to the old problem - non disengaging clutch - double bu88er  Scratched my head a bit - had a think about it - then stared at it for a while - then resolved it - I do have clutch clearance but the pedal is capable of taking the clutch over centre at which point the clutch fork clatters and locks up with the fingers on the pressure plate  So providing the pedal is not allowed to travel further than this point - its fine  Knock an adjustable pedal stop together and weld it insitu then  Just needs the edges taking off it with the angle grinder tomorrow (not running any machinery in the workshop currently over the weekend whilst working on my own car - I want to see how far the pair of idiots next door push their luck on the issue first)  Then connected everything back up in the engine bay  I had noticed a weep on a core plug on the left hand head  Hence that got changed prior to adding coolant to the car  Then drained the oil  Oil refilled to both the engine & gearbox  Back to the electrics then - connected the battery - and found no power at all to the dash / ignition Scratched my head again - did a load of checking and eventually found a live feed - worked out that this would go to the ammeter on the delux model (although its not shown on the wiring diagram & its in a unidentified colour that is not listed on the diagram) then found a spur link that should run back from this point to the ignition switch - again not shown on the diagram - so I made some assumptions & connected them up  Which gave me power to the ignition switch - starter cranked over and eventually I got the car to start - but the timing on the new distributor is out and needs setting up properly - job for another day  But the side lights check out at the front (all 3 candle power of them) - has does the wiper motor  Dipped beam  Along with main beam Still absolute tons of work to get done on it - going to have to be done on the night shift though has the momentum on the day job needs to be maintained |

| |

Last Edit: Apr 28, 2019 21:44:49 GMT by Deleted

|

|

|

|