|

|

|

|

|

|

I lost track of this build for some reason and have been looking for it!....glad its back up top....Ill have to keep and eye out for it!

love the work being done....labor of love or high craft or both....

JP

|

| |

I know its spelled Norman Luxury Yacht, but its pronounced Throat Wobbler Mangrove!

|

|

|

|

|

|

|

|

|

Two of the roof rails were dead so machined a piece of ash down to two lengths    Fortunately I managed to salvage the radius sections at each end of the rails which are splined / toothed - just need to check for fit tomorrow and then they can be glued up together |

| |

|

|

|

|

|

|

|

|

Love these threads..

Bookmarked..

|

| |

|

|

|

|

|

May 12, 2017 11:06:59 GMT

|

|

This is a blast from the past for me - I owned and drove Jowett Bradford as every day transport in NZ from 1979 - 1987. My father and I did up 2 vans and 1 utility. (I also restored a Jowett Javelin car). Several times between 1982 and 1986 I drove the Bradford from home in Auckland to university in Christchurch a 1200km / 600 mile trip which took 2 days given slow speed of the Bradford when any hill was encountered and the 1/2 day gap in the middle for the Cook Strait ferry crossing

For the vans, instead of replacing the roofing with the original flimsy vinyl type fabric we got a fibreglass fabrication place to make a whole one piece top in-situ, black coloured and about 5mm thick. Looked really good, completely watertight and massively strong and rigid and helped hold the whole body together. We refitted the original guttering back afterwards and unless you were really close up it wasn't that obvious that the roof was fibreglass.

The other thing I recall we did was to extend the chassis outrigger brackets as the originals were shorter than the woodwork they supported which lead to slumping of the bodywork at the outer edges where it was unsupported

Looking forward to seeing future instalments !

|

| |

|

|

|

|

|

May 12, 2017 17:58:36 GMT

|

|

how did they get the bends originally, steamed ? or hand picked only the finest wonky bows ?

edit, just seen the join

|

| |

Last Edit: May 12, 2017 18:00:18 GMT by darrenh

|

|

mgmrw

Part of things

Posts: 701

|

|

May 12, 2017 21:54:02 GMT

|

|

All sorts of awesome.

|

| |

|

|

|

|

|

Jun 13, 2017 22:06:57 GMT

|

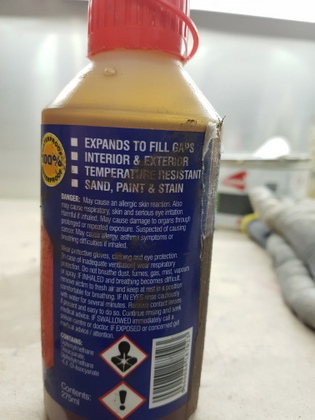

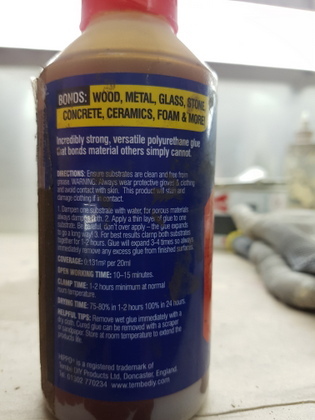

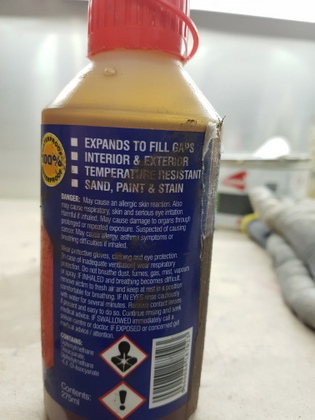

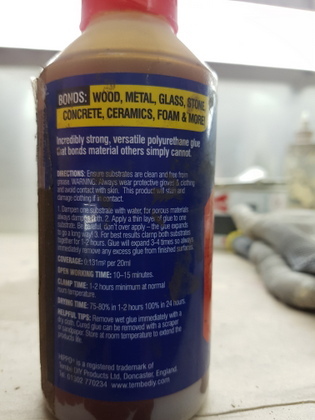

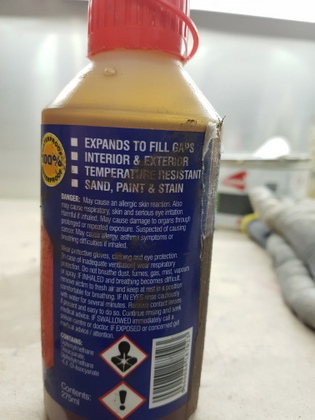

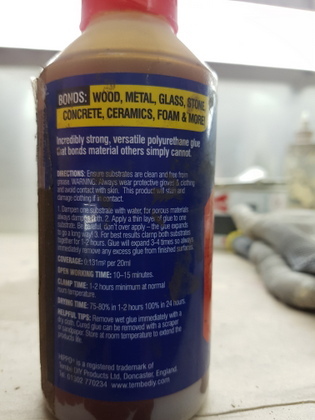

Managed to get a bit done on this today - so fastened the two repaired roof rails on and then trimmed in and fitted the lathes  From what I can see most of the joints on the body were assembled dry - i.e. without any glue - in order to return some strength back into the ash frame I opted to use an expanding wood glue which did the job remarkably - along with twin thread woodscrews which were impact driven - certainly a lot stronger now Next to sort is the nearside rear door pillar which has fractured across the upper hinge - I cut this back to a sound section and will now use the two removed pieces has a pattern to form a new section which I shall splice in   |

| |

Last Edit: Jun 13, 2017 22:09:38 GMT by Deleted

|

|

|

|

|

|

|

Little bit more done on this yesterday - Made up the repair section from a piece of ash for the rear door pillar using the U/S section as a pattern  Opted to bolt through the spliced section rather than use screws - used the expanding wood glue again   Really strong repair - helped by the original metal brace bracket which fastens the side member, roof rail and the door pillar together Made up one side of the A post edge repair which was shrunk to match the post radius   |

| |

Last Edit: Jun 15, 2017 8:07:11 GMT by Deleted

|

|

|

|

|

Jun 16, 2017 11:51:39 GMT

|

|

really nice woodworking skills mated to the automobile....but I guess thats the way things used to be with traditional coach building...

JP

|

| |

I know its spelled Norman Luxury Yacht, but its pronounced Throat Wobbler Mangrove!

|

|

|

|

|

|

|

|

|

| |

Last Edit: Aug 4, 2017 21:59:23 GMT by Deleted

|

|

|

|

|

|

|

|

|

|

|

|

I don't know if it would be appropriate, but have you thought about soaking all the timber in wood hardener to help prevent any future/further decay and softening?

|

| |

|

|

|

|

|

|

|

I don't know if it would be appropriate, but have you thought about soaking all the timber in wood hardener to help prevent any future/further decay and softening? It's not a bad idea - however a lot of it is inaccessible - the ash frame on the Bradford is something that gains it's full strength once all the panels are attached to it - what I will do is spray all the accessible timber frame with a wood preservative once I have the panels sorted - my method of strapping & gluing the loose joints with an expandable glue works well |

| |

|

|

|

|

|

|

|

Progress on the nearside with the windscreen aperture / A Post panel fitted - this is screwed to the ash frame on the inner windscreen aperture & nailed down the outer edge of the A Post - next was sorting the door fit / aperture - the door was dropping at the bottom rear corner and dragging on the top of the B post in the top corner  The top door hinge was loose on both the door and the A post  I had to strip the door of it's internals to access the hinge bolts  It's all very simple - virtually agricultural in construction   The frame / van is 70 years old so with movement / damp / rust / shrinking of the timber etc things have just come loose or seized - Top hinge just tightened up on the door side but I had to put new countersunk machine screws in has the old ones just sheared when I went to tighten them up - I made up a couple of alloy hinge packers for the bottom hinge to give me the 2 mm gapping that I required  I then had to pack the lock / latch keep out on the B post to ensure that worked  But now a decent fit for most of the door aperture  With exception of the A post / door frame aperture - the A post is tight onto the ash frame and the door fits the rest of the aperture so the A post will require some modification to close up this gap - I can achieve this with some 5 mm round bar then lead the area up to achieve the profile - the fits were never perfect but again it's a 80 year old agricultural design, hand built to no exact tolerances on a vehicle that has spent the last 35 years abandoned in a very damp half roofed shed - More soon |

| |

Last Edit: Aug 13, 2017 7:54:40 GMT by Deleted

|

|

glenanderson

Club Retro Rides Member

Posts: 4,353

Club RR Member Number: 64

Member is Online

|

|

|

|

|

What glue do you use? I've used Cascamite in the past, with good results, but time and technology moves on and I'm more than a bit out of touch.

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

Aug 13, 2017 10:54:22 GMT

|

I don't know if it would be appropriate, but have you thought about soaking all the timber in wood hardener to help prevent any future/further decay and softening? It's not a bad idea - however a lot of it is inaccessible - the ash frame on the Bradford is something that gains it's full strength once all the panels are attached to it - what I will do is spray all the accessible timber frame with a wood preservative once I have the panels sorted - my method of strapping & gluing the loose joints with an expandable glue works well I can see accessibility being an issue. It does soak in very deep though. Put enough on and it will penetrate a 1" piece of timber from one side. It basically resinises (making up words now) the wood. Would be good on the more rot prone areas. On the other hand, the van doesnt have to do another 30 Years hard service in the rain so its probably not going to rot again anyway. |

| |

|

|

|

|

|

Aug 13, 2017 11:14:17 GMT

|

What glue do you use? I've used Cascamite in the past, with good results, but time and technology moves on and I'm more than a bit out of touch. This stuff    Cascamite was good in it's day but this stuff is streets ahead - all manufacturing joiners use it - available through most builders merchants if you google it - it lists the stockists - I think the gorilla brand has a version of it but not tried it - I'm perfectly happy with this stuff - it's about £10 ish and you don't need to use a lot to achieve the bond |

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,353

Club RR Member Number: 64

Member is Online

|

|

Aug 13, 2017 11:31:53 GMT

|

|

Ta very much. I was sure there'd be an alternative.

The best/worst thing about cascamite is that it takes so long to cure.

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

Aug 13, 2017 14:44:16 GMT

|

|

You can also get it in a variety of curing times, I have found though that for furniture repairs especialy on hardwoods epoxy seems stronger.

|

| |

|

|

|

|

|

Aug 13, 2017 15:09:41 GMT

|

What glue do you use? I've used Cascamite in the past, with good results, but time and technology moves on and I'm more than a bit out of touch. This stuff    Cascamite was good in it's day but this stuff is streets ahead - all manufacturing joiners use it - available through most builders merchants if you google it - it lists the stockists - I think the gorilla brand has a version of it but not tried it - I'm perfectly happy with this stuff - it's about £10 ish and you don't need to use a lot to achieve the bond They are also good to use in other house areas conveniently Ref: you other project! |

| |

|

|

|

|